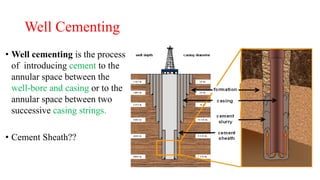

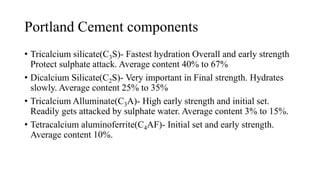

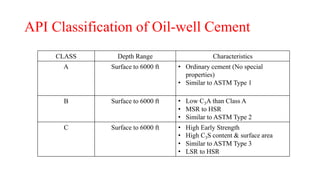

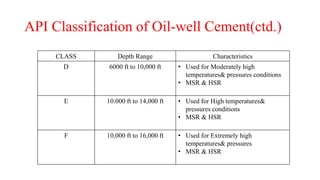

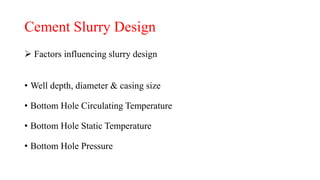

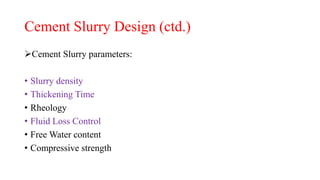

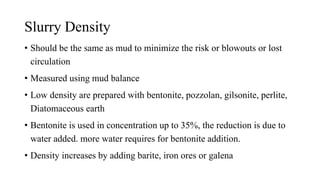

This document discusses cement classification, slurry design, and additives used in oil well cementing. It describes the four main components of Portland cement and their functions. It outlines the API classification system for oil well cements based on depth and characteristics. Key factors influencing cement slurry design are identified as well depth, temperature, and pressure. Important slurry parameters like density, thickening time, rheology, and fluid loss are discussed. Common additives used as accelerators, retarders, dispersants, and for fluid loss control are identified.