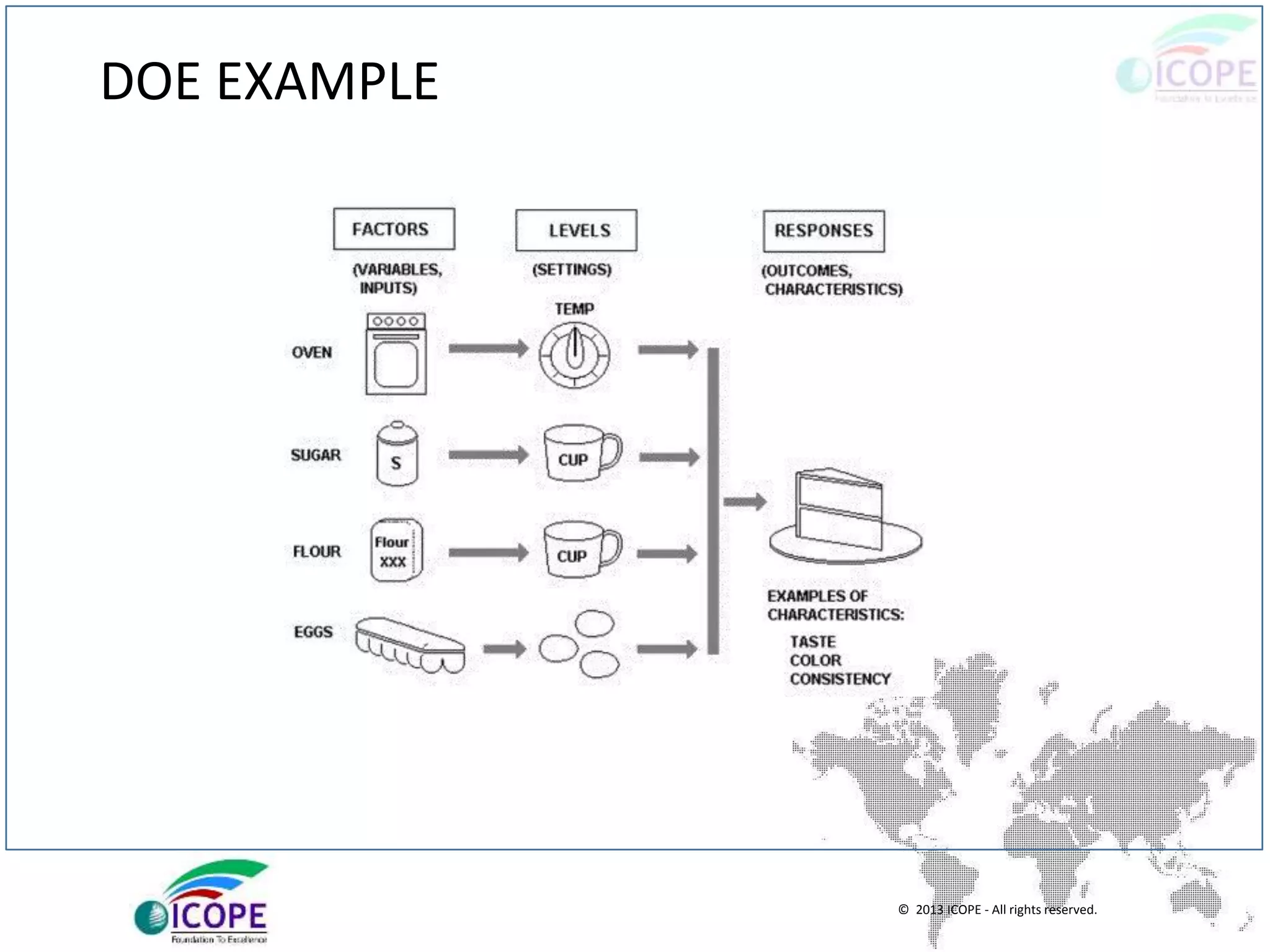

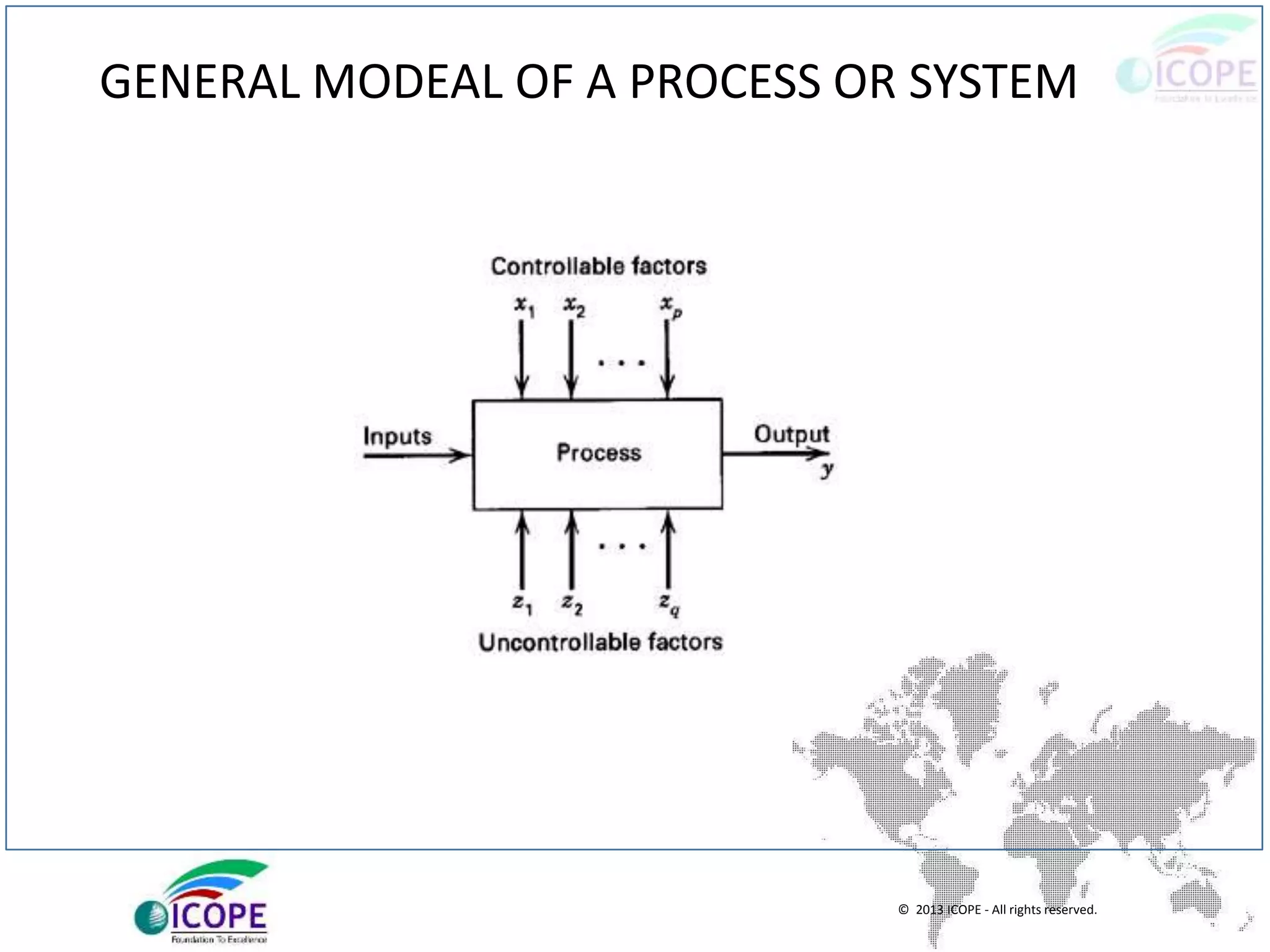

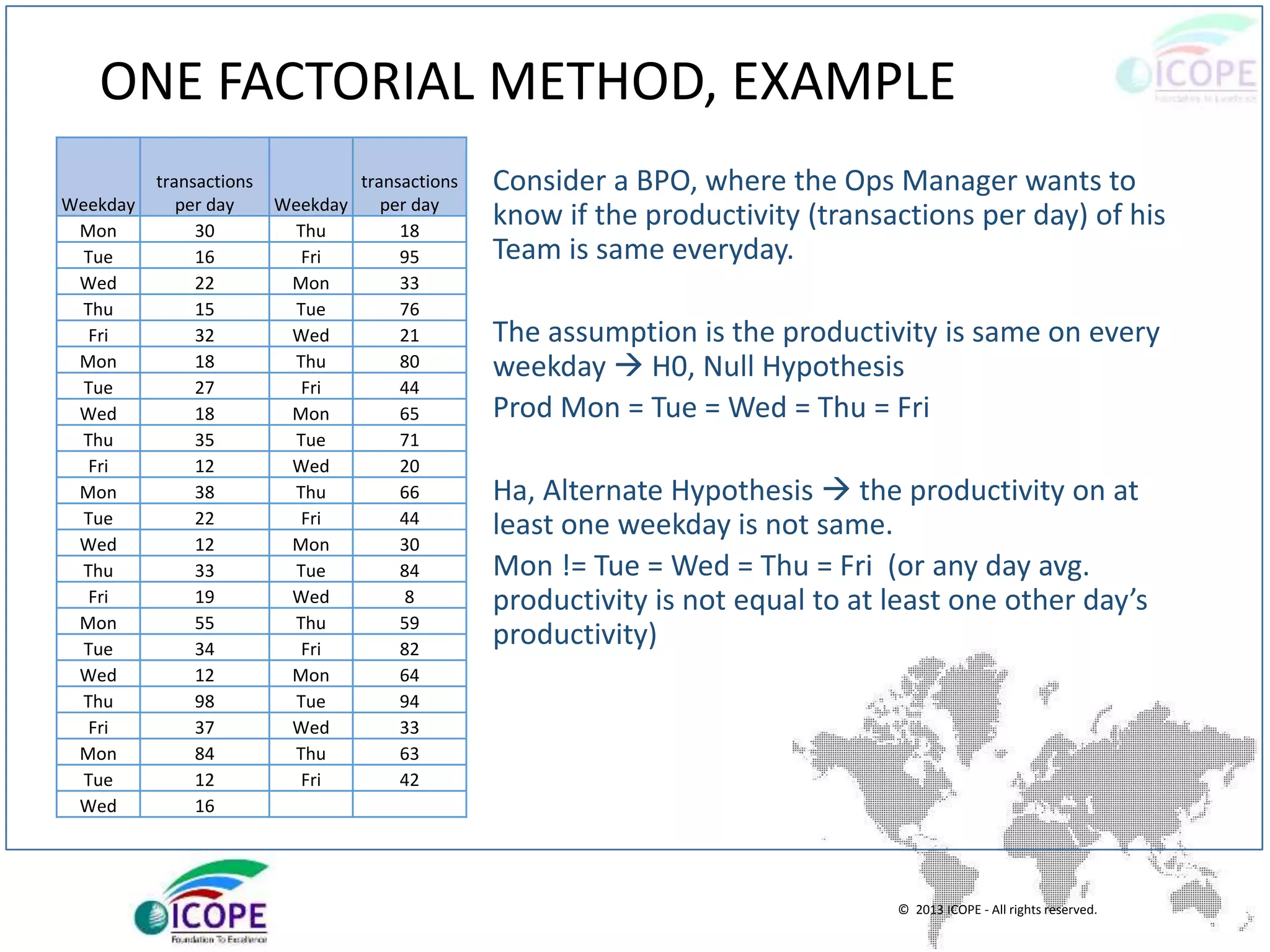

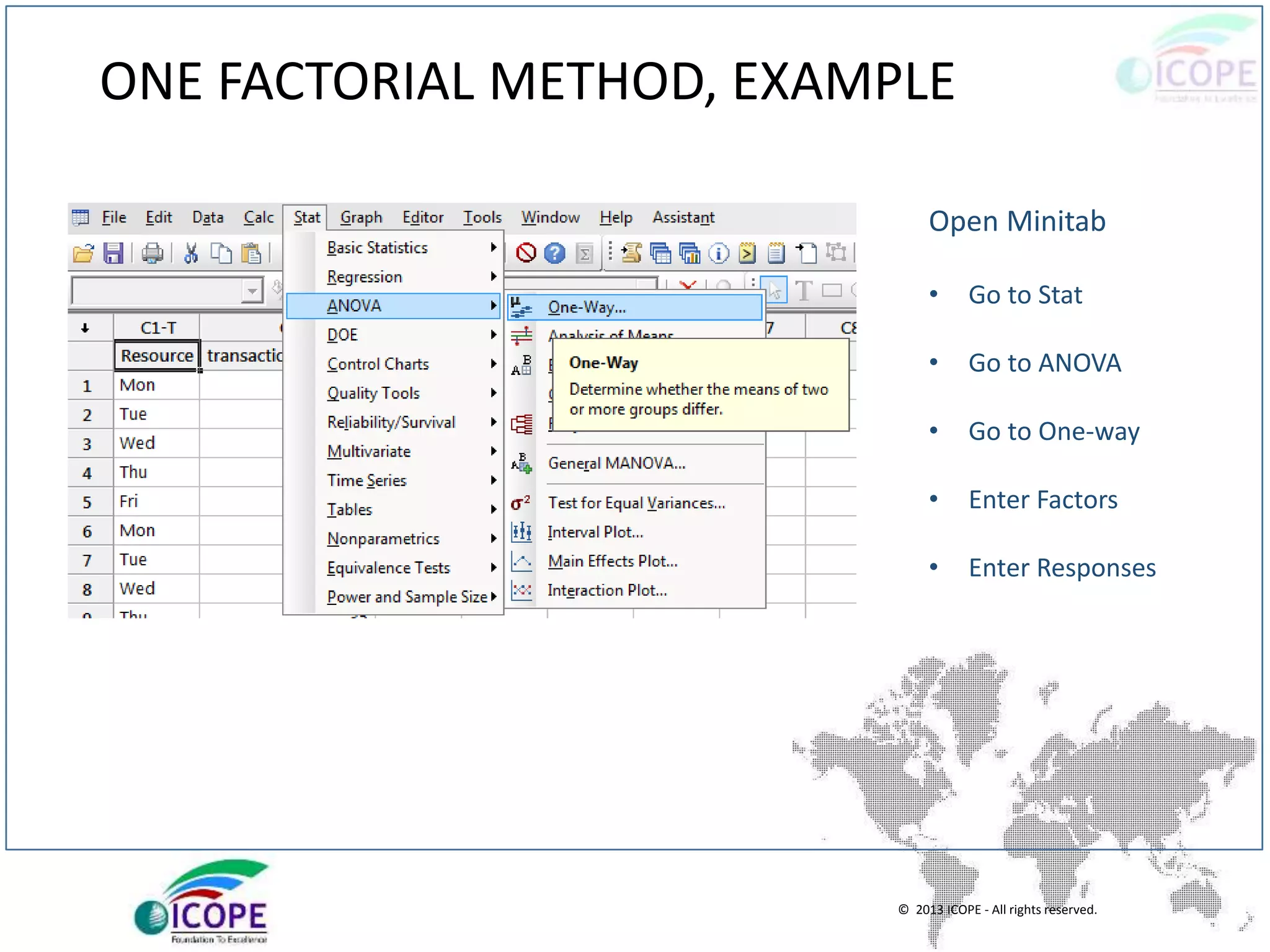

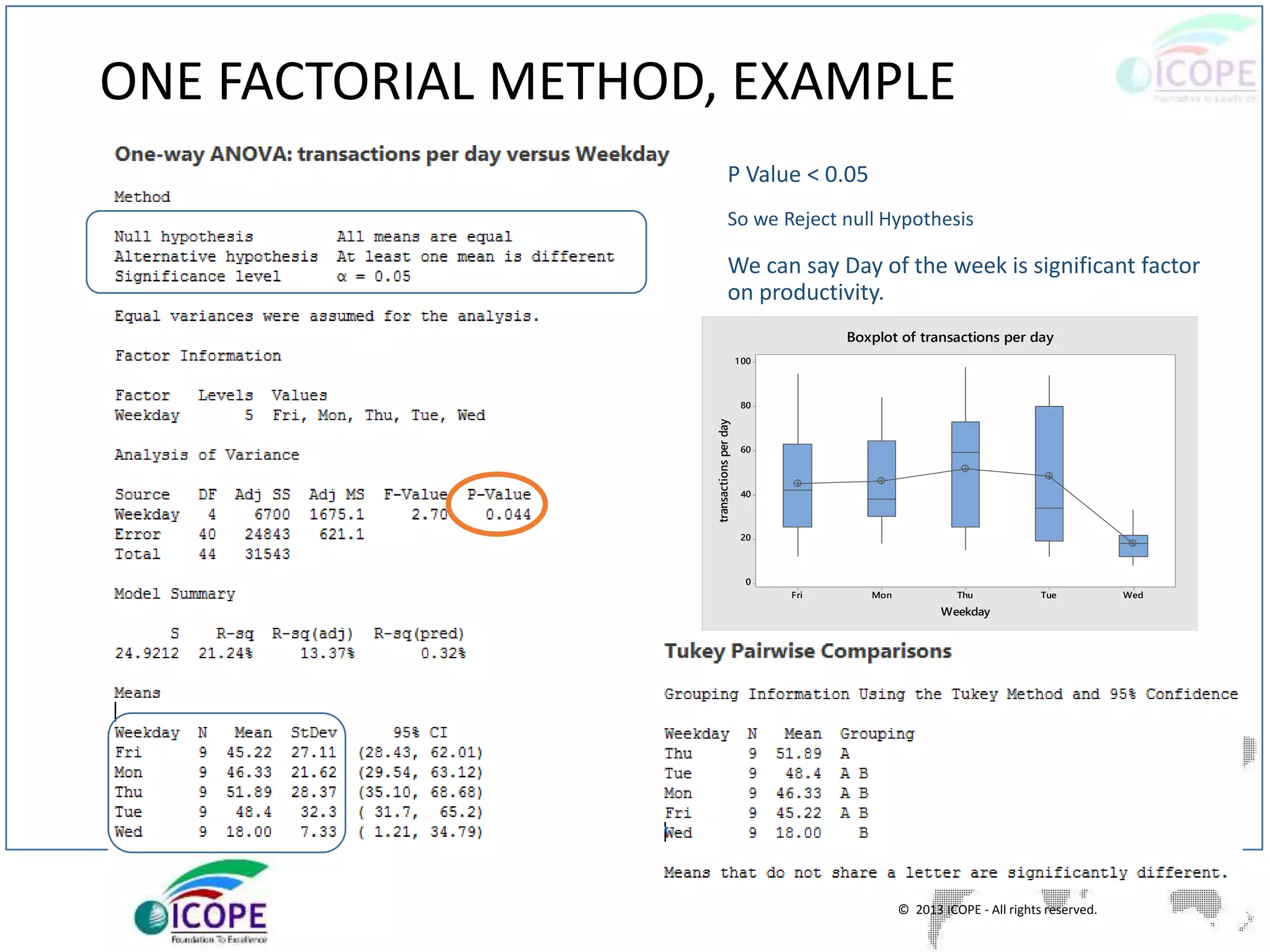

