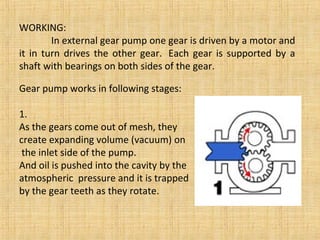

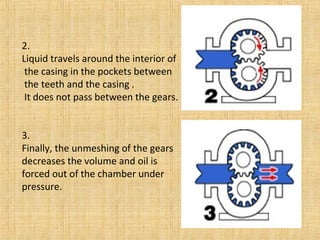

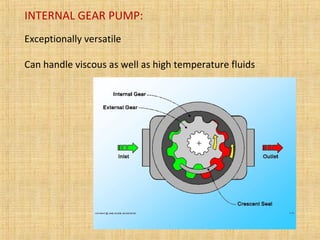

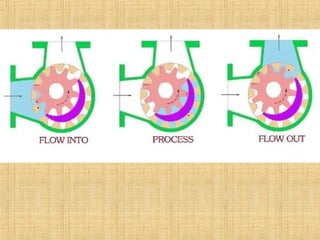

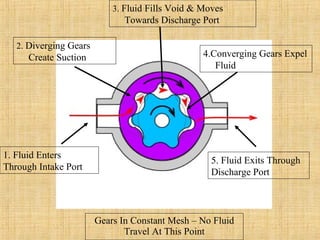

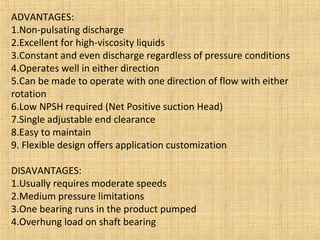

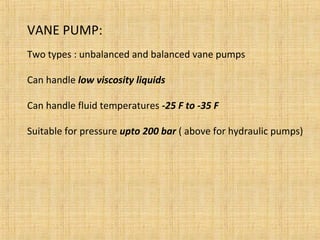

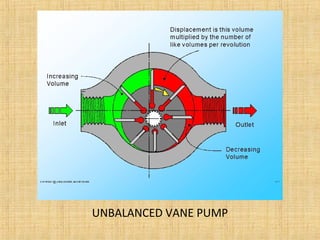

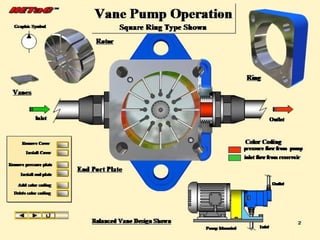

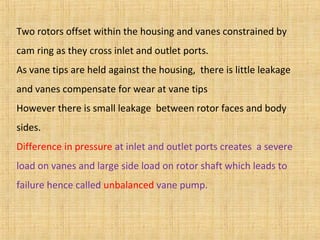

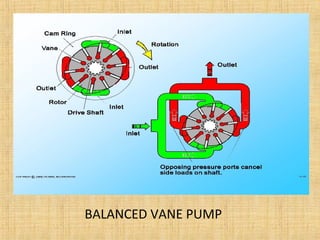

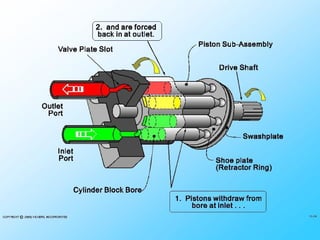

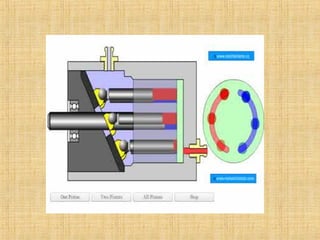

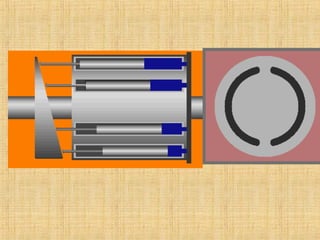

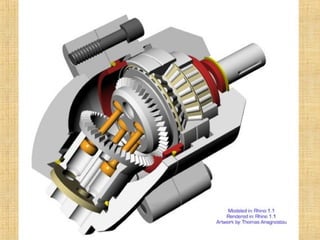

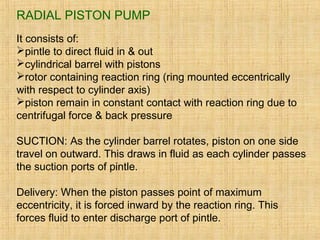

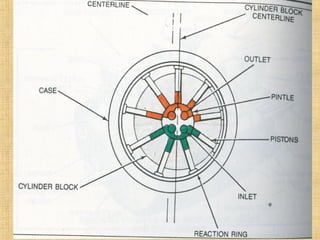

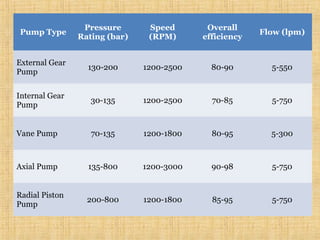

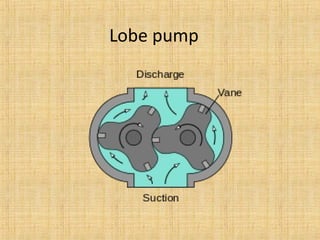

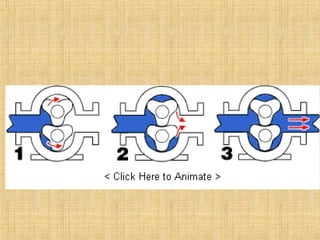

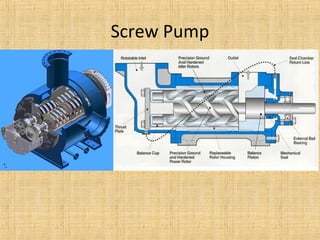

Pumps can be classified as positive displacement pumps or nonpositive displacement pumps. Positive displacement pumps include gear pumps, vane pumps, piston pumps, and lobe pumps. Gear pumps are further classified as external gear pumps and internal gear pumps. External gear pumps have straight or helical gears that transport fluid through the expanding and contracting space between gears. Internal gear pumps have gears that remain constantly meshed to pump fluid. Vane pumps use a rotor with sliding vanes to pump fluid, and can be balanced or unbalanced. Piston pumps use reciprocating pistons to draw in and expel fluid and include axial, radial, and bent-axis configurations. Each pump type has different operating characteristics, advantages, and limitations for various industrial