544893593-Kaizen-Viewpoint-2.pdf

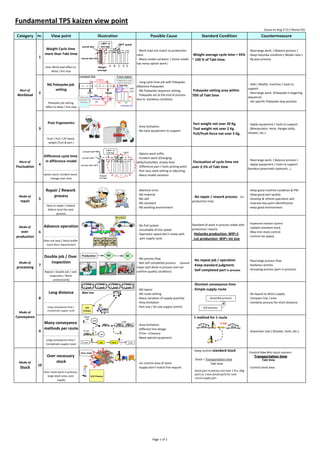

- 1. Fundamental TPS kaizen view point (Issue on Aug 2'13 / Revise 02) Category No. View point Illustration Possible Cause Standard Condition Countermeasure Weight Cycle time more than Takt time Over Work load effect to delay / line stop NG Pokayoke job setting Pokayoke job setting effect to delay / line stop Poor Ergonomics Push / Pull / Lift heavy weight.(Tool & part ) Difference cycle time in difference model option work, incident work, change over time Repair / Rework process Have to repair / rework before send the next process Advance operation Over sub assy / Stock buffer more than requirement Double job / Over inspection Repeat / double job / over Inspection / Work unnecessarily Long distance Long conveyance time / Complicate supply route Many conveyance methods per route Long conveyance time / Complicate supply route Over necessary stock Over stock work in process, large stock area, over supply - Rearrange work. ( Balance process ) - Apply equipment / tools to support. (karakuri,pneumatic,hydraulic…) 3 - Apply equipment / tools to support. (Manipulator, Hoist, Hanger,dolly, shooter, etc.) Fluctuation of cycle time not over ± 5% of Takt time Muri of Workload 1 Mura of Fluctuation 4 2 - Add / Modify machine / tools to support. - Rearrange work. (Pokayoke in begining sequence) - Set specific Pokayoke stop position - Work load not match to production ratio. - Many model variation. ( Some model has many option work ) Weight average cycle time = 95% ~ 100 % of Takt time. - Rearrange work. ( Balance process ) - Keep heijunka condition.( Model ratio ) - By pass process - Long cycle time job with Pokayoke. (Machine Pokayoke) - NG Pokayoke sequence setting. - Pokayoke set at the end of process due to Kanketsu condition. Pokayoke setting area within 70% of Takt time - Option work suffix. - Incident work (Changing dolly/tools/dies, empty box) - Difference part / tools picking point. - Part assy need setting or adjusting. - Many model variation. - Area limitation. - No have equipment to support. Part weight not over 20 Kg. Tool weight not over 2 Kg. Pull/Push force not over 5 Kg. - NG process flow - Not self completed process. (assure major part done in process and can confirm quality condition) - No repeat job / operation - Keep standard judgment. - Self completed part in process - NG layout - NG route setting - Many variation of supply quantity. - Area limitation - Part size / lot size supply control - Shortest conveyance time - Simple supply route - Re-layout to direct supply. - Compact line / area - Combine process for short distance. - Rearrange process flow - Kanketsu activity - Grouping process (part in process) - Control stock area - Automatic tool ( Shooter, hoist ,etc.) 9 - Area limitation - Different line design (Trim-->Chassis) - Need special equipment. 1 method for 1 route - Un-control area of stock. - Supply don't match line require. - Keep control standard stock Stock = Transportation time Takt time Muda of Conveyance 8 Muda of Stock 10 Muda of processing 7 - Update standard stock. - Max-min stock control. - Control ine speed. Muda of repair 5 - Machine error. - NG material - NG skill - NG standard - NG working environment - No repair / rework process (in production line) - Keep good machine condition & PM - Keep good part quality - Develop & refresh operation skill - Improve key point identification - keep good environment Muda of over production 6 - No Pull system - Unsuitable of line speed - Operation speed don’t relate with part supply cycle. Standard of work in process relate with production require. Heijunka production: WIP=1 Lot production: WIP= lot size Assembly process S/A process E-Car - Implement Kanban System -Control Max-Min stock concern Transportation time Takt time Stock part in process not over 1 Pcs. (Big part) or 1 box (Small part) for next round supply part Hand lif t E- car Line E- car จอด Hand Line 1 1 1st 2 nd Over stock S/A Process QG QC Production start 1 Pitch Finish Pokayoke job 70% If delay can't cover with in Takt time Conveyor line Fixed station NG OK 70% 100% Cycle time Pokayoke job If delay can't cover with in Takt time T.T. S F S/A Table Many Stock S/A Process Main line A B C D E actual takt actual takt-5% OPT work Waight average LIMIT of average A B C D E actual takt actual takt-10% OPT W aig ht averag e LIM IT o f averag e actual takt+10% Page 1 of 2

