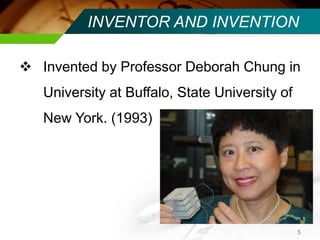

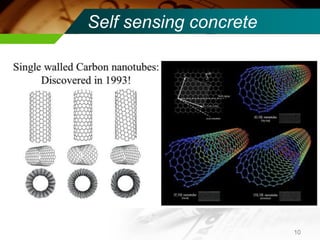

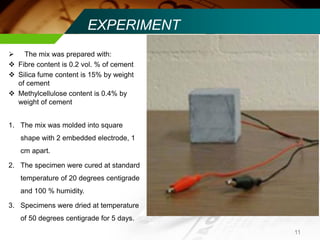

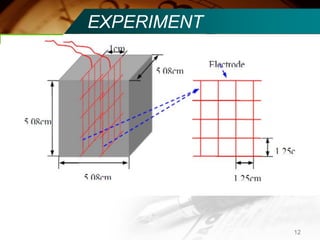

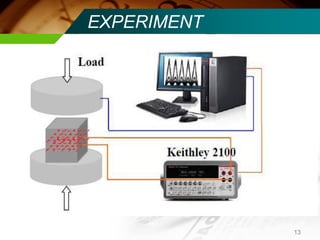

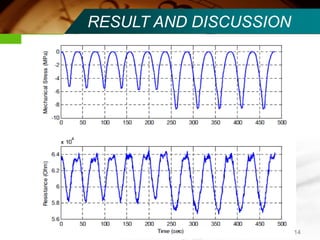

This document discusses smart concrete invented by Professor Deborah Chung. Smart concrete is concrete that can sense its own strain or stress without embedded sensors. It has been modified with admixtures so that changes in electrical resistance allow it to function as a sensor. Two types were studied: one with short carbon fibers and one with carbon nanotubes. Laboratory experiments showed that when molded into squares with electrodes, both types demonstrated piezoresistive properties and were able to detect internal stress and strain, showing potential as sensors for pavement monitoring.

![RFERENCES

REFERENCES

[1] B. Demirel, S. Yaziciog˘lu and N. Orhan. (December 2006). Electrical behaviour of carbon fibre-reinforced. Magazine of

Concrete Research, 7.

[2] Chung, D. D. (2006). The Road to Scientific Success. Singapore: World Scientific Pubilishing Co.Pte.Ltd.

[3] Chung, D. D. (1994). Carbon Fiber Composite. Washington: Butterworth-Heinemann.

[4] Chung, D. D. (13 October 1994). Strain sensor based on resistance change accompanying the reversible pull-out of

conducting short fibers in a less conducting matrix. Smart Mater. Strum.

[5] Dr. Xun Yu, Dr. Eil Kwon. (April 2012). Carbon Nanotube Based Self-sensing Concrete for Pavement. Washington:

University of Minnesota Duluth.

16

[1]](https://image.slidesharecdn.com/smartconcrete-141112035548-conversion-gate02/85/Smart-concrete-16-320.jpg)