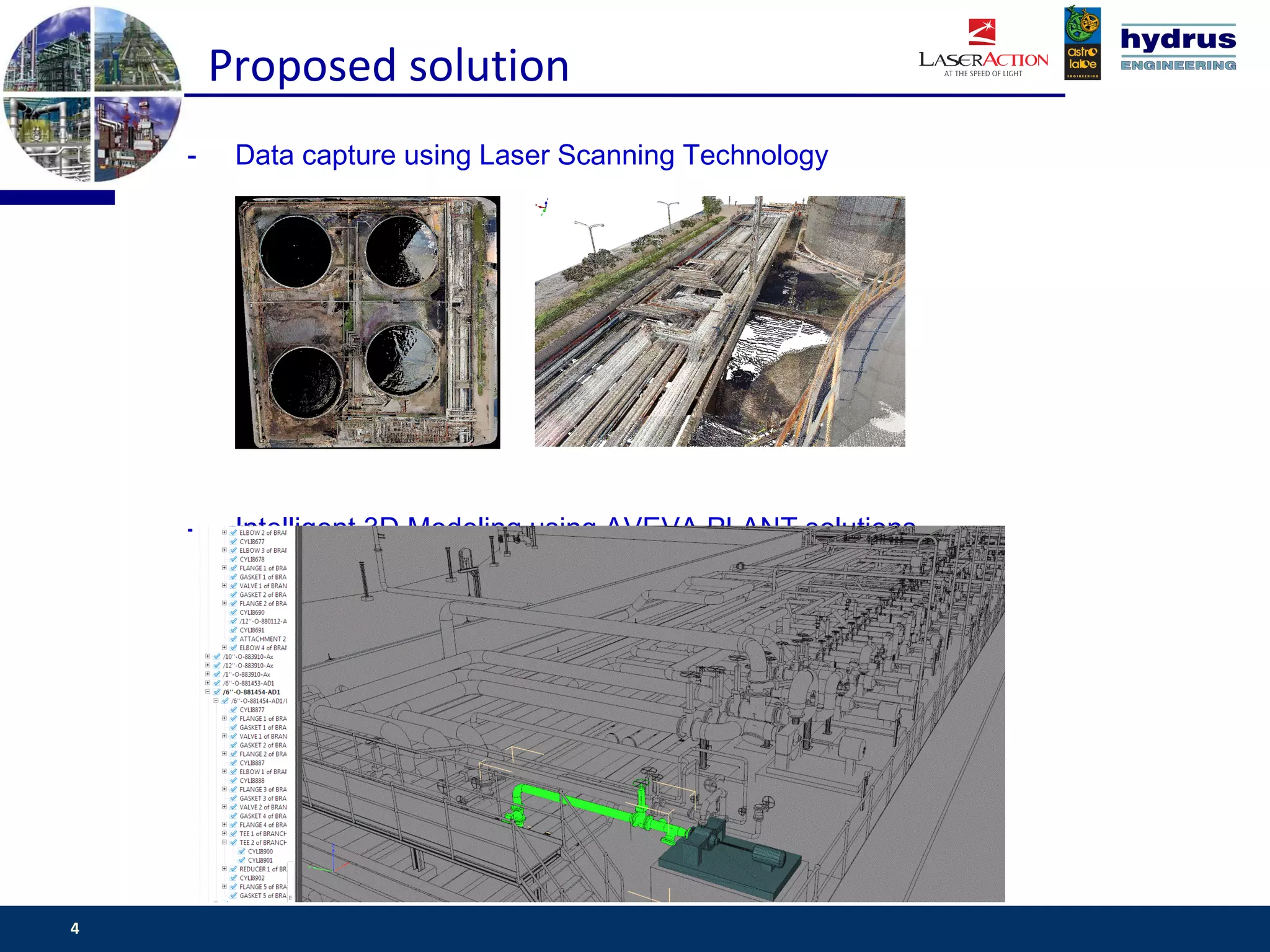

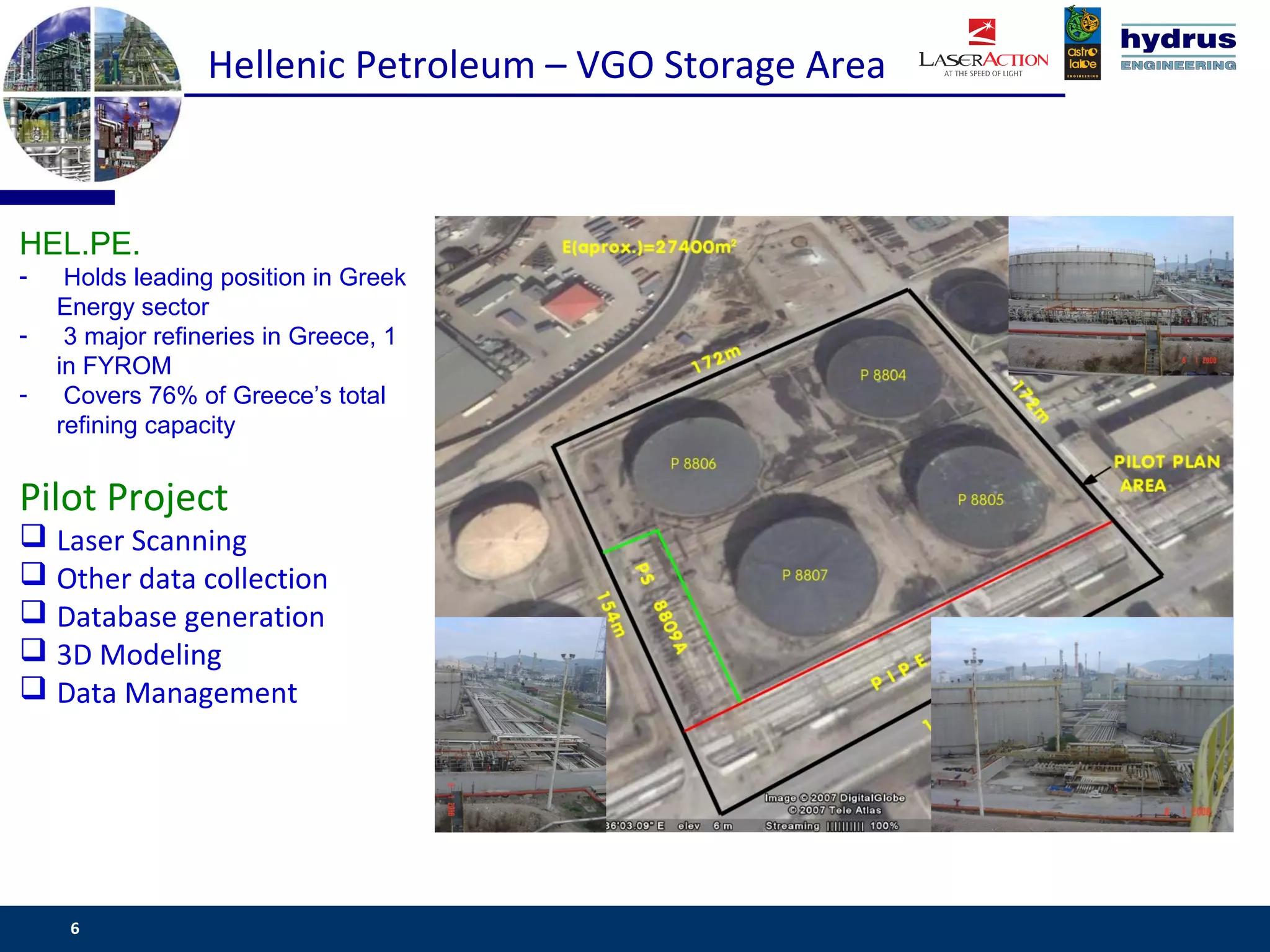

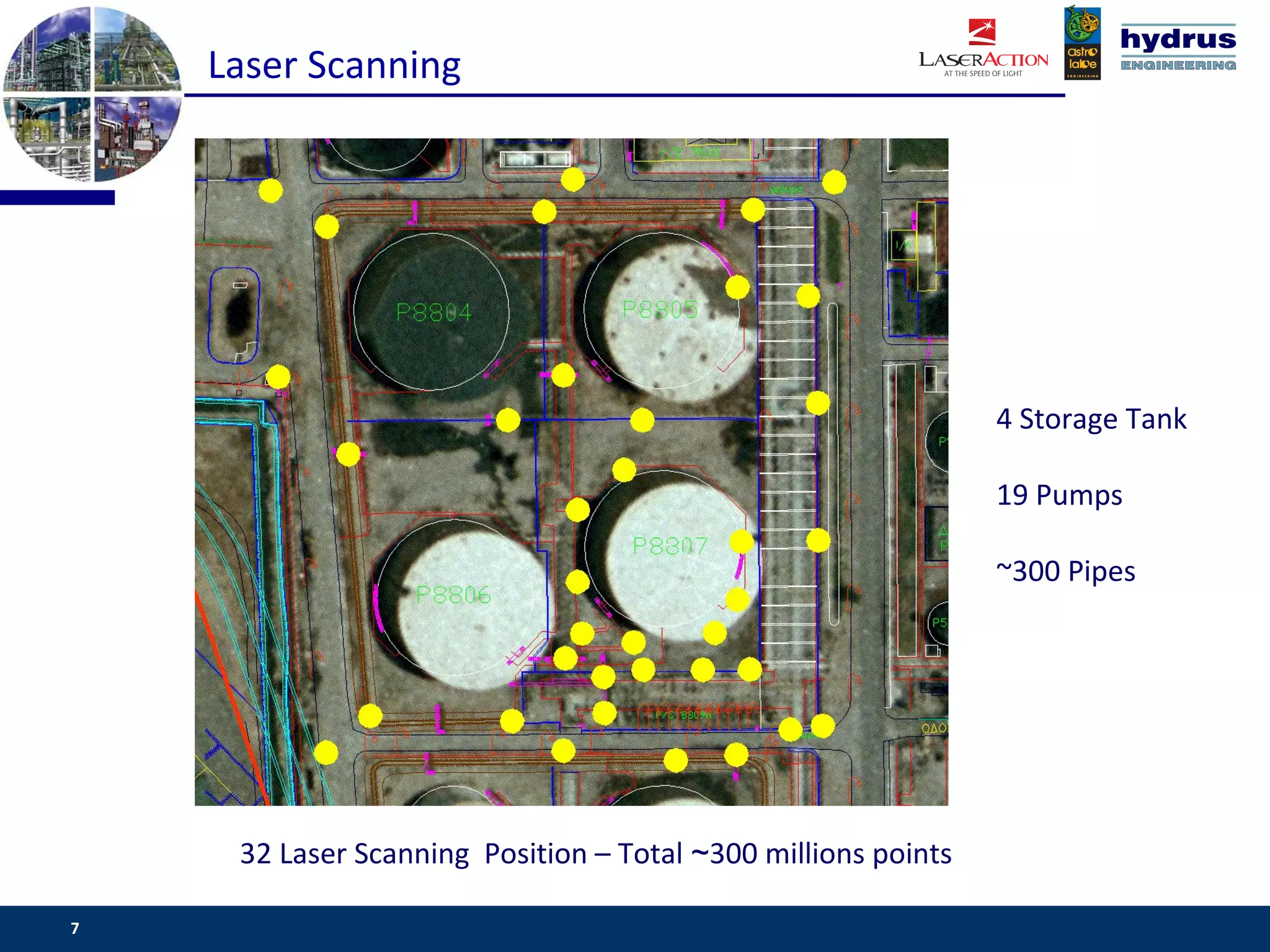

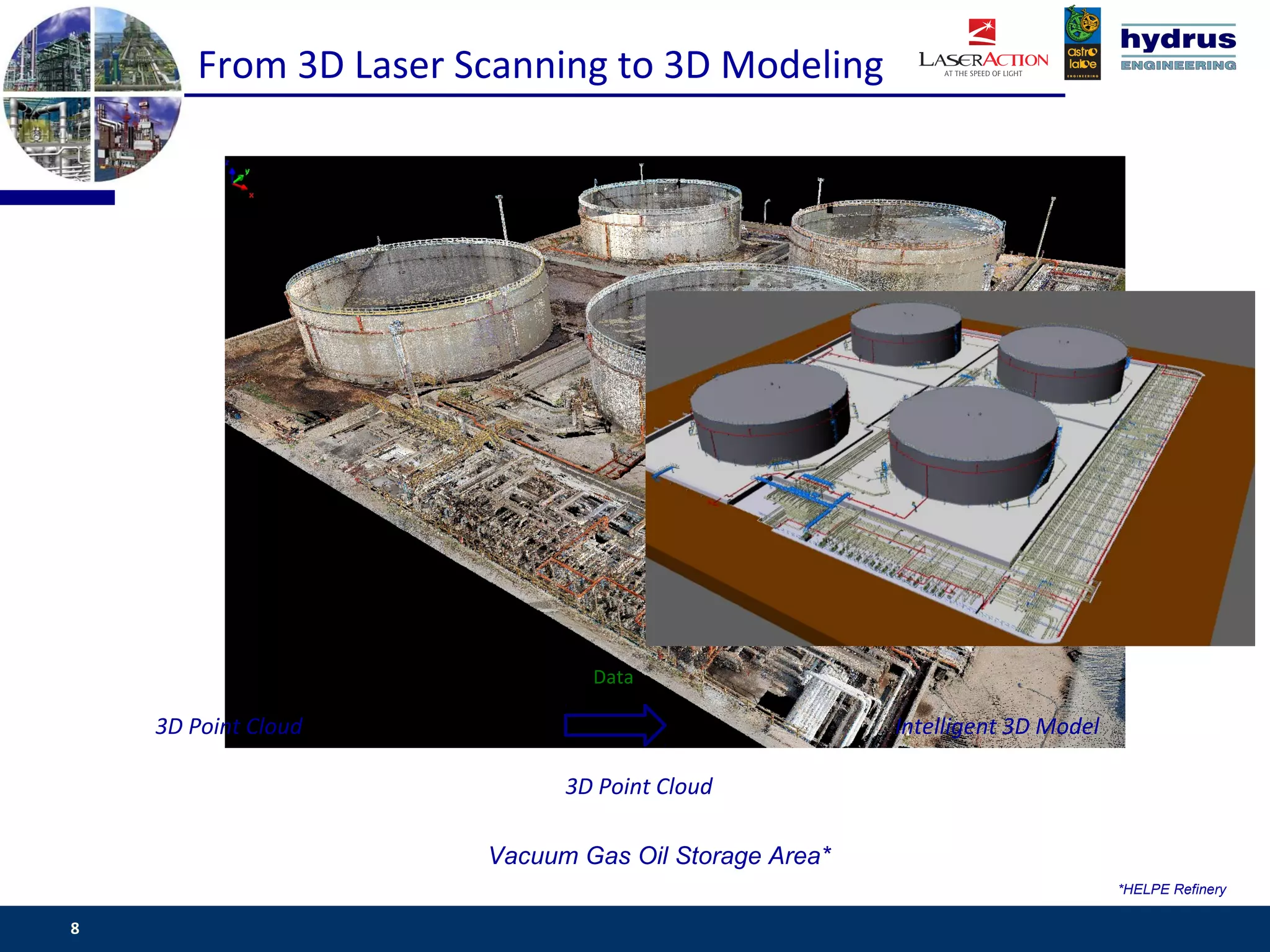

