GE Power Services EHS Manual Table of Contents

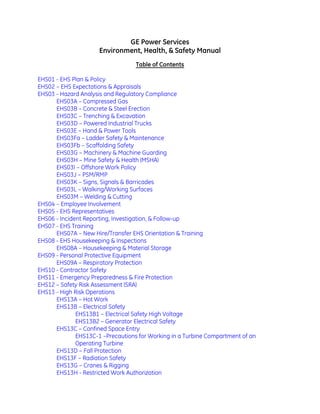

- 1. GE Power Services Environment, Health, & Safety Manual Table of Contents EHS01 - EHS Plan & Policy EHS02 – EHS Expectations & Appraisals EHS03 - Hazard Analysis and Regulatory Compliance EHS03A – Compressed Gas EHS03B – Concrete & Steel Erection EHS03C – Trenching & Excavation EHS03D – Powered Industrial Trucks EHS03E – Hand & Power Tools EHS03Fa – Ladder Safety & Maintenance EHS03Fb – Scaffolding Safety EHS03G – Machinery & Machine Guarding EHS03H – Mine Safety & Health (MSHA) EHS03I – Offshore Work Policy EHS03J – PSM/RMP EHS03K – Signs, Signals & Barricades EHS03L – Walking/Working Surfaces EHS03M – Welding & Cutting EHS04 – Employee Involvement EHS05 - EHS Representatives EHS06 - Incident Reporting, Investigation, & Follow-up EHS07 - EHS Training EHS07A – New Hire/Transfer EHS Orientation & Training EHS08 - EHS Housekeeping & Inspections EHS08A – Housekeeping & Material Storage EHS09 - Personal Protective Equipment EHS09A – Respiratory Protection EHS10 - Contractor Safety EHS11 - Emergency Preparedness & Fire Protection EHS12 – Safety Risk Assessment (SRA) EHS13 - High Risk Operations EHS13A – Hot Work EHS13B – Electrical Safety EHS13B1 – Electrical Safety High Voltage EHS13B2 – Generator Electrical Safety EHS13C – Confined Space Entry EHS13C-1 –Precautions for Working in a Turbine Compartment of an Operating Turbine EHS13D – Fall Protection EHS13F – Radiation Safety EHS13G – Cranes & Rigging EHS13H - Restricted Work Authorization

- 2. EHS14 - Review of New / Modified Facilities & Equipment EHS14A – Machinery & Equipment Decomissioning EHS15 - Industrial Hygiene EHS15A – Asbestos EHS15B – Hearing Conservation Program EHS15C – Lead Program EHS15D – Hexavalent Chromium EHS15E – Reporting Substantial Risk From Chemicals EHS16 - Chemical Management EHS16A – Chemical Procurement EHS16B – HAZCOM EHS16C – Hazardous Materials Deliveries EHS16D – Flammable/Combustible Liquids & Gases EHS16D2 – Material Shipping EHS16E – Special Provisions for Generator Chemicals EHS16F – Control & Handling Of Corrosive Chemicals EHS17 - Ergonomics EHS18 - Motor Vehicle Safety EHS19 - Medical Services EHS19A – Blood Borne Pathogens EHS19B – First Aid/CPR EHS19C – Automatic External Defibrilator (AED) EHS20 - Program Evaluation EHS21 – Lockout-Tagout EHS22 – OSHA EHS22A - OSHA Inspections EHS22B - OSHA Safety Standards Recordkeeping EHS23 – General Environmental Management EHS23A – Regulatory Inspections EHS23B – Waste Management EHS23C – Spill Management EHS24 - Forms EHS25 - Glossary

- 3. EHS Plan and Policy EHS-01/ 2.0 Page 1 of 7 GE Energy Services -Company Confidential Effective Date: April 27, 2007 2009 PS Version – Anne McEntee Approved By: Robin Sevinsky : EHS PLAN AND POLICY 1. PURPOSE & SCOPE 1.1 The purpose of this policy is to state General Electric Energy Service’s (GEES) commitment to achieving environmental, health and safety (EHS) excellence. This commitment is the responsibility of management and employees in all functions. 2. DEFINITIONS Refer to EHS Manual Glossary 3. PROCEDURE GE Energy Services recognizes that people are its most vital resource, and their safety and health is one of our principal responsibilities. GE Energy Services will strive to provide a safe and healthy working environment and to avoid adverse impact and injury to the environment and the communities in which we do business. 3.1 Procedures 3.1.1 The purpose of procedures is to identify regulatory requirements, address business-specific applicability, and leverage Best Practice elements learned throughout GEES. 3.1.2 GEES EHS Headquarters has the responsibility to develop, maintain, and update the EHS Procedures Manual, which is accessible and controlled on- line. Each business within GEES will be responsible for completing the business-specific template. 3.1.3 In the event of conflict between GEES EHS Procedures and Governmental standards (i.e. country-specific, Federal, State, County, and City regulations, codes, statutes, rules, and orders), those of the governing authority prevail. 3.1.4 The Reference Sections used within procedures are for additional information only, and do not imply additional requirements beyond those specified in the procedure. 3.2 Education and Training 3.2.1 Education and training is comprised of regulatory required training, procedural training, Best Practice Training, and on-going efforts to increase general EHS awareness. 3.2.2 EHS Training requirements are outlined in the GEES EHS Training Matrix. 3.3 Hazard Elimination 3.3.1 From facility design to facility closure, there is always the potential for hazards to exist in the workplace. The goal of every facility should be to identify and promptly correct all hazards that are found.

- 4. EHS Plan and Policy EHS-01/ 2.0 Page 2 of 7 GE Energy Services -Company Confidential Effective Date: April 2009 Approved By: Anne McEntee 3.3.2 All employees are responsible for notifying management of hazardous conditions in the workplace, whether at a GE facility or a customer site. 3.3.3 Site management, in some cases working with the facility owner, has the responsibility to take prompt action to correct identified hazards. 3.4 Compliance Assurance 3.4.1 Auditing - the purpose of auditing is to ensure compliance. 3.4.2 Enforcement – employees who violate the spirit or letter of this policy are subject to disciplinary action up to and including discharge. The following are examples of conduct which may result in discipline: 3.4.2.1 Actions which violate this policy. 3.4.2.2 Requests, which result in others violating this policy. 3.4.2.3 Failure to promptly report a known or suspected policy violation. 3.4.2.4 Failure to cooperate in GE investigations of possible violations. 3.4.2.5 Retribution against another employee for reporting a policy concern. 3.4.2.6 Failure to demonstrate the leadership and diligence needed to ensure compliance with GE policies and applicable law. 3.5 Employee Involvement 3.5.2 Each employee has the responsibility to be proactive with regards to safety, and to perform their work while conscious of the associated hazards and means of avoiding them. 3.5.3 Each employee must understand that safety is not to be sacrificed for performance, but rather the most productive means of working in a compliant manner should be sought. 3.6 Safety Culture 3.6.1 Management has the responsibility of creating an environment that promotes compliance, encourages employees to raise their policy questions and concerns, aids in the process of resolving any concerns, and prohibits retribution. 3.6.2 A safety culture is achieved, in part, by management showing support of safety initiatives going on at the site, evaluating and rewarding performance that promotes the tenets of this policy, demonstrating that performance is never more important than compliance, and taking prompt remedial action when required. 3.7 Reporting Concerns 3.7.1 If a report of a concern about this policy has been made and the issue is not resolved, the issue shall be raised to a GE Manager (including the GE EHS Manager; GE General Manager, Operations; GE General Manager; GE Human Resources; GE Legal Counsel; GE Energy ombuds or other designated person).

- 5. EHS Plan and Policy EHS-01/ 2.0 Page 3 of 7 GE Energy Services -Company Confidential Effective Date: April 2009 Approved By: Anne McEntee 3.7.2 GE employees at all levels are prohibited from taking retribution against anyone for reporting or supplying information about a policy concern. 3.8 Business-Specific EHS Policy 3.8.1 Each business must finalize an EHS policy, including goals and objectives based on EHS metric trending, which is to be signed by the business Manager. 3.8.2 A final copy of the business-specific policy should be placed in Appendix A. It should also be readily accessible and effectively communicated to all employees (e.g. posted in a well-traveled area) annually. 3.8.3 Each business must determine how to include resource allocation for EHS objectives into their annual budget (e.g. specific line item, planning with business management, provide funds on an as needed basis). 4. RESPONSIBILITIES 4.1 GEES Management shall: 4.1.1 Participate in and contribute toward an effective EHS program. 4.1.2 Regularly evaluate the effectiveness of managers and other staff employees on their implementation of this policy and the GEES EHS Procedures. 4.1.3 Work cooperatively with GEES customers, business partners, contractors, and suppliers to ensure that relationships with them are supportive of this policy. 4.2 GEES EHS HQ shall: 4.2.1 Develop EHS policies, programs, procedures, support their proper implementation, and revise them as necessary. 4.2.2 Consult with Corporate Environmental Programs and GE Energy, as appropriate, on the adequacy of GEES EHS programs. 4.3 Business Manager shall: 4.3.1 Participate in and contribute toward an effective EHS program. 4.3.2 Regularly evaluate the effectiveness of managers and other staff employees on their implementation of this policy and the GEES EHS Procedures. 4.3.3 Ensure compliance with GEES EHS Procedures. 4.3.4 Communicate responsibly with employees, P&L Headquarters, communities, customers, and government agencies regarding environmental, health and safety issues. 4.3.5 Regularly assess operations and management and establish Health and Safety measurements to ensure compliance with this policy and applicable laws and regulations. 4.3.6 Ensure that employees with EHS responsibility are appropriately screened before appointment and that their continued appropriateness for their positions is periodically reviewed.

