Scor 9.0 reference guide

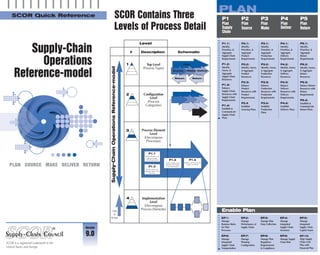

- 1. PLAN SCOR Quick Reference SCOR Contains Three P1 P2 P3 P4 P5 Levels of Process Detail Plan Plan Plan Plan Plan Supply Source Make Deliver Return Chain Supply-Chain Level P1.1: P2.1: P3.1: P4.1: P5.1: Identify, Identify, Identify, Identify, Identify, Prioritize, & Prioritize, & Prioritize, & Prioritize, & Prioritize, & # Description Schematic Aggregate Aggregate Aggregate Aggregate Aggregate Operations Supply-Chain Product Production Delivery Return Requirements Requirements Requirements Requirements Requirements 1 Top Level Plan P1.2: P2.2: P3.2: P4.2: P5.2: Reference-model (Process Types) Identify, Identify, Assess, Identify, Assess, Identify, Assess, Identify, Assess, Supply-Chain Operations Reference-model Source Make Deliver Assess, & & Aggregate & Aggregate & Aggregate & Aggregate Aggregate Product Production Delivery Return Supply-Chain Resources Resources Resources Resources Return Return Resources P2.3: P3.3: P4.3: P5.3: P1.3: Balance Balance Balance Balance Return Balance Product Production Delivery Resources with Supply-Chain Resources with Resources with Resources with Return 2 Configuration Resources with Product Production Delivery Requirements Level Supply-Chain Requirements Requirements Requirements Requirements P5.4: (Process P2.4 P3.4: P4.4: Establish & Categories) P1.4: Establish Establish Establish Communicate Establish & Sourcing Plans Production Delivery Plans Return Plans Communicate Plans Supply-Chain Plans 3 Process Element Level (Decompose Processes) P1.1 Identify, Prioritize, and Aggregate Supply- Chain Requirements P1.3 P1.4 Establish and Communicate PLAN SOURCE MAKE DELIVER RETURN Balance Supply-Chain Resources with Supply- Supply-Chain Plans P1.2 Chain Requirements Identify, Assess, and Aggregate Supply-Chain Resources 4 Implementation Level (Decompose Not Process Elements) Enable Plan in Scope EP.1: EP.2: EP.3: EP.4: EP.5: Manage Manage Manage Plan Manage Manage Business Rules Performance of Data Collection Integrated Integrated Version for Plan Supply Chain Supply Chain Supply Chain Processes Inventory Capital Assets 9.0 EP.6: EP.7: EP.8: EP.9: EP.10: Manage Manage Manage Plan Manage Supply Align Supply SCOR is a registered trademark in the Integrated Planning Regulatory Chain Risk Chain Unit Supply Chain Configuration Requirements Plan with United States and Europe Transportation & Compliance Financial Plan

