ELECTRIC ARC FURNACE AC COMPONENTES.pdf

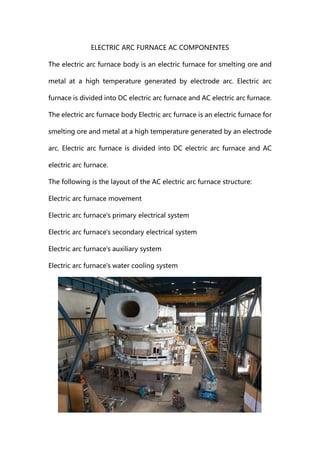

- 1. ELECTRIC ARC FURNACE AC COMPONENTES The electric arc furnace body is an electric furnace for smelting ore and metal at a high temperature generated by electrode arc. Electric arc furnace is divided into DC electric arc furnace and AC electric arc furnace. The electric arc furnace body Electric arc furnace is an electric furnace for smelting ore and metal at a high temperature generated by an electrode arc. Electric arc furnace is divided into DC electric arc furnace and AC electric arc furnace. The following is the layout of the AC electric arc furnace structure: Electric arc furnace movement Electric arc furnace's primary electrical system Electric arc furnace's secondary electrical system Electric arc furnace's auxiliary system Electric arc furnace's water cooling system

- 2. 1. THE ELECTRIC ARC FURNACE STRUCTURE 1.1 ELECTRIC ARC FURNACE BODY The furnace body is composed of furnace body and furnace cover (furnace top). The shell of the furnace body is made of steel plate, and the inner part is the furnace lining. The furnace wall is made of magnesia brick (MgO) or chrome magnesia brick (Cr2O3, MgO). There is a magnesia (clay) layer on the bottom of the furnace, which is in the shape of magnesia brick. 1.2 ELECTRIC ARC FURNACE LINING The lining of acid furnace is built with quartz brick (SiO2) and quartz sand. In addition to the basic requirements of strength, high-temperature resistance and thermal insulation, the refractory of furnace lining is also required to be able to withstand the chemical erosion of furnace slag, the thermal shock of repeated rapid changes of furnace temperature and the collision between furnace charge block and operating machinery. 1.3 ELECTRIC ARC FURNACE DOOR The furnace door and tapping trough are respectively arranged at both ends of the furnace body diameter. The furnace door frame and the furnace door cover are cooled by water, and the contact between them is tight, so as to maintain the reducing atmosphere in the furnace. The tapping port is blocked with crushed dolomite and chiseled with a steel

- 3. chisel during tapping. In order to facilitate the operation of large capacity electric arc furnace, the second furnace door is set at 90 ° with the first door. 1.4 ELECTRIC ARC FURNACE COVER The furnace cover is embedded in the steel furnace cover ring with high aluminum brick or chrome magnesia brick in an arch shape. The furnace cover ring sits on the furnace wall, and there is sand seal at the place in contact with the shell of the furnace body. Its function is also to maintain the sealing of the furnace and facilitate the alignment of the furnace cover. 1.5 ELECTRIC ARC FURNACE ELECTRODES The three electrodes extend into the furnace through three water-cooled sealing rings (electrode holes) equidistant from each other in the center of the furnace cover. The electrode shall have good conductivity, sufficient mechanical strength and stable structure resistant to thermal shock, and contain less impurities. High-quality graphite electrode is mostly used in actual production. Both ends of each electrode are respectively made into female and male threads to facilitate the connection of the electrode. Due to the inevitable high-temperature oxidation, thermal collapse and mechanical damage, the average consumption of electrodes per ton of steel is 3 ~ 7kg.

- 4. 2. ELECTRIC ARC FURNACE MOVEMENTS The scrap steel is simply processed, crushed, cut and packaged and then loaded into the electric arc furnace. The heat generated by the electric arc between the graphite electrode and the iron material is used to smelt the iron material, and the refining furnace is equipped to complete the functions of degassing, adjusting composition, temperature and removing impurities, so as to obtain qualified molten steel. The subsequent rolling process is basically the same as the long process. 3. PRIMARY ELECTRICAL SYSTEM 3.1 POWER SUPPLY SYSTEM Electric arc furnace steelmaking consumes huge electric energy, and a complete power supply system can ensure the normal progress and safety of smelting. The main electrical circuit from the high-voltage cable

- 5. to the furnace is equipped with disconnector, high-voltage switch, plug current coil (reactor), shunt switch of plug current coil and furnace transformer. The main circuit is also connected with voltage and current transformers, which are connected with detection, indication, recording instruments and control devices. The disconnector is used to cut off and close the high-voltage line when there is voltage load. It can only act after the high-voltage switch is disconnected. The electric arc furnace requires repeated power on and power off for many times. In order to ensure the reliability of the high-voltage switch, it is also equipped with oil circuit breaker or air circuit breaker. 3.2 ELECTRIC ARC FURNACE TRANSFORMER The transformer is the core equipment of electric arc furnace power supply system, which is required to bear large overload; Good insulation under high temperature and high pressure; High mechanical strength; Large transformation ratio; The secondary side voltage can be changed in many stages and can be changed under load, so as to timely and effectively regulate the electric energy input into the furnace. 4. SECONDARY ELECTRICAL SYSTEM 4.1 ELECTRIC ARC FURNACE PLUG COIL The function of plug current coil is to increase the stability of arc combustion; Control the impact strength of the current in case of short circuit between electrode and charge. The plug current coil shall be

