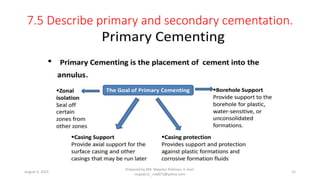

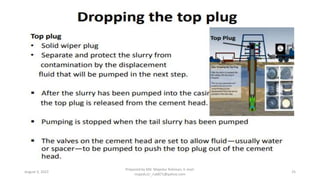

This document discusses cementing in oil and gas wells. It covers factors that affect cement slurry design like well depth and temperature. It describes cement additives that can control setting time. Float equipment like float collars and shoes are used to guide casing and enable cement circulation. Primary cementing involves pumping cement between casing and borehole to isolate formations. Secondary cementing through squeeze cementing can repair isolation barriers. Liner cementing cases off the open hole below an existing casing string. Cement plugs placed in casing are used for abandoning wells or zonal isolation.