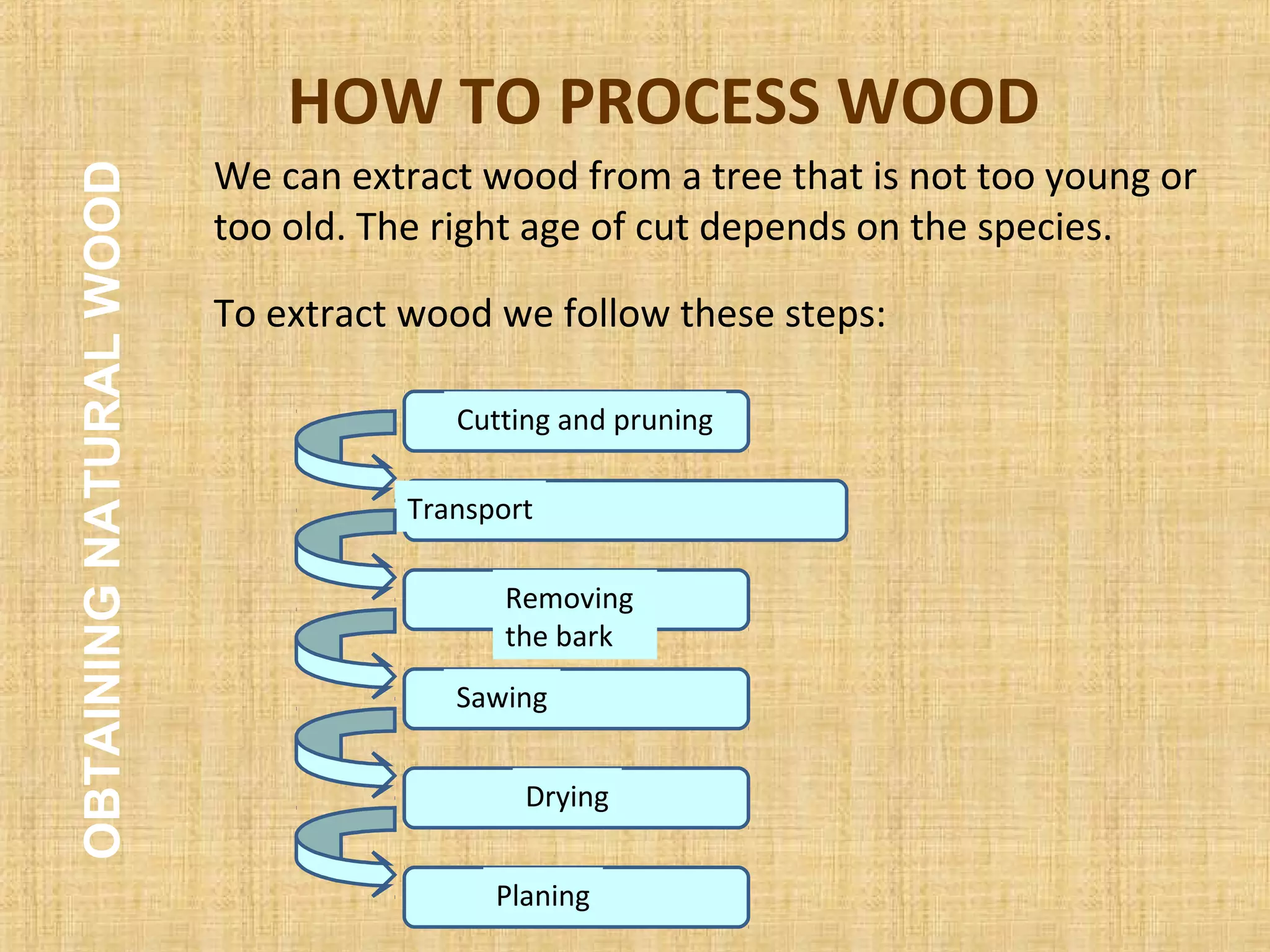

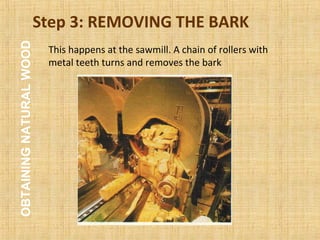

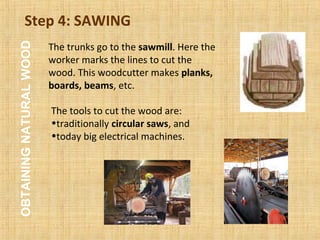

Cutting trees in the winter with chain saws and machinery. Transporting trunks by truck to sawmills. At the sawmill, removing the bark with metal rollers and sawing the wood into planks, boards and beams using circular saws and machines. Drying the wood so it doesn't warp and lasts longer, then planing it to make the wood smooth, flat and finished.