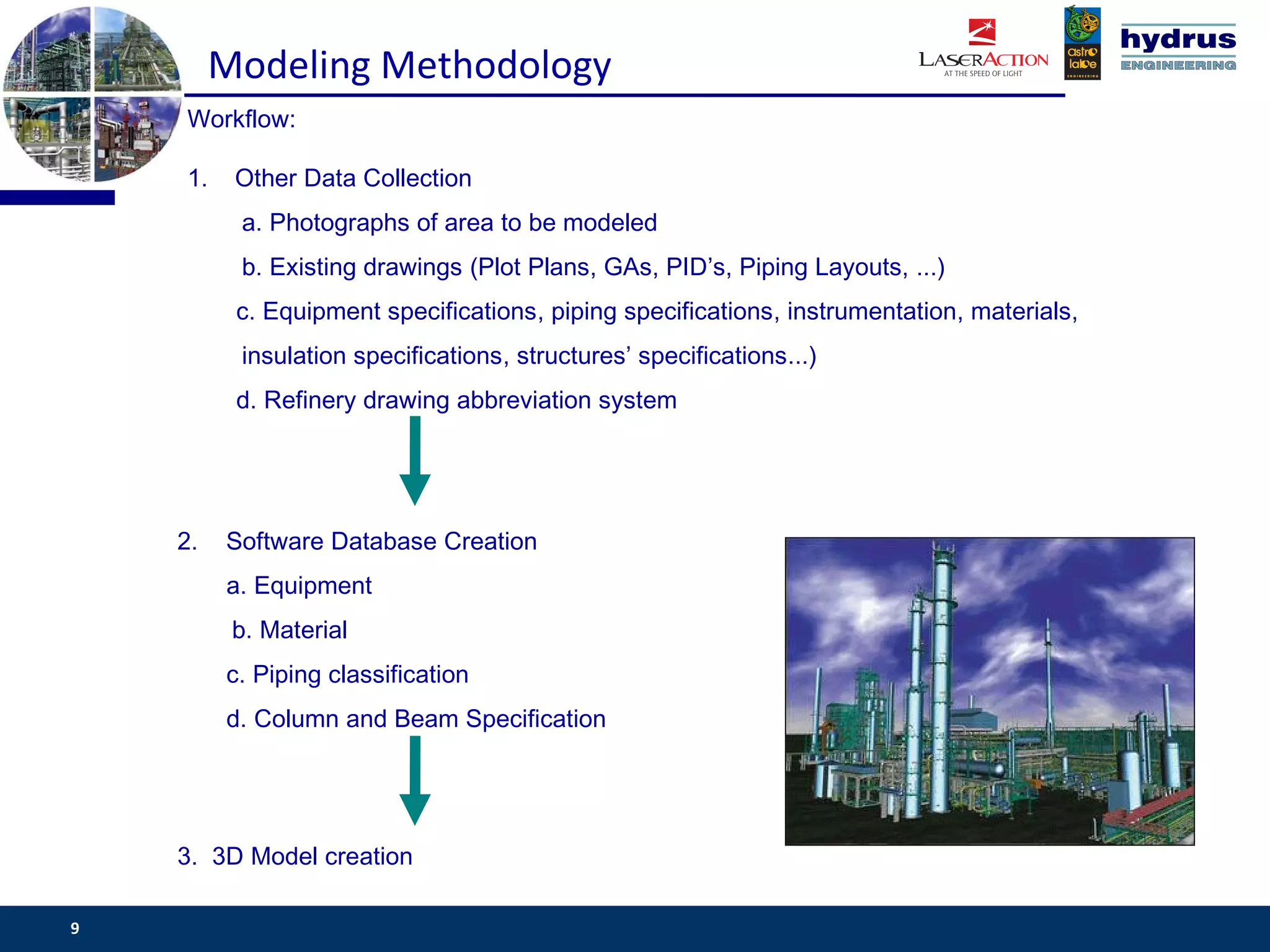

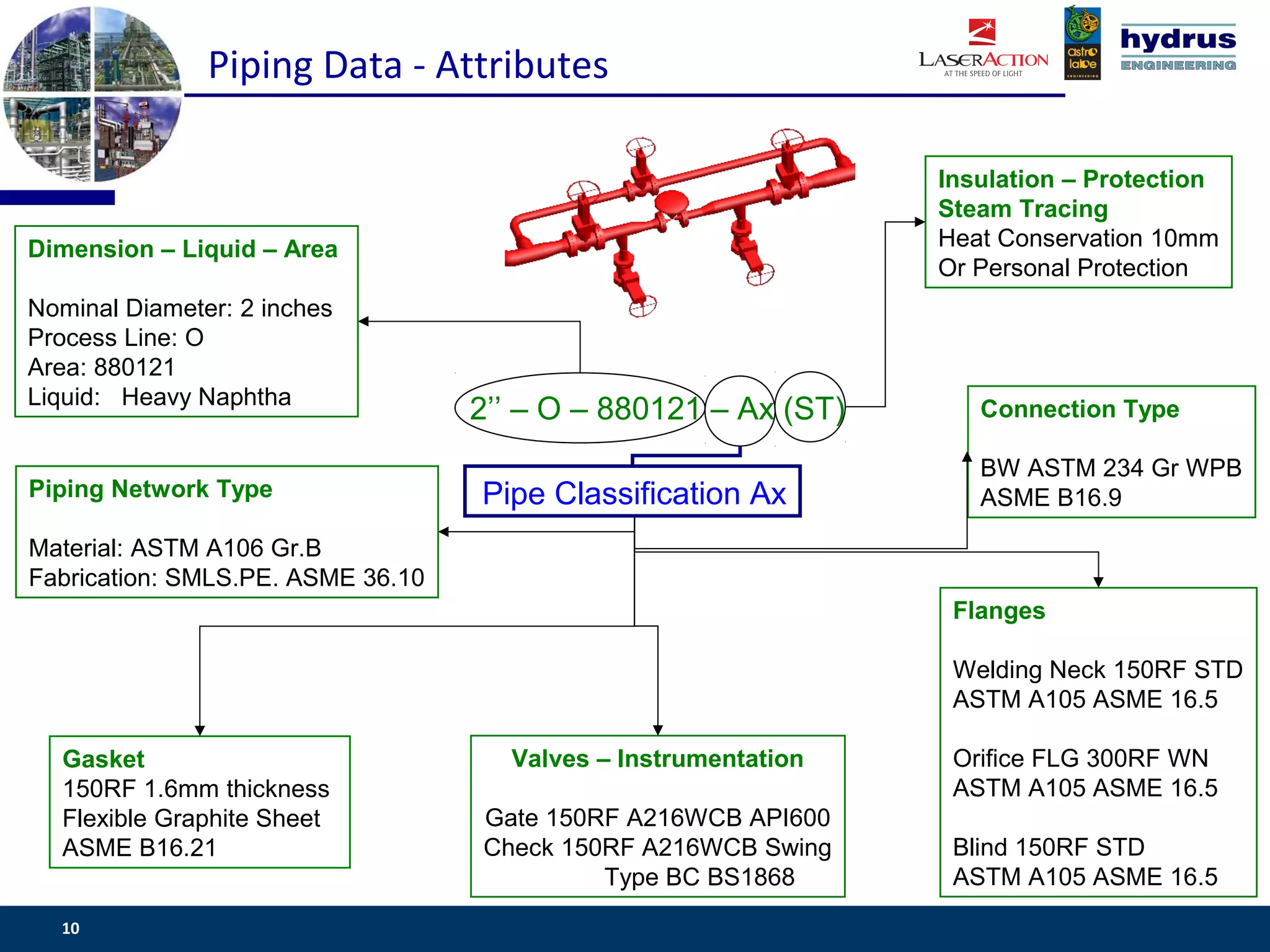

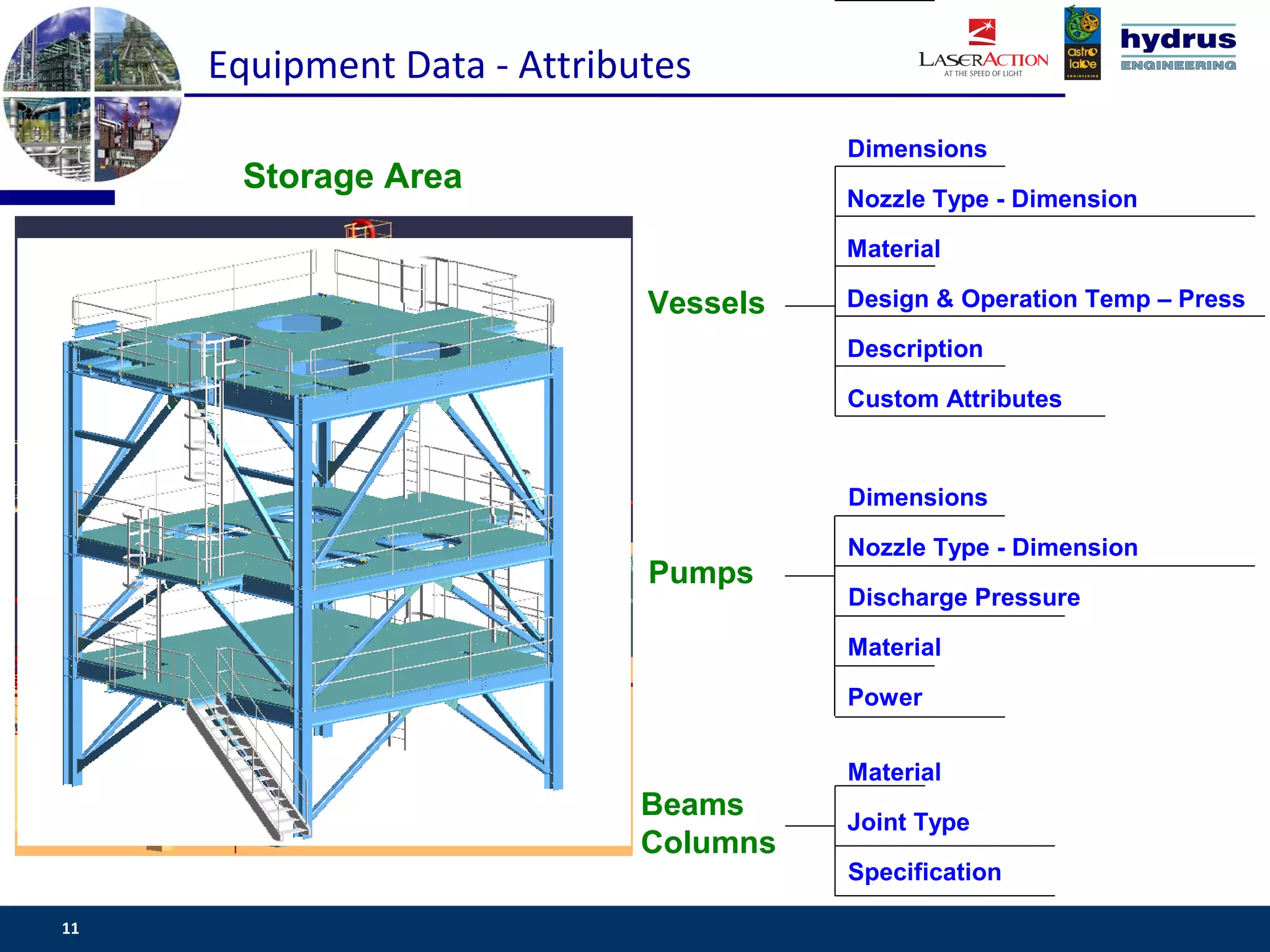

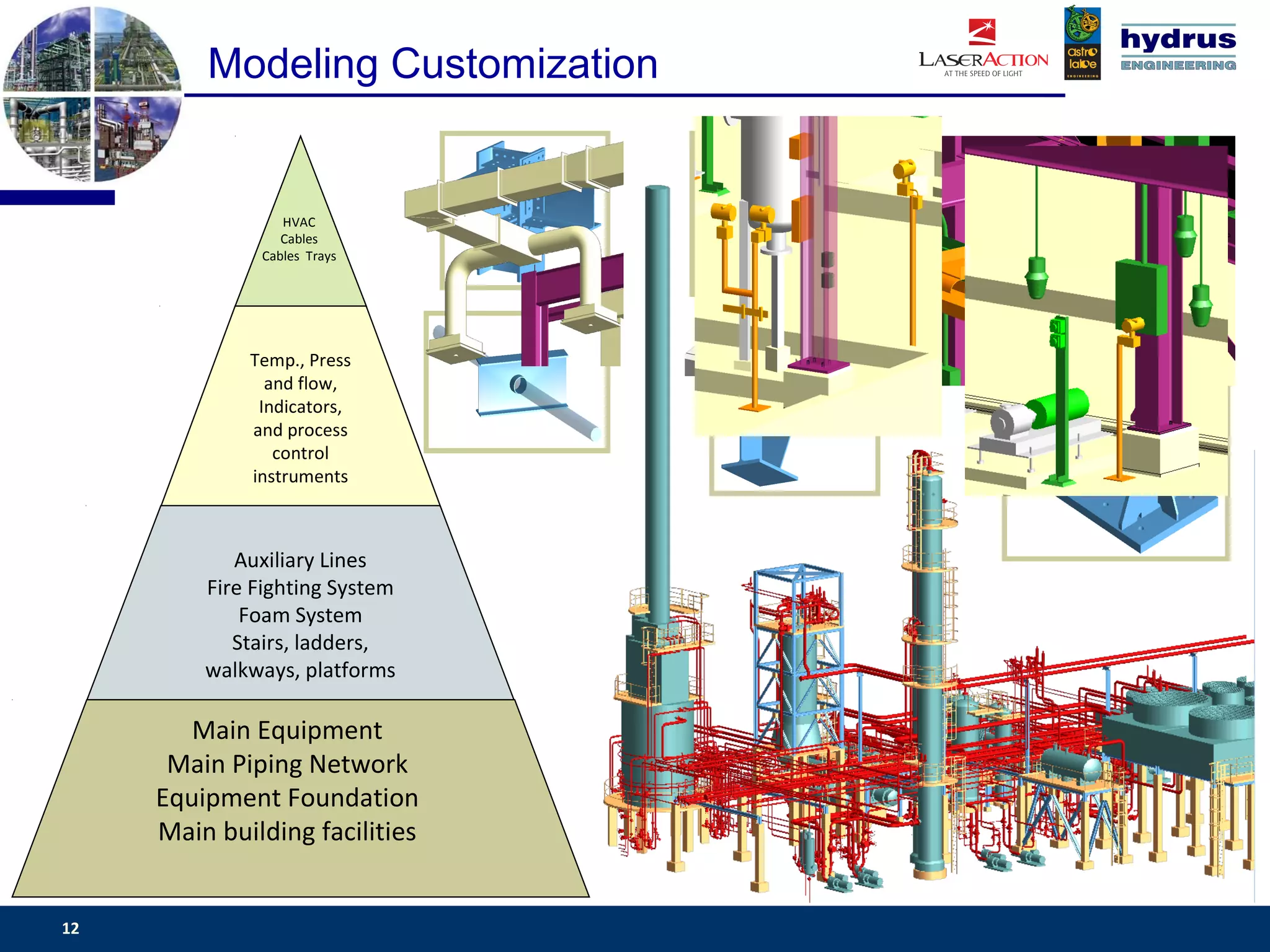

