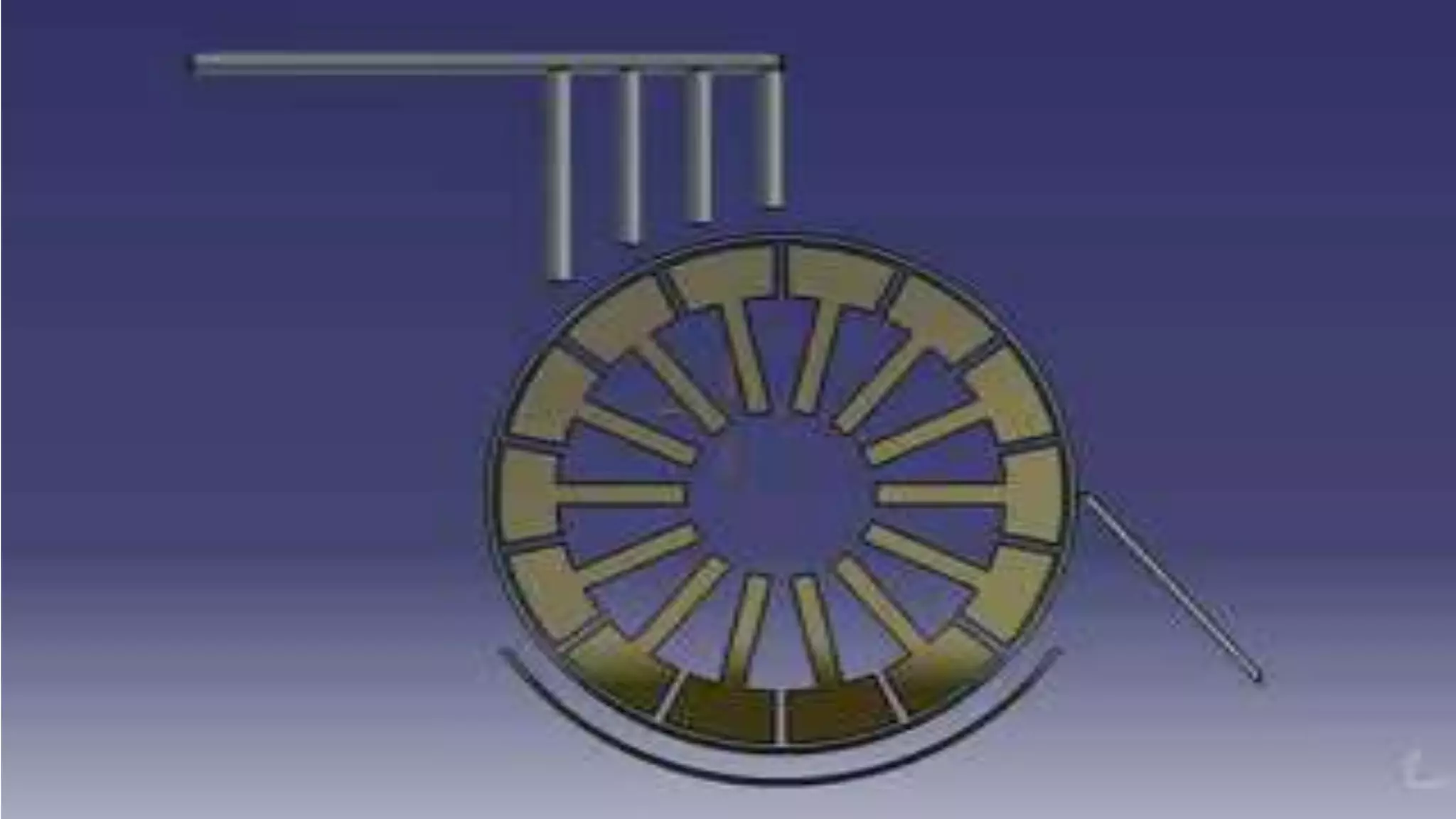

The document summarizes the key components and functioning of a rotatory drum vacuum filter. It consists of a sheet metal drum divided into sections covered with a filter cloth. Liquor is sucked through the filter cloth onto the rotating drum to deposit a cake of solids. As the drum rotates, the cake moves through different zones - first forming in the filtration zone, then being washed and dried before the cake is removed in the removal zone by a doctor knife. Various methods are used to discharge the cake, including scrapers, belts, pre-coat, rolls or strings depending on the cake properties. It is widely used in industrial processes that require continuous large-volume solid-liquid separation.