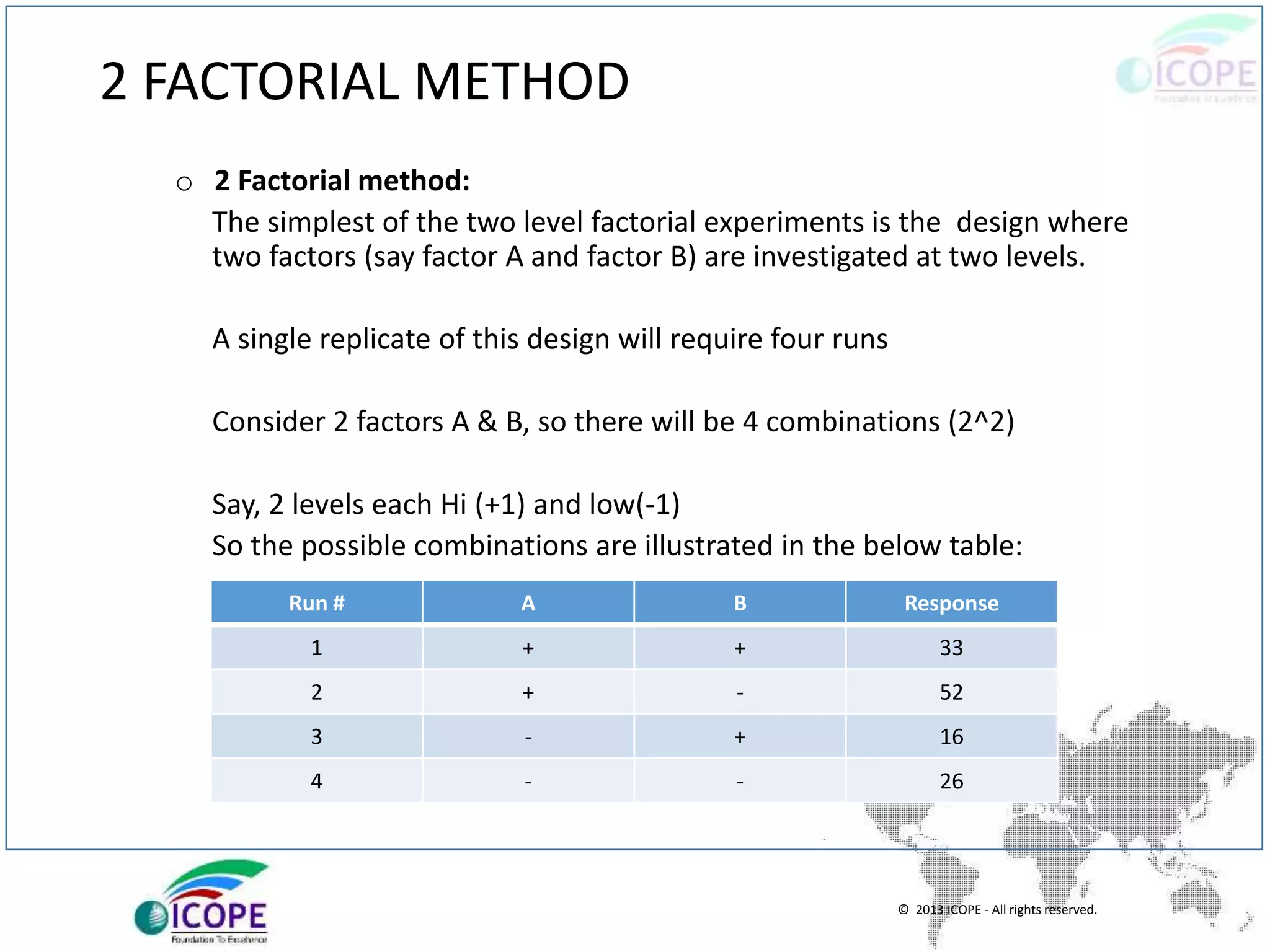

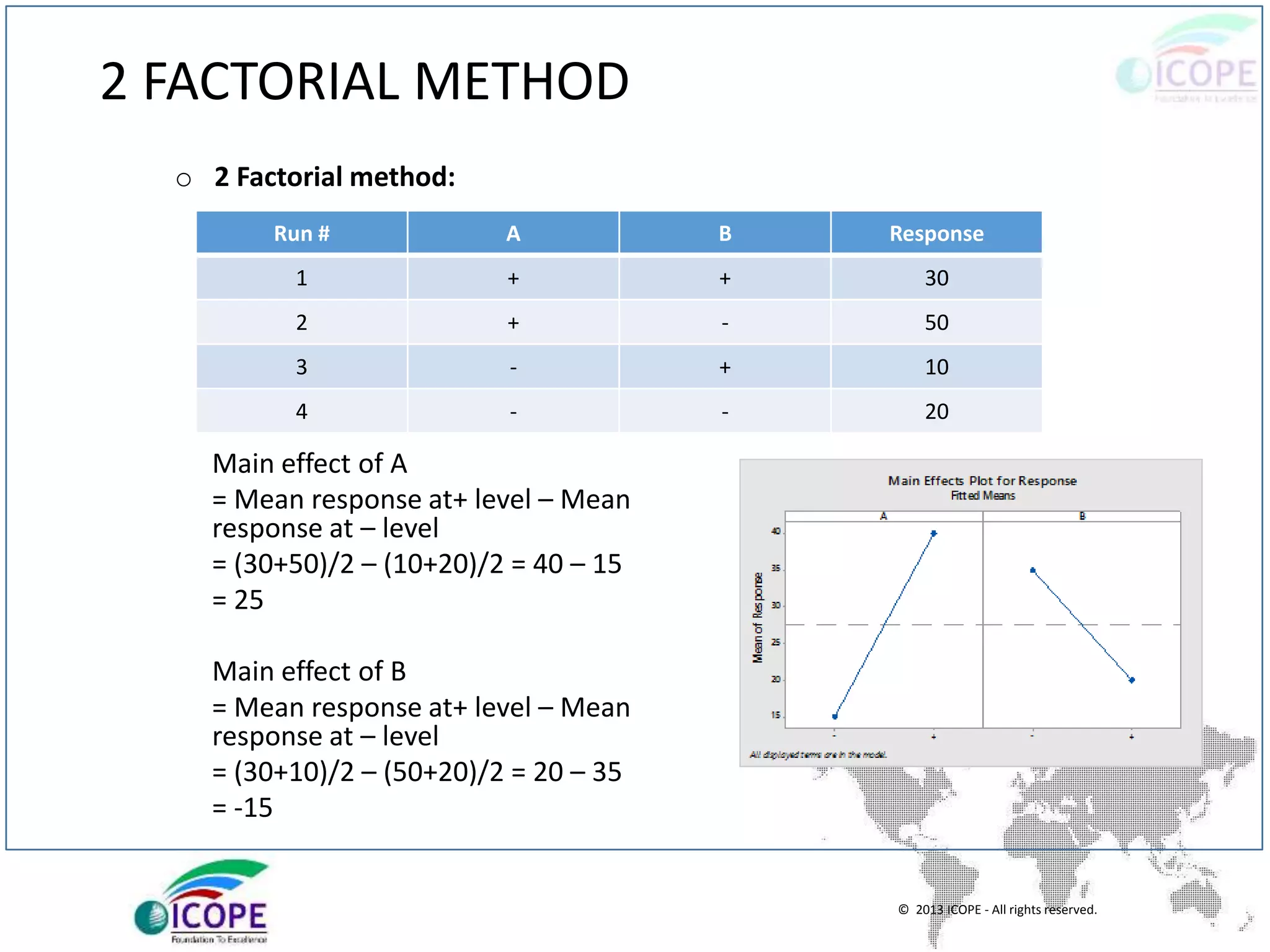

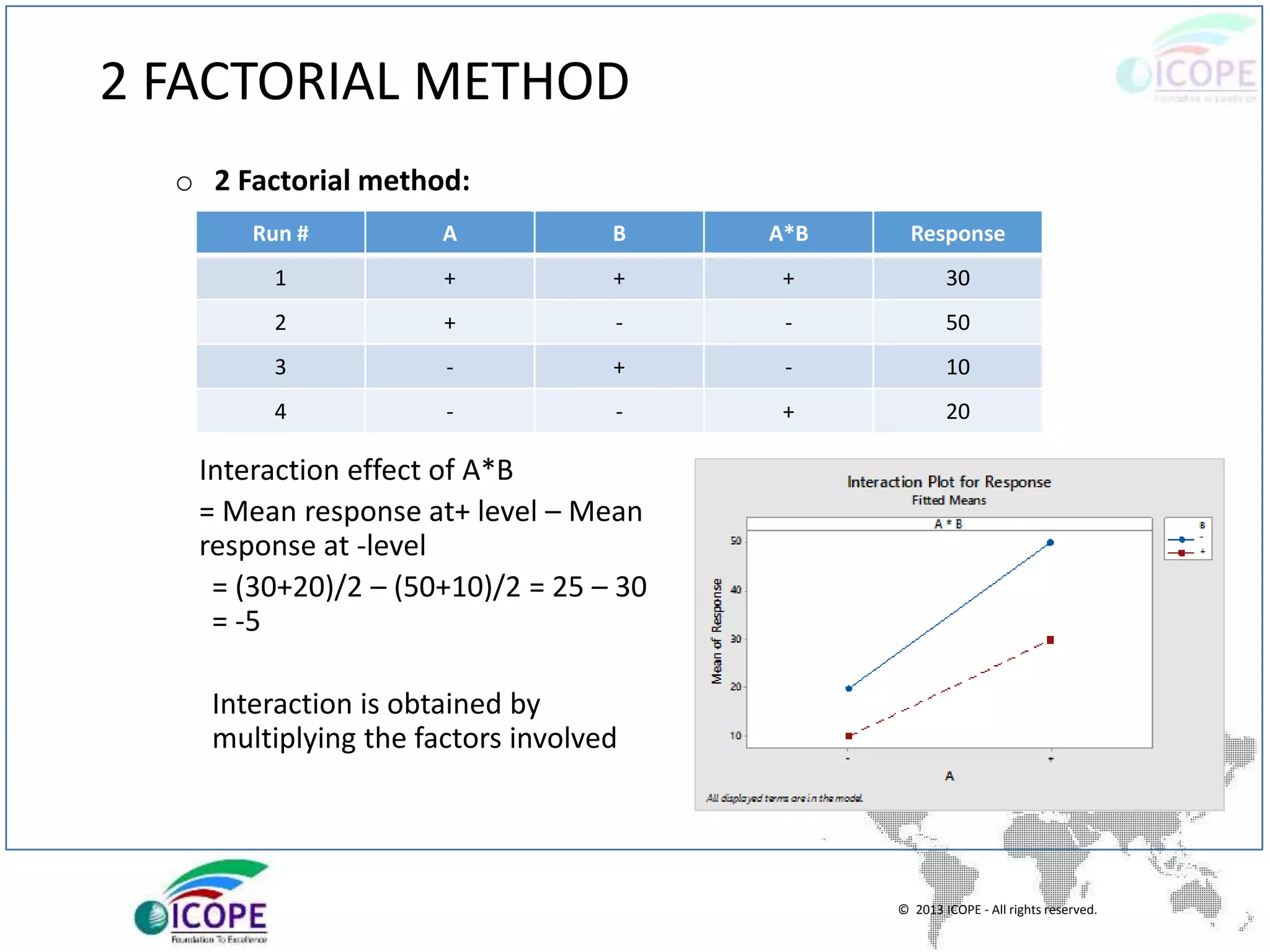

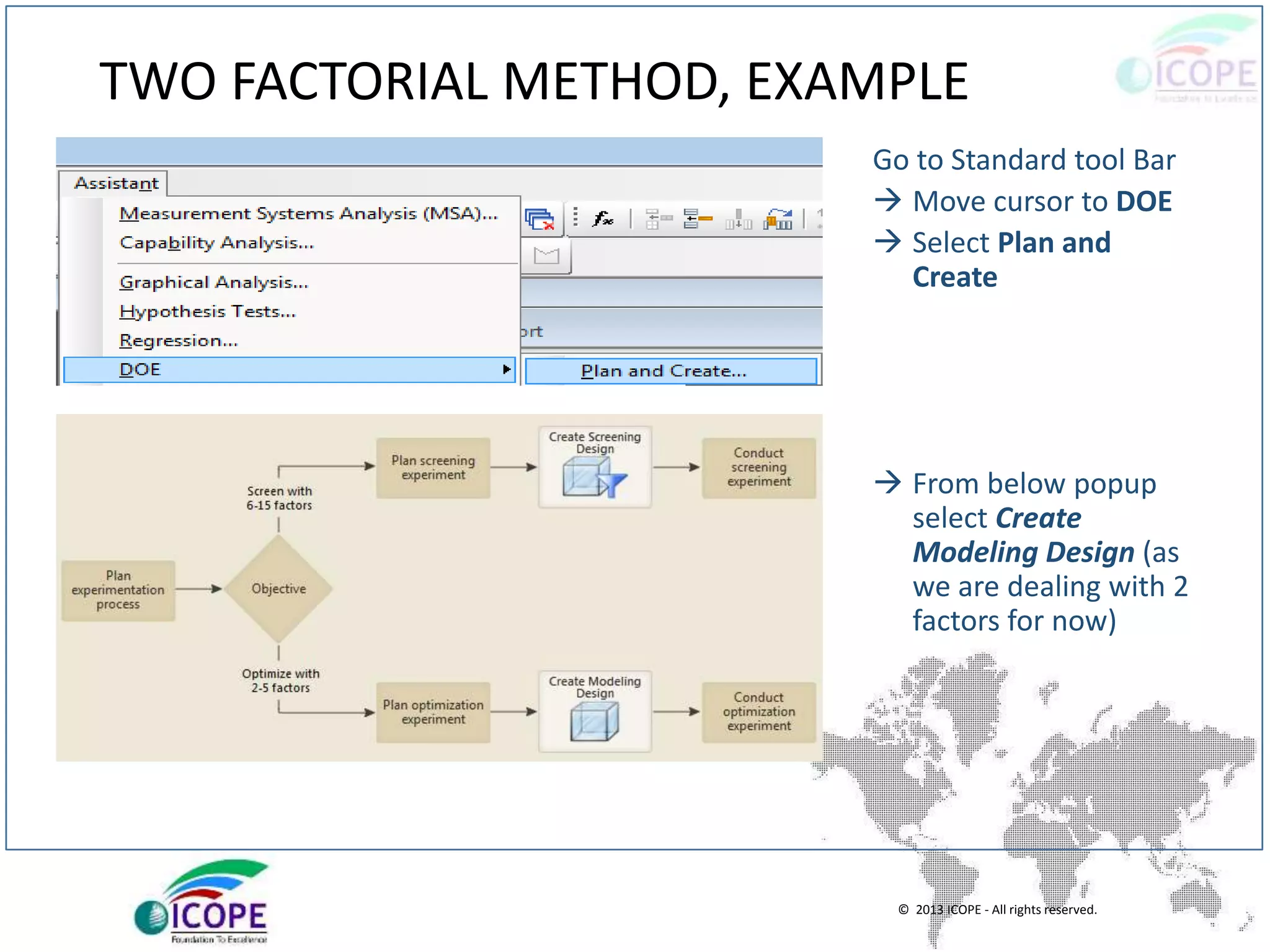

