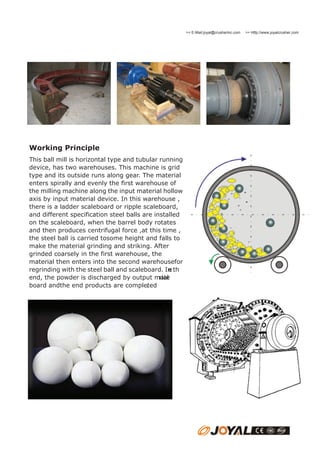

The ball mill is a key piece of equipment used for regrinding in various industries. It can grind materials using either a wet or dry process. The ball mill works by rotating a hollow cylinder with steel balls inside. Materials are introduced and the steel balls cause grinding and impact through the centrifugal force created by the rotation of the cylinder. Ground materials are discharged through discharge ports at the end. Ball mills come in various sizes to produce powder from different materials for uses such as building materials, chemicals, and metals.