- 6. EHS Plan and Policy EHS-01/ 2.0 Page 4 of 7 GE Energy Services -Company Confidential Effective Date: April 2009 Approved By: Anne McEntee 4.3.7 Work cooperatively with customers, business partners, contractors, and suppliers to ensure that relationships with them are supportive of this policy. 4.3.8 Promptly report EHS matters. 4.3.9 Review and sign the business-specific EHS policy found in Appendix A. 4.4 Business EHS HQ Shall: 4.4.1 Develop Business-specific EHS policies and programs specific to their needs, supporting their proper implementation, and revising them as necessary. 4.4.2 Provide training resources to P&L facilities as needed. 4.5 All Employees shall: 4.5.1 Follow this policy and all applicable laws and regulations to protect their health and safety as well as that of other workers, the public and the environment. 4.5.2 Present ideas that support the goals of this policy to their manager or the P&L EHS Manager. 4.5.3 Seek assistance from their manager, Facility Operations Management, EHS HQ, Human Resources, or Legal Counsel when a question arises about application of this policy 4.5.4 Promptly report: 4.5.4.1 Any concerns about possible violations of this policy. 4.5.4.2 Any concerns others may have about a possible violation of this policy. 4.5.4.3 Any concerns about a possible request to violate this policy. 4.5.5 Report concerns to their manager, Facility Operations Management, EHS HQ, Human Resources, Ombudsperson, or Legal Counsel. The report may be written or oral, and it may be anonymous. 4.5.6 Cooperate with GE investigations into concerns covered by this policy. 4.5.7 Take appropriate measures to prevent workplace injuries and illnesses. 4.5.8 Eliminate unreasonable environmental, health and safety risks from GE facilities, services and activities. 4.5.9 To the extent practicable, reduce the use and release of toxic and hazardous materials. 4.5.10 Where appropriate, implement ways to prevent pollution and conserve, recover and recycle raw materials.

- 7. EHS Plan and Policy EHS-01/ 2.0 Page 5 of 7 GE Energy Services -Company Confidential Effective Date: April 2009 Approved By: Anne McEntee 5. TRAINING See GEES Training Matrix 6. AUDITING 6.1 This program shall be reviewed annually. The review shall be documented and shall reflect changes/updates based on audit findings, trends, regulatory changes, etc. 7. APPENDECIES Appendix A – Site-Specific Template 8. REFERENCE DOCUMENTS AND LINKS 8.1 General Electric Company Corporate Policy, Health, Safety and Environmental Protection - 20.3 ( http://cep.corporate.ge.com/ )

- 9. EHS Expectations and Appraisals EHS-02/2.0 Page 1 of 7 GE Energy Services-Company Confidential Effective Date: April 27, 2007 Approved By: Robin Sevinsky EHS EXPECTATIONS & APPRAISALS 1. PURPOSE & SCOPE This procedure outlines the GE Energy Services (GEES), Environmental, Health and Safety (EHS) Expectations and Appraisal program for all GEES and customer sites. It includes expectations and guidelines for EHS appraisals for all employees. 2. DEFINITIONS Refer to EHS Manual Glossary 3. PROCEDURE 3.1 Environmental, Health and Safety Expectations 3.1.1 Specific EHS responsibilities have been developed for every job description at GEES and customer sites where work is performed. Management and employees are held accountable for complying with their responsibilities. 3.1.2 Appendix A includes a form that can be used for Site Manager EHS performance appraisals and Appendix B includes a form that can be used for employee performance appraisals. 3.1.3 EHS should be included in the performance appraisal process for all employees on an annual basis, including proactive and accountability for compliance with all EHS rules. The method chosen for each site is documented in the Site-Specific Information (Appendix C) section of this procedure 3.1.4 Each site must be able to demonstrate accountability for EHS rules. This can be accomplished by any or a combination of the following: 3.1.4.1 Proof of disciplinary action (i.e. warning notices, etc.) 3.1.4.2 Annual EHS performance appraisals by management 3.1.4.3 Self-appraisal process where employee completes evaluation form and reviews with management 4. RESPONSIBILITY 4.1 GEES HQ shall: 4.1.1 Conduct Management EHS Performance Appraisals. 4.2 GEES Site Managers or Designees shall: 4.2.1 determine an annual schedule to conduct EHS Performance Appraisals that incorporates each employee. This schedule shall be entered into the EHS Compliance Calendar or similar process. 4.2.2 Conduct Employee EHS Performance Appraisals.

- 10. EHS Expectations and Appraisals EHS-02/2.0 Page 2 of 7 GE Energy Services-Company Confidential Effective Date: April 27, 2007 Approved By: Robin Sevinsky 4.2.3 Not permit an employee to continue work if they have reasonable grounds to believe that that employee may not be physically able or prepared to perform effectively the work assigned, 4.2.4 Reinforce employee use of good EHS practices through disciplinary actions and positive recognition programs, 4.2.5 Perform observations of work to detect and correct unsafe acts, 4.2.6 Actively participate in accident, injury and illness prevention activities, 4.2.7 Review the EHS performance of personnel and contractors against objectives and goals, 4.2.8 Maintain knowledge of specific compliance requirements for their area of responsibility and ensure active implementation and verification of compliance, and 4.2.9 Meet the employee responsibilities as listed below 4.3 GEES EHS Site/Field Representative shall: 4.3.1 Complete the site-specific information in Appendix C, (For fixed facilities employees only) 4.3.2 Review and update the site-specific information in Appendix C on an annual basis and (For fixed facilities employees only) 4.3.3 Meet the employees’ responsibilities, as listed below: 4.4 All Employees shall: 4.4.1 Act in such a manner as to ensure, at all times, maximum safety to self, fellow employees and the public, 4.4.2 Accept and demonstrate responsibility for their own safe work practices, 4.4.3 Assess their own qualifications with regard to job conditions, and neither perform nor attempt to perform any action which cannot be performed safely, 4.4.4 Not attempt work for which they do not feel qualified or physically fit, 4.4.5 Be familiar with and implement the safety and regulatory compliance requirements and procedures described in this EHS manual and carefully read through safety instructions or procedures provided, 4.4.6 Obtain specific instructions and/or clarification from Manager before proceeding with work in situations where conditions are not covered by these safety requirements and procedures, or when a requirement of a procedure is not completely understood, 4.4.7 Obtain from Manager, specific instructions regarding hazards present in unusual work situations,

- 11. EHS Expectations and Appraisals EHS-02/2.0 Page 3 of 7 GE Energy Services-Company Confidential Effective Date: April 27, 2007 Approved By: Robin Sevinsky 4.4.8 Observe and adhere to all warning signs, notices and EHS procedures, 4.4.9 Not use intoxicating beverages and/or substances while on the job, 4.4.10 Promptly report observed hazards to Manager or supervisor, 4.4.11 Promptly report all accidents, injuries and illnesses to Manager or supervisor, and maintain housekeeping in their work area. 5. TRAINING Employees will be made aware of the EHS Expectations and Appraisals process, along with the disciplinary policy. This can be accomplished via monthly safety and/or all-employee meetings or updates, creation of an EHS bulletin board to post pertinent postings and announcements, or distribution of memos directly to all employees. 6. AUDITING No specific audit will be assigned to this procedure. 7. APPENDICIES Appendix A Management EHS Performance Appraisal Appendix B Employee EHS Performance Appraisal Appendix C Site-Specific Expectations and Appraisals Information

