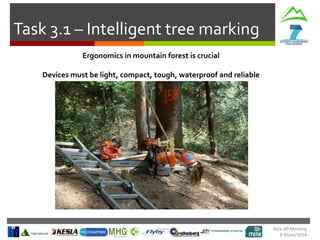

This document outlines tasks related to intelligent tree marking (Task 3.1) as part of a larger project. It involves developing a system using RFID tags, a programming tool, and insertion device to effectively mark trees in a forest for harvesting. The system aims to be easy to use, robust, and integrate with other tasks like felling and processing trees. Challenges include developing a non-cumbersome system that can reliably mark and identify trees over time as part of improving traceability in the forestry process.