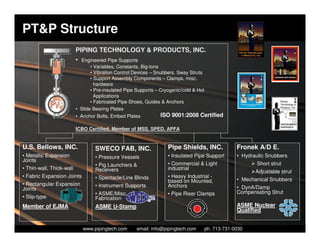

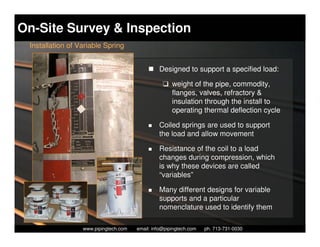

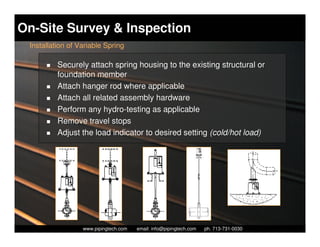

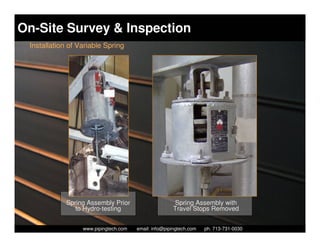

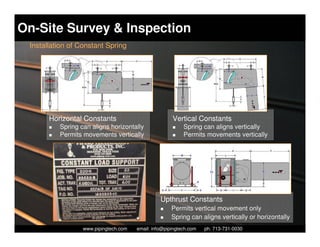

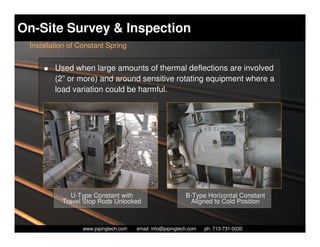

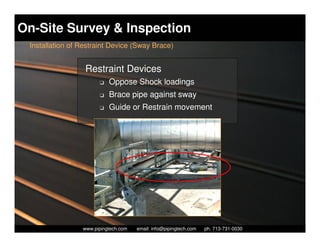

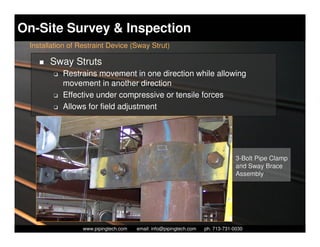

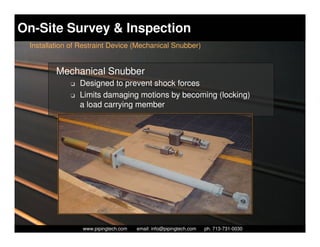

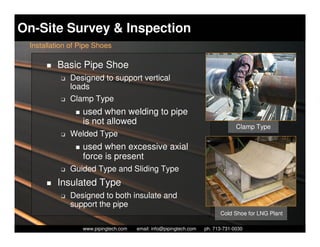

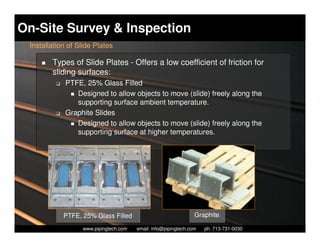

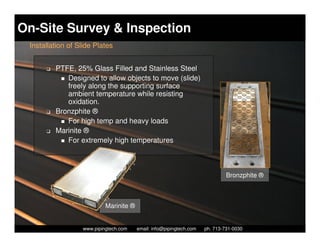

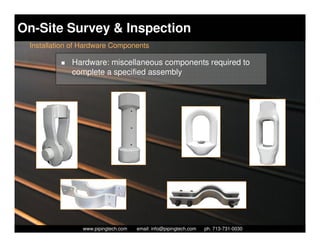

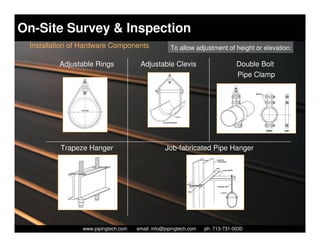

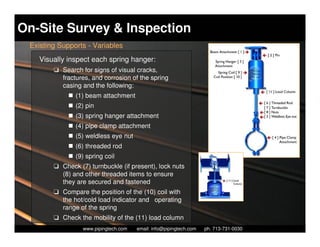

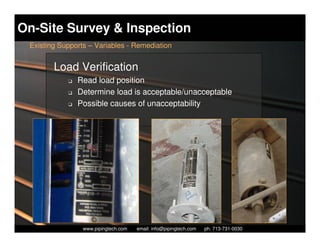

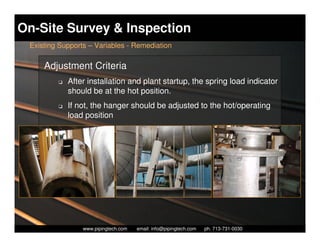

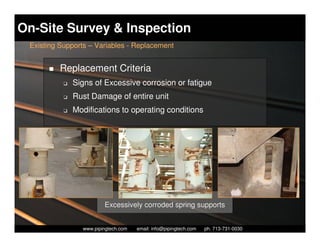

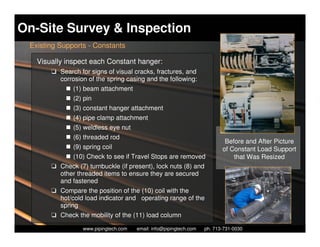

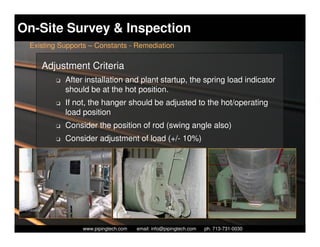