- 2. SOURCE MAKE DELIVER S1 S2 S3 M1 M2 M3 D1 D2 D3 D4 Source Stocked Source Source Make-to-Stock Make-to-Order Engineer-to-Order Deliver Deliver Deliver Deliver Product Make-to-Order Engineer-to-Order Stocked Make-to- Engineer-to- Retail Product Product Product Order Order Product Product M1.1: M2.1: M3.1: D1.1: D2.1: D3.1: D4.1: S1.1: S2.1: S3.1: Process Inquiry & Process Inquiry & Obtain & Respond to Generate Stocking Schedule Product Schedule Product Identify Sources of Supply Schedule Production Schedule Production Finalize Engineering Quote Quote RFP/RFQ Schedule Deliveries Deliveries Activities Activities S3.2: M3.2: D1.2: D2.2: D3.2: D4.2: S1.2: S2.2: Select Final Supplier(s) M1.2: M2.2: Schedule Production Receive, Enter & Receive, Configure, Negotiate & Receive Receive Product at Receive Product Receive Product and Negotiate Issue Product Issue Product Activities Validate Order Enter & Validate Contract the Store S1.3: S2.3: S3.3: M1.3: M2.3: M3.3: Order D1.3: D3.3: D4.3: Verify Product Verify Product Schedule Product Produce and Test Produce and Test Issue Product Reserve Inventory & D2.3: Enter Order, Commit Pick Product from Deliveries Determine Delivery S1.4: S2.4: M1.4: M2.4: M3.4: Reserve Resources & Resources & Launch Backroom Date Determine Delivery Program Transfer Product Transfer Product S3.4: Package Package Produce & Test Date D4.4: Receive Product D1.4: S1.5: S2.5: M1.5: M2.5: M3.5: D3.4: Stock Shelf Consolidate Orders D2.4: Schedule Installation Authorize Supplier Authorize Supplier S3.5: Stage Product Stage Product Package Consolidate Orders D4.5: Payment Payment Verify Product D1.5: M1.6: M2.6: M3.6: D3.5: Fill Shopping Build Loads D2.5: S3.6: Release Product Release Finished Stage Product Build Loads Cart Transfer Product to Deliver Product to Deliver D1.6: Build Loads M3.7: D3.6: D4.6: Route Shipments S3.7: M1.7: M2.7: Release Product D2.6: Route Shipments Checkout Authorize Supplier Waste Disposal Waste Disposal to Deliver D1.7: Route Shipments Select Carriers & D3.7: D4.7: Payment M3.8: Rate Shipments D2.7: Select Carriers & Deliver and/or Waste Disposal Select Carriers & Rate Shipments install D1.8: Rate Shipments Receive Product from D3.8: Source or Make D2.8: Receive Product Receive Product from Source or Make D1.9: from Source or Make Pick Product D3.9: D2.9: Pick Product D1.10: Pick Product Pack Product D3.10: D2.10: Pack Product D1.11: Pack Product Load Product D3.11: & Generate D2.11: Load Product & Shipping Docs Load Product & Generate Shipping Generate Shipping Docs D1.12: Docs Ship Product D3.12: D2.12: Ship Product D1.13: Ship Product Receive & Verify D3.13: Product by Customer D2.13: Receive & Verify Receive & Verify Product by Customer D1.14: Product by Customer Install Product D3.14: D2.14: Install Product D1.15: Install Product Invoice D3.15: D2.15: Invoice Invoice Enable Source Enable Make Enable Deliver ES.1: ES.2: ES.3: ES.4: ES.5: EM.1: EM.2: EM.3: EM.4: EM.5: ED.1: ED.2: ED.3: ED.4: ED.5: Manage Assess Supplier Maintain Manage Manage Manage Manage Manage Make Manage Manage Manage Assess Delivery Manage Manage Manage Sourcing Performance Source Data Product Capital Assets Production Production Information In-Process Equipment and Deliver Performance Deliver Finished Deliver Capital Business Rules Inventory Rules Performance Products (WIP) Facilities Business Rules Information Product Assets Inventories ES.6: ES.7: ES.8: ES.9: ES.10: EM.6: EM.7: EM.8: EM.9: Manage Manage Manage Manage ED.6: ED.7: ED.8: ED.9: Manage Manage Manage Manage Manage Incoming Supplier Import/Export Supply Chain Supplier Transportation Production Production Supply Chain Manage Manage Manage Manage Product Network Requirements Source Risk Agreements Network Regulatory Make Risk Transportation Product Life Import/Export Supply Chain Compliance Cycle Requirements Deliver Risk

- 3. RETURN The Supply-Chain Operations SR1 DR1 SR2 DR2 SR3 DR3 Reference-model (SCOR) is the Source Deliver Source Deliver Source Deliver Return Return Return Return Return Return Defective Defective MRO MRO Excess Excess product of the Supply-Chain Council Product Product Product Product Product Product (SCC), an independent, not-for-profit, SR1.1: DR1.1: SR2.1: DR2.1: SR3.1: DR3.1: Identify Authorize Identify Authorize Identify Authorize global corporation with membership Defective Defective MRO MRO Excess Excess Product Product Product Product Product Product Condition Return Condition Return Condition Return open to all companies and organizations SR1.2: DR1.2: SR2.2: DR2.2: SR3.2: DR3.2: Disposition Schedule Disposition Schedule Disposition Schedule interested in applying and advancing Defective Defective MRO MRO Excess Excess Return Product Return Receipt Product Return Product Receipt the state-of-the-art in supply-chain Receipt SR1.3: DR1.3: SR2.3: SR3.3: DR3.3: Request Receive Request DR2.3: Request Receive management systems and practices. Defective Defective MRO Return Receive Excess Excess Product Product Authorization MRO Product Product Return (includes Product Return (includes The SCOR-model captures the Authorization verify) SR2.4: Authorization verify) (includes Schedule verify) SR1.4: DR1.4: MRO SR3.4: DR3.4: Council’s consensus view of supply Schedule Transfer Shipment DR2.4: Schedule Transfer Defective Defective Transfer Excess Excess Product Product SR2.5: Product Product chain management. While much of the MRO Shipment Return Product Shipment MRO SR1.5: Product SR3.5: underlying content of the Model has Return Return Excess Defective Product Product been used by practitioners for many years, the SCOR-model provides a unique framework that links business process, metrics, best practices and technology features into a unified For more information: In USA: structure to support communication Supply Chain Council among supply chain partners and 1400 Eye Street, Suite 1050 Washington DC, 20005 to improve the effectiveness of Tel: +1 202-822-4660 Fax: +1 202-822-5286 supply chain management and Email: info@supply-chain.org related supply chain In Europe: Supply Chain Council improvement activities. 287 Avenue Louise Enable Return 2nd Floor ER.1: ER.2: ER.3: ER.4: ER.5: BE - 1050 Brussels Manage Manage Manage Manage Manage Tel: +32 2 627 0160 Business Rules Performance of Return Data Return Return Capital for Return Return Collection Inventory Assets Fax: +32 2 645 2671 Processes Processes Email: Europe@supply-chain.org ER.6: ER.7: ER.8: ER.9: Manage Manage Return Manage Return Manage Return Network Regulatory Supply Chain www.supply-chain.org Transportation Configuration Requirements Return Risk & Compliance

