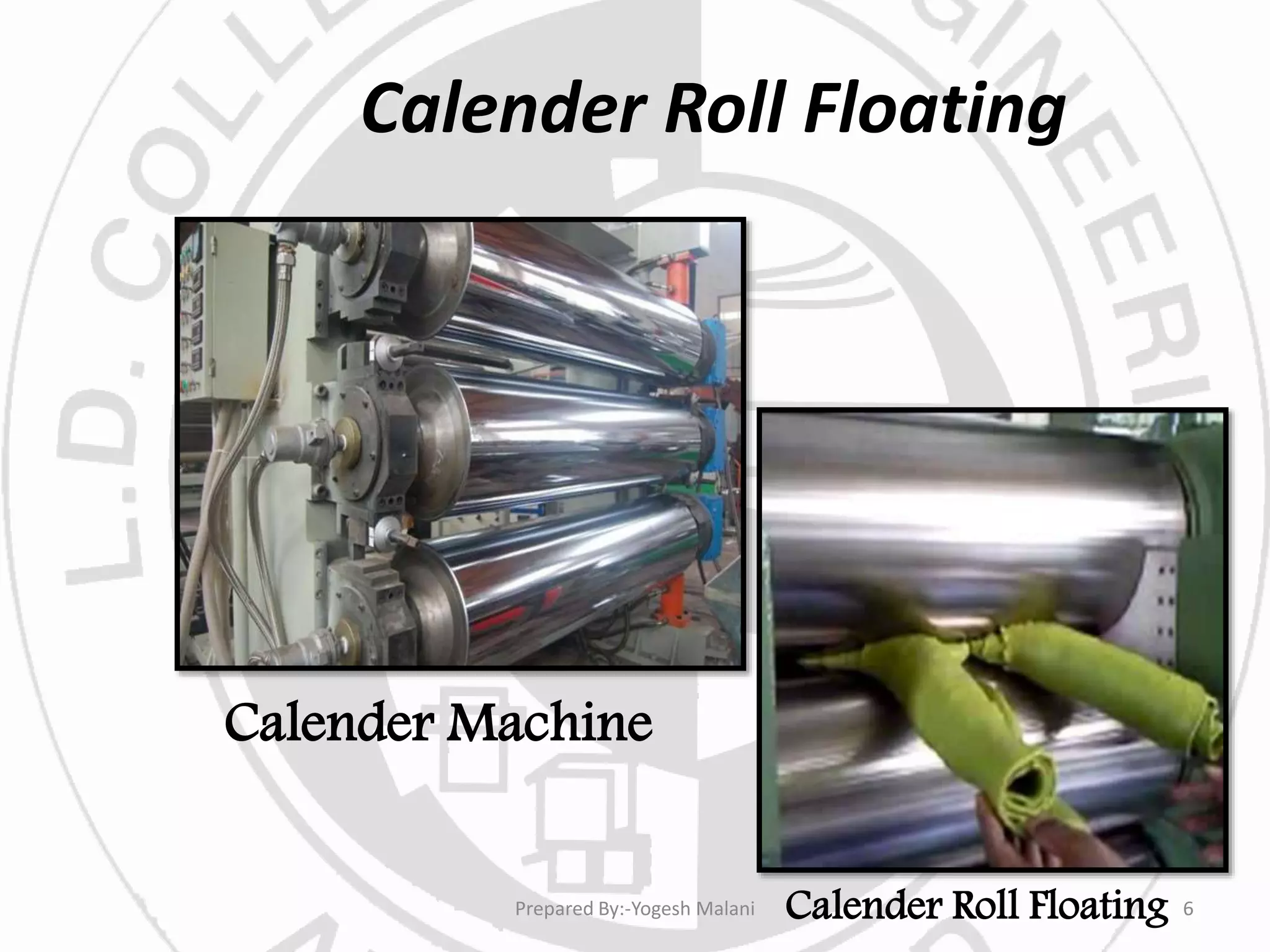

The document discusses calendering in rubber manufacturing, explaining the function of calenders and the challenges associated with achieving accuracy, particularly focusing on calender roll floating. It outlines the causes of inaccuracies, the disadvantages of roll floating, and presents a solution involving a preloading device to mitigate this issue. References include notable texts and web resources on calendering technology.