- 6. made into transformer shape and placed in a separate oil tank, which shall also have high mechanical strength. When the arc is stable and not prone to short circuit, it shall be cut off from the circuit in time. 4.2 SHORT NET Short network refers to the section of line from the outgoing line of the secondary side of the transformer to the electrode holder. Due to the current of more than tens of thousands of AMPS, the short network needs to adopt special structure to reduce the resistance and inductive reactance of the line. 4.3 ADJUSTING ELECTRODE LIFTING The automatic control system for adjusting electrode lifting must have high sensitivity. The commonly used automatic regulating devices are: motor amplifier - DC motor type; Thyristor DC motor type; Thyristor

- 7. electromagnetic slip clutch type and electric servo valve hydraulic differential type, etc. The hydraulic differential electric servo valve has the advantages of fast regulation speed and high sensitivity. Its system lag time is only 0.15 ~ 0.3s, and the transmission power is large. 5. TILTING MECHANISM of ELECTRIC ARC FURNACE AND FURNACE TOP CHARGING SYSTEM 5.1 The tilting mechanism shall be able to gently and smoothly tilt the furnace body 40 ° ~ 50% towards the steel tapping groove or 12 ° ~ 15 ° towards the working door. 5.2 The adjustment of tilting speed shall be sensitive and reliable. There shall be no vibration, deflection and retention during tilting. 5.3 The electrode holder shall have sufficient mechanical strength and resistance to high-temperature corrosion and oxidation. 5.4 The cross arm of the electrode lifting mechanism shall be kept horizontal when it rises and falls, and the left-right swing shall be small. 5.5 The insulation structure between the electrode holder and cross arm shall be reliable, firm and shockproof. The insulating material shall be able to withstand temperatures above 200 ℃. 5.6 The electrode lift truck shall be fixed on the pillar surface and move smoothly without damaging the pillar and blocking. 5.7 The lifting height shall meet the design requirements to ensure that the electrode can fall to the bottom of the furnace when melting the

- 8. furnace charge, and the electrode can be lifted to the electrode hole on the top of the electric furnace when loading. 5.8 The shape of the "s" curve section of the furnace cover lifting mechanism shall be determined correctly, and the inertia force generated when starting and stopping rotation shall be minimized. 5.9 The position of the rotation center shall enable the torque on the ejector rod and the rotation angle of the furnace cover to be small, and offset a certain distance to the front of the furnace. 5.10 The guide roller shall roll steadily when rising and falling without jamming or sliding. 5.11 The furnace body opening mechanism, furnace body and locking device must meet the design requirements. The furnace car shall operate flexibly and reliably. 5.12. The furnace body must be equipped with a limit switch to ensure that the furnace body can automatically align with the center of the furnace cover when driving in; The furnace body can meet the charging process requirements when it is opened. 5.13 The furnace cover opening mechanism and the furnace cover lifting mechanism shall place the furnace cover on the movable door bridge stably and reliably. 5.14 The traveling mechanism of the bridge shall operate flexibly and reliably. The bridge must be equipped with a limit switch.

- 9. 5.15 The hydraulic transmission components of the hydraulic transmission furnace top charging mechanism shall not vibrate, crawl, stagnate or have a significant impact within the working speed range. 6. WATER COOLING SYSTEMS In practical application, due to the water-cooling equipment and overall design of the electric arc furnace, the water-cooling wall of the electric arc furnace can bear higher temperatures to ensure the operation of the electric arc furnace. Combined with the conduction law of the water cooling system of the electric arc furnace in the work, the water cooling equipment of the electric arc furnace and the overall design of the electric arc furnace are also the key factors affecting the service life of the water cooling wall of the electric arc furnace. It plays a very important role in the operation and practical application of the electric arc furnace

- 10. and is the focus of the operation and maintenance of the water cooling equipment of the electric arc furnace. During the operation of the electric arc furnace, the correctness of the overall design of the electric arc furnace can balance the water flow in the direction of the thermal gradient of the electric arc furnace, so as to ensure the operation quality and service life of the water-cooling equipment and system of the electric arc furnace; On the other hand, the correctness of operation control of electric arc furnace plays a positive role in the monitoring of the high-power operation of electric arc furnace and the realization of operation and maintenance of electric arc furnace; Finally, in the operation of an electric arc furnace, by establishing the communication relationship between the production and supply of electric arc furnace and the equipment maintenance department and strengthening the information exchange between them, the productivity of electric arc furnace equipment operation can be improved and improved, which also has a positive role and significance. IF YOU HAVE ANY QUESTIONS, PLEASE FEEL FREE TO CONTACT ME. EMAIL: marketing2@hanrm.com. I am looking forward to receiving your response.