- 2. Fundamental TPS kaizen view point (Issue on Aug 2'13 / Revise 02) Category No. View point Illustration Possible Cause Standard Condition Countermeasure Many times of returning Frequency of walk between work position and flow-rack Many working position change Number of movement for change working position (Buishuyaku) Part area over working area Part area over working area / 1 pitch NG work posture Reach, bend (body), twist, turning (body,face), looking for Double handling Many handling job for parts / tools Interfere process Interfere of Man-Man, Man- Part/Tool, Man-Machine Multi processes work together Dual process, Continuous process NG time matching of man & machine Waiting machine operate / home position Weight average cycle time lower than Takt Waiting before start next vehicle assembly 15 - Same part same process - Rearrange work sequence - Direct supply - Grouping process - Rearrange working position (Bui) & suitable density. - Design suitable working area ( Machine operation route, swing arm of wagon dolly) - Working in same position-same time - Area limitation - High density process - Area limitation - NG production line design (overhead assy) - Part/tool direction not match with assy condition. - Big size part - Temotoka (STD. work posture) (Movement within 1 reach) - Body bend 45 degree - Body turning 90 degree - No have judgement by eye. - Cannot keep same part in same process. - NG work sequence (pick & assy) - 1 side supply condition. - Many tools in process Single handling part / tool - SPS supply - Sequence part supply - Slim flow-rack - Improve flow rack efficiency - Rearrange work. (Balance process) - Grouping job for working position - Auto jig return (spot / spray) Muda of Waiting - Different working position in same working time. - Keep standard density process. ( Ex. Conveyor : 2 processes in 1 pitch) 18 17 - Together work start different time. - Safety condition (Clamp - Unclamp) Together work start same time - Work load unmatch to production ratio. Weight average cycle time = 95% ~ 100 % of Takt time. 19 Muda of Motion 11 16 Part area within the length of the pitch - Apply equipment / tool to support (Sliding seat, Stand, balancer, flow-rack level, shooter, Auto turning) - Lamp,light (DPS), voice signal. (for judgement) - Rearrange work. - Modify machine to speed up. - Add hand work while machine operate. - Machine work & hand work unrelated. - Low machine speed. - Keep safety condition while machine operating. Must have hand work while machine operating. - Rearrange work - Apply automation to support one process operating. ( Manipulator, Hoist, Hanger, Auto spot, Auto spray ) - Using synchronize dolly - Relocate flow-rack to match with work sequence. - SPS supply - Shooter supply - Big part picking - Many part assy. - Flow-rack location not match with work sequence. 1 pitch 1 return 14 13 - Long cycle time work (part quantity) - Many part variation - Big size part - Long cycle time work - Many model variation 12 0 ~ 1 working position change 0 TT. Waiting M/C operate Right process Left process A Interference ! B 1 2 3 (Part area) work area 1 Pitch Flow rack part area work area 1pitch 1 Pitch Flow rack 1 2 3 4 5 6 7 8 9 Flow rack 1 2 3 7 4 8 9 5 1 return Wagon 6 4 working position transfer CF LF C1 C2 C3 L3 R3 C4 C3 C5 C9 C8 C7 L2 L1 L4 R4 R2 R1 LE CE L1 RF RR CR LR 1 4 3 2 1 2 3 4 Jig Fix Station Conveyer Line CF LF C1 C2 C3 L3 R3 C4 C3 C5 C9 C8 C7 L2 L1 L4 R4 R2 R1 LE CE L1 RF RR CR LR 1 Jig Conveyer Line Fix Station actual takt-5% A B C D E actual takt Weight average LIMIT of average Page 2 of 2