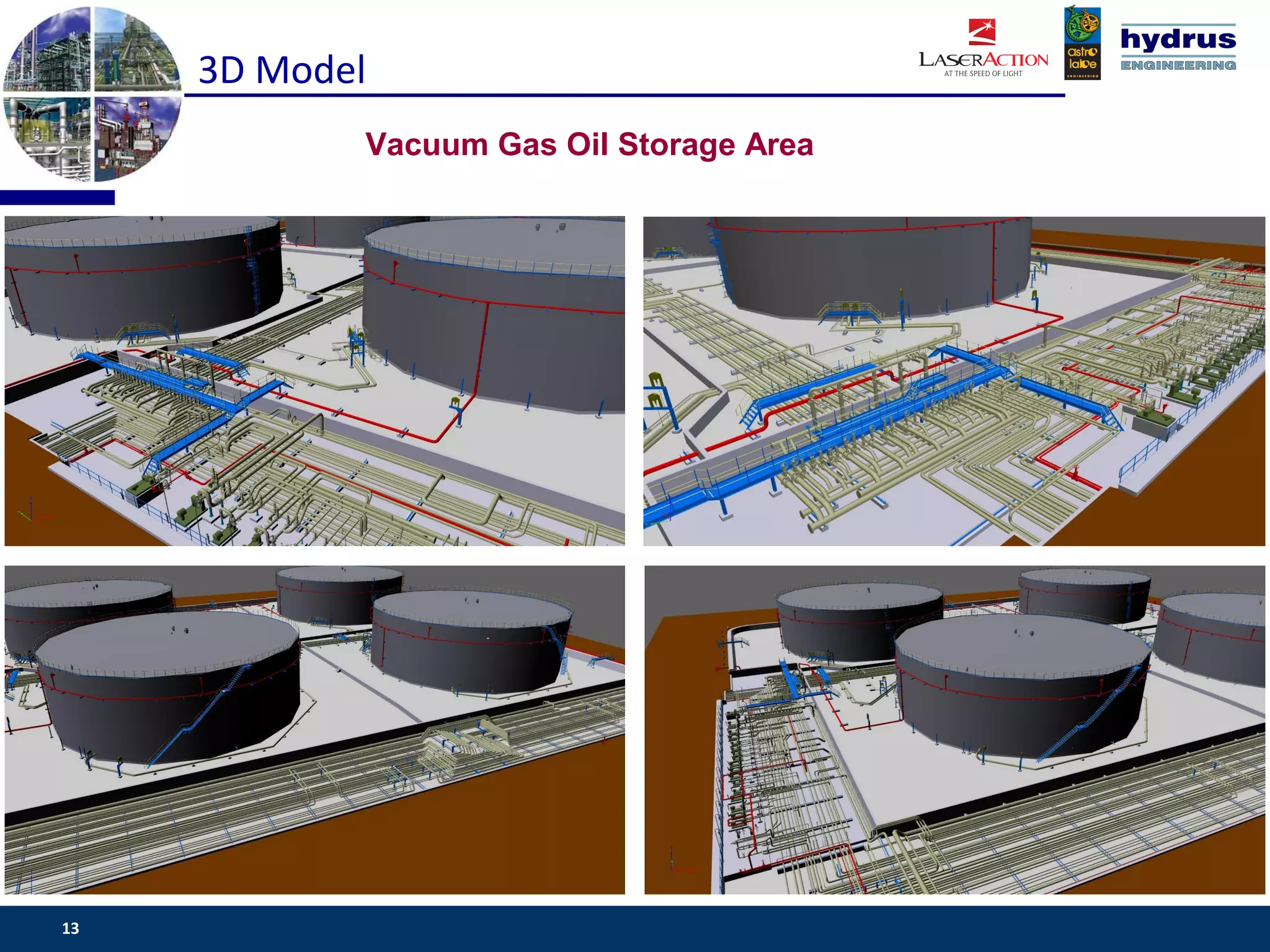

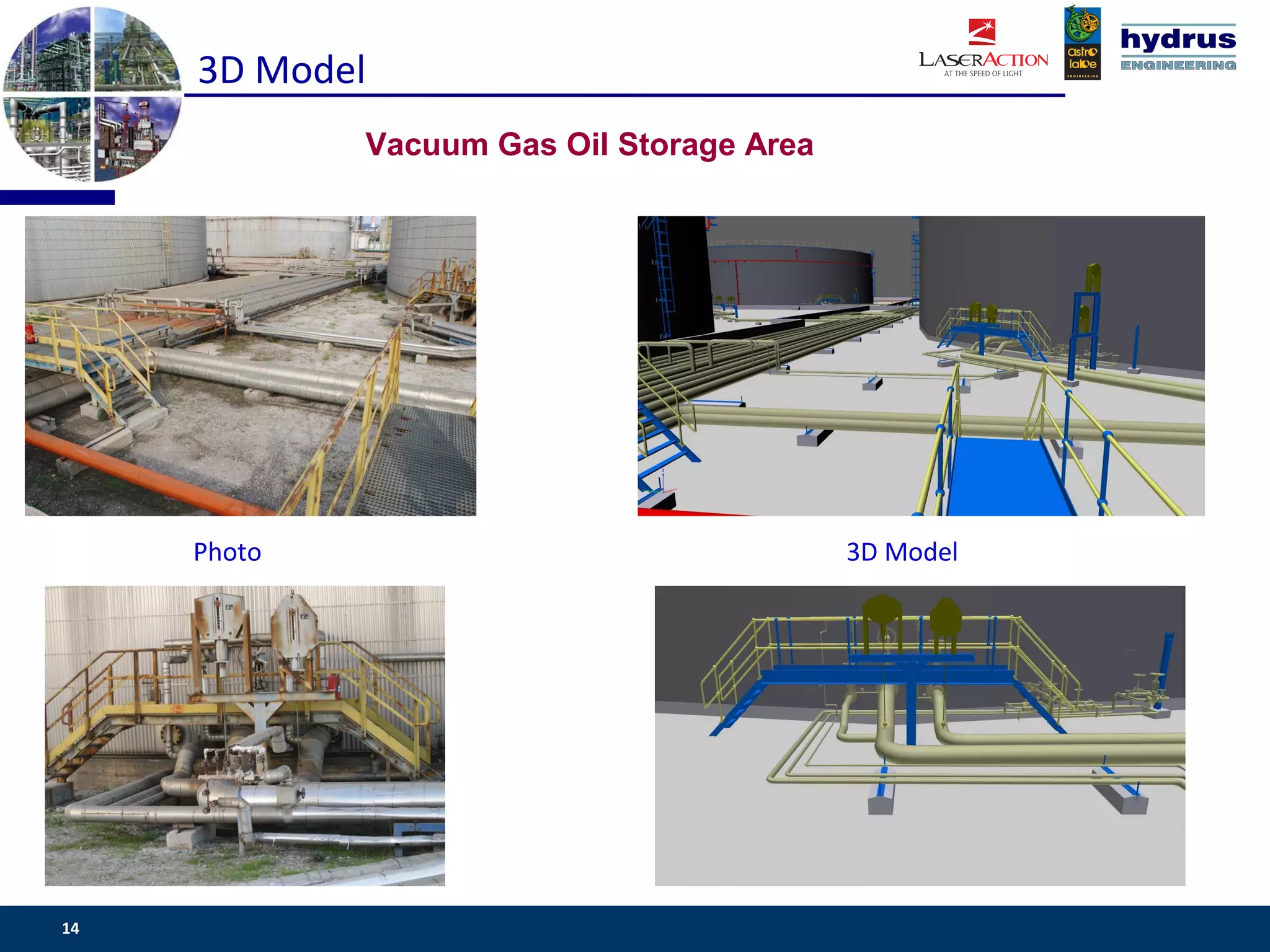

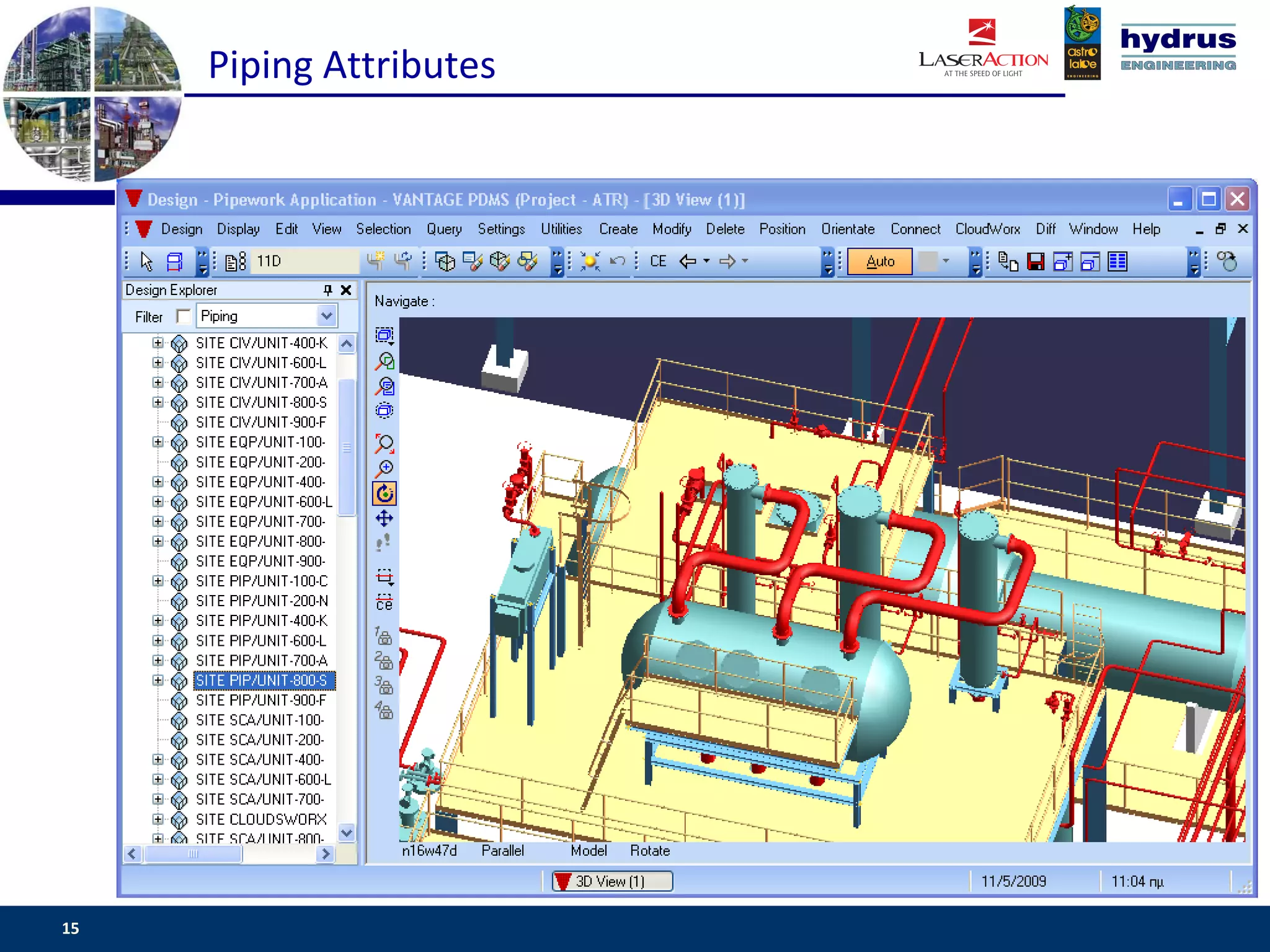

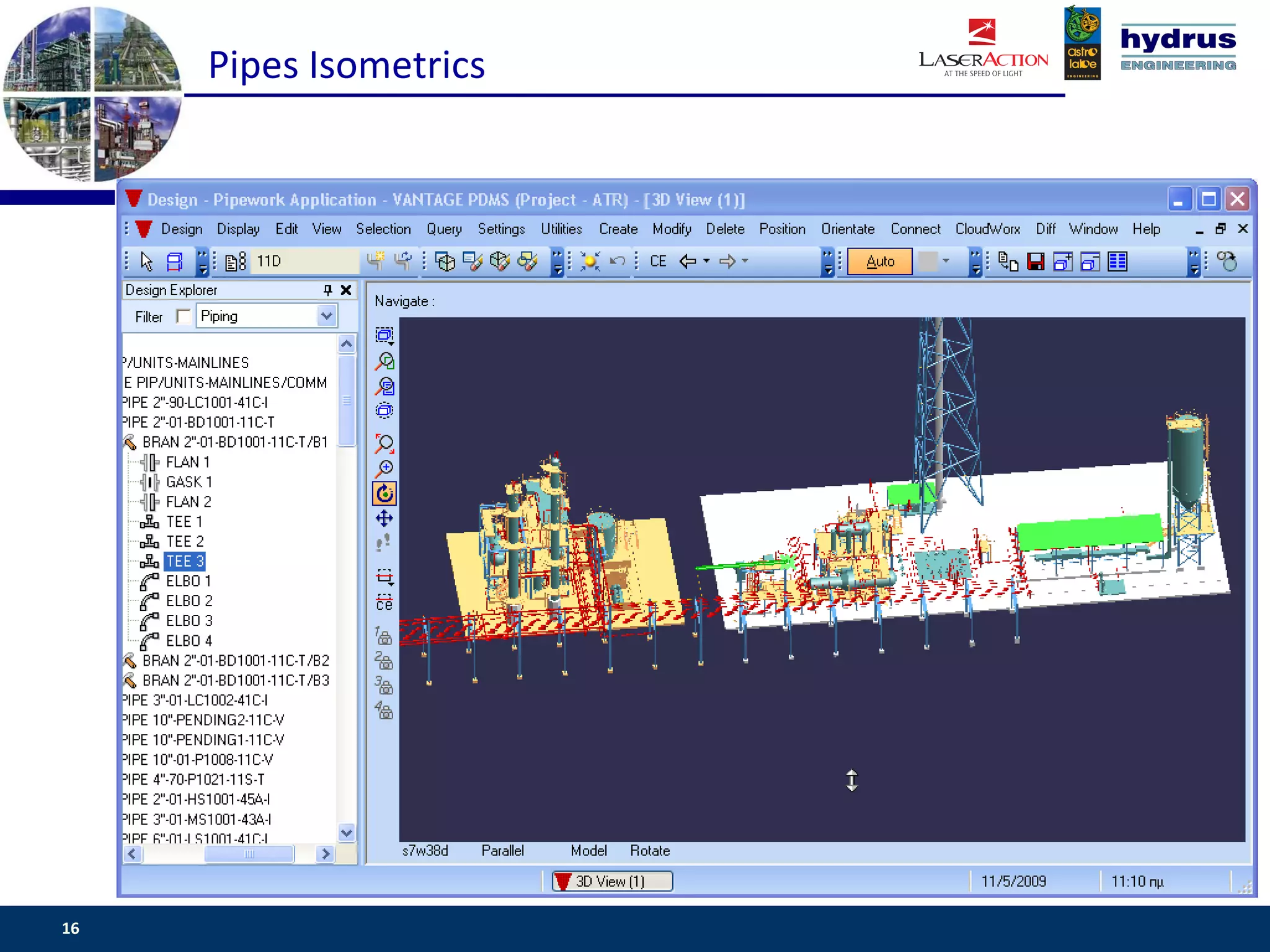

