Dosing solutions Palamatic Process

- 2. CONTENT 01 I 04 Volumetric Weighing system Microfeeder Examples of realizations I 15 Drop through rotary airlock feeder Blow through rotary airlock feeder 22 For wood pellets 30 Dust valve 32 Examples of realizations I 35 Butterfly valve 36 Rotary valve Pinch valve Slide gate valve Examples of realizations I 49 EXISTE SUR MESURE Means that the equipment can be ins- talled in ATEX zone Means that design and options can be customised Means that the equipment is available for testing at PALAMATIC PROCESS

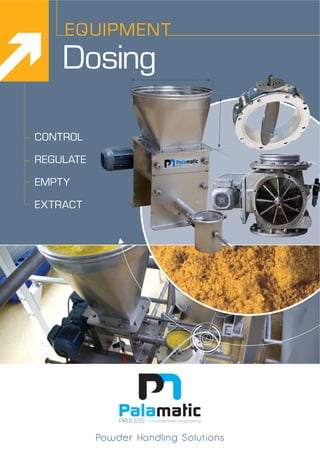

- 3. Range of Feeding Feeder Microfeeder Rotary Valve Slide Gate Valve Rotary Valve Pinch Valve Automation Feeder and agitator for a conti- nuous or batch feeding with an accuracy < at 3% Rotary valve for a continuous feeding process and totally sealed at the pressure between the downstream and upstream machines Microfeeders dor a quick and accurate feeding process. It is ideal in a continuous or batching operation Butterfly Valve with pneumatic actuator for a absolute sealing and with electric regulation (4-20 mA) Slide gate valve has no flow res- triction when fully open even with poorly flowing material Rotary valve specially designed for sanitary dosing applications Pinch valve, controlled pneumati- cally, adapted to be installed inline into pneumatic pipeline Valves and feeders control is ma- naged by the Pal'Touch® technology which is configured by PALAMATIC PROCESS automations Page 4 Page 12 Page 15 Page 36 Page 44 Page 40 Page 42 Page 49 - 02 Equipment EXISTE SUR MESURE To get a precise batch Regulation to introduce powder into process Batch automatisation to save time 03www.palamaticprocess.com/powder-machine/powder-dosing Downloadable videos & plans on our website F

- 4. 04 - consistent, regular or weak throughputs, depending on the variety of your bulk pro- ducts. F F F The volumetric feeder provides precise feeding of a wide variety of bulk products. The ingredients feeding is realized through a dosing screw which conveys the ®. The feeding pre- cision is about 7 to 8%. The weight feeder enables an automatic feeding of powdery or bulk materials by batch or in continuous process. The feeders are placed on a stable platform with a weighing system very efficient. This system works in gain-in-weight or loss-in- weight and provides accurate measurement of 3%. SCREW FEEDERS The micro-batch feeders provide accurate and precise feeding of powders and grains and are adapted to poorly flowing materials (which tend to clog) and others sticky materials. Our micro-batch feeders are suitable for low or average flow rate feeding. - form, constant and controlled feeding of your powders held in a hopper. Thanks to the exchangeable screw design system, our feeders can handle a wide variety of materials with a gentle and precise feeding of free-flowing product. Capacity: Objectives: dosing of any king of bulk materials Volumetric 05 Screw Feeder EXISTE SUR MESURE Models Flow rates Ø of the pipe 76 05 tool Closing valve of the feeding tube Agitator F Design and quick feeder disas- sembly to facilitate the cleaning steps F Dosing valve to ensure an accurate feeding. Very easy and quick disassembly. VolumetricFeeders www.palamaticprocess.com/powder-machine/powder-dosing/feeders/weight Downloadable videos & plans on our website

- 5. F No mechanical friction on the handled material F Hygienic design: allows an easy access at every parts of the feeder to clean, control and disinfect F Agitator ensuring a constant feeding volume Advantages F High linear feed 06 I I I Round section spiral without centre pipe Ribbon spiral on pipe Standard screw 07 I footprint and throughput) Application Throughputs at fixed speed Type 1/... l./h. Light sticky materials: flour, sugar, cocoa, pellets, granulat products, light and slightly sticky oxides 98 28 polymères en pellets 82 28 29 20 matallic granules 90 60 28 32 22 295 18 51 154 160 667 1063 500 361 250 560302 862 360 200 131 220 161 Screw Feeder EXISTE SUR MESURE Volumetric Technical layouts F The pneumatic gate stops the product flow and avoids any mois- ture recovery. F The agitator control- ler rotates constantly or intermittently with period. This intermit- tently operation allows the effective feeding of delicate, friable products whih might bridge unless gently and regularly activited. www.palamaticprocess.com/powder-machine/powder-dosing/feeders/weight Downloadable videos & plans on our website

