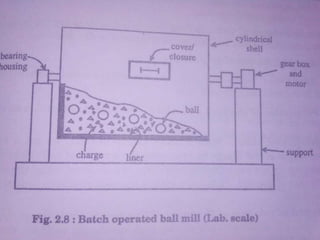

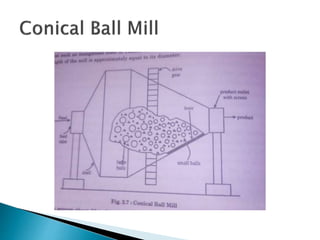

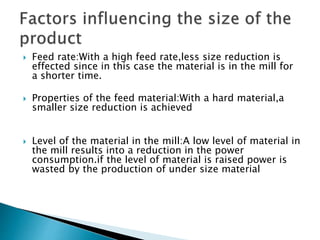

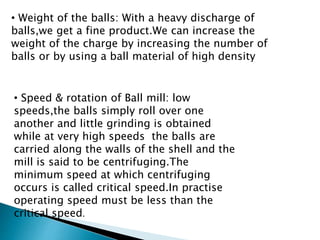

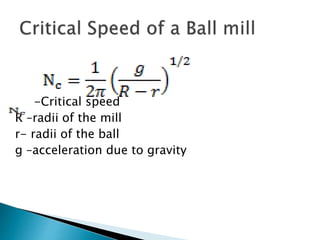

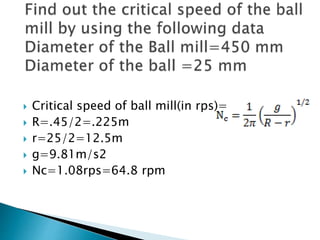

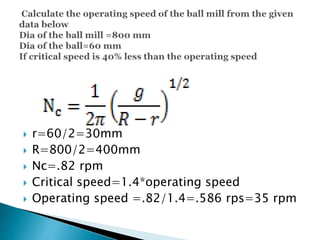

The document discusses the principles and operation of a ball mill. It describes how a ball mill works by rotating a hollow cylindrical shell partially filled with balls to grind materials by impact and attrition. The grinding medium is the balls, which can be made of steel, stainless steel, or rubber. The document outlines factors that affect grinding efficiency such as feed rate, ball size and weight, and rotation speed relative to critical speed.