Production of Cellulase from Trichoderma Reesei rut30

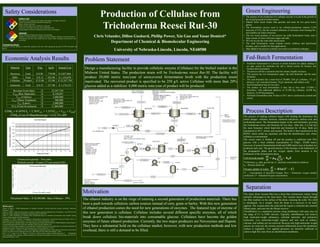

- 1. Production of Cellulase from Trichoderma Reesei Rut-30 Chris Velander, Dillon Gushard, Phillip Power, Xin Gao and Yasar Demirel* Department of Chemical & Biomolecular Engineering University of Nebraska-Lincoln, Lincoln, NE68588 Problem Statement: Design a manufacturing facility to provide cellulytic enzyme (Cellulase) for the biofuel market in the Midwest United States. The production strain will be Trichoderma reesei Rut-30. The facility will produce 20,000 metric tons/year of unrecovered fermentation broth with the production strain inactivated. The recovered product is specified to be 250 g/L active Cellulase with more than 20% glucose added as a stabilizer. 8,000 metric tons/year of product will be produced. Problem Statement Motivation The ethanol industry is on the verge of entering a second generation of production materials. There has been a push towards cellulosic carbon sources instead of corn, grain or barley. With this new generation of ethanol production comes the need for new generations of enzymes. The featured type of enzyme of this new generation is cellulase. Cellulase includes several different specific enzymes, all of which break down cellulosic bio-materials into consumable glucose. Cellulases have become the golden enzymes of future ethanol production. Currently, the two major producers are Novozymes and Dupont. They have a substantial hold on the cellulase market, however, with new production methods and low overhead, there is still a demand to be filled. Green Engineering Separation Process Description Fed-Batch Fermentation Safety Considerations Economic Analysis Results References Adney, B. Baker, J. (2008) Measurement of Cellulase Activities. National Renewable Energy Laboratory. Retrieved February 2, 2015. Aftab, A. (2008). Culture-based strategies to enhance cellulase enzyme production from Trichoderma reesei RUT-C30 in bioreactor culture conditions. Biochemical Engineering Journal 399–407 Allen, A. (1981) Production of Cellulase from Trichoderma Reesei in Fed-Batch Fermentation from Soluble Carbon Sources. Biotechnology and Bioengineering Evenleigh, D. (1987). Cellulase: A Perspective. Philosophical Transactions of the Royal Society of London. Series A, Mathematical and Physical Sciences, 321(1561), 435-447. Retrieved February 2, 2015. EPA CO2 emissions standards https://www.federalregister.gov/articles/2014/01/08/2013-28668/standards-of-performance- for-greenhouse-gas-emissions-from-new-stationary-sources-electric-utility#h-194 Fang, H. (2014) Cellulase production by recombinant Trichoderma Reesei and its application in enzymatic hydrolysis of agricultural residues. Biotechnology and Bioengineering. Retrieved February 2, 2015. Lambert, P., Meers, J., & Best, D. (1983). The production of industrial enzymes. Philosophical Transactions of the Royal Society of London. Series B, Biological Sciences, 300(1100), 263-282. Retrieved February 3, 2015, Ma, L., Li, C., Yang, Z., Jia, W., Zhang, D., & Chen, S. (2013). Kinetic studies on batch cultivation of Trichoderma reesei and application to enhance cellulase production by fed-batch fermentation. Journal of Biotechnology, 166, 192-197. Retrieved February 2, 2015. The process of making cellulase begins with feeding the fermenters the initial charges: cellulose, dextrose, ammonia anhydrous, sulfuric acid, and trichoderma reesei. The fermentation begins in the seed-fermenter, growing the trichoderma reesei, and ferments for two days. After this, it is fed into the main fermenter which batch-fed and ferments for 10 days. Both are maintained at 28 C, stirred, and aerated. The broth is then transferred to the RDVF, where solids are separated, and then the ultrafiltration unit, where cellulase is concentrated. The excess water is flashed off and the product is stabilized with 20% glucose with a final cellulase concentration of 250g/L. 20,000 metric tons/year of unused fermentation broth and 8,000 metric tons of product are produced each year. The growth kinetics of the biomass is the bottleneck of the propagation phase and the oxygen uptake from aeration is the bottleneck of the fermentation phase. Cell Growth model: *X-Biomass, µm-Max