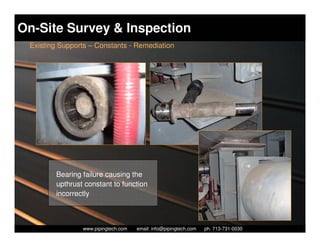

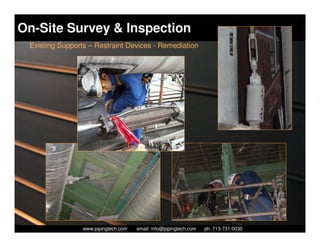

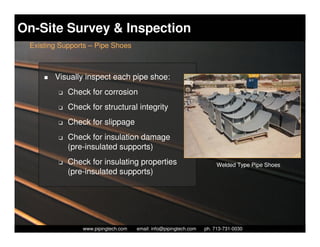

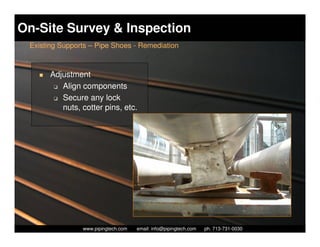

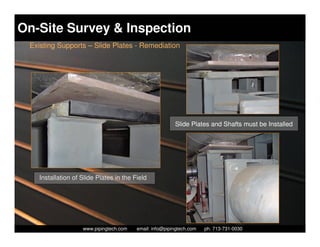

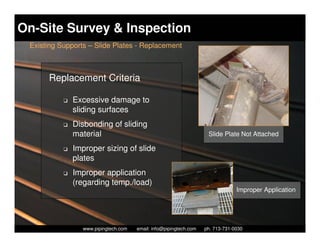

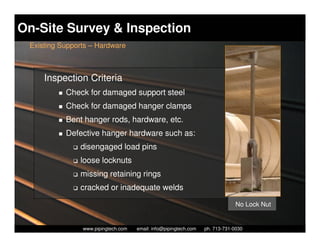

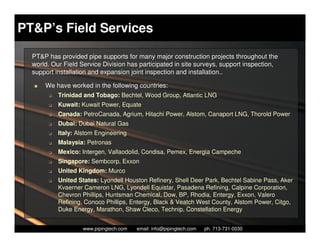

The document is about a webinar on pipe support field inspection, installation, and maintenance presented by Jerry Godinaer. It provides information on inspecting, installing, and maintaining different types of pipe supports including variable and constant spring hangers, restraint devices, pipe shoes, slide plates, and hardware components. It discusses guidelines for on-site surveys, what to inspect for existing supports, and criteria for adjusting or replacing supports if needed.