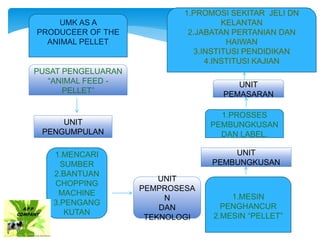

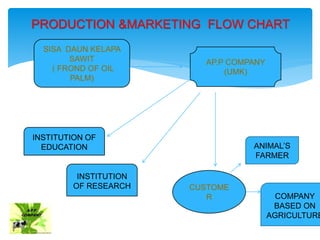

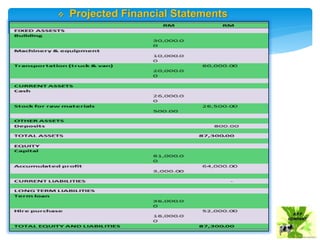

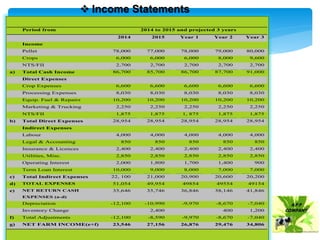

The document outlines plans for an animal feed pellet production company called A.P.P Company. The company aims to produce high quality animal feeds using oil palm fronds as a low-cost raw material. This will help local farmers reduce livestock feeding costs. The company plans to market its pellets locally in Kelantan and expand sales across Malaysia. Financial projections estimate the company will become profitable within 3 years as sales increase and costs decrease with experience.