Dr TU PPT.pptx

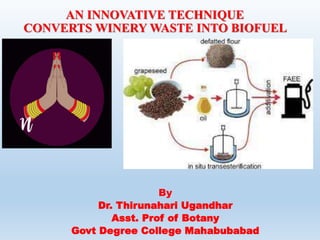

- 1. AN INNOVATIVE TECHNIQUE CONVERTS WINERY WASTE INTO BIOFUEL By Dr. Thirunahari Ugandhar Asst. Prof of Botany Govt Degree College Mahabubabad

- 3. Abstract • The chemical components that power biofuel may be found in every part of the grape plant, including the vines, the seeds, the peels, the pulp, and even the stems. laboratory analysis to determine their potential application in producing bio-ethanol. • A recently developed method for breaking down waste products from the process of making wine could potentially be used to produce biogas and biofuel. • a new approach to the generation of biofuel that makes use of the components of grapes and vines that are discarded during the winemaking process. found a way to convert waste from the wine industry, which is mostly made up of cellulose, pectins, and lignins, into simpler molecules that may be utilized to make ethanol or other types of biofuels. • These enzymes convert the waste to soluble sugars, which may subsequently be transformed into other products

- 4. • Grape fruit peels had the highest polyphenol concentration of 54.45%. • In the mixed fruit pulps, the dilute acid (H2SO4) pretreatment (DAP) followed by Various fungi is known to decompose this waste by producing an assortment of enzymes. • This fermentation process can take anywhere from one to three weeks, and it results in the production of alcohols, acids, and simple sugars that have potential use in industry and medicine. • The method of biodegradation through the use of fungus is not particularly novel; nevertheless, the implementation of symbiotic fungi to enhance the process of biomass degradation is relatively recent. • In order for this method to be a financial success, chemists, engineers, and economists will need to contribute significantly. • We are working on developing a method that any nearby vineyard would be able to utilize to convert its waste materials into either biofuel like ethanol or other compounds that are significant from a business perspective.

- 5. • At 42 hours of incubation, the hydrolysates derived from dilute H2SO4 pretreated Grapefruit peels generated a high of 13.84 percent ethanol with a fermentation efficiency of 27.13 percent • The fermentation of hydrolysates obtained from dilute acid pretreatment followed by enzymatic saccharification of mixed fruit pulps (Grape ) was determined to be the best for higher ethanol production under the optimum condition in the current study.

- 7. Introduction • Since it is produced from biomass, biofuel is considered a sustainable fuel source. • Ethanol is clear, colorless alcohol made from a variety of biomass materials called feedstocks (the raw materials used to make a product). • U.S. producers mostly use food grains and crops with high starch and sugar content as feedstocks for making ethanol such as corn, sorghum, barley, sugar cane, and sugar beets. • Ethanol can also be made from grasses, trees, and agricultural and forestry residues such as corn cobs and stocks, rice straw, sawdust, and wood chips. Ethanol is made from these feedstocks in several ways.

- 9. Descriptionof the ResearchProblem: • Urbanization and rapid population growth are responsible for increasing the consumption of energy in the world. • The worldwide consumption of energy has increased 17- 20 % in the last century". • On the other hand, conventional energy sources (non- renewable) such as fossil fuels are limited and thus cannot meet the demand in the long term. • Moreover, the use of fossil fuels also has a negative environmental impact, e.g. increased greenhouse gas emissions.