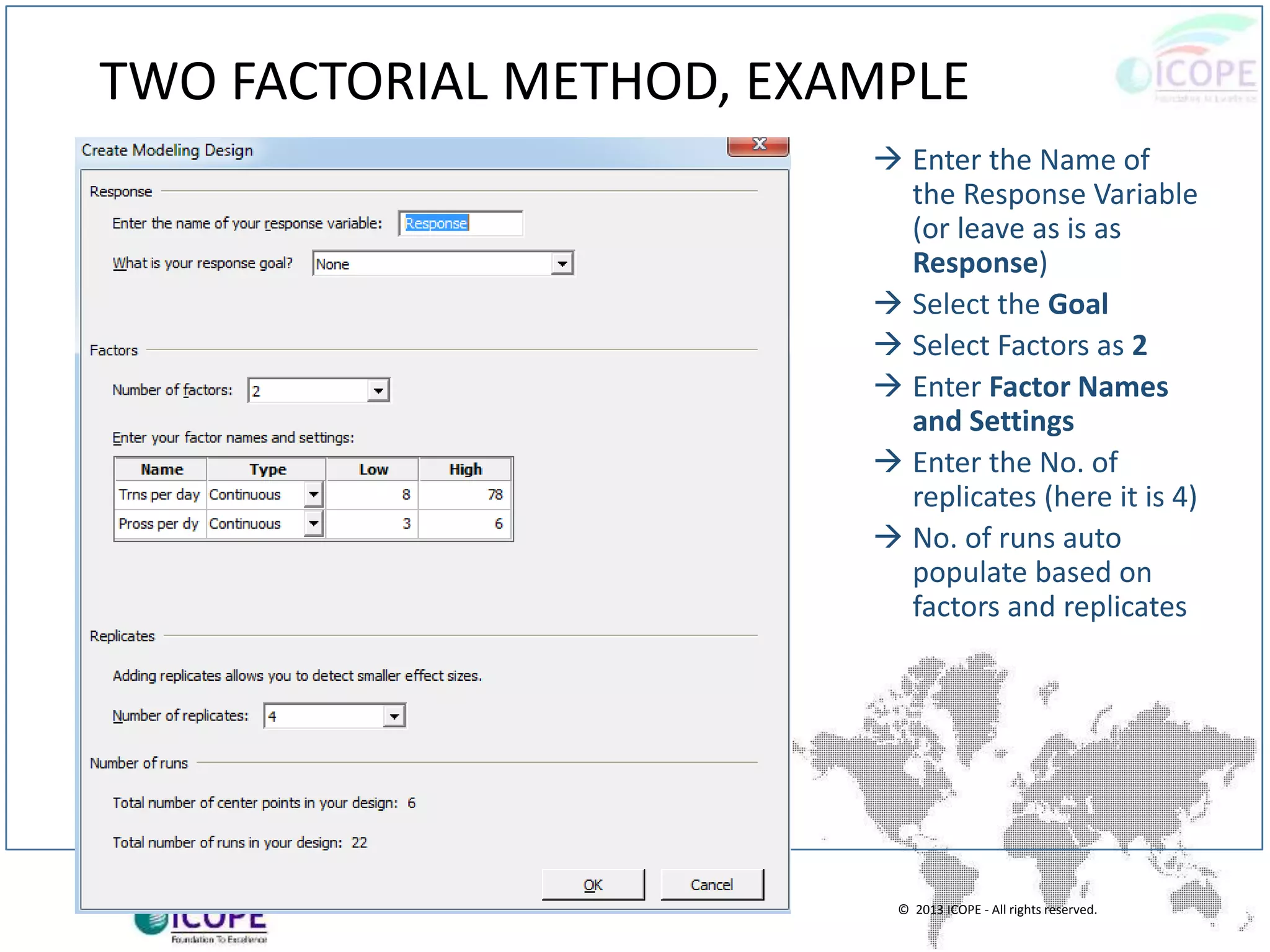

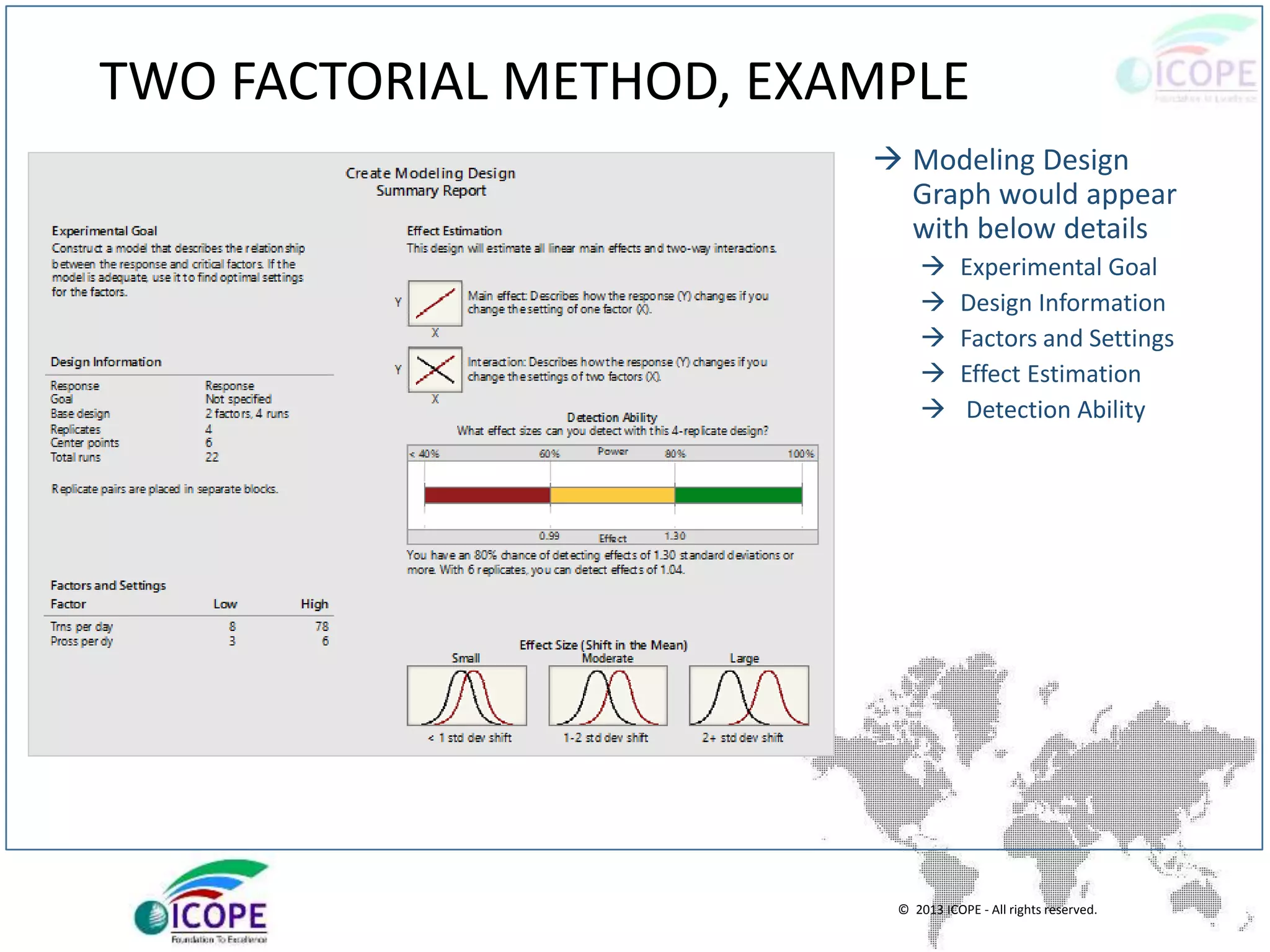

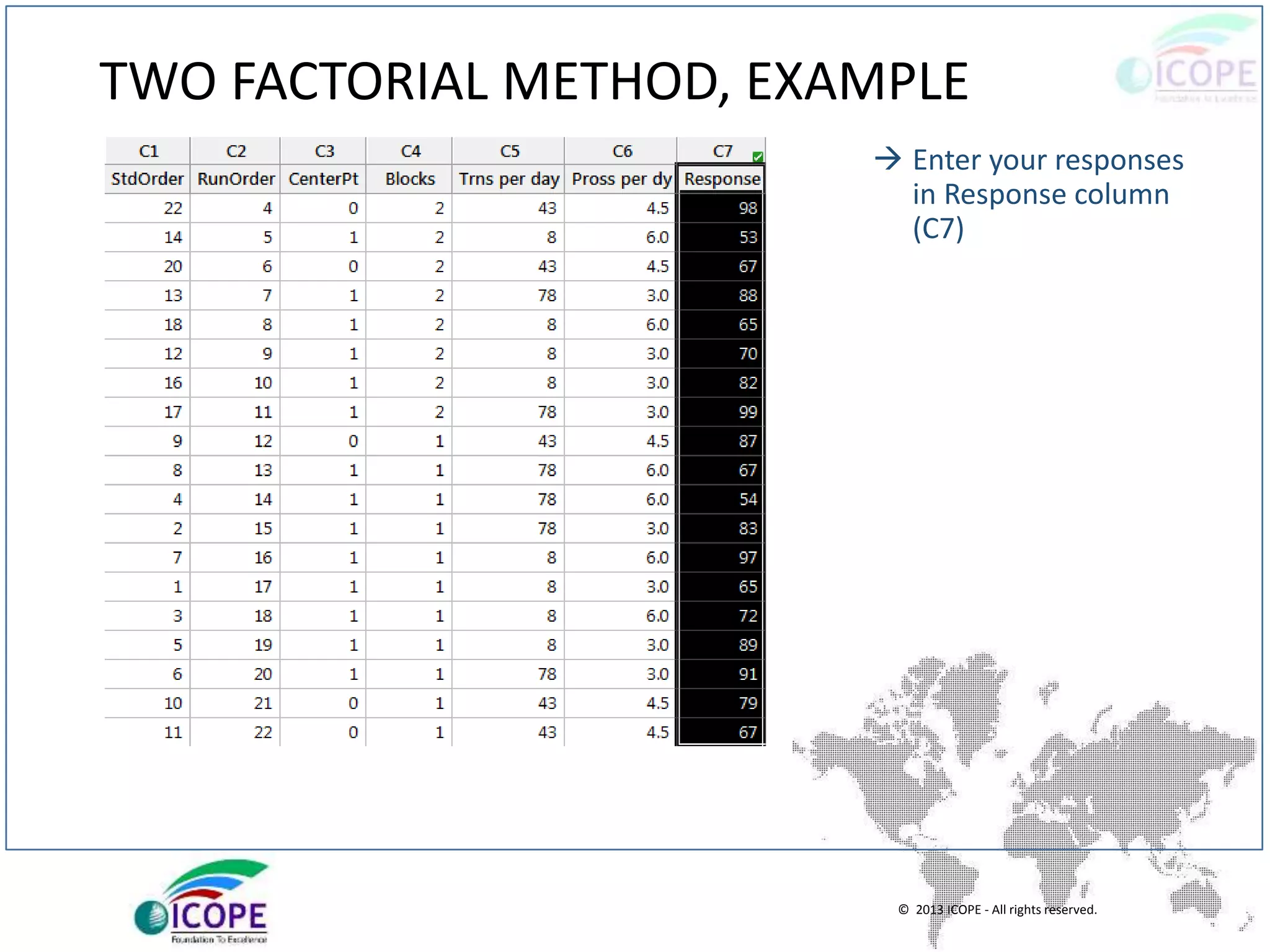

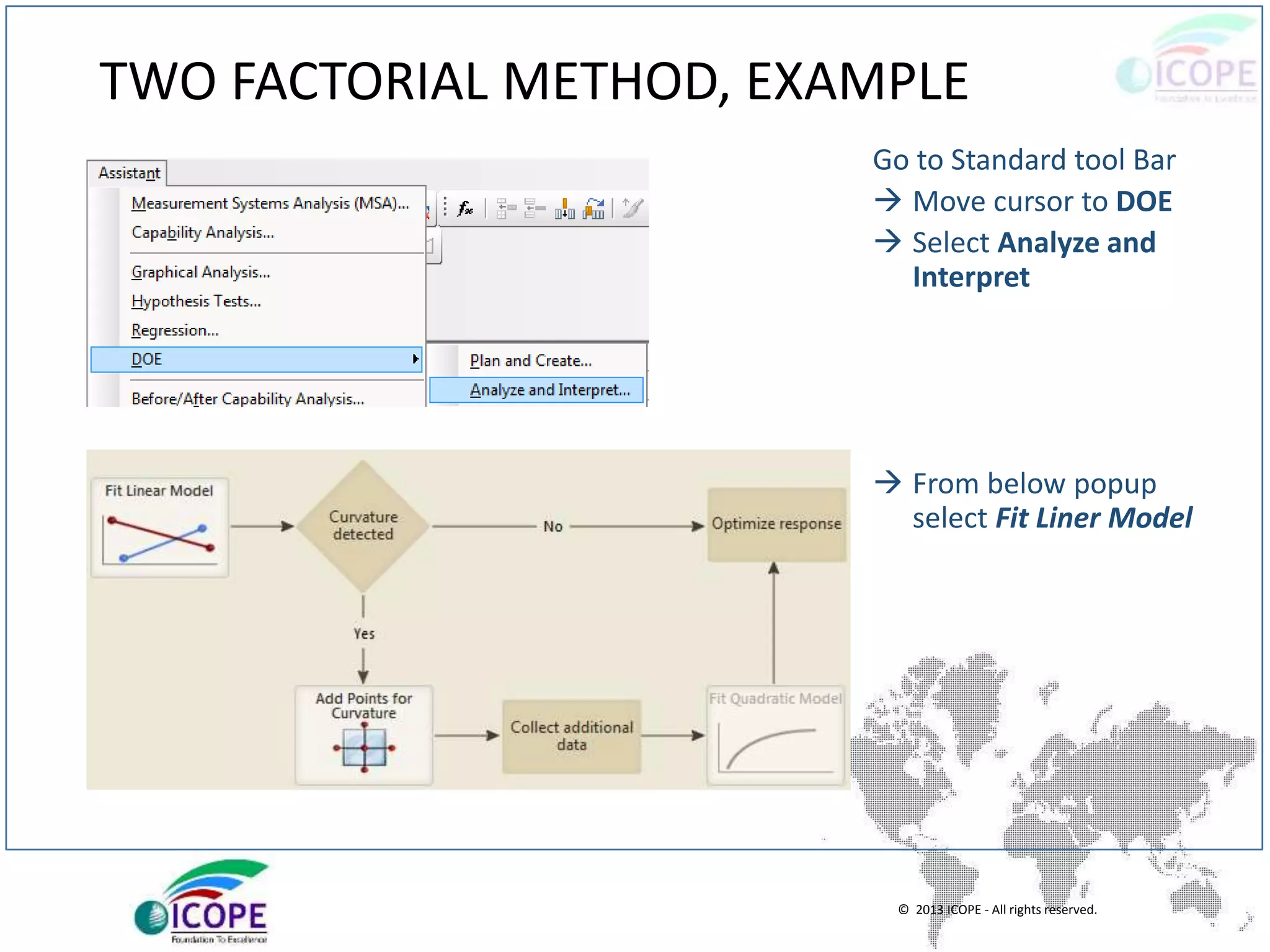

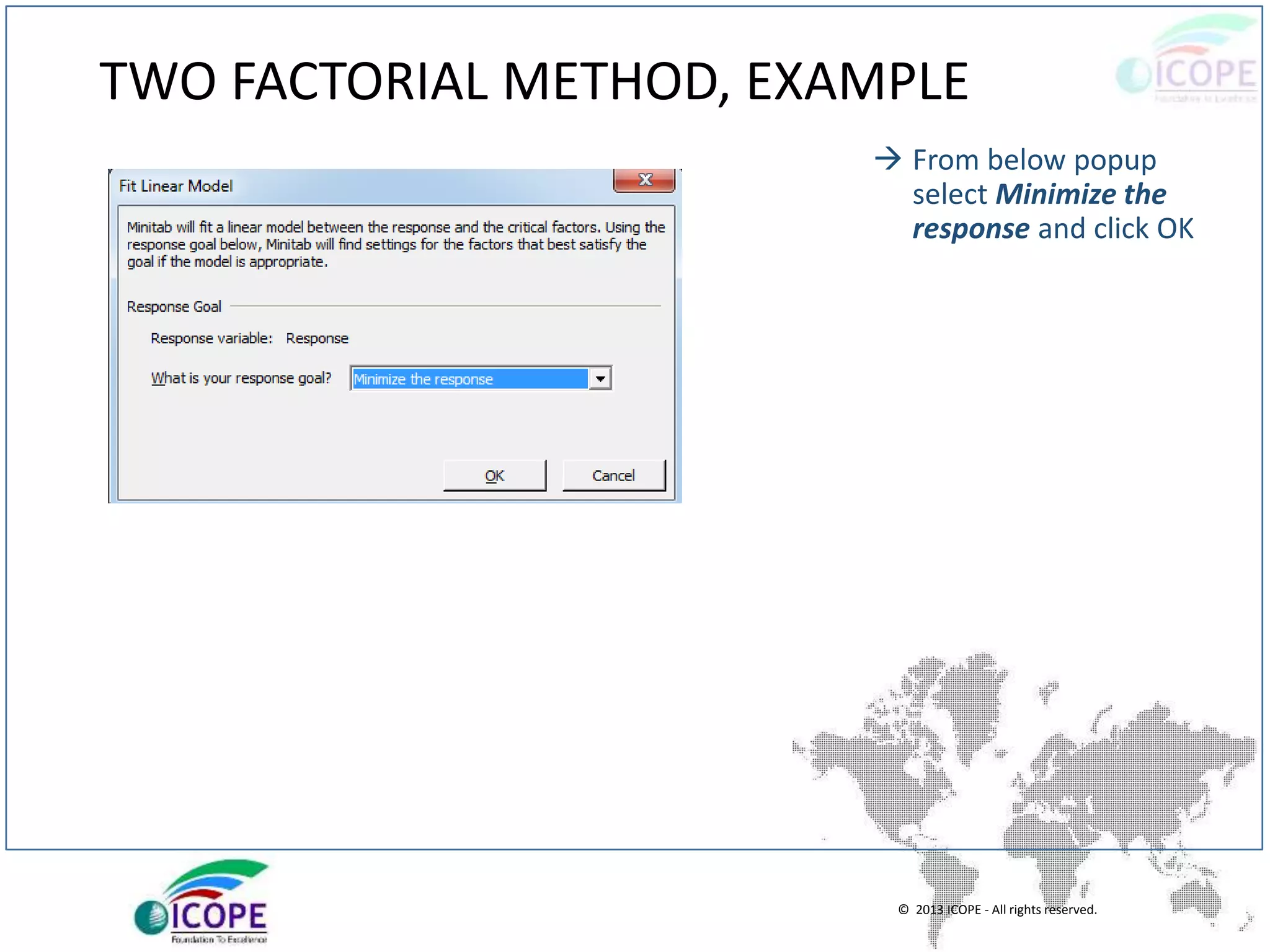