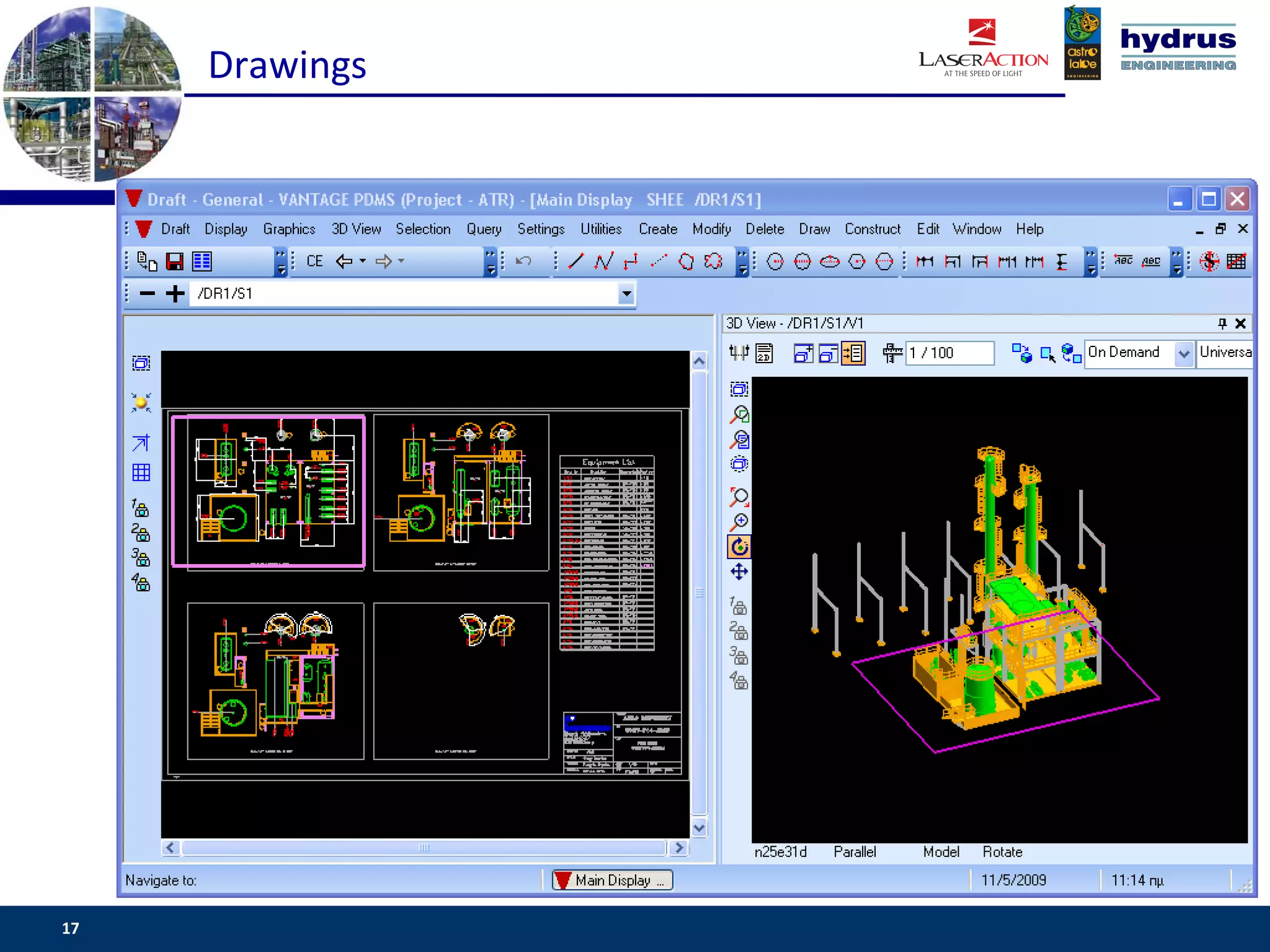

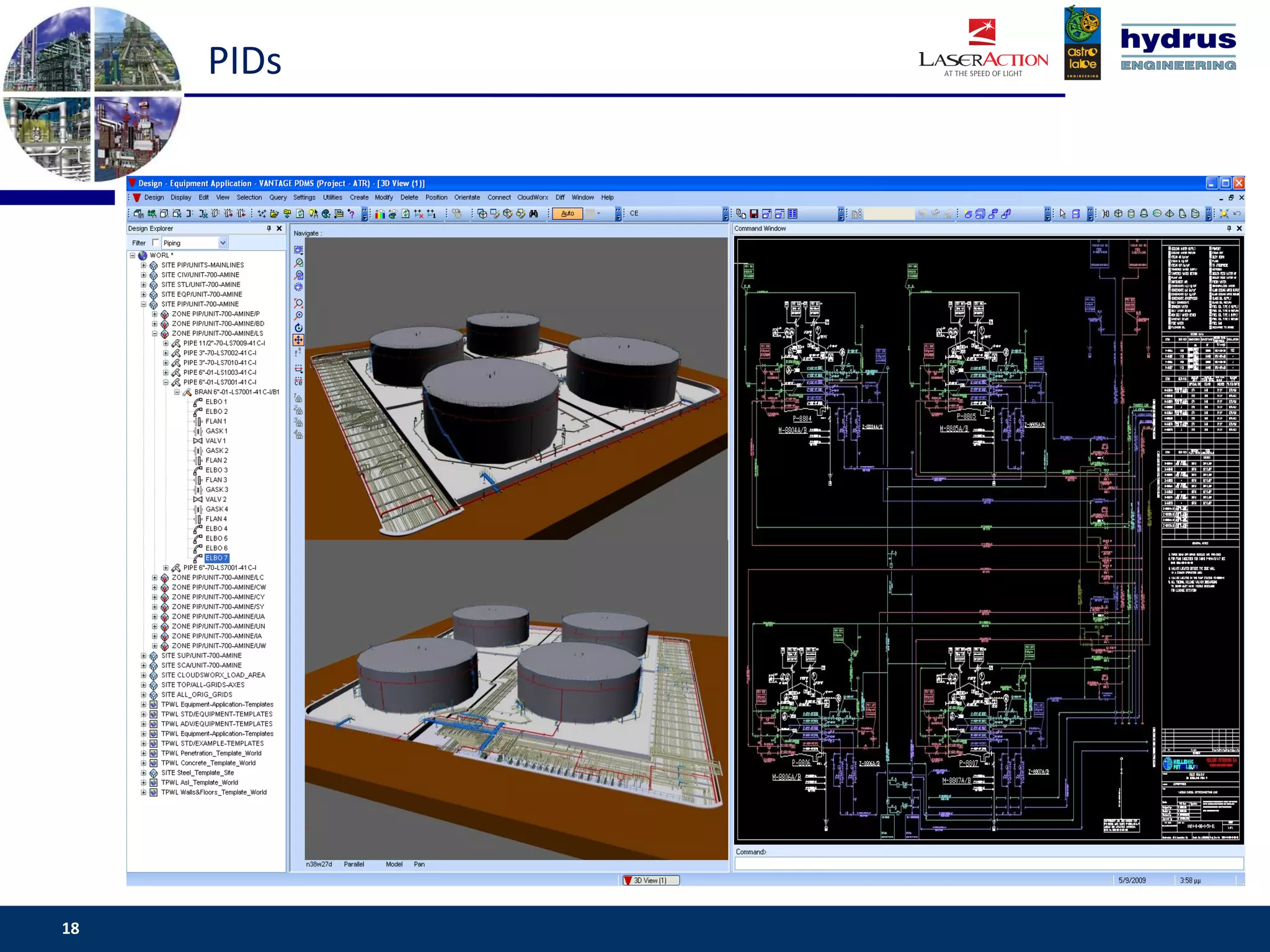

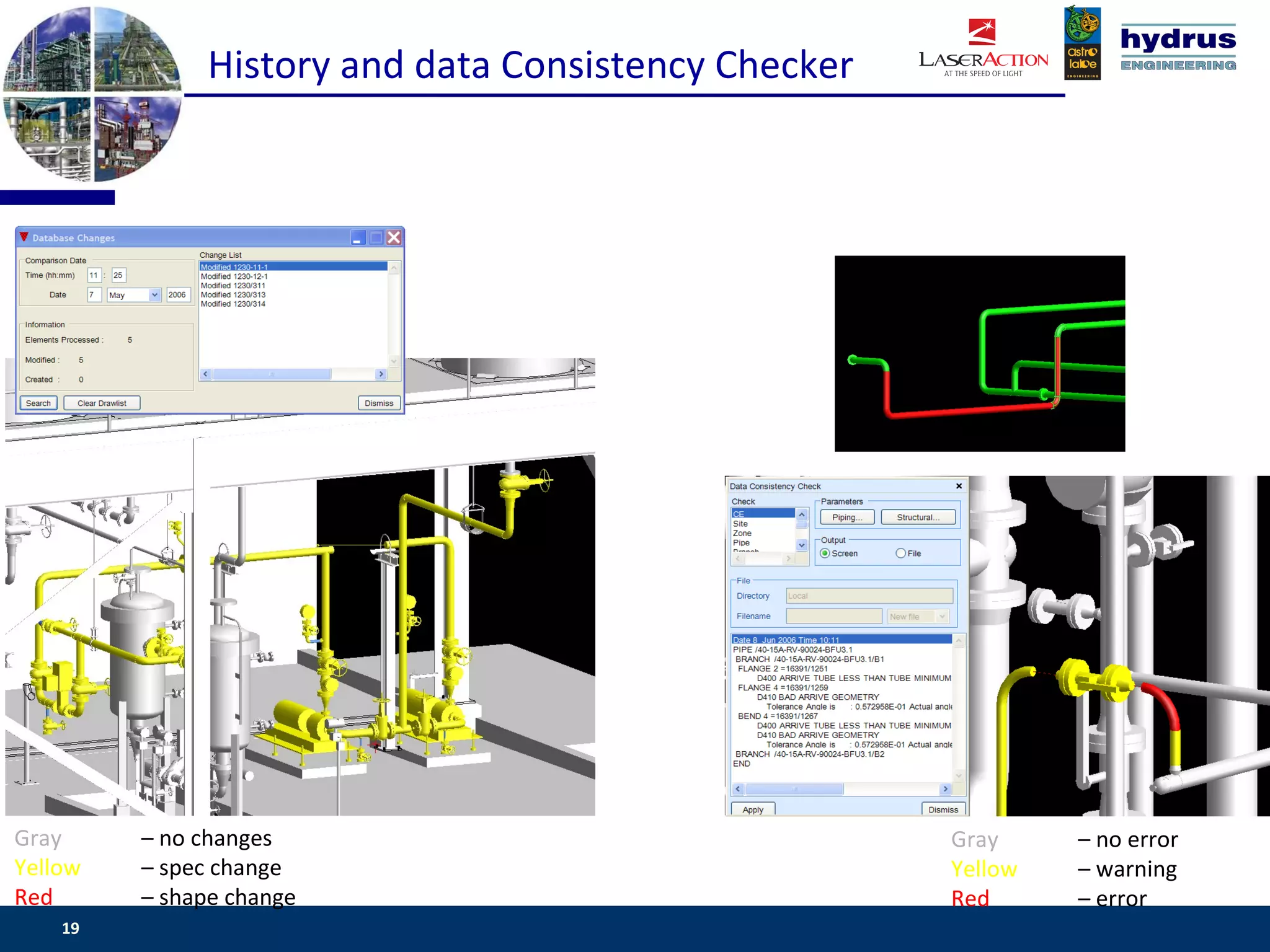

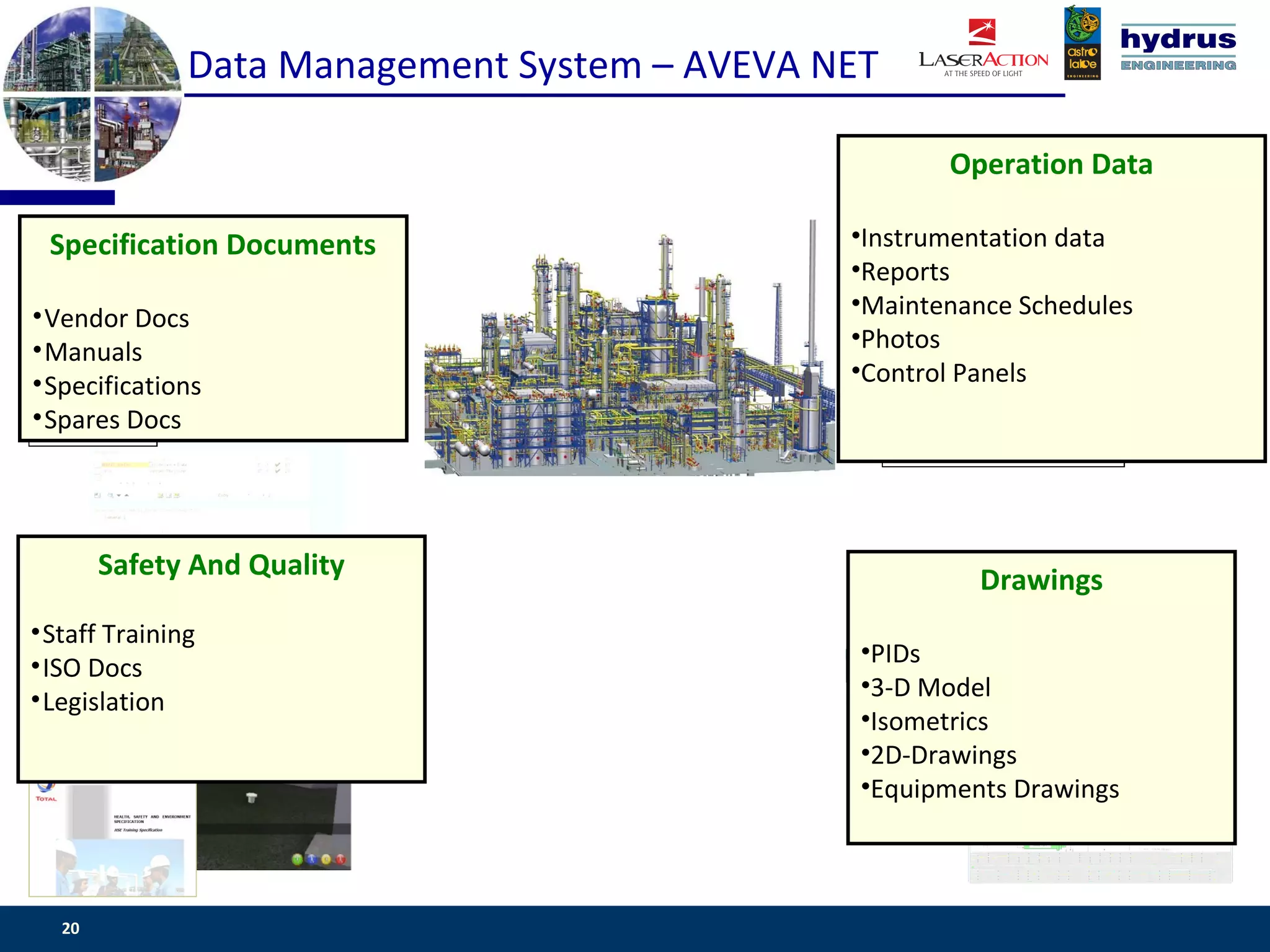