- 11. Biofuel push: India is set to be the third- largest ethanol market by Prime Minister Narendra Modi had said in June that the government has resolved to meet the target of 20% ethanol blending in petrol by 2025. Earlier the target was set for 2030. India is set to become the third-largest market for ethanol in the world after the US and Brazil by 2026, a recent report by the International Energy Agency (IEA) said, adding that the country has tripled ethanol demand to an estimated 3 billion litres between 2017 and 2021. Buoyed by India’s growing appetite, Asia is set to overtake Europe in terms of biofuels production by 2026, the agency said. While

- 13. •Objectives • The major objectives of large-scale production of biofuel are: diversification of the sugarcane Ripen fruits, industry, reduction of energy imports, better resource use, and, indirectly, better environmental management. • Develop a method to convert cellulose and hemicellulose from amaranth lignocellulose Into fermentable sugars. • For bioethanol to become more sustainable to replace petrol, the production process has to be more efficient. • Reducing cost of conversion • Increasing yields Increase the diversity of crops used. • Enhance participant understanding of fermentation processes and chemistry. • Enhance participant understanding of microbial growth processes. • Provide an opportunity for participants to gain hands-on experience with state-of-the-art fermentors and fermentation monitoring equipment.

- 14. • Fermentation is the most common method for producing fuel ethanol • The most common ethanol production processes today use yeast to ferment the starch and sugars in corn, sugar cane, and sugar beets. • Corn is the main feedstock for fuel ethanol in the United States because of its abundance and relatively low price historically. • The starch in corn kernels is fermented into sugar, which is then fermented into alcohol. • Sugar cane and sugar beets are the most common feedstocks used to make fuel ethanol in other parts of the world. Because alcohol is made by fermenting sugar, sugar crops are the easiest ingredients to convert into alcohol. • Brazil, the world's second-largest fuel ethanol producer after the United States, makes most of its fuel ethanol from sugar cane. Most of the cars in Brazil can run on pure ethanol or on a blend of gasoline and ethanol.

- 15. •Review of Literature • Fuel ethanol production has been fascinating now because many countries look for reducing oil imports, boosting rural economies, and improving air quality. • The world ethanol production has reached about 51,000 million liters (RFA (2007), being the USA and Brazil being the first producers and India standing fourth among the top fuel ethanol producers. • Main feedstocks for bioethanol production are sugarcane (in Brazil) and corn grains (in the USA), while many other agricultural raw materials are also used worldwide.

- 16. • Among the three major types of raw materials, the production of ethanol from sugary and starchy materials are easier as compared to lingo cellulosic materials since it requires additional technical challenges such as pretreatment (Petersson et. al., 2007). • Furthermore, the use of high technology and complicated instrumentation methods with high operating costs may in turn limit their commercialization and industrial application in the developing countries (Isarankura et al., 2007). • Ethanol was first prepared synthetically in 1826, through the independent effort of Henry Hennel in Britain and S.G in France. Michael Faraday prepared ethanol by the acid- catalysed hydration of ethylene in 1828, in a process similar to that used for industrial synthesis of ethanol today.

- 17. • Materials and methods: • Grape vines, grape seeds, skins, pulp, and stalks were collected from the local wholesale fruit market. • The fresh plant materials were brought to the laboratory, washed, and separated into pulp and peels. • The fruit pulps were homogenized by using a simple wet milling technique without adding water and the pulverized puree was taken for further experimental studies. • A mixed fruit pulp sample was also prepared by mixing both fruits in an equal ratio (B1:O1 w/w). • The fresh Grape vines, grape seeds, skins, and pulp were chopped into small pieces (2-3 cm) and dried in a hot air oven at 65ºC for 24 h. • The dried materials were ground in a Wiley mill to pass through a 1 mm screen and the powdered materials were stored at room temperature for further analysis. • Composite samples of both fruit peels were also prepared in the same manner.

- 19. Mechanism of the acid-catalyzed transesterification of vegetable oils

- 20. • Preparation of Growth Medium • The growth medium prepared for ethanol production consists of 20 g substrate (Winery pulp) • in 250 ml of the conical flask containing 100 ml of distilled water (pH-5.5). The flasks were autoclaved at 121°C for 20 minutes. This medium is poured into Petri plates and set aside to solidify. • Preparation of Inoculum: • The cells of S.cereviacae were aseptically cultured in Yeast Extract Peptone Dextrose (YEPD) broth and incubated at 30°C for 24hrs. 3.5 Saccharification of the Fermentation Medium with Aspergillus • The substrate medium as prepared above was inoculated with spores of Aspergillus. The culture was incubated at 28C for 7 days under rigorous aerobic culture.