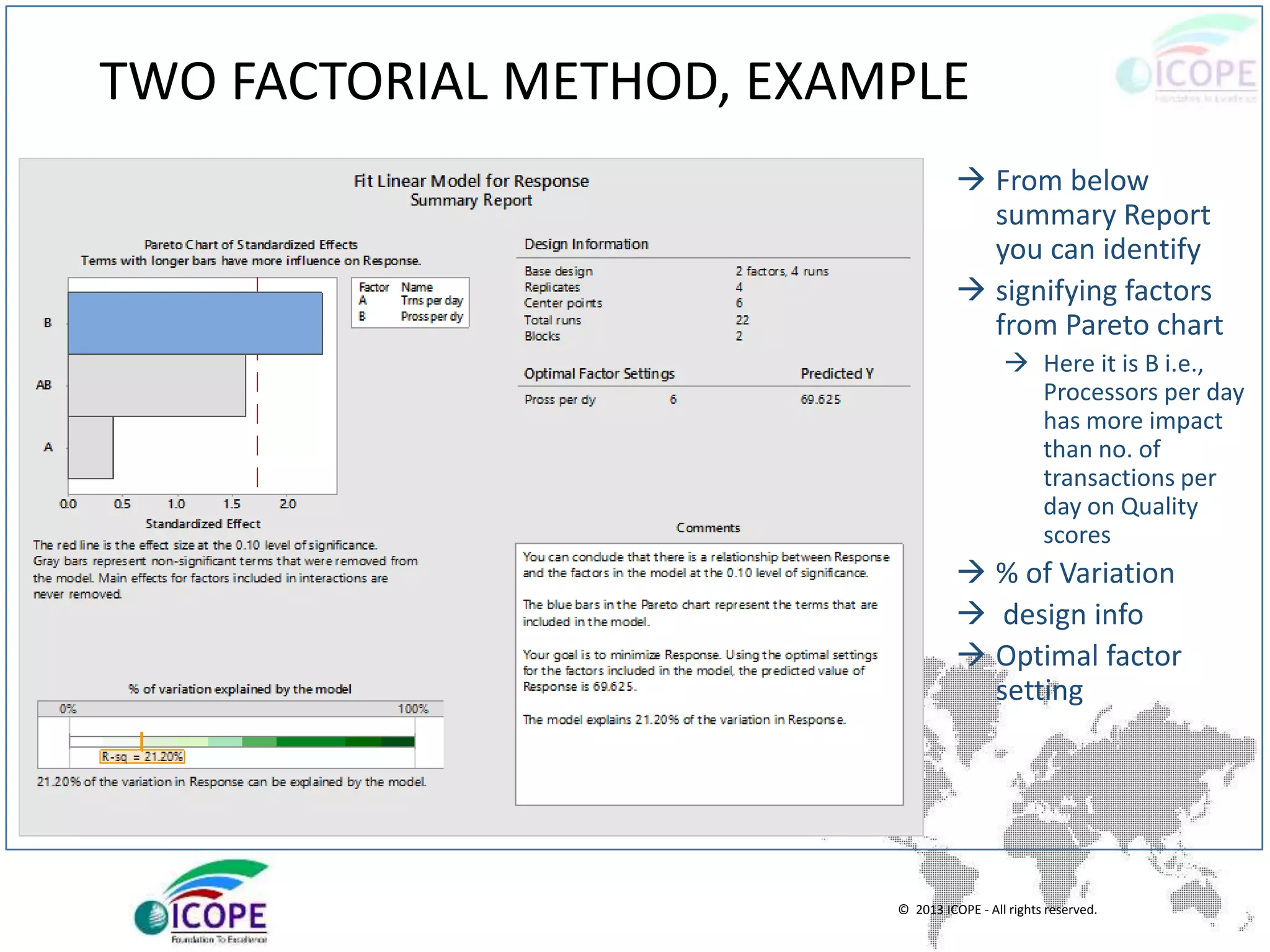

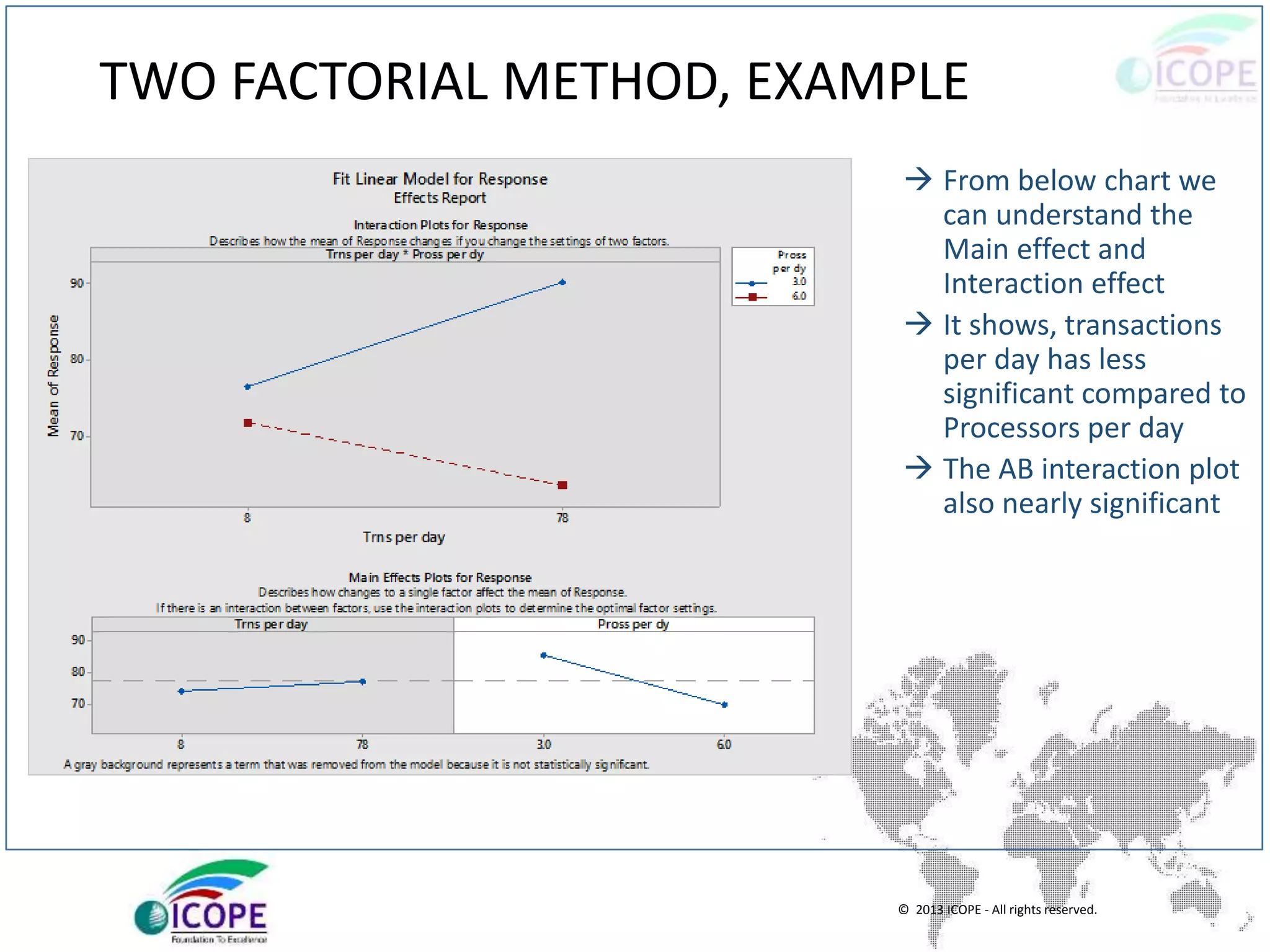

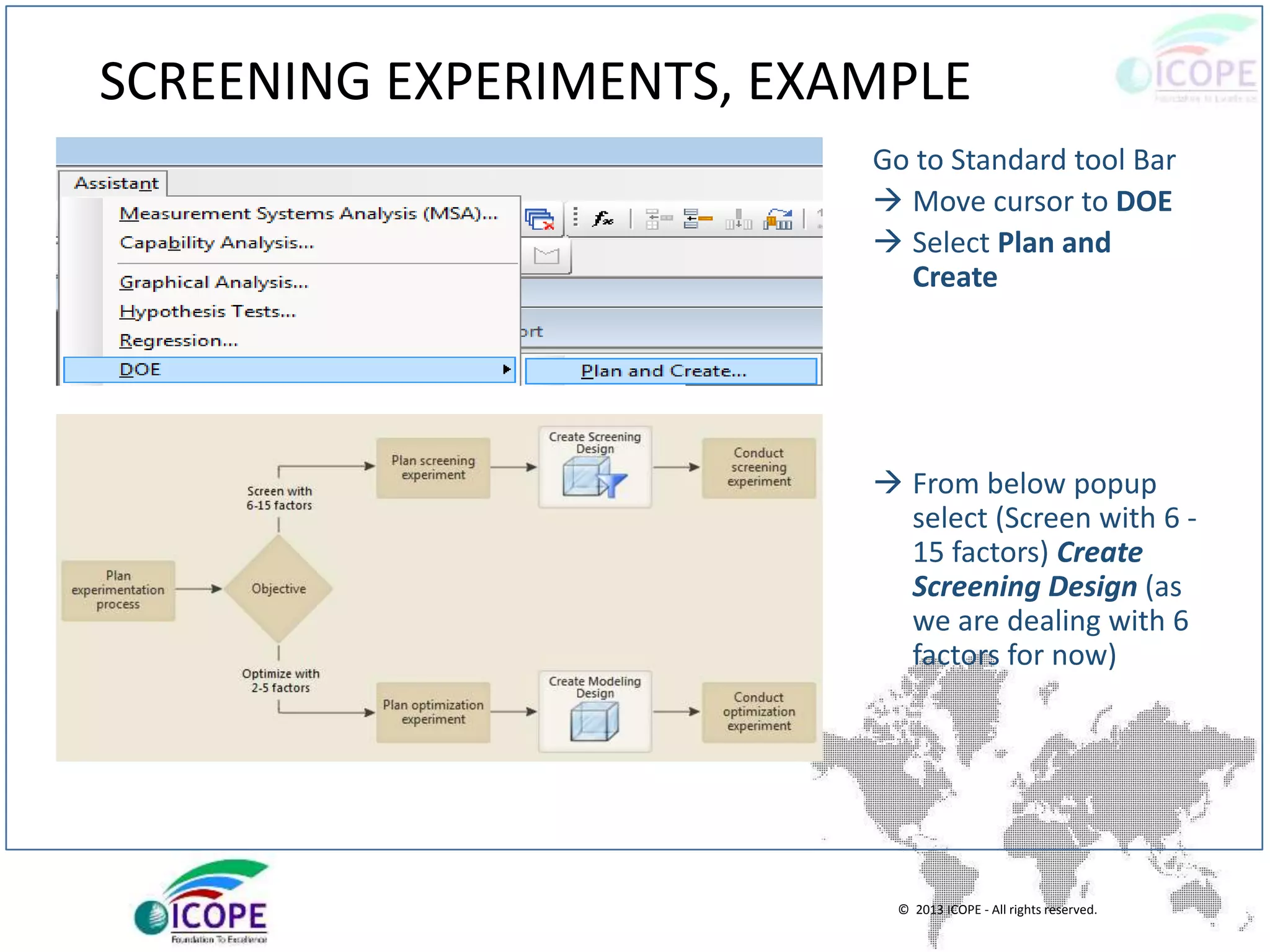

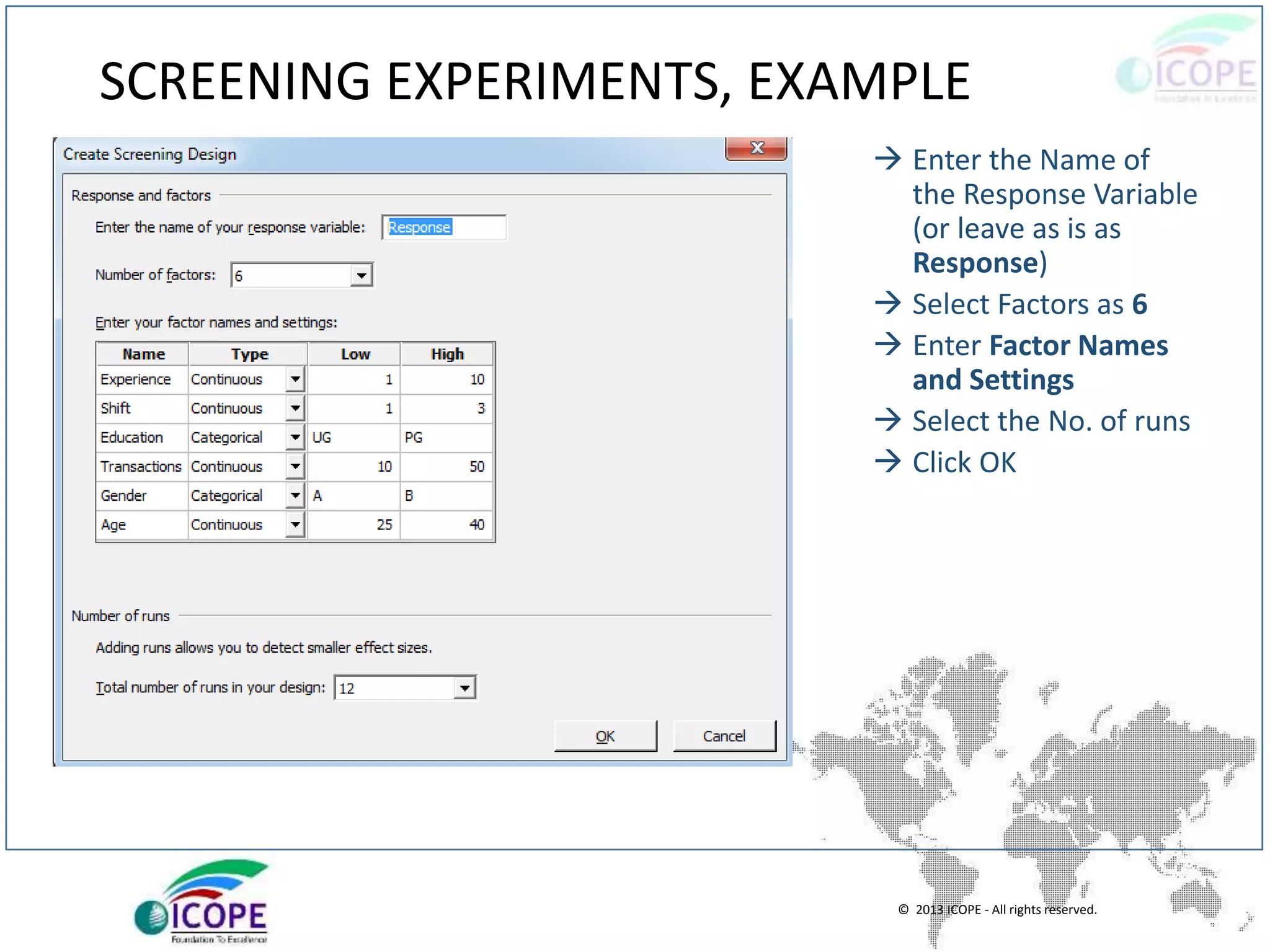