- 6. 08 I footprint and throughput) Application Throughputs at fixed speed Type 1/... l./h. Light sticky materials: flour, sugar, cocoa, pellets, granulat products, light and slightly sticky oxides 798 20 399 28 heavy oxides, clays 20 308 28 220 matallic granules 688 20 28 370 I footprint and throughput) Application Throughputs at fixed speed Type 1/... l./h. Light sticky materials: flour, sugar, cocoa, pellets, granulat products, light and slightly sticky oxides 20 28 heavy oxides, clays 20 28 680 matallic granules 2 762 20 2 079 28 09 491 15 350319 268 239 144 76 154 356 748,5 500 350 277 1319 575 850 352 390 498 491 15 350319 270 237 144 114 154 356 748,5 500 350 277 1319 574,6 850 352 390 498 Screw Feeder Technical layouts EXISTE SUR MESURE Volumetric Plans téléchargeables sur www.palamaticprocess.fr www.palamaticprocess.com/powder-machine/powder-dosing/feeders/weight Downloadable videos & plans on our website

- 7. Capacities: Objectives: a controlled feeding of ma- terials F Load cells: system of three load cells to control the quantity of powder introduced F Slide gate valve to cut off the product flow and avoid moisture recovery F Motor dedicated to drive the dosing system F Inverter to adjust through- puts Advantages Sealed flexible connection without weighing interfe- rence z00 Hz0 Hz0 Hz zz50 H50 H50 H EXISTE SUR MESURE 11 Local weighing display for direct information I Parts in contact with the material / Structure and bolts Finishes of flange extremity Base capacity Options Screw Feeder There is three types of weight feeders: Weight feeder in loss-in-weight: it provides the fastest and most accurate measurement and control of individual ingredients fed into a batch process Gain-in-weight batching: it feeds and controls the wei- ghing downstream the feeder Continuous weight feeder: the feeder enables a conti- nuous feeding by regulating its speed depending on the feeder loss weight to get a constant flow rate Load cells to ensure a constant weight neumatic slide gate valve osing screw tool rotor 10 Weighing System Models Flow rates Ø of the pipe 76 The batch feeding system guarantees an accurate weighing for each batch (granule or powder). The batch weighing provides a homoge- nous and complete control of the product flows, a better accuracy and contributes to processing efficiencies. WeightFeeders www.palamaticprocess.com/powder-machine/powder-dosing/feeders/weight Downloadable videos & plans on our website

- 8. - duct feeding are ideal for poorly flowing materials which tend to clog. Our feeders ensure a quick and accurate feeding process. They are particularly suitable for high cadency batching or continuous operations with low flow rates. Capacity: Objectives: a high accurate feeding process 3 models: MD01, MD02, MD03 12 F Asymmetric screw F Plastic slide gate valve to shut off the materials flow F Feeding for an automatic conditioning process Advantages F For any kind of products EXISTE SUR MESURE 13 I Structure and bolts Finishes of flange extremity Finishes of attaching plate: aluminium Finishes of reductor: aluminium Parts in contact with the material Micro-batch Feeder Models A C ØT ØU ØV X Kg - - 80 - - 77,0 8 302 70 60 390 920 390 300 76 Control box Micro-batch feeder Models 9 88 782 I ø T 26025 F X C Q S R S A ø N M L K 211 D A G ø W ø U ø V J L 45 218 H B I E Microfeeder www.palamaticprocess.com/powder-machine/powder-dosing/feeders/micro-feeder Downloadable videos & plans on our website

- 9. 15 The main function of a rotary airlock valve is to regulate the flow from one chamber to another while maintaining a good airlock condition. The material handled is usually dry free flowing powder, dust or granules. The rotary airlock valves are mainly used in the dust filtration field, the pneumatic conveying industry, for the pressure differentials or to control the rotor-stator gap. F F F F The blow through rotary feeder has been designed to feed and convey bulk pro- to clog, this airlock valve is the ideal solution. The drop through rotary airlock feeder are designed to feed and discharge in a controlled way powdery or granular products coming from silos, hoppers, pneu- matic conveying installations, bag filters houses, cyclones. This rotary valve is adapted when a high throughput is required. The effective flow rate are very va- riable depending on the products flowing. This rotary airlock valve feeds and discharges, in a controlled way, wood pellets and chippings from silos, hoppers, pneumatic conveying installations, bag filter houses, cyclones. The dust rotary airlock feeder are specially dedicated for a combined using with separators of silos, hopper, dust filters, dust cyclones or even dosing systems. This rotary airlock feeder suits to simple or undemanding industrial applications. Its main function is to be a airlock. ROTARY AIRLOCK VALVES 500 14 EXAMPLES OF REALIZATIONS Industrial feeders F Cleaning products F StationeryF F water treatment F www.youtube.com/user/Palamaticpro- cess F Insecticides + de 500 installations of feeding equipment in and ABROAD FF r engineering of ce is at o r disposal for an speci c options. EXISTE SUR MESURE www.palamaticprocess.com/powder-machine/powder-dosing/rotar - al e Downloadable videos & plans on our website

- 10. Capacity Objectives: material extraction and feeding Rotary Airlock Feeders F Easy access to internal mechanical parts for a quick and simple cleaning F Compact and robust design F High feeding accuracy Advantages F ATEX version to resist at explosions and flame flow I Manufacturing materials: cast iron body or stainlss steel Surface treatment of the rotor: nickel plating, tefloning, hardened vanes Motorisation: direct or chain sprocket