- 21. • The samples were taken at regular intervals every 24 hr for analysis. After 7 days in culture maximum total sugar was obtained. 3.6 Ethanol Production Medium (270 ml) was prepared and transferred to a Duran wide-mouth bottle. • The media was autoclaved at 121C for 20 minutes and cooled. The culture broth (30 ml) from the Saccharification step was added to the medium. This broth contains the cellulolytic enzyme complex elaborated by Aspergillus. • The bottle was inoculated with 5% v/v of previous activate Saccharomyces cerevisiae. • The bottles were cultured in static conditions. The samples were withdrawn at regular time intervals every 24 h. 3.7 • Primary Product Isolation: • The samples were centrifuged at 5000 rpm for 5 minutes and stored at -20C for further analysis. • The raw ethanol yield was measured by ethanol assay using the potassium dichromate method. 3.8

- 22. • Estimation of Biofuel: • 10 ml of sample was drawn in a 250 ml volumetric flask. The water was added to make the volume up to 250 ml. From this diluted sample, a 20 ml aliquot was drawn and drawn in a conical flask. • 10 ml of 40% sulphuric acid was added to each flask using a measuring cylinder. Stopper each flask loosely and heat for 10 minutes in a water bath at 45–50°C. After 10 minutes the flasks were removed from the bath and 2 g of potassium iodide was added to each flask. • A burette was filled with standard thiosulphate solution. • Titrate the contents of the flask with the thiosulphate solution. 1– 2 ml of starch was added to the solution when the brown colour of the solution becomes green. The equivalence point of the titration is reached when blue colour of the starch iodine complex just disappears, leaving a clear green colour.

- 23. Results & Observations • Pre-treatment of Fruit peels and pulp: The media consisting of the oven-dried substrate (20gms) was used and volume was made up to 250 ml and pH was adjusted to 5.5. • The media was inoculated with spores of Aspergillus niger. The culture was incubated at 28°C for 7 days under aerobic culture. The enzyme activity was qualitatively determined by Starch Agar plate assay and Cellulose Agar plate. • The maximum residual sugar was obtained during 192 hr- 216 hrs. During the fermentation concentration of reducing sugars was determined by finding out the refractive index of the solution.

- 24. • The culture was replenished with fresh media and inoculated with an activated culture of Sacchromyces cerevisiae. • The culture was transferred to Duran wide mouthed bottles. The bottles were sealed and kept static in an incubator at 28°C. • The samples were withdrawn in every 24hrs and the changes in pH, RI and ethanol concentration are displayed graphically as follows’. Similar procedure was carried out with different substrates. The profile of change in pH, residual sugar and ethanol production was monitored regularly at 24hr intervals

- 25. • Conclusion • The massive utilization of fuel ethanol in the world requires that its production technology be cost-effective and environmentally sustainable. • The current research tendencies for improving fuel ethanol production are linked to the nature of employed raw materials, processing steps, and related process engineering issues. • Agro-processing techno-economic activities are to be generated for the conservation and handling of agricultural produce and to make it usable as food, feed, fiber, fuel, or industrial raw material.

- 26. • In this present study, efforts were made to identify the fruit wastes as potential raw material for bioethanol production and the results showed that mixed ripened fruit biomass of banana and Orange can yield 36% of ethanol and similarly the banana fruit peels treated with dilute acid and microbial enzymes showed a potential production of 14% ethanol. • The high nonstructural carbohydrates, reserve starch content and low fiber contents showed the potentiality of bananas as a good feedstock for ethanol production. • The major costs for a bio refinerys are feedstock collection, storage, transportation, and pretreatment, hence, optimizing these unit operations through using fruit peels and un-marketed fruit wastages should prove beneficial