- 12. EHS Expectations and Appraisals EHS-02/1.0 Page 5 of 7 GE Energy Services-Company Confidential Effective Date: April 27, 2007 Approved By: Robin Sevinsky Appendix A - MANAGEMENT EHS PERFORMANCE APPRAISAL Manager: Reviewed By: Overall Performance Appraisal: Date: Expectations Criteria Exceed Meet Below 1. Actively participate in accident, injury and illness prevention activities: • Ensure job specific safety procedures are established via job safety analysis. • Train employees in safe work practices. • Ensure routine inspections are conducted by trained personnel. • Correct hazards and unsafe conditions. • Accident, near-miss accident or potential hazard investigations. Pro-active approach to prevention; Develops and updates safe working procedures; Acts upon identified hazards and corrective actions; Conducts activities in a timely fashion; Actively participates in investigations, analysis and inspections. 2. Communicate environmental, health & safety information to employees. Ensures safety is the leading agenda item in all operating and employee meetings; Keeps employees aware of current environmental, health & safety information; Actively communicates with employees on a regular basis (e.g., accident causes). 3. Ensure the effective and timely training on environmental, health & safety procedures. Employees trained prior to job assignment; Employees current on all environmental, health & safety training; Training updated with changes in operations or risks. 4. Facilitate employee involvement in environmental, health & safety activities. Solicits input from employees; Acts upon employee input; Encourages employee participation in depot programs. 5. Perform job task observations to detect and correct unsafe acts. Continually evaluates (informally) environmental, health & safety practices in area; Corrects unsafe acts on the spot. 6. Reinforce employee use of good environmental, health & safety practices through disciplinary actions and positive recognition programs. Positive attitude towards environmental, health & safety practices; Leads by example. 7. Enforce environmental, health & safety rules and procedures. Demonstrates enforcement of and develops/implements positive recognition programs; Employees aware of disciplinary procedures; Takes corrective actions on employee compliance issues; Does not "look the other way". 8. Demonstrate commitment to environmental, health & safety: • Make safety a priority in daily depot operations. • Participate in depot environmental, health & safety activities. • Participate in environmental, health & safety training. Leads by active demonstration that safety is the priority in conducting job tasks and maintenance of facilities. 9. Frequently review the environmental, health & safety performance of the area, personnel and contractors against established objectives and goals. Reaches site safety objective goals; Continually sets and meets new goals for the area; Ensures adequate environmental, health & safety resources for area. 10. Knowledgeable of specific compliance requirements in their area of responsibility and ensures active implementation and verification of compliance. Review of compliance status indicates effective implementation. Overall Comments/Follow Up:

- 13. EHS Expectations and Appraisals EHS-02/1.0 Page 6 of 7 GE Energy Services-Company Confidential Effective Date: April 27, 2007 Approved By: Robin Sevinsky Appendix B - EMPLOYEE EHS PERFORMANCE APPRAISAL Employee: Evaluator: Overall Performance Appraisal: Date: Expectations Criteria Exceed Meet Below 1. Know and follow established job specific and site wide environmental, health & safety procedures and rules. Knows and follows rules and procedures; Maintains "good" personal environmental, health & safety record. 2. Maintain housekeeping in work area. Keeps the area, walkways and equipment clean and orderly. 3. Maintain environmental, health & safety equipment in good working order. Appropriately maintains and stores equipment; Reports defective equipment needing repair or replacement. 4. Actively participate in environmental, health & safety training and demonstrate competency based on training received. Attends, actively participates, learns and applies training. 5. Keep other employees aware of environmental, health & safety practices and activities by actively observing fellow employee work practices and incorporating safety. Communicates with other employees on safe work practices and actively participates in safe behavior observation. 6. Actively participate in accident, injury and illness prevention activities: • Develop job safety analysis and safe working procedures. • Identify and correct hazards and unsafe conditions. • Accident, near-miss accident or potential hazard investigations. Provides information and suggestions for accident investigations, job hazard analysis and inspections; Helps with correcting hazards and unsafe conditions. 7. Participate actively in providing suggestions for the environmental, health & safety program improvement. Positive attitude towards environmental, health & safety; Provides input on environmental, health & safety issues. 8. Bring environmental, health & safety issues, unsafe acts and safety suggestions to management's attention or correct those they can. Keeps eye open to area safety practices; Provides solicited and unsolicited input on environmental, health & safety issues. 9. Know and implement regulatory compliance requirements in their work area. Follows compliance requirements; actively reports needs and non-compliance issues. Overall Comments/Follow Up:

- 14. EHS Expectations and Appraisals EHS-02/1.0 Page 7 of 7 GE Energy Services-Company Confidential Effective Date: April 27, 2007 PS Approved – Troy Henagan – July 2009 Approved By: Robin Sevinsky Appendix C - SITE SPECIFIC EHS EXPECTATIONS & APPRAISALS INFORMATION 1. Name of Site Manager: Troy Henagan – PS HR Manager 2. Name of GEES EHS Site Representative: Jim DeMouy – PS EHS Manager 3. Management EHS Appraisals will take place as follows: Part of routine EMS Cycle – objective data used (as applicable to role) includes OP Metrics, Overall Training Completion of Manager and direct reports, injury trends, and ATS findings and closure rates. Subjective data includes overall behavioral support and engagement as it relates to the role. Review occurs in one on one review setting. All Management should have formal EHS goals specified in annual G&O process 4. Employee EHS Appraisals will take place as follows: Part of routine EMS Cycle – objective data used (as applicable to role) overall training completion and injury trends. Subjective data includes overall behavioral support and engagement as it relates to the role. Completed By: ________________ Date: _________ Troy Henagan PS HR Manager

- 15. Hazard Analysis and Regulatory Compliance EHS-03/ 2.0 Page 1 of 9 GE Energy Services -Company Confidential Effective Date: April 27, 2007 Approved By: Robin Sevinsky: HAZARD ANALYSIS AND REGULATORY COMPLIANCE 1. PURPOSE & SCOPE 1.1 The purpose of this policy is to outline the GE Energy Services’ (GEES) strategy for Hazard Analysis and Regulatory Compliance. It defines the system used to identify, analyze, communicate and train employees with respect to the hazards they may encounter while working at GEES sites. 2. DEFINITIONS Refer to EHS Manual Glossary 3. PROCEDURE GE Energy Services strives to provide a safe and healthy working environment; as such, it is critical that our employees understand how to identify, evaluate and control hazards in their workplaces. 3.1 Procedures 3.1.1 A Hazard Analysis and Regulatory Compliance System shall be implemented at all GEES sites to ensure that our employees continually identify and address workplace hazards and review applicable regulatory requirements, codes and GE policies for compliance. 3.1.2 Each site shall have a trained individual perform a detailed analysis to identify hazards and regulatory requirements for GEES sites (Complete Appendix B). The following topics have been identified and may be addressed in separate procedures: 3.1.2.1 Compressed Gas Cylinders 3.1.2.2 Cranes and Rigging 3.1.2.3 Powered Industrial trucks (e.g. fork lifts, walkie trucks, etc.) 3.1.2.4 Hand & Power Tools 3.1.2.5 Ladders, Scaffolding, Elevated Work Platforms 3.1.2.6 Machinery & Machine Guarding 3.1.2.7 Signs, Signals & Barricades 3.1.2.8 Walking, Working Surfaces 3.1.2.9 Welding, Cutting & Brazing 3.1.2.10 Confined Space Entries, Confining or Hazardous Enclosures 3.1.2.11 Electrical Work 3.1.2.12 Work at Heights

- 16. Hazard Analysis and Regulatory Compliance EHS-03/ 2.0 Page 2 of 9 GE Energy Services -Company Confidential Effective Date: April 27, 2007 Rev 2 Approved By: Robin Sevinsky: 3.1.2.13 Temperature Extremes 3.1.2.14 Ionizing Radiation 3.1.2.15 Lasers 3.1.2.16 Cryogenic Materials 3.1.2.17 Work at Mine Safety and Health (MSHA) regulated sites 3.1.2.18 Off-Shore Platforms 3.1.2.19 Refrigerant Handling Ozone Depleting Compounds (ODC) Procedure 3.1.3 Additional hazards may also be addressed via the following EHS procedures: 3.1.3.1 Accident Reporting, Investigation and Follow-up (HS 6) 3.1.3.2 Health, Safety & Housekeeping Inspections (HS8) 3.1.3.3 Fire Prevention and Emergency Response (HS 11) 3.1.3.4 Safety Risk Assessment (HS12) 3.1.3.5 High Risk Operations (HS13) 3.1.3.6 Health & Safety Reviews of New & Modified Facilities and Equipment (HS14) 3.1.3.7 Industrial Hygiene (HS15) 3.1.3.8 Motor Vehicle Safety (HS 18) 3.1.3.9 Lockout Tagout 3.1.4 Each site shall implement a formal inspection process which seeks the input of employee in a given work area, see Health, Safety & Housekeeping Inspections for specific guidance (Link to HS 8). 3.1.4.1 Inspections shall be focused on identifying risk and compliance issues and driving employee involvement. 3.1.4.2 Open action items shall be systematically tracked to closure (e.g. Audit Tracking System). 3.1.4.3 The department manager shall review at least monthly, open items. 3.1.4.4 Each site using contractors shall routinely review contractor operations to assess hazards in accordance with HS 10 Contractor Safety (link to HS 10). 3.1.5 Each site shall develop and communicate a process for employees to report hazards. Describe the process in Appendix A. 3.1.6 Each site shall implement a review process to ensure new or modified processes or equipment undergoes a formal hazard assessment prior to being introduced in the workplace. This can be accomplished by compliance with HS 14 New and