growth rate, S –substrate concentration (cellulose) kd – Biomass death rate Oxygen uptake in water: ∗ *C – Concentration of dissolved Oxygen, KLa – Volumetric oxygen transfer coefficient, C* - Saturated Oxygen concentration The rotary drum vacuum filter has a drum that continuously rotates, being partially submerged in the feed slurry. The vacuum draws liquid through the filter medium on the surface of the drum, retaining the solid. The solid is discharged, via a scraper, from the drum to a conveyor to be land- applied. The vacuum dries the solid and the liquid is collected into internal filtrate pipes, and sent into the filtrate receiver. Ultrafiltration is a separation process using membranes with pore sizes in the range of 0.1 to 0.001 microns. Typically, ultrafiltration will remove high molecular-weight substances, colloidal materials, and polymeric molecules. Low molecular-weight organics and ions such as sodium, calcium, and sulfates are not removed. Because only high-molecular weight species are removed, the osmotic pressure differential across the membrane surface is negligible. Low applied pressures are therefore sufficient to achieve high flux rates from an ultrafiltration membrane. • Fed-batch fermentation is a process in which nutrients are added, making it an open system for substrates but still a closed system for biomass and biomass-derived products. • The process still has a retention time but volume steadily increases. • This process has two fermentation stages: the seed fermenter and the main fermenter. • The seed fermenter has a total feed of 70,000L (236 g/L cellulose, 173 g/L dextrose, 5 g/L inoculum biomass, 10 g/L ammonia, and sulfuric acid) • Seed fermentation lasts for two days. • The product of seed fermentation is then fed to four main 175,000 L fermenters, with additional additives of 52,500 Kg cellulose, 38,500 Kg dextrose, 14,595 Kg ammonia • Fed-batch fermentation lasts 10 days at 28 C and is continuously aerated and stirred. Revenue From Sales $ 32,247,750 CRM (Raw Materials) $ 8,158,057 CUT (Utilities) $ 3,600,000 CWT (Waste Treatment) $ 500,000 COL (Labor) $ 2,000,000 FCIl (Fixed Investment) $ 11,800,000 Material Dextrose Type Feed $/kg $ 0.90 kg/hr 778.00 Annual Cost $ 5,827,064 DDG Feed $ 0.15 925.00 $ 1,154,678 Cellulase Product $ 25.00 155.00 $ 32,247,750 Ammonia Feed $ 0.55 257.00 $ 1,176,315 COMd = 0.18*FCIL + 2.76*COL + 1.23*(CUT + CWT + CRM) COMd (Cost of Manufacturing) = $ 22,721,409 Construction period – Two years. Payback period – 9 years (12 year project life) 0 250 500 750 1000 -5 0 5 10 15 20 25 30 35 40 CumulativeNumberofDataPoints Net Present Value (millions of dollars) Net Present Value Data Net present Value ~ $ 18,500,000 : Rate of Return – 39% Sulfuric Acid: May cause a fire or explosion if in contact with organic or inorganic chemicals. Contact with metals liberates flammable hydrogen gas. Reacts violently with water. Sulfuric acid is highly toxic if inhaled or swallowed. Is corrosive if in contact with eyes, skin or respiratory tract. Strong inorganic acid-mists containing sulfuric acid are carcinogenic. Ammonia: Can be extremely irritating to the throat, nose and lungs. Symptoms: burning sensations, coughing, wheezing, headache, shortness of breath and nausea. Overexposure may also cause central nervous system effects including unconsciousness and convulsions. Trichoderma Reesei: Exposure over time, allergies or asthma-like symptoms may occur. Wear appropriate gas-mask for PPE and handle with gloves. • The purpose of the production of a cellulase enzyme is to aid in the growth of the second generation biofuel market. • Ethanol burns much cleaner than gasoline and emits far less green house gasses. • The fermentation process used in our cellulose-production releases 5,550 tons/year of CO2, but the eventual reduction of emissions from burning bio- fuel justifies our minor emissions. • The two waste products of our process are solid fermentation waste, and a large volume of water with trace sugars and salts. • We will recycle the water after deactivation. • The solid fermentation waste contains mostly cellulose and deactivated biomass, and is suitable for land applications. • Heat added to the process is mostly recovered via insulated exchangers