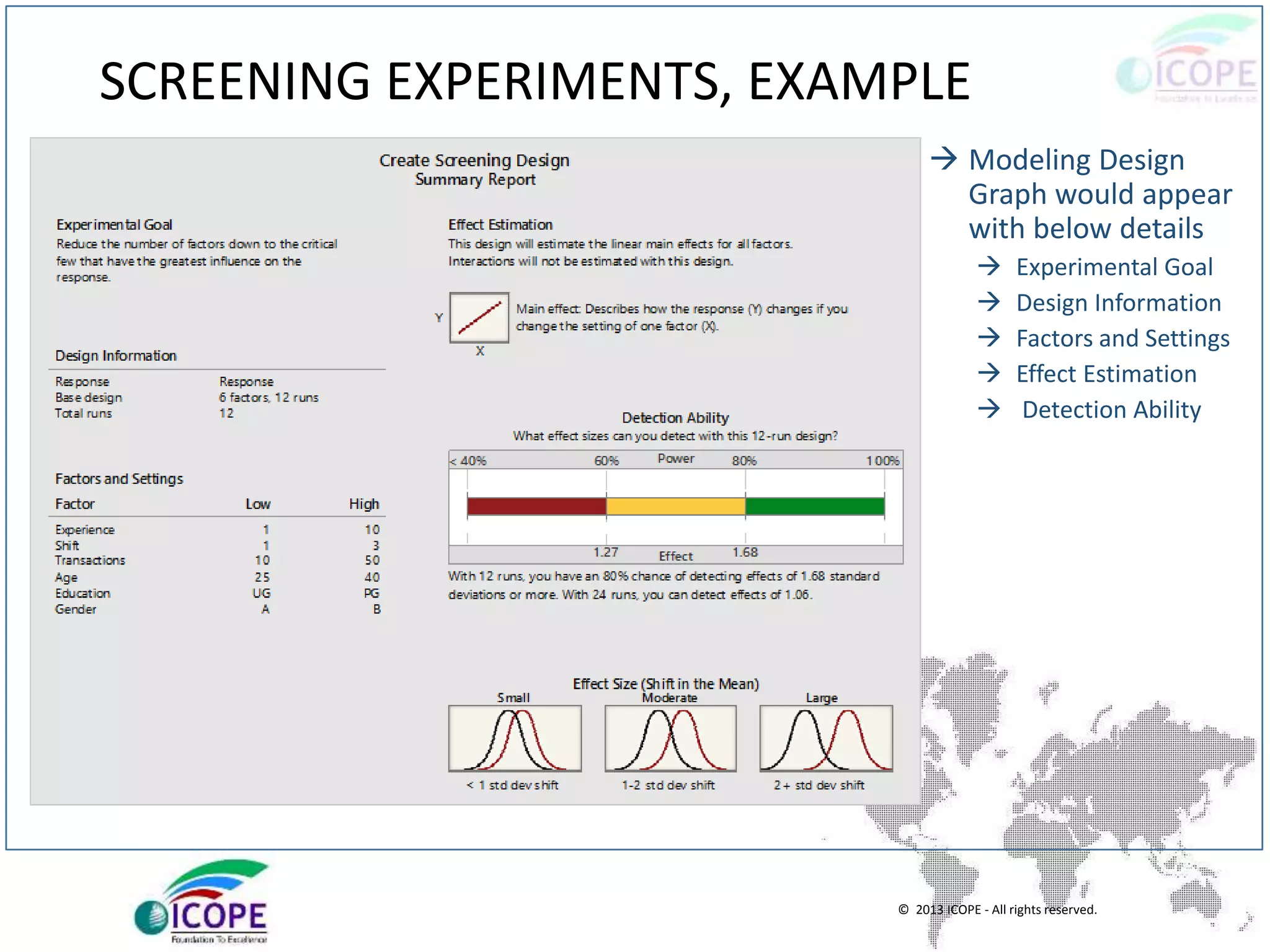

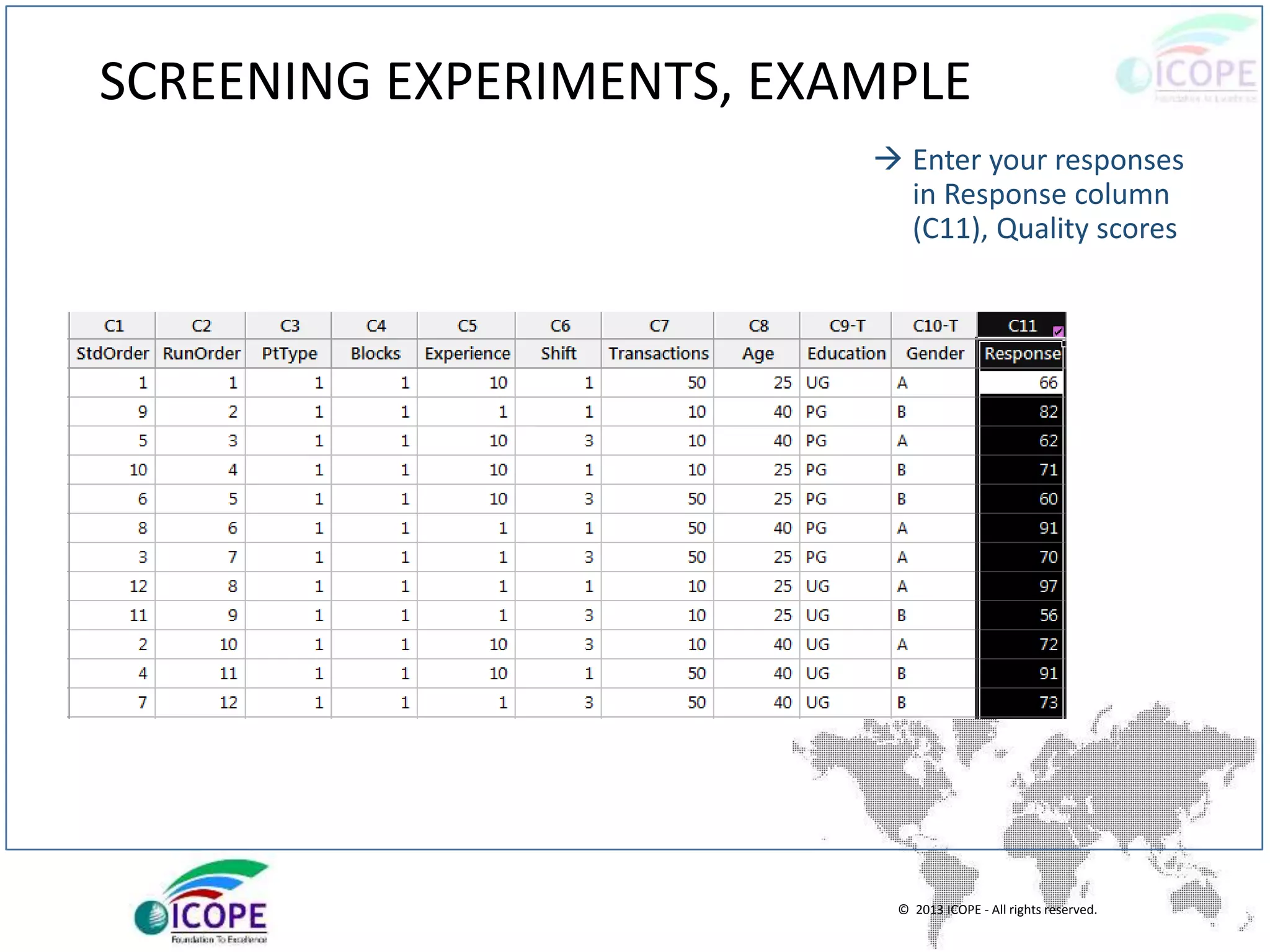

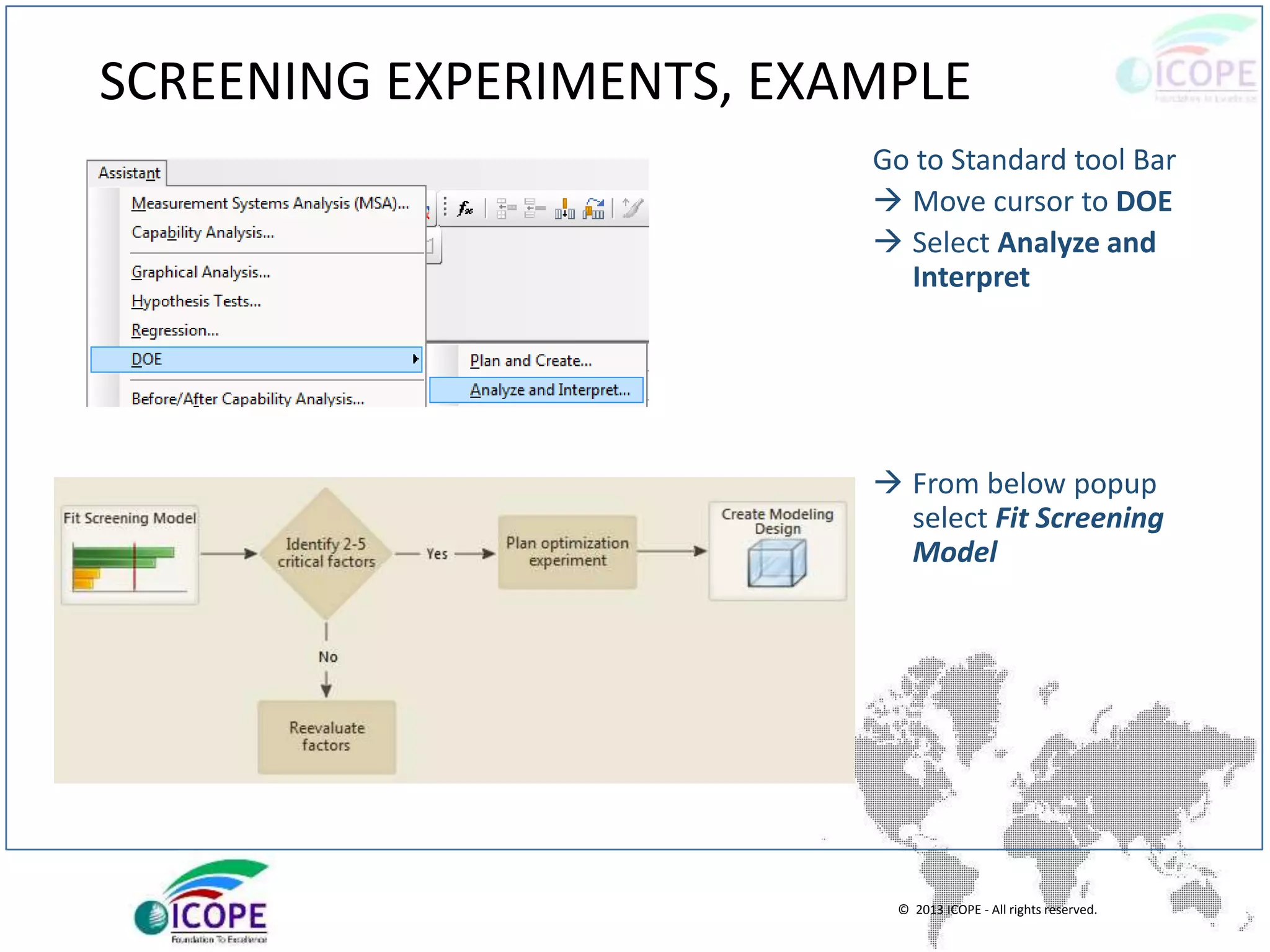

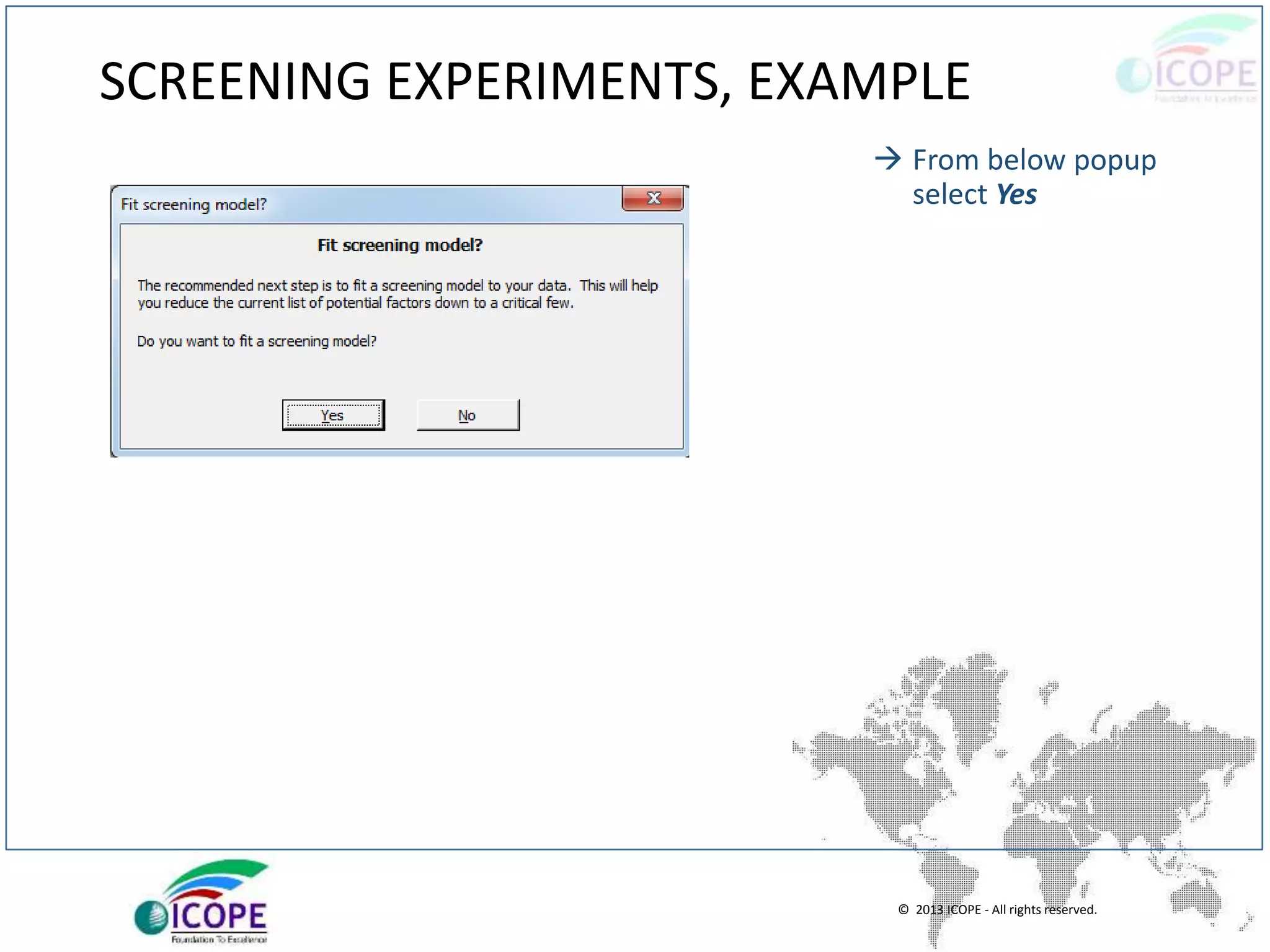

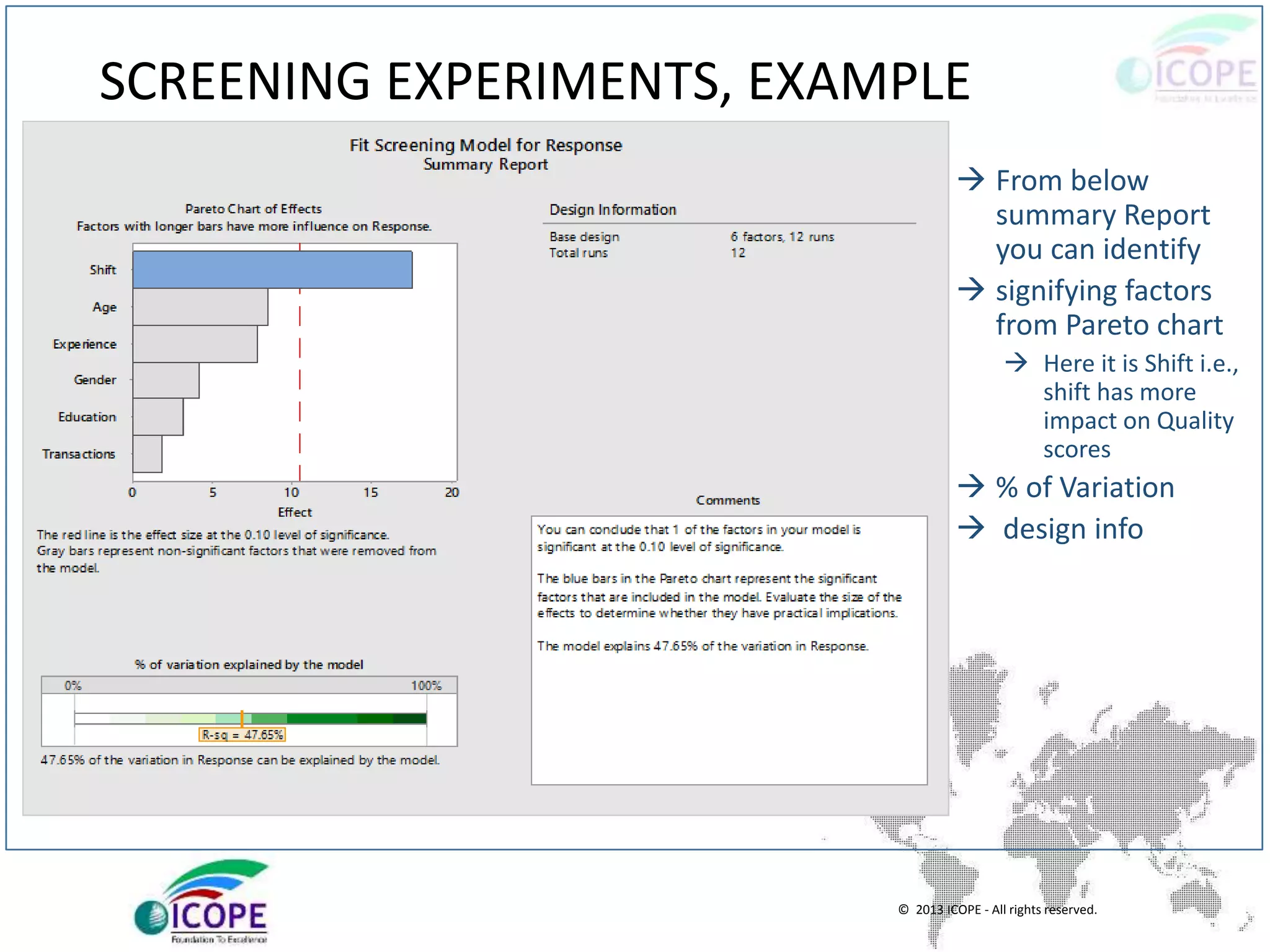