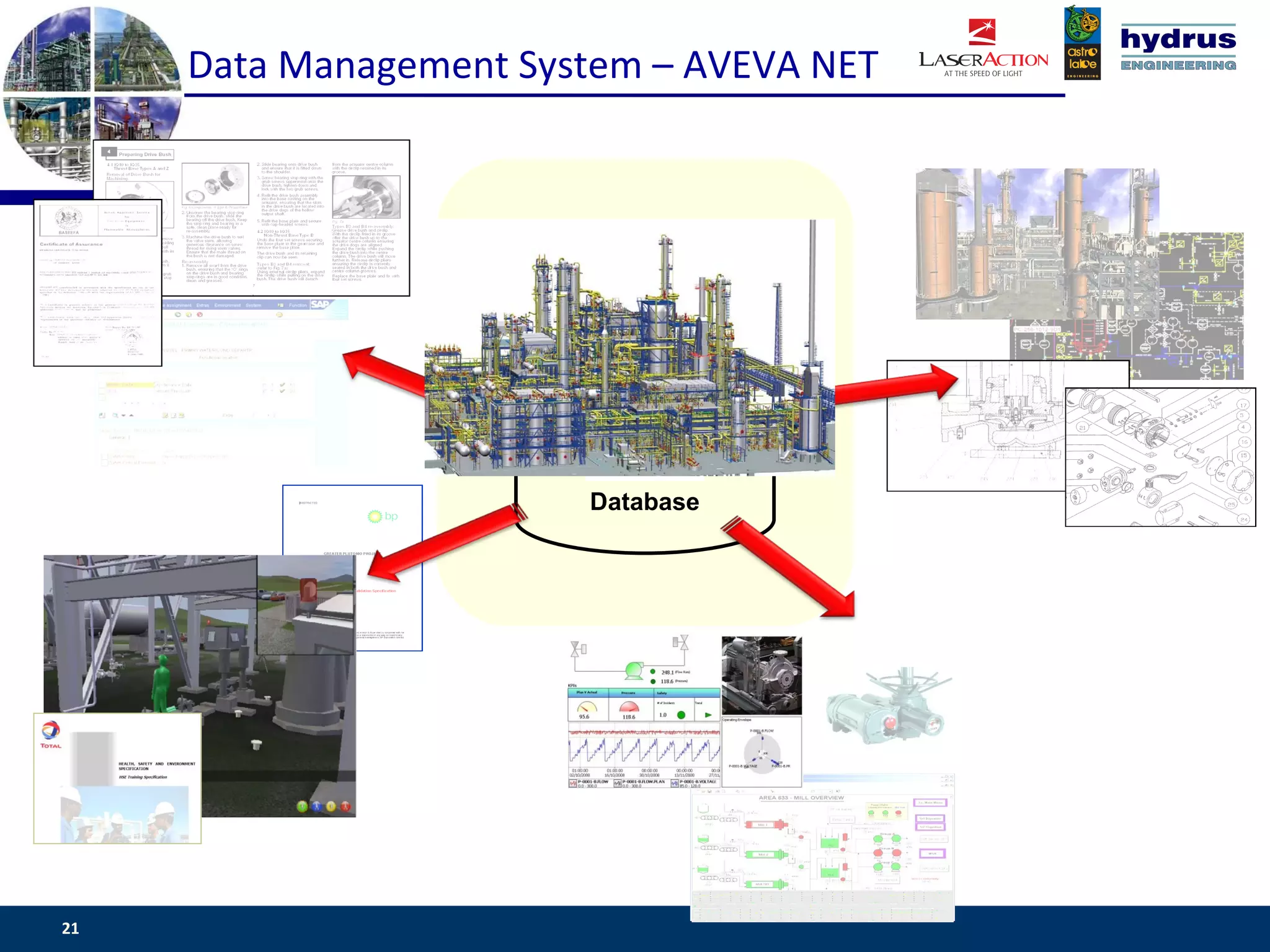

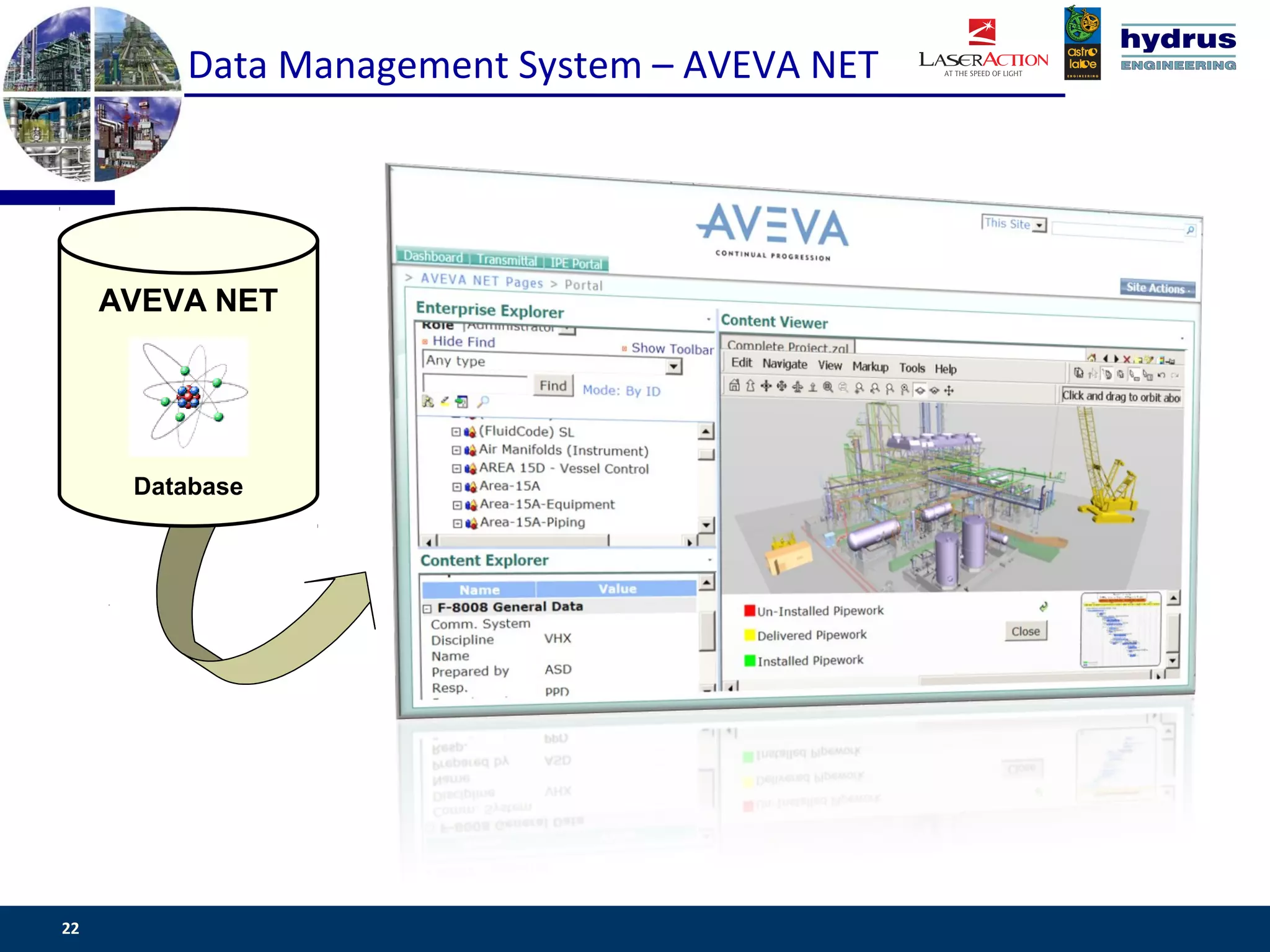

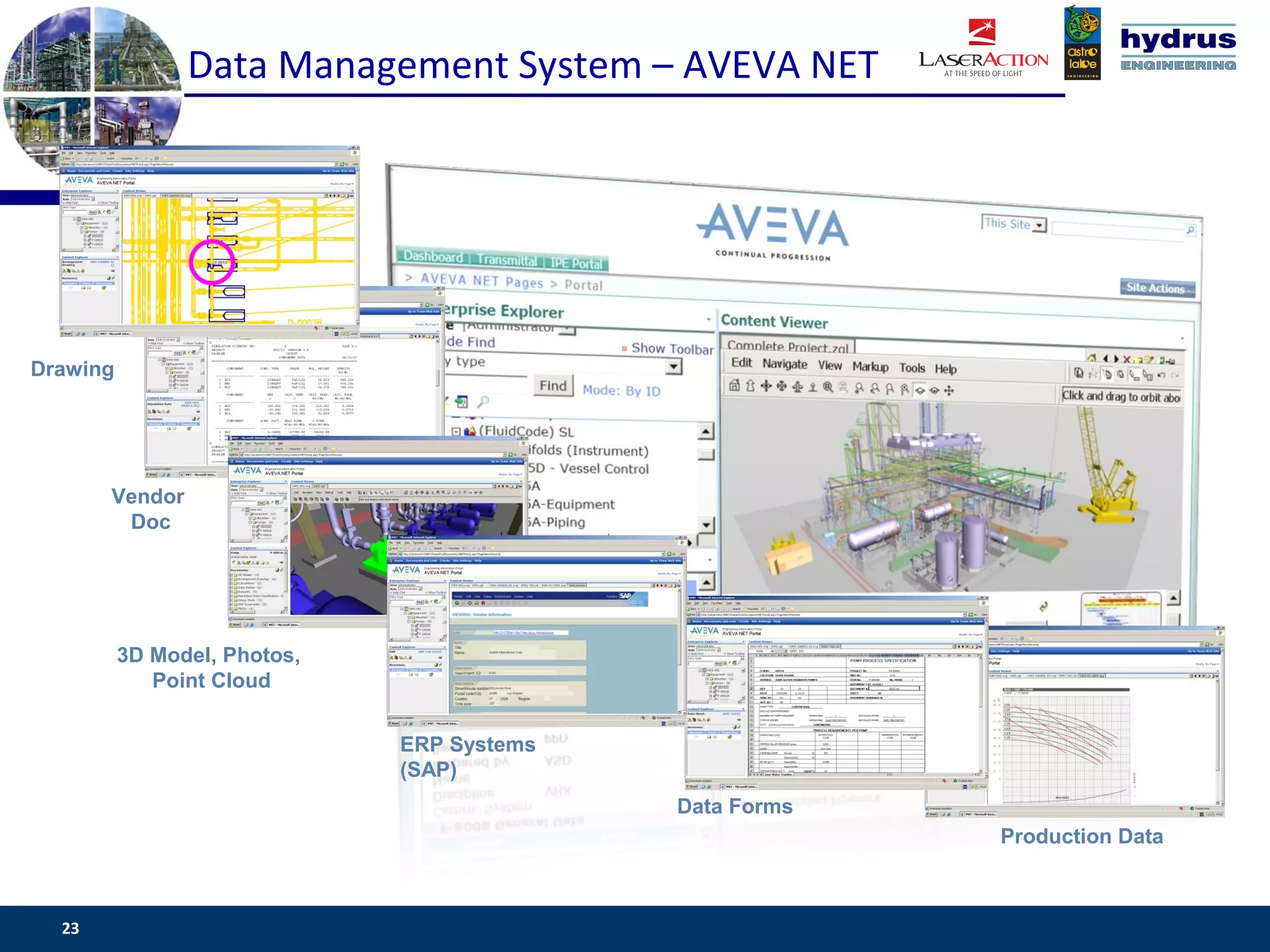

This document discusses using laser scanning and 3D modeling software to create an accurate digital as-built model of a vacuum gas oil storage area at a Hellenic Petroleum refinery in Greece. Laser scanning was used to capture over 300 million data points, which were then converted into an intelligent 3D model using AVEVA PLANT software. The 3D model integrates piping, equipment, and structural attributes and will be connected to a data management system for accessing drawings, specifications, and other documentation.