Microstructure and Heat Treatment of Steels.pptx

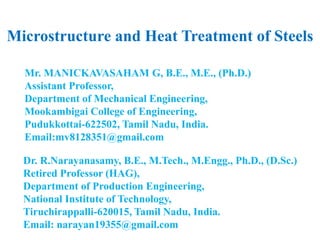

- 1. Microstructure and Heat Treatment of Steels Dr. R.Narayanasamy, B.E., M.Tech., M.Engg., Ph.D., (D.Sc.) Retired Professor (HAG), Department of Production Engineering, National Institute of Technology, Tiruchirappalli-620015, Tamil Nadu, India. Email: narayan19355@gmail.com Mr. MANICKAVASAHAM G, B.E., M.E., (Ph.D.) Assistant Professor, Department of Mechanical Engineering, Mookambigai College of Engineering, Pudukkottai-622502, Tamil Nadu, India. Email:mv8128351@gmail.com

- 2. What is Hardening and Tempering? Hardening and tempering of engineering steels is performed to provide components with mechanical properties suitable for their intended service. Steels are heated to their appropriate hardening temperature (usually between 800-900°C), held at temperature, then "quenched" (rapidly cooled), often in oil or water. This is followed by tempering (a soak at a lower temperature) which develops the final mechanical properties and relieves residual stresses.

- 3. The actual conditions used for all three steps are determined by steel composition, component size and the properties required. Hardening and tempering can be carried out in "open" furnaces (in air or combustion products), or in a protective environment (gaseous atmosphere, molten salt or vacuum) if a surface free from scale and decarburisation (carbon loss) is required ("neutral hardening", also referred to as "clean hardening"). Cont.

- 4. What are the Benefits of Hardening and Tempering? Hardening and tempering develops the optimum combination of hardness, strength and toughness in an engineering steel. This offers the component designer a route to savings in weight and material. Components can be machined or formed in a soft state and then hardened and tempered to a high level of mechanical properties.

- 5. Cont. Hardening from open furnaces is often employed for products such as bars and forgings that are to be fully machined into components afterwards. Neutrally clean hardening is applied to components that require surface integrity to be maintained. Examples: Include nuts, bolts, springs, bearings and many automotive parts. Neutral clean hardening is carried out under tightly-controlled conditions to produce a precision component needing the minimum of final finishing.

- 6. What Sort of Steels can be Hardened and Tempered? Almost all engineering steels containing over 0.3% carbon will respond to hardening and tempering. The majority of hardenable steels used for engineering components.

- 7. What are the Limitations? The response of a steel component to hardening and tempering depends on steel composition, component size, and method of treatment. Every steel has a "limiting" section size ("ruling section") above which full hardening cannot be achieved. A higher grade of steel will be required to ensure optimum properties in a larger section.

- 8. Cont. It may be possible to harden larger components in lower-grade steels by using non-standard treatments such as faster quench rates or lower-temperature tempers. Faster quench rates always increase the risk of distortion or cracking. Low-temperature tempers can seriously impair mechanical properties such as toughness. Serious consideration should be given to these facts.

- 9. Steel Conditions Steels that are purchased after open treatments (e.g. 'black bar') are liable to have lost some carbon from the surface layers (decarburisation). Decarburised layers must be fully removed by machining from all surfaces before components are hardened. Otherwise excessive distortion or even cracking are likely.

- 10. Cont. Steels that are purchased in cold-worked conditions, such as 'bright bar', contain residual stresses. These stresses can contribute to distortion during machining and in hardening. It is recommended that rough-machined blanks have these stresses removed, by normalising or soft annealing before hardening, in order to reduce the risk of excessive distortion.

- 11. Temper Embrittlement Certain steels, particularly alloy steels containing nickel and chromium, suffer from embrittlement. lf tempered in the range 250-450°C; this limits the acceptable mechanical properties they can attain. Check that the selected steel is not prone to this problem, and if in doubt consult your heat treater.

