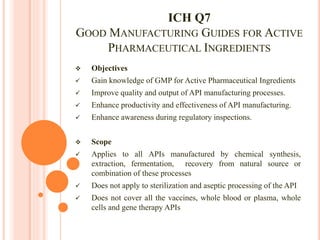

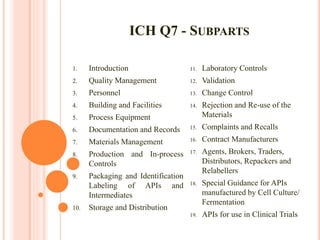

The document discusses ICH Q7, a guideline for good manufacturing practices for active pharmaceutical ingredients. It aims to improve quality, enhance productivity and effectiveness of API manufacturing. ICH Q7 applies to APIs made through chemical synthesis, extraction, fermentation or combinations and establishes requirements for quality management, personnel, facilities, equipment, documentation, materials management, production controls, packaging and more. Adherence to ICH Q7 helps ensure APIs are safe, effective and of good quality and prepared according to cGMP standards expected by regulatory agencies like the FDA.