- 17. Hazard Analysis and Regulatory Compliance EHS-03/ 2.0 Page 3 of 9 GE Energy Services -Company Confidential Effective Date: April 27, 2007 Rev 2 Approved By: Robin Sevinsky: modified Equipment and Processes. (Link to HS 14) or use of an equivalent process approved by the business EHS Headquarters personnel. 3.1.7 Should a site determine that their employees perform hazardous tasks or activities that are not listed above, they should prioritize those tasks based on employee risk using a formal hazard assessment tool (e.g. Safety Risk Assessments, Risk Assessment, Failure Mode Effect Analysis), and complete a hazard assessment for each hazardous task or operation. Additionally, the Site EHS Representative should notify the business EHS Headquarters personnel of the newly identified hazards in the event additional EHS procedures require development. 3.1.8 Operation-specific information for each site is documented in Appendix A and must be reviewed on an annual basis. This review should be tracked in the site’s Compliance Calendar or an equivalent system to ensure it is completed in a timely manner. 3.2 Communication of Hazards 3.2.1 Each site shall formally communicate hazards identified in the operation to employees who may be potentially exposed to those hazards through the following mechanisms: 3.2.1.1 EHS Training, (see Health & Safety Matrix) 3.2.1.2 Safety Risk Assessments (HS 12) 3.2.1.3 Implementation of additional EHS Policies and Procedures, as necessary 3.2.1.4 Review of inspection and accident trend information on a routine basis, e.g. safety meetings, tool box talks 3.2.1.5 The site may also communicate hazards to employees informally, through department Tool Box talks, posting of Injury and Illness Pictograms, during all-employee meetings, or through any other accepted means of communication used at the site. 3.2.2 High Priority Hazards and Regulatory Compliance Issues 3.2.2.1 The responsible manager will address high priority hazards (e.g. Imminent Danger to Life or Health) and regulatory compliance issues immediately at each site. In addition to being immediately addressed, these items should be entered into the site’s action tracking system (e.g. Audit Tracking System Web tool) to document that they have been identified and addressed. Consult with the business EHS Headquarters personnel for further guidance. 3.2.2.2 Each GEES Employee has the authority to immediately shut down operations whenever high priority hazards are present. They shall also notify any employees in the immediate area of the hazard, isolate the work area when possible (e.g. signs, barricades, tape) and identify the hazard to their Manager for resolution. Employees are requested to follow-up on high priority hazards if they see no action, by contacting their Site EHS Representative.

- 18. Hazard Analysis and Regulatory Compliance EHS-03/ 2.0 Page 4 of 9 GE Energy Services -Company Confidential Effective Date: April 27, 2007 Rev 2 Approved By: Robin Sevinsky: 3.2.3 Injury and Inspection Trend Analysis 3.2.3.1 The Site EHS Representative shall perform at least annually, an injury and inspection finding trend analysis for the business by department or operation level to identify potential program improvement areas. 3.2.3.2 This trend analysis shall be made available to each department or site to identify potential program improvement areas and to assist with setting EHS goals for the site, communicating performance to goal and generally raising awareness about workplace hazards with all employees. 3.2.3.3 Businesses working with contractors or sub-contractors should perform similar trending for contractors’ hazards or ensure the contractor representative does the same on a routine basis. 4. RESPONSIBILITIES 4.1 EHS Headquarters shall: 4.1.1 Assist with the determination of hazardous tasks and the creation of site-specific Safety Risk Assessment, as necessary. 4.1.2 Provide support to Site EHS Representative for writing additional EHS procedures to address newly identified hazards. 4.1.3 Provide trending analysis for inspections and accidents, as necessary. 4.2 Site Manager shall: 4.2.1 Ensure that this Hazard Analysis and Regulatory Compliance program is fully implemented at their site/service operation. 4.2.2 Perform a quarterly review of trending information from accidents and inspections, and communicate any expected performance improvements as a result of that review to site leadership team. 4.2.3 Work with EHS Site Representative to resolve all hazards brought to them by employees, and communicate corrective actions for these hazards to employees in their area, and 4.2.4 Complete Hazard Recognition Training in accordance with the Energy Services Training Matrix. 4.2.5 Communicate to employee the right to report hazards for corrective action. 4.2.6 Communicate to employees the right to stop work if high priority hazards are identified, along with the expectation that the proper notification process is followed. 4.3 Site EHS Representative shall: 4.3.1 Ensure that all known hazards at their site are addressed either by a specific procedure or Safety Risk Assessment.

- 19. Hazard Analysis and Regulatory Compliance EHS-03/ 2.0 Page 5 of 9 GE Energy Services -Company Confidential Effective Date: April 27, 2007 Rev 2 Approved By: Robin Sevinsky: 4.3.2 Complete Hazard Recognition Training in accordance with the Energy Services Training Matrix, 4.3.3 Communicate known hazards at their site or service operation to all affected employees, 4.3.4 Complete the operation-specific information in Appendix A, 4.3.5 Review and update the operation-specific information in Appendix A on an annual basis, and 4.3.6 Complete Appendix B initially, and ensure information is maintained at least annually. 4.4 Employees shall: 4.4.1 Report all hazards immediately to their supervisor, Site EHS Representative or Business EHS Headquarters, 4.4.2 Look for and correct hazards in their work areas, and 4.4.3 Communicate with co-workers about hazards they identify, to raise the awareness among their work group. 5. TRAINING 5.1 The Site EHS Representative and members of the site’s management team will receive training in accordance with the Energy Services Training Matrix. This training will be tracked in the site’s Training Tracker. Completion of a site-customized Hazard Recognition course is an acceptable alternative, if approved by the business EHS Headquarters personnel. 5.2 Provide training on other related HS policies in accordance with the Energy Services Training Matrix. 6. AUDITING 6.1 Each site will conduct an annual audit of the site’s Hazard Analysis and Regulatory Compliance program by conducting a review of the Health & Safety Element ‘3.0 – Hazard Analysis & Regulatory Compliance’ in the Corporate Environmental Programs Framework Scorecard. Describe the site’s approach in Appendix A. 7. APPENDICES: 7.1 Appendix A Site-Specific Information 7.2 Appendix B Site-Specific Risk Matrix

- 20. Hazard Analysis and Regulatory Compliance EHS-03/ 2.0 Page 1 of 9 GE Energy Services -Company Confidential Effective Date: April 27, 2007 Approved By: Robin Sevinsky: 8. REFERENCE DOCUMENTS AND LINKS 8.1 EHS Procedure No. HS 6 Accident Reporting, Investigation and Follow-up 8.2 EHS Procedure No. HS 7 Health & Safety Training 8.3 EHS Procedure No. HS 8 Health, Safety and Housekeeping Inspections 8.4 EHS Procedure No. HS 12 Safety Risk Assessment 8.5 EHS Procedure No. HS 13 High Risk Operations 8.6 EHS Procedure No. HS 14 Health & Safety Reviews of New & Modified Facilities & Equipment 8.7 EHS Procedure No. HS 15 Industrial Hygiene 8.8 EHS Procedure No. EHS 13E Lockout Tagout

- 21. Hazard Analysis and Regulatory Compliance EHS-03/ 2.0 Page 1 of 9 GE Energy Services -Company Confidential Effective Date: April 27, 2007 Approved By: Robin Sevinsky: Appendix A - SITE-SPECIFIC HAZARD ANALYSIS & REGULATORY COMPLIANCE INFORMATION 1. Name and Location of Site: 2. Site Manager: ________ 3. Site EHS Representative: __ 4. Method through which state and local regulations are available and specific location (e.g. hardcopy and physical location or web link): ______________________________________________________________________________________ ______________________________________________________________________________________ ______________________________________________________________________________________ __________________________________________________ 5. Method(s) Employees Use to Report Hazards: _______________________________________ ____________________________________________________________________________ 6. Person(s) Responsible for Completing Injury and Inspection trend analysis: ________________ ____________________________________________________________________________ 7. Methods for Communicating New Hazard Information to Employees: ______________________ _____________________________________________________________________________ 8. Complete Site-Specific Risk Matrix (See Appendix B). Define additional business-specific procedures implemented to address other hazards: _______________________________ ______________________________________ _______________________________ ______________________________________ _______________________________ ______________________________________ 9. Titles or Person(s) scheduled in Training Tracker to receive Hazard Recognition course or equivalent (e.g. Site EHS Representative, key supervisors, EHS team members): 10. Describe the process to ensure formal hazard assessments are conducted prior to implementing new or modified equipment or processes. ___________________________________________ _____________________________________________________________________________ 11. Describe the method for completing the annual review of the program and site-specific appendices: ......................................................................................................................................................................................................................... Name of Person Completing this Form: ________________________................................Date:________________

- 22. Hazard Analysis and Regulatory Compliance EHS-03/ 2.0 Page 2 of 9 GE Energy Services -Company Confidential Effective Date: April 27, 2007 Rev 2 Approved By: Robin Sevinsky: Appendix B- Site-Specific Risk Matrix Site Name: ______________________________________________ Location: ___________________________________________ Hazard or Regulatory Compliance Issues Priority: H M L NA Management/Control Action(s) Chemical Use and Exposure Highly Hazardous Chemicals in Processes (Process Safety) Flammable, Explosive, and High Pressure Materials Physical Hazards (e.g., radiation, heat, and noise/vibration) Biological Exposure (e.g., bloodborne pathogens and TB) Emergencies (e.g., medical, fire, chemical release, and evacuation) Fire Prevention Confined Space Entry Control of Hazardous Energy Sources (lockout/tagout) Hot Work (e.g., welding /burning) Machine Guarding Ergonomics Motor Vehicle Use Powered Industrial Truck/Lift Use Crane Use Walking and Working Surfaces (e.g.,

- 23. Hazard Analysis and Regulatory Compliance EHS-03/ 2.0 Page 3 of 9 GE Energy Services -Company Confidential Effective Date: April 27, 2007 Rev 2 Approved By: Robin Sevinsky: Hazard or Regulatory Compliance Issues Priority: H M L NA Management/Control Action(s) platforms, scaffolds, and ladders) Electrical Activities Construction Activities (e.g., excavations and demolition) Asbestos and Lead Activities Conducted By: Date:

- 24. Compressed Gas EHS03A/1.0 Page 1 of 14 GE Energy Services - Company Confidential Effective Date:07/12/2005 Approved By: Greg Sbrocco COMPRESSED GAS 1.0 PURPOSE AND SCOPE 1.1 This procedure provides the information necessary for the safe receiving, storage, handling and use of various compressed gases, the tanks or cylinders containing the gases, the regulators and valves used to control gas flow, and the piping used to confine gases during flow. 1.2 The procedure applies to employees and contractors who use compressed gases. 1.3 Compressed gases are found in many work areas. 1.3.1 More than 200 different substances are shipped in compressed gas cylinders, portable tanks, rail tank cars or motor vehicle cargo tanks. 1.3.2 Compressed gases are used for fuels, fire-suppression systems, welding, cutting and brazing activities, research laboratory activities, refrigeration, heating, semiconductor processes, scientific diving and welding. They may be used in distribution piping systems. 2.0 DEFINITIONS Refer to the EHS Manual Glossary. 3.0 PROCEDURE 3.1 GENERAL SAFETY 3.1.1 Compressed gases are stored in a pressured state, some under extreme pressure. Compressed gases may be combustible, explosive, corrosive, poisonous, inert or a combination of hazards. High concentrations of compressed gases present additional hazards such as reactivity, toxicity, and asphyxiation. Containers of compressed gases and cryogenic liquids can be extremely dangerous if damaged or misused and could cause catastrophic property damage, personal injury, and death. Employees who handle, store, and use compressed gas are subject to serious potential hazards. To avoid serious injury or property damage, take precautions to store, use and handle equipment properly. 3.1.1.1 Compressed gases present a unique risk of simultaneous exposure to both chemical and physical or mechanical hazards. The chemical hazards are associated with the container contents which may be corrosive, toxic, or flammable. The physical hazards are represented by the high pressure vessel. The potential energy resulting from the compression of the gas makes the container, especially a cylinder, potentially dangerous and uncontrollable if the energy is released through damage, puncture, over-pressure, or fire. 3.1.1.2 Mishandled cylinders or vessels may rupture violently, release their hazardous contents or become dangerous projectiles. If the neck of a pressurized cylinder is accidentally broken off, the energy released would propel the cylinder over three-quarters of a mile (1200 meters) in height. A standard 250 cubic foot cylinder pressurized to 2500 PSIG can

- 25. Compressed Gas EHS03A/1.0 Page 2 of 14 GE Energy Services - Company Confidential Effective Date:07/12/2005 Approved By: Greg Sbrocco become a rocket attaining a speed of over 30 miles per hour (50 kph) in a fraction of a second after venting from the broken cylinder connection. 3.1.2 Select the least hazardous gas for the operation. Purchase only the necessary quantities. Select the smallest returnable cylinder available. 3.1.2.1 Non-returnable cylinders are strongly discouraged. 3.1.2.2 If you must use non-returnable cylinders, ensure that a procedure is available to handle the remaining contents of the cylinder so that the valve can be removed prior to disposal. 3.1.3 Do not use cylinders of compressed gases for rollers, supports or any purpose other than to contain gas. 3.1.4 Do not repaint cylinders, change any engraved markings or remove a label. Even when a cylinder is empty, contents remain. A cylinder is never truly empty until it is evacuated. 3.1.5 Never use a flame to detect flammable gas leaks. Always use soapy water. 3.1.6 Use cryogenic liquids with caution because of the potential for skin and eye damage due to the low temperature and the hazards associated with pressure buildup in enclosed piping or containers. Wear the proper personal protective equipment (PPE). 3.1.6.1 A full face shield, loose fitting cryogenic handling gloves, and cuffless pants are the recommended PPE for transferring cryogenic fluids. 3.1.7 Ensure that Material Safety Data Sheets (MSDSs) are available for all compressed gases. 3.2 Controls 3.2.1 Each gas application requires unique engineering controls depending upon the hazard. Note: The engineering group responsible for designing facilities and equipment for gases for welding, cutting and brazing should review cylinder handling precautions, materials of construction and additional requirements listed in 29CFR 1910.253. Engineering controls include: 3.2.1.1 Fume hoods 3.2.1.2 Gas cabinets 3.2.1.3 Ventilation systems 3.2.1.4 Smoke detectors 3.2.1.5 Sprinkler systems 3.2.1.6 Flow restrictors 3.2.1.7 Scrubbers 3.2.1.8 Leak monitors 3.2.1.9 Gas cylinder storage areas 3.2.2 Each gas application requires administrative controls and a hazard assessment, including: 3.2.2.1 Employee training 3.2.2.2 Segregation of gas containers 3.2.2.3 Inspections and audits 3.2.2.4 Signs 3.2.2.5 Assignment and use of PPE

- 26. Compressed Gas EHS03A/1.0 Page 3 of 14 GE Energy Services - Company Confidential Effective Date:07/12/2005 Approved By: Greg Sbrocco 3.2.2.6 Identification of authorized employees 3.2.2.7 Procedures for receiving, handling, use and storage 3.2.2.8 Emergency procedures 3.3 Emergency Procedures 3.3.1 Do not remove leaking cylinders of hazardous compressed gas. 3.3.1.1 Actuate the remote emergency gas shutoff valve. 3.3.1.1.1 Properly installed hazardous compressed gases have flow limiting devices or automatic cylinder shutoff valves to limit and shutoff the gas supply. 3.3.1.1.2 Close the main cylinder valve if a leak is stopped and it is clearly safe to approach. 3.3.1.2 Actuate emergency evacuation procedures in the work area if a hazardous compressed gas is released and the gas supply cannot be promptly shutoff as described above. 3.3.2 Gas monitors may also automatically trigger the building evacuation alarm. 3.3.3 Promptly report accidental discharges of cylinder contents to EHS. 3.4 Special Equipment Maintenance Concerns 3.4.1 Hazardous compressed gases may be absorbed into vacuum pump oils. Maintenance personnel who change vacuum pump oil on pumps used with highly toxic gases must use SCBA. 3.4.1.1 Write standard operating procedures and define PPE and training requirements for this task. 3.4.2 Allow hot pump oil to cool before changing it to minimize airborne hazards of toxic materials. 3.4.3 Consider reaction byproducts and use proper skin and eye PPE when cleaning process chambers or vacuum pumps. 3.4.3.1 Write standard operating procedures and define PPE and training requirements for this task. 3.4.4 Low hazard gases, such as Freon, generate chlorine and fluorine decomposition products. See individual MSDSs for recommended safe handling practices. 3.4.5 Compressed gases are hazardous energy sources that require lockout/tagout (LOTO) procedures. LOTO upstream gas lines leading to equipment prepared for maintenance. 3.4.6 Adequately purge lines following the LOTO procedure and before beginning maintenance. 3.4.7 Inspect each regulator valve annually. 3.4.7.1 Gauges on welding regulators are indicators only and not calibrated units. If there are any doubts about their operation, obtain new or service exchanged regulators.

- 27. Compressed Gas EHS03A/1.0 Page 4 of 14 GE Energy Services - Company Confidential Effective Date:07/12/2005 Approved By: Greg Sbrocco 3.4.8 Cryogenic Liquids: 3.4.8.1 When plumbing cryogenic liquids, include a pressure relief valve between any two shutoff valves whenever feasible. 3.4.8.2 Protect spaces where cryogenic fluids may accumulate, such as leakage into enclosed equipment, with overpressure relief devices. 3.4.8.3 Lines carrying cryogenic liquid should be well insulated. 3.5 REGULATIONS 3.5.1 Compressed gases are regulated by federal, national and local codes, and industry standards. The applicability of these regulations is specific to the gas and operations. See the References Section at the end of the procedure. 3.5.1.1 In the United States, OSHA standards contain requirements for compressed gases and directives, standard interpretations, and compliance letters related to compressed gases. The Department of Transportation (DOT) and the NFPA also publish recommendations. 3.5.1.2 Many European and Asian standards follow the United Nations Recommendations on the Transport of Dangerous Goods. Note: The United States DOT Pipeline and Hazardous Materials Safety Administration proposed in 2005 to amend the Hazardous Materials Regulations to adopt the standards for cylinders and multiple element gas containers based upon the standards contained in the UN regulations. This initiative promotes flexibility and facilitates international commerce in the transportation of compressed gases. 3.6 RECEIVING AND INSPECTION 3.6.1 Always securely support compressed gas cylinders. 3.6.1.1 Do not leave cylinders free standing. 3.6.1.2 Secure cylinders being unloaded from a truck to a loading dock until they are placed on a hand truck or approved truck for delivery to the storage area. 3.6.2 Check for proper labeling and that the cylinder was last tested within the country- specific required time, which for the US is 5 years. 3.6.2.1 Ensure that the contents of compressed gas containers or cylinders are clearly marked and identified with proper labels or tags on the shoulder of the cylinder. 3.6.2.1.1 Mark compressed gas cylinders legibly with either the chemical or trade name of the gas and the hazard warning. 3.6.2.1.2 Mark the cylinders by stenciling, stamping or labeling that is not readily removable. 3.6.2.2 Verify that the tag indicates the compressed gas you have ordered. 3.6.2.3 If two labels are associated with one cylinder, affix the labels 180 degrees apart on the shoulder of each cylinder. 3.6.2.4 Do not accept unidentified cylinders. 3.6.2.4.1 Do not use a cylinder with unidentified contents. 3.6.2.4.2 Return unidentified cylinders to the manufacturer. 3.6.2.5 Do not rely on color codes for identifying cylinder contents, for example, red cylinder for acetylene. Different suppliers may use different colors for cylinders of the same gas. In addition, colors appear different under artificial lights and also some individuals are color blind.

