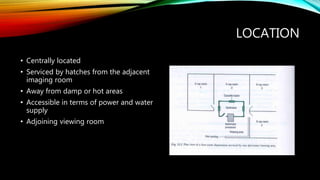

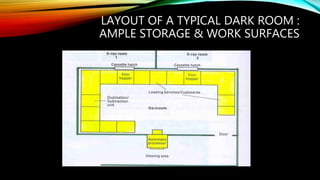

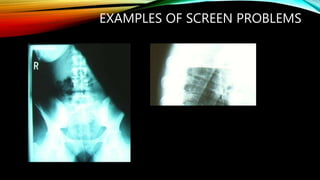

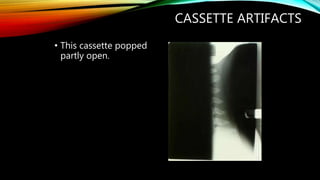

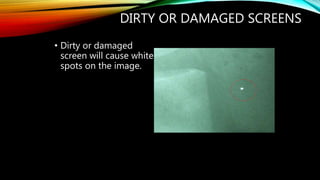

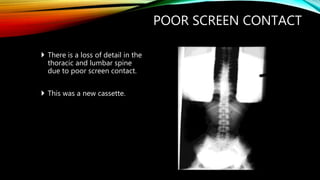

This document discusses the proper construction, equipment, and safety procedures for a radiology dark room. It outlines important considerations for the location, size, ventilation, lighting, entrance types, and hazards associated with a dark room. Key pieces of equipment like cassettes, film hangers, and processing chemicals and their uses are described. Common problems that can occur with screen film radiography like crossover exposure, cassette artifacts, and dirty/damaged screens are also reviewed.