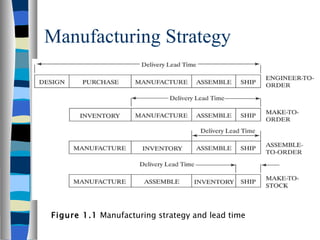

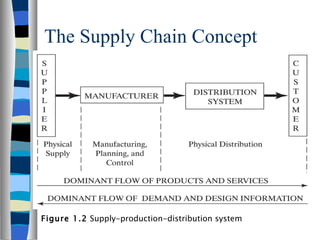

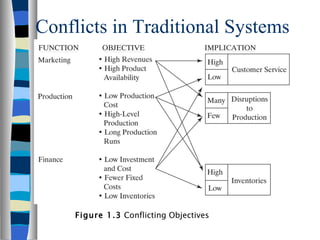

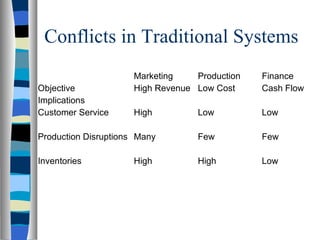

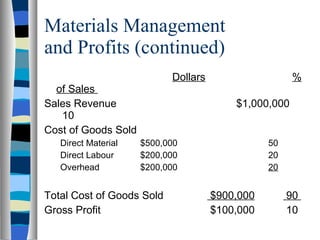

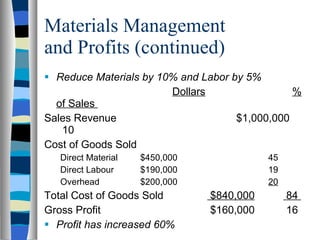

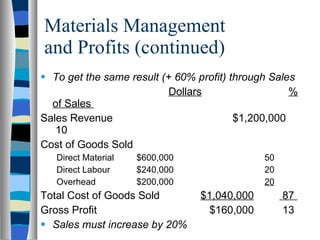

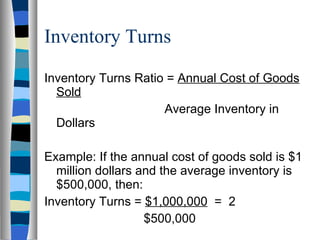

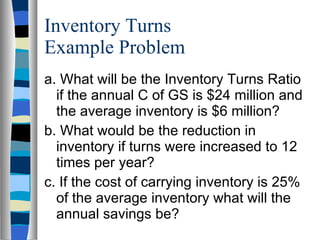

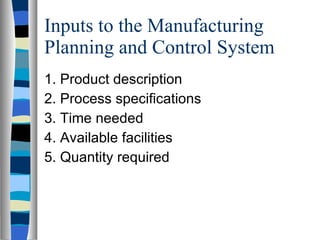

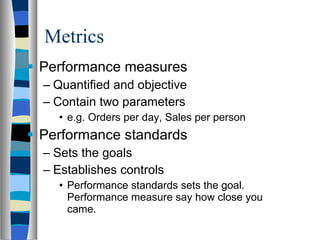

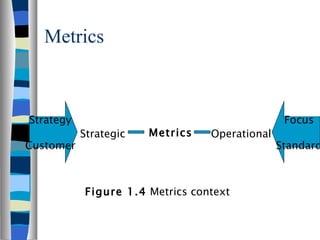

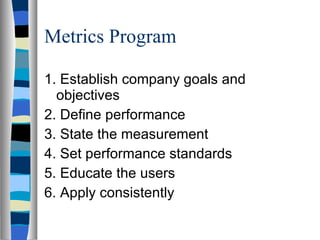

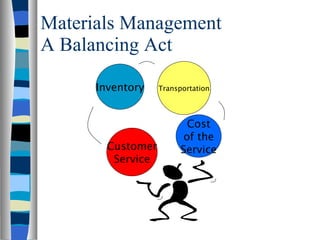

The document provides an introduction to materials management. It discusses how manufacturing creates wealth by transforming raw materials and adding value. It also summarizes that materials management aims to balance customer service needs with the costs of supplying materials through the supply chain, from suppliers to manufacturing to distribution. Key aspects of materials management systems that were highlighted include production planning and control, inventory management, and the use of metrics to meet organizational goals.