- 28. Compressed Gas EHS03A/1.0 Page 5 of 14 GE Energy Services - Company Confidential Effective Date:07/12/2005 Approved By: Greg Sbrocco 3.6.2.6 Read the label. 3.6.2.7 Do not destroy or remove identification tags or labels. Do not remove or change the marks and numbers stamped on cylinders. 3.6.3 Accept only cylinders approved for use in interstate commerce for the transportation of compressed gases. 3.6.3.1 In the US, cylinders should bear the markings of the Department of Transportation stamped in metal at the top of the cylinder. 3.6.3.2 The United Nations Recommendations on the Transport of Dangerous Goods are used internationally as guidance for transportation of compressed gases. Address the appropriate regulations in Appendix A – Site-Specific Information. 3.6.4 Hazardous compressed gases must be transported directly from the shipper to the end use location. 3.6.4.1 Do not temporarily stage hazardous compressed gases, including flammable, toxic, corrosive and pyrophoric gases. 3.6.4.2 Perform a leak test on hazardous compressed gases when they are received. 3.6.4.2.1 Develop procedures for receiving gases and include them in the Site-Specific Information. 3.6.4.2.2 The procedures should include at a minimum checks for odors, visible fumes or hissing sounds. 3.6.4.3 Low hazard compressed gases, such as inert gases, oxygen, and Freon, may be stored temporarily in designated locations if the cylinders are secured properly. 3.6.5 When receiving containers, check for leaks, visually inspect the cylinder for damage, and ensure that the valve cover is properly secured and shipping safety caps are on where provided. 3.6.6 Cryogenic liquids 3.6.6.1 Do not accept containers showing evidence of loss of vacuum in their outer jacket, such as ice buildup on the outside of the container. 3.6.6.1.1 Loss of vacuum can result in frostbite from touching the cold surface, dripping liquid air, and exploding insulation when air condenses between the metal surface and the insulating layer. When air warms, it vaporizes and can rip off insulation with explosive force. 3.6.6.2 Contact with air or gases with a higher boiling point can cause an ice plug in a cryogenic container. If you note an ice plug, contact the gas supplier to return the container. 3.6.6.2.1 An ice plug could lead to overpressure and vessel failure if the location port is used for pressure relief. 3.6.7 All regulators, gauges, valves, manifolds must be designed for the particular pressures and gases involved. 3.6.7.1 In the US, the equipment should bear the inspection seal of either Underwriters’ Laboratories (UL) or the Factory Mutual Engineering Division of Associated Factory Mutual Fire Insurance Companies (FM). 3.6.7.2 Include specific approved non-US sources in Appendix A – Site-Specific Information.

- 29. Compressed Gas EHS03A/1.0 Page 6 of 14 GE Energy Services - Company Confidential Effective Date:07/12/2005 Approved By: Greg Sbrocco 3.6.7.3 The threads and configuration of valve outlets are different for each family of gases to prevent mixing of incompatible gases. 3.6.7.3.1 Never force a regulator onto a cylinder or use pipe wrenches or other tools to force a regulator onto a cylinder. 3.6.7.3.2 If a regulator does not fit, verify that you have a compatible regulator and that it is properly functioning. 3.6.7.3.3 Inspect the threads and seek assistance from the gas supplier. 3.6.8 If a cylinder is damaged, in poor condition, leaking, or the contents unknown, contact the manufacturer to return the cylinder immediately. 3.6.8.1 Do not repair damaged cylinders. If a cylinder valve is damaged, the contents can exit with great force. 3.6.8.2 Take the cylinder out of use immediately. 3.6.8.3 Implement emergency response procedures for leaking cylinders. 3.6.8.4 Include Emergency Response Procedures in Appendix A – Site-Specific Information. 3.6.9 Examine each regulator valve annually. Ensure that gauges are functioning and seat leaks have not developed that could allow pressure to build up in equipment attached to the regulator. Verify that the regulator is designed for the gas in the cylinder. 3.7 STORAGE 3.7.1 Store cylinders in a cool, dry, well-ventilated area away from all sources of heat or flames. 3.7.1.1 Ventilate storage rooms for cylinders containing flammable compressed gases to prevent the accumulation of explosive concentrations of gas. Do not keep cylinders in unventilated enclosures such as lockers and cupboards. 3.7.1.1.1 The amount and type of ventilation depends on the type and amount of compressed gases and the size and layout of the storage area. 3.7.1.1.2 Assess the area to determine whether existing ventilation controls are adequate. 3.7.1.1.3 Some gases, such as chlorine, may require an additional emergency ventilation system or continuous monitoring with appropriate alarms. 3.7.1.1.4 Ensure that hoods, ducts, air cleaners and fans are made from materials compatible with the gas used. Systems may require explosion-proof and corrosion-resistant equipment. 3.7.1.1.5 Separate ventilation systems may be needed for some compressed gases to keep them away from systems exhausting incompatible substances. 3.7.1.1.6 Facilities must include any specific ventilation system requirements in Appendix A. 3.7.1.2 Keep cylinders at least 20 feet (6.1m) away from flammable substances including oil, greases and gasoline. 3.7.1.3 Keep cylinders away from radiators, furnaces, steam pipes, boilers or other heat sources.

- 30. Compressed Gas EHS03A/1.0 Page 7 of 14 GE Energy Services - Company Confidential Effective Date:07/12/2005 Approved By: Greg Sbrocco 3.7.1.4 Keep cylinders away from electrical circuits and ignition sources such as sparks, flames or hot surfaces. 3.7.1.5 Where required, the area may be fire-resistant and supplied with suitable fire protection equipment, including sprinklers. Include country- specific or local Fire Code regulations in Appendix A – Site-Specific Information. 3.7.1.6 To store compressed gas cylinders outside, use a well-drained, securely fenced area. Store the cylinders on a raised concrete pad or other non- combustible rack. Protect cylinders from weather, wet areas, soil, and direct sunlight. 3.7.1.7 Follow the gas supplier’s recommendations for storage temperatures. 3.7.1.7.1 To prevent excessive pressure buildup, do not subject any part of the container or cylinder to a temperature higher than 125 degrees F (52 degrees C). 3.7.1.7.2 Do not subject any part of the container to temperatures below -20 degrees F (-29 degrees C) unless they are designed for those temperatures. 3.7.1.7.3 Cylinders that are frozen to a surface can be freed by using warm water less than 125 degrees F. Never apply direct heat to any part of a cylinder. 3.7.1.8 Do not place a cylinder where it may become part of an electrical circuit. All permanent wiring must be in conduit. Electric lights, both portable and fixed, must be equipped with guards to prevent breakage. Electric switches must be located outside the room. 3.7.1.9 Handle compressed gases as high-energy sources and dangerous projectiles. 3.7.1.10 Some small cylinders, such as lecture bottles and cylinders of highly toxic gases, are not fitted with rupture devices and may explode if exposed to high temperatures. 3.7.2 Store compressed gas cylinders on a level fireproof floor. 3.7.3 Do not store fuel gases in an enclosed area, such as a closet or locker. 3.7.4 Never store cylinders under stairways or in hallways designated for emergency egress. Do not store flammable gases next to an exit or egress. 3.7.5 Do not store cylinders where objects may strike or fall on them. 3.7.6 Do not store cylinders near elevators, gangways, stairwells or other places where they could be knocked down or damaged. Do not store cylinders in public areas or other unprotected areas. 3.7.7 Do not store cylinders in damp areas or near salt, corrosive chemicals, fumes, heat or direct sunlight. 3.7.8 Store cylinders by gas type in accordance with local fire code requirements: 3.7.8.1 Separate flammable gases from oxygen cylinders or oxidizing gases.