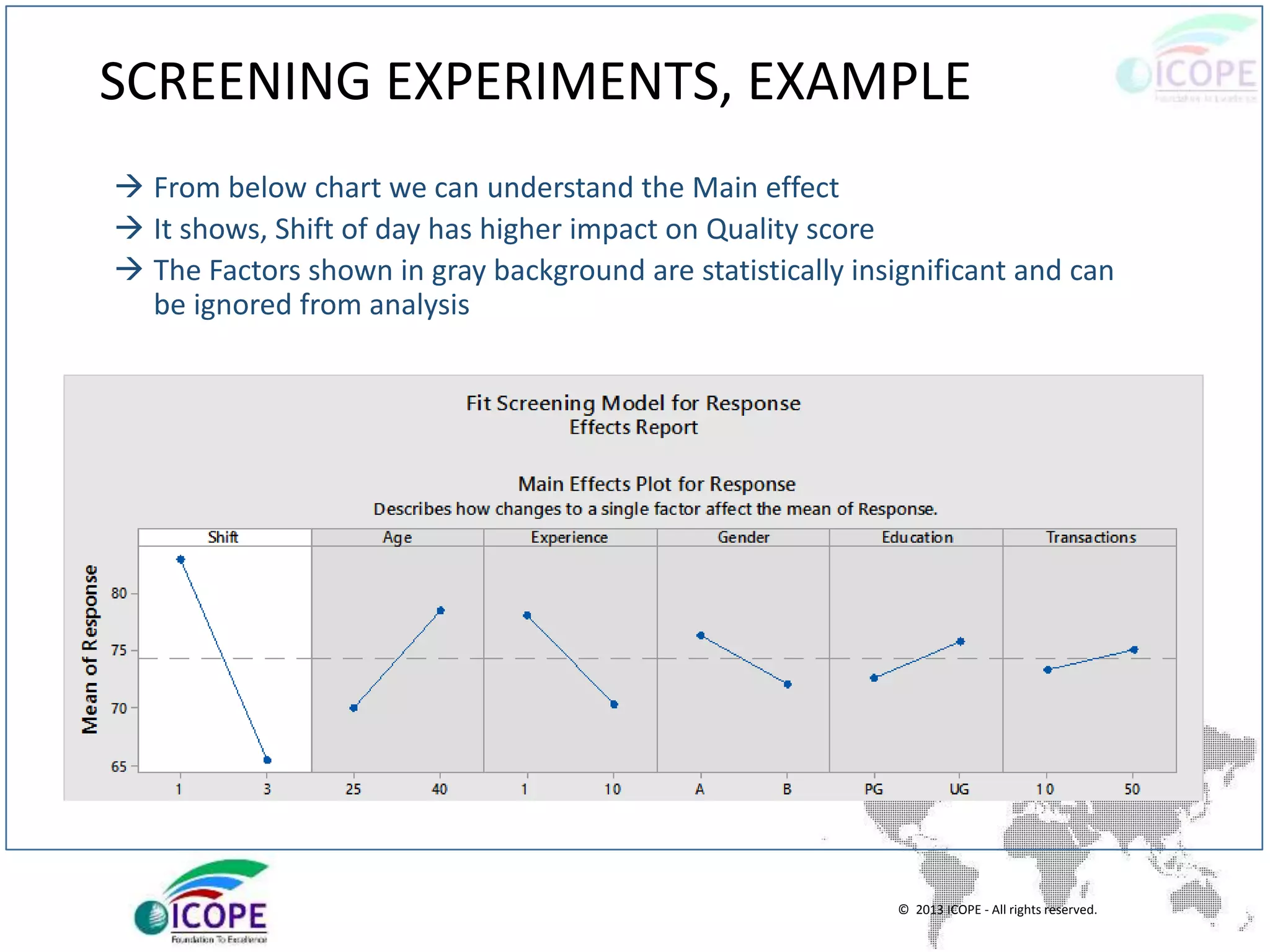

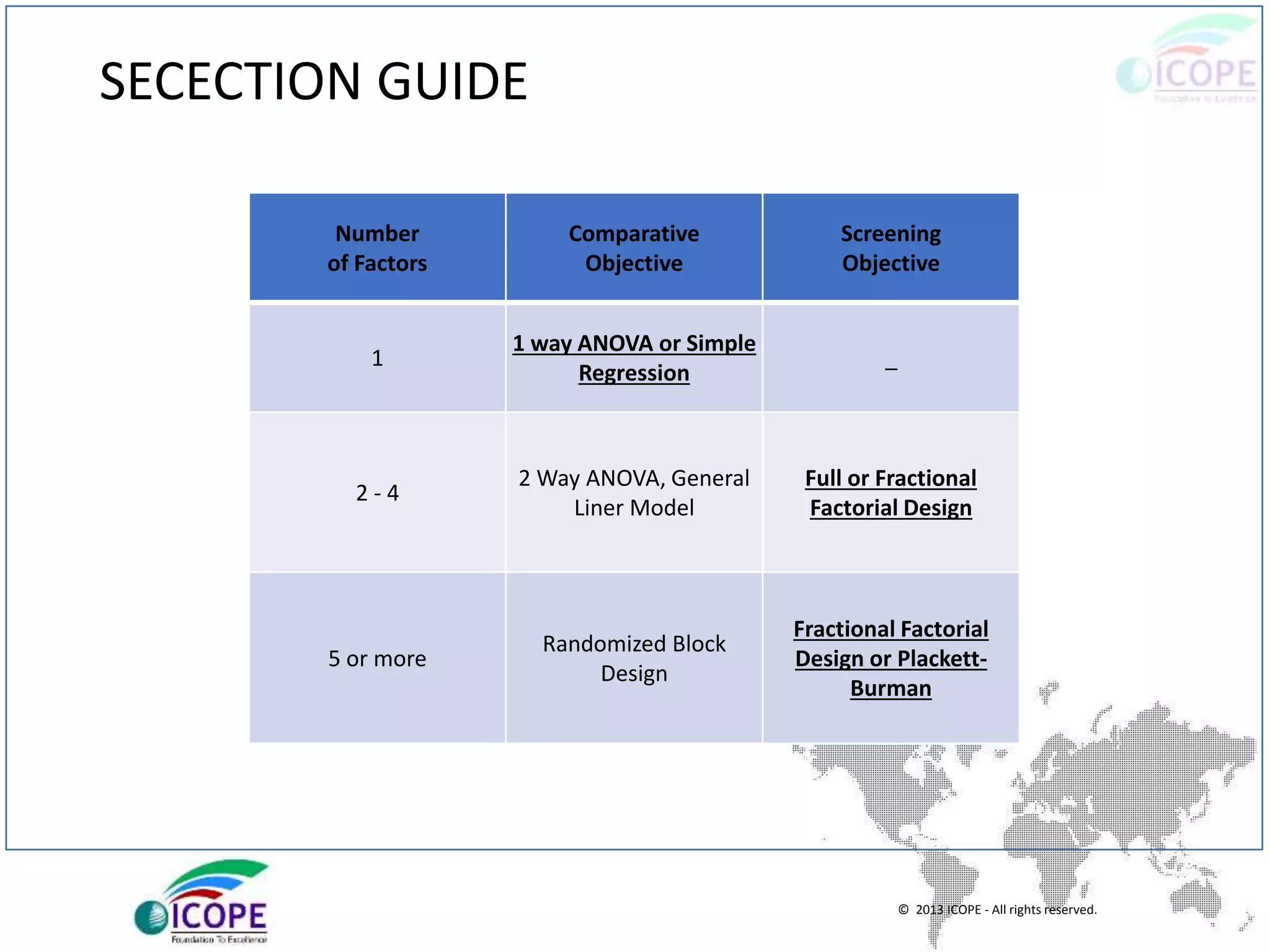

The document provides a comprehensive overview of Design of Experiments (DOE), detailing its history, methodologies, and applications in improving product and process designs. It includes key concepts such as factors, levels, responses, and various experimental designs including factorial and fractional factorial approaches. Additionally, it covers important statistical concepts like randomization, blocking, and replication, along with practical examples and exercises using Minitab software.