- 4. S1 Source Stocked Product S1.2 Detail Supplier SCOR Model Structure A set of standard notation is used throughout the Model. P depicts Plan elements, S depicts Source From DR1.4: Transfer Defective Product elements, M depicts Make elements, D depicts Deliver elements, and R depicts Return elements. in DR1 Deliver Return Defective SR = Source Return and DR = Deliver Return. An E preceding any of the others (e.g., EP) indicates that the From DR2.4: Transfer MRO Product in process element is an Enable element associated with the Planning or Execution element (in this case, EP DR2 Deliver Return MRO Product would be an Enable Plan element). Every Level 1 Process has Enable Processes associated with it. Product As indicated in the chart showing the Three Levels of Process Detail, the Model is hierarchical with three Defective Products levels. Here is a sample of the detailed workflow for S1.2. S1.2 is a notation that indicates a third level From DR3.4: Transfer Excess Product process element. In this case, it is a Source (S = Level 1 Source) element that is concerned with sourcing MRO Products in DR3 Deliver Return Excess Product stocked product (S1 = Level 2 Source Stocked Product) and is specific to receiving product (S1.2 = Level 3 Excess Products Source Stocked Product Receive Product). Though the other S1 processes are shown here to Level 2, the Level 3 detail is only included for S1.2. Scheduled Receipt Receipt Transferred S1.1 Schedule Receipts Verification Verification Product S1.5 Authorize S1.2 Receive Product S1.3 Verify Product S1.4 Transfer Product Product Deliveries Supplier Payment Receipt verification Receipt verification Receipt verification Receipt verification Performance Attributes and Level 1 Metrics Receipt verification Level 1 Strategic Metrics are primary, high level measures that may cross multiple SCOR processes. Level 1 Metrics To ES.2: Assess Supplier Performance in ES do not necessarily relate to a SCOR Level 1 process (PLAN, SOURCE, MAKE, DELIVER, RETURN). The Metrics Enable Source Chapter also now includes a unique code for every metric based on its attribute, level and alphabetical sequence To ES.1: Manage Sourcing under each level. This is especially useful for benchmarking. For coding, see the SCOR Model. Business Rules in ES Enable To ES.6: Manage Incoming Product Performance Attributes in ES Enable Source Customer-Facing Internal-Facing To ES.8: Manage Import/Export Requirements in ES Enable Source Level 1 Metrics Reliabilty Responsiveness Agility Cost Assets To ED.8: Manage Import/Export Perfect Order Fulfillment Requirements in ED Enable Deliver Order Fulfillment Cycle Time Upside Supply Chain Flexibility Upside Supply Chain Adaptability Level 1 Strategic Metrics Downside Supply Chain Adaptability The Level 1 Metrics are the calculations by (Level 2 and 3 metrics) are generally associated which an implementing organization can with a narrower subset of processes. Level 2 Supply Chain Management Cost measure how successful they are in achieving and 3 metrics associated with Level 1 metrics Cost of Goods Sold their desired positioning within the competitive are included in the SCOR 9.0 Metrics Cash-to-Cash Cycle Time market space. Most metrics in the Model are Hierarchy in the Metrics Chapter. Additional hierarchical – just as the process elements are metrics that do not “roll up” to Level 1 are Return on Supply Chain Fixed Assets hierarchical. Level 1 Strategic Metrics are cre- needed as diagnostics (used to diagnose varia- Return on Working Capital ated from lower level calculations and are pri- tions in performance against plan) and are mary, high level measures that may cross mul- included in the Metrics chapter with definitions tiple SCOR processes. Lower level calculations and process locations listed.