- 31. Compressed Gas EHS03A/1.0 Page 8 of 14 GE Energy Services - Company Confidential Effective Date:07/12/2005 Approved By: Greg Sbrocco 3.7.8.2 Keep oxygen cylinders a minimum of twenty (20) feet from flammable gas cylinders or highly combustible materials such as oil, grease, and wood shavings. 3.7.8.3 If this cannot be done, consult EHS for guidance. 3.7.8.4 For welding operations, oxygen and acetylene are typically paired on a common transfer cart for use. 3.7.8.4.1 In the US, if cylinders are stored closer than 20 feet, separate them by a wall with a fire-resistant rating of at least 30 minutes. 3.7.8.4.2 Include country-specific regulations in Appendix A – Site- Specific Information. 3.7.8.5 Label Hydrogen cylinder storage locations with a permanent placard reading: “HYDROGEN - FLAMMABLE GAS – NO SMOKING – NO OPEN FLAMES”. 3.7.8.6 Store acetylene and liquefied fuel gas (LP) cylinders with the valve end up. 3.7.8.6.1 If storing cylinders within 100 feet (30.5 meters) of each other and not protected by automatic sprinklers, the total capacity of acetylene cylinders stored and used inside a building should be limited to 2500 cubic feet. 3.7.8.6.2 Use the appropriate ventilation and prohibit open flames and other ignition sources. 3.7.8.6.3 Acetylene storage rooms should contain no other compressed gases. 3.7.9 Cylinders should be properly fastened and supported by straps, belts, buckles or chains to prevent them from falling and causing bodily harm. 3.7.9.1 Keep cylinders upright. 3.7.9.2 Never lay cylinders that contain flammable gases on their sides. 3.7.9.3 During storage, affix cylinders to a permanent building fixture such as a bench or wall with two brackets. 3.7.9.4 Use brackets that can be screwed into the mounting surface instead of clamp-type brackets. 3.7.10 Do not smoke in areas where compressed gases are stored. In the US, post NO SMOKING signs, even if it is a non-smoking facility. 3.7.11 Plan cylinder storage so that the cylinders are used in the order that they are received from the supplier. 3.7.12 Return corrosive gases to the supplier within one year to avoid regulator and cylinder valve problems due to corrosion. 3.7.13 Separate empty and full cylinders during storage. 3.7.14 Protect compressed gas cylinders that are stored outdoors. 3.7.14.1 Provide proper drainage to prevent standing water. 3.7.14.2 Protect from contact with the ground. 3.7.14.3 Provide an overhead cover avoid sunlight and rain. 3.7.14.4 Protect against extreme weather conditions such as freezing. 3.7.14.5 Provide security. 3.7.15 Allow only trained, authorized employees into storage areas. 3.7.16 Keep the amount of compressed gases in storage as small as possible.

- 32. Compressed Gas EHS03A/1.0 Page 9 of 14 GE Energy Services - Company Confidential Effective Date:07/12/2005 Approved By: Greg Sbrocco 3.7.17 Where cylinders are connected to a manifold or header, make sure that gas supplier specialists properly design and install the system. 3.7.17.1 Use flashback arrestors acetylene and other flammable gas systems. 3.8 HANDLING 3.8.1 Wear the appropriate PPE when moving or transporting cylinders. See the MSDS for guidance, and include it on JSAs. 3.8.1.1 Wear safety toed shoes. 3.8.1.2 Use protective gloves, aprons or other clothing depending upon the risk of skin contact. 3.8.1.2.1 This is especially important when handling cylinders containing cryogenic gases, which are very cold. 3.8.1.3 Always wear eye protection. Ordinary safety glasses may not be sufficient. Chemical safety goggles or face shields may be required. 3.8.1.4 If respirators must be used for breathing protection, include in the Respiratory Protection Program. 3.8.2 Ensure that the cylinder valves are protected with protective caps. To protect the valve, leave caps on until you are about to use the gas. 3.8.3 Never transport a cylinder with a regulator attached. 3.8.4 Move cylinders only with a suitable hand truck or wheel cart. 3.8.4.1 Only trained personnel can transport cylinders. 3.8.4.2 Strap the cylinder to ensure stability. 3.8.4.3 Attach valve safety caps. 3.8.4.4 Do not roll or drop cylinders. Do not drag, push or pull across the floor. Do not lift by the valve or valve cap. 3.8.4.5 Do not let cylinders bump violently against each other. 3.8.4.6 Do not use cylinders for rollers, supports or any purpose other than to contain gas. 3.8.4.7 Do not transport poisonous compressed gases with food or other items intended for human consumption. 3.8.4.8 Gas cylinder lifts provide a stable and easy way to lift and move heavy gas cylinders, and are designed to reduce muscular strain and injury. Alternatively, use a wagon for transport and storage. For an example, see Unidex TAL series lifts, transporters, and positioners. 3.8.5 To transport cylinders by motor vehicle, use vehicles equipped with racks or other means of securing the cylinders. 3.8.5.1 Do not transport cylinders in the same enclosure as the driver or any employee due to the possible replacement of oxygen in the enclosure with the escaping compressed gas. Do not transport cylinders in the passenger compartment of a motor vehicle or the back of a van. 3.8.5.2 Transport cylinders containing liquefied hydrogen or toxic gases in open body vehicles. 3.8.5.3 Do not transport flammable gases and oxidizers with poisonous or corrosive gases.

- 33. Compressed Gas EHS03A/1.0 Page 10 of 14 GE Energy Services - Company Confidential Effective Date:07/12/2005 Approved By: Greg Sbrocco 3.8.6 Do not lift compressed gas cylinders with an electromagnet. 3.8.6.1 When moving cylinders by a crane or derrick, carry them in a cradle or suitable platform. 3.8.6.2 Do not drop or bump the cylinders. 3.8.6.3 Do not use slings. 3.8.7 Secure cylinders with a chain or strap positioned around the upper third of the cylinder. 3.8.7.1 Small cylinders may be put on their side and blocked to prevent rolling. 3.8.8 Clear cylinder valves of any dust or dirt before attaching proper regulators. Do not use lubrication on valve regulators. 3.8.9 Some regulators are only for specific gases and should not be interchanged. 3.8.10 Never force valve or regulator connections and fittings. 3.8.10.1 Do not tamper with safety devices in cylinder valves or regulators. 3.8.11 Release the adjusting screw on the regulator before opening the cylinder valve. 3.8.11.1 Stand to the side of the regulator when opening the valve. 3.8.11.2 Open the valve slowly. 3.8.11.3 Open valves by hand, rather than with a tool, unless the supplier recommends a specific tool. 3.8.11.3.1 If a special wrench is required to open the valve, leave it in position while in use, so that the flow of gas can be stopped quickly in an emergency. 3.8.12 Do not use the recessed top of the cylinder as a storage area for tools or materials. 3.9 USE 3.9.1 Do not smoke in areas where compressed gases are being used. 3.9.2 Read the label on the cylinder before connecting a new cylinder of compressed gas. 3.9.2.1 Perform a leak test on hazardous compressed gases. 3.9.2.2 Hazardous gases require special procedures such as a purge panel and an adequate purge procedure. 3.9.2.3 Employees who require SCBAs to change gas cylinders must work with a partner who is identically equipped. 3.9.3 Select a regulator recommended for use with the cylinder. 3.9.3.1 Use the pressure, purity, and corrosive properties of the gas to determine the correct regulator. 3.9.3.2 Never use a cylinder without a regulator or some other pressure- reducing device in place. 3.9.4 When preparing to withdraw gas from a high-pressure cylinder, close the regulator first. Open the main cylinder valve until it stops and adjust the gas flow rate using the regulator. 3.9.4.1 For cylinders containing fuel gases, open the cylinder valve one-quarter turn, and adjust the regulator.

- 34. Compressed Gas EHS03A/1.0 Page 11 of 14 GE Energy Services - Company Confidential Effective Date:07/12/2005 Approved By: Greg Sbrocco 3.9.5 When not in use, close cylinder valves. The main cylinder valve should be tightly closed, but needle valves should only be finger tight to avoid ruining the valve and valve stem. 3.9.6 Visually inspect compressed gas cylinders daily for leaks and cracks. 3.9.6.1 Inspect the cylinder, safety relief devices, valves, protective caps and stems. 3.9.6.2 Check gauges to ensure that the gas does not remain in hoses when operations are completed. 3.9.7 Cryogenic Liquids: 3.9.7.1 Use special vacuum jacket containers with loose fitting lids to handle small quantities. Vacuum jacketed containers provided by the gas supplier have overpressure relief devices in place. 3.9.7.2 Fill containers with cryogenic liquids slowly to avoid splashing. 3.9.8 When using a compressed gas system, turn off the main cylinder valve, bleed the regulator and lines, and close the regulator. 3.9.8.1 Do not leave the regulator under pressure by closing down flow from the regulator without shutting off the main cylinder valve. 3.9.8.2 Be sure to LOTO upstream gas lines leading to equipment prepared for maintenance. 3.9.8.3 Compressed gases are a hazardous energy source requiring LOTO procedures. 3.9.8.4 Adequately purge lines following LOTO procedures and before beginning maintenance. 3.9.9 Do not drain or bleed a cylinder completely. 3.9.9.1 Leave a slight pressure to keep contaminants out. 3.9.9.2 Air can be sucked back through the valve, contaminating the cylinder or creating an explosive mixture. 3.10 RETURN 3.10.1 Mark empty cylinders “EMPTY” or “MT” and date the tag. 3.10.2 Before returning a cylinder, close the valve and replace the protective cap. 3.10.3 Perform a leak test for hazardous gases. Store in ventilated enclosures until shipped back to the manufacturer. 3.10.4 Separate empty containers from full containers. 4.0 RESPONSIBILITIES 4.1 The Facility Plant Manager: 4.1.1 Ensures compliance with this procedure 4.2 The Maintenance or Facility Manger: 4.2.1 Ensures that Maintenance technicians are familiar with and comply with the responsibilities defined in Section 3 for the receiving, storage, handling, use and return of compressed gases or the delivery system.