- 12. What Problems Could Arise? Distortion or cracking Changes in size or shape can arise in hardened components from a variety of causes. some inherent in the high-temperature / rapid cool process, some attributable to component design shortcomings and others relating to earlier manufacturing steps (e.g. thermal relief of stresses introduced by prior forming). Where final dimensions are critical, finish grinding or machining will be necessary and must be planned.

- 13. Components hardened and tempered to high mechanical- property levels are often impossible to straighten later. In extreme circumstances, the stresses generated by quenching can even be high enough to crack components. It is necessary for the manufacturer to take all reasonable steps to minimise the risk through careful component design (e.g. avoid stress-raising features such as sudden changes in section, deep slots, cutouts) and steel selection. It is always helpful to consider potential hardening and tempering problems at the design stage. Cont.

- 14. Scaling and Decarburisation If open furnace treatment is selected, scaling and decarburisation are likely. Large components spend longer at high temperatures and suffer more. Allowance must be made for removal of affected layers after treatment. The alternative is clean/neutral hardening in a protective environment which avoids scaling and decarburisation. Cont.

- 17. TTT diagram showing how to make tempered steel

- 18. TTT diagram showing how to make Martempered steel

- 19. TTT diagram showing how to make Austempered steel

- 20. Hardening involves controlled heating to a critical temperature dictated by the type of steel (in the range 760-1300 C) followed by controlled cooling. Dependent on the type of material, appropriate cooling rates vary from very fast (water quench) to very slow (air cool). Hardening of steels

- 21. Tempering involves reheating the hardened tool/die to a temperature between 150-657°C, depending on the steel type. A process which controls the final properties whilst relieving stresses after hardening, tempering can be complex. some steels must be subjected to multiple tempering operations. Tempering of Steels

- 22. Brittlenesss exhibited by some steels after being heated to some temperature within the range of 300° to 650°F, and more especially if the steel is worked at the elevated temperature. There can be an increase in strength and a substantial decrease in ductility or impact strength. Blue brittleness temperature range must be avoided during tempering. Cont. Blue Brittleness

- 23. Microstructure development in eutectoid steel with increasing cooling rate in arrow direction Source: E.C. Bain: Functions of the alloying elements in steel, American Society for Metals, Metals Park, Ohio, USA, 1939.

- 25. Microstructure of Martensite Formed After Hardening of Steel Needle like structure indicates Martensite

- 26. TEM micrographs of the specimens: (a,c) for the bright and dark field image of 1.54Si- 60s; (b,d) for the bright and dark field image of 1.26Al-60s; (e,f) for the 1.54Si-1800s and 1.26Al-1800s, respectively. TEM micrographs with Nanoscale-Martensite (M) and Retained Austenite (RA)

- 27. TEM micrographs of the specimens: (a,c) for the bright and dark field image of 1.54Si- 60s; (b,d) for the bright and dark field image of 1.26Al-60s; (e,f) for the 1.54Si-1800s and 1.26Al-1800s, respectively. Cont.

- 28. TEM micrographs of the specimens: (a,c) for the bright and dark field image of 1.54Si- 60s; (b,d) for the bright and dark field image of 1.26Al-60s; (e,f) for the 1.54Si-1800s and 1.26Al-1800s, respectively. Cont. TEM micrographs with Nanoscale-Martensite (M) and Retained Austenite (RA)

- 30. Figure 2.5: Martensitic microstructures (low optical micrograph) (a) lath martensite (low-alloy steel with 0.17 wt.%C, 1200℃ hot bath) (b) plate martensite (casehardening steel, 1100℃ hot bath). Obtained from [15].

- 31. Microstructure of a martensitic carbon steel (optical micrograph)

- 32. Microstructure of Tempered Martensite in Carbon-Iron-Chromium Steel

- 33. Schematic of a TRIP steel microstructure showing a matrix of Ferrite, with Martensite, Bainite and Retained Austenite as the additional phases.

- 34. Comparison between normalized and quenched and tempered Plain Carbon Steel

- 35. Thank You References: Authors of Technical articles and Scopus Journals are Acknowledged.