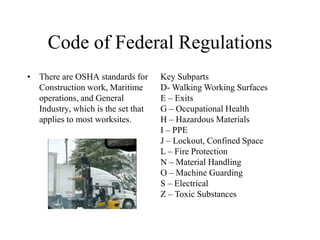

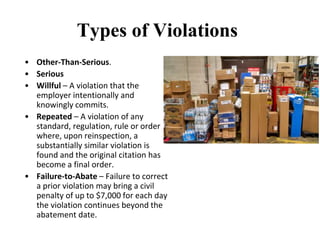

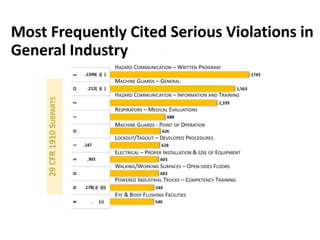

This document outlines the objectives and key elements of an introductory course on the Occupational Safety and Health Administration (OSHA). It describes the major provisions of the OSH Act of 1970 that established OSHA, including its functions and positive impact on worker safety. Employer and worker rights and responsibilities are also covered. The document further explains the organization of OSHA standards in the Code of Federal Regulations, and the inspection, citation, and appeals processes.

![General Duty Clause

• Section 5(a)(1)

• "a place of

employment which is

free from recognized

hazards that are

causing or are likely to

cause death or serious

physical harm to [its]

employees."

Not wearing seatbelts is a

common citation under the

general duty clause.](https://image.slidesharecdn.com/511introductiontooshawithobjectivesandtest-200530230254/85/Introduction-to-OSHA-17-320.jpg)

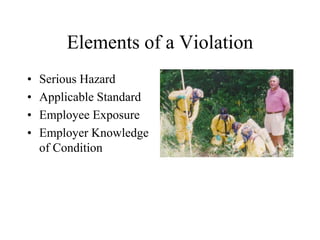

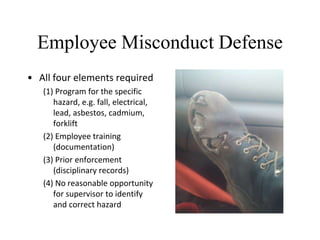

![37

Level

2020 Maximum Penalty

Serious $13,494 per violation

OTS $13,494 per violation

Willful or

Repeat

$134,937 per violation

Failure to

Abate

$13,494 per day unabated

beyond the abatement date

[generally limited to 30 days

maximum]

OSHA Penalty Levels: 2019](https://image.slidesharecdn.com/511introductiontooshawithobjectivesandtest-200530230254/85/Introduction-to-OSHA-37-320.jpg)