- 35. Compressed Gas EHS03A/1.0 Page 12 of 14 GE Energy Services - Company Confidential Effective Date:07/12/2005 Approved By: Greg Sbrocco 4.3 The MSO: 4.3.1 Ensures that operators are familiar with and comply with the responsibilities defined in Section 3 for the handling and use of compressed gases or the delivery system. 4.4 The EHS Leader: 4.4.1 Provides the materials needed for Maintenance and MSO review. 4.4.2 Audits this procedure and operation. 5.0 TRAINING 5.1 Ensure that employees who receive, store, handle, or use compressed gases are properly trained before beginning work or being reassigned. At a minimum, the training must include: 5.1.1 Training on the inherent hazards of the cylinders, such as fire, explosion, health, chemical reactivity, corrosivity, and pressure. Employees must be thoroughly familiar with the mechanical and physical concerns. 5.1.2 Review the operating and safety procedures for the task, such as proper receiving, handling, storage and use procedures. 5.1.3 Review the appropriate MSDSs. Employees who receive, handle, use and store compressed gases must be thoroughly familiar with the properties of the gases they are using. 5.1.4 Hands-on assistance by an experienced gas user. 5.1.5 Additional safety training may be provided by EHS. 5.1.5.1.1 Employees must know the proper personal protective equipment (PPE) to wear. 5.1.5.1.2 Employees must know how to report emergencies such as fires, leaks, or personal injuries. 5.1.5.1.3 Employees must be trained on the contents of this procedure. 5.2 Ensure that personnel who respond to emergencies involving compressed gases are properly trained, including GE sites and customer sites. 5.2.1 Ensure that the Emergency Medical Response Team knows the first-aid requirements for gases being used. Ensure that MSDSs are available. 5.2.2 Ensure that the Emergency Spill Response Teams are properly trained in the hazard control and safety requirements for gases being used. Ensure that MSDSs are available. 5.2.2.1 At customer sites, GE personnel must notify the customer of all compressed gases they intend to move to the site and provide the appropriate MSDSs. 5.2.3 Ensure that Emergency Fire Preparedness brigades or local fire response departments and maintenance personnel understand that they must not extinguish a flame caused by a gas until the gas source has been shut off, otherwise it can reignite, causing an explosion. 6.0 AUDITING 6.1 Conduct auditing with this procedure, self-assessments, cross business audits or any other audits conducted by GEES. 7.0 APPENDICES 7.1 Appendix A – Site-Specific Information

- 36. Compressed Gas EHS03A/1.0 Page 13 of 14 GE Energy Services - Company Confidential Effective Date:07/12/2005 Approved By: Greg Sbrocco 8.0 REFERENCES 8.1 Safety and Health Topics Compressed Gas and Equipment; Standards, Directives, Standard Interpretations and Compliance Letters www.OSHA.gov 8.2 Compressed Gas Safety Training www.chem.purdue.edu/chemsafety/Chem/gaslaws.htm 8.3 Quick Refresher Training form sample www.twcc.state.tx.us/information/videoresources/t5_gas_cyl.pdf 8.4 Compressed Gas Association www.cganet.com 8.5 Compressed Gas Cylinders training material http://web.utk.edu 8.6 Gas Cylinder Lift, Transporter and Positioner example www.unidex-inc.com 8.7 Worksafe Publication: Compressed Gas www.accidentfund.com 8.8 Compressed Gas Cylinders: Articles and Information www.pp.okstate.edu/ehs/LINKS/GAS.HTM 8.9 Compressed Gas Safety www.hornbullequipment.com 8.10 Compressed Gas – General Practices www.mwsco.com 8.11 Compressed Gas Safety http://medical.smis.doi.gov 8.12 British Compressed Gas Association http://www.hse.gov.uk/foi/internalops/hid/din/517.pdf 8.13 http://www.firstsafety.com/codes.html 8.14 http://www.usmra.com/oxygen.htm 8.15 Proposed DOT regulation changes 2005 http://www.regulations.gov/freddocs/05-03859.htm

- 37. Compressed Gas EHS03A/1.0 Page 14 of 14 GE Energy Services - Company Confidential Effective Date:07/12/2005 Approved By: Greg Sbrocco APPENDIX A SITE-SPECIFIC INFORMATION 1. Name and location of site _ 2. Site Manager _ 3. Site EHS Representative _ 4. Country-specific required cylinder testing frequency _ 5. Appropriate regulations for cylinders approved for use and transportation _ 6. Procedure for leak testing of hazardous compressed gases at the receiving location _ 7. Identifying seal that is acceptable for regulators, gauges, valves and manifolds _ 8. Emergency response procedure _ 9. Country-specific ventilation system requirements _ 10. Country-specific, site-specific, or local fire code requirements for storage area _ 11. Country-specific or site-specific regulations for storing oxygen and acetylene on welding carts _ 12. Location of cylinder storage areas _ 13. Contacts for cylinder work practices, security, inspections and emergency response _ 14. Cylinder vendors or suppliers, contacts, and emergency phone numbers _ Name of person completing this form _ Date

- 38. Concrete Construction & Steel Erection EHS03B/1.0 Page 1 of 5 GE Energy Services - Company Confidential Effective Date: 01/11/05 Approved By: Greg Sbrocco CONCRETE CONSTRUCTION & STEEL ERECTION 1.0 PURPOSE & SCOPE 1.1 This procedure outlines GE Energy Services’ (GEES) Environmental, Health and Safety (EHS) Concrete Construction & Steel Erection Program and provides the basic requirements for safe concrete construction and steel erection operations. For more specific requirements, refer to ANSI standards. For a copy, contact EHS Department. 2.0 DEFINITIONS Refer to the ES EHS Glossary. 3.0 PROCEDURE 3.1 General 3.1.1 Provide and maintain adequate access roads into and through the site for the movement of cranes, trucks, other necessary equipment, the delivery of material, and for pedestrian and vehicular control. 3.1.2 Pre-plan all hoisting operations. See EHS – 13G for additional information about cranes and rigging requirements. 3.1.3 Prevent employees from standing under elevated loads or concrete buckets being elevated or lowered. 3.1.4 Secure unused materials, equipment, and tools against accidental displacement. 3.2 Concrete Construction 3.2.1 Reinforcing Steel 3.2.1.1 Do not work near or above vertically protruding reinforcing steel unless it has been guarded or bent over to eliminate the impalement hazard. Cover the ends of steel with timber or another appropriate material, by bending the ends over, or by using other effective methods. 3.2.1.2 When moving bundles of reinforcing steel by crane or cableway, tie the bundles together securely to prevent slipping. Use long two-part slings, properly spaced for bundles over 20 feet (6 m). 3.2.1.3 Guy and support reinforcing steel for vertical structures to prevent collapse. 3.2.2 Elevated Work Access 3.2.2.1 Provide walkways or scaffolding with standard guardrails and toeboards in access areas and points of concrete placement in walls, piers, columns and other locations which are over 10 feet (3 m) above the floor, ground, or water level. Note: For additional information on scaffold and guardrail requirements, see EHS – 03F Scaffolding Safety and EHS – 03L Walking/Working Surfaces.

- 39. Concrete Construction & Steel Erection EHS03B/1.0 Page 2 of 5 GE Energy Services - Company Confidential Effective Date: 01/11/05 Approved By: Greg Sbrocco 3.2.3 Concrete Bucket Procedures 3.2.3.1 Use shackles or approved safety type hooks with latches when suspending concrete buckets by cranes or cableways. The load must not exceed the lifting capacity of the crane at the designated boom radius. 3.2.3.2 Do not ride concrete buckets. Do not stand under suspended concrete buckets. Note: For additional information on crane and rigging requirements, see EHS – 13G Cranes & Rigging. 3.2.4 Framework and Shoring 3.2.4.1 When placing concrete, provide formwork and shoring that safely support all loads imposed upon it. 3.2.4.2 Make available the drawings or plans showing formwork and shoring. 3.2.4.3 Inspect erected shoring equipment immediately before, during, and immediately after concrete placement. Immediately reinforce or reshore any damage or weakness. 3.2.4.4 To prevent the collapse of masonry walls due to wind or other forces, provide temporary shoring and bracing on masonry walls until the designed lateral strength is reached. 3.2.5 Masonry Wall Construction 3.2.5.1 Use a limited access zone when constructing masonry walls. The limited access zone must be: 3.2.5.1.1 Established prior to construction. 3.2.5.1.2 Equal to the height of the wall to be constructed plus 4 ft. (1.2 m) and run the entire length of the wall. 3.2.5.1.3 Established on the side of the wall on which a scaffold will not be constructed. 3.2.5.1.4 Restricted to entry by employees who are actively engaged in the construction of the wall. 3.2.5.1.5 Remain in place until the wall is adequately supported to prevent overturning or collapse. 3.2.5.1.6 Walls over 8 ft. (2.4 m) must be braced in addition to establishing a limited access zone. 3.2.6 Bull Float Protection 3.2.6.1 Deenergize electrical conductors if handles on bull floats are to be used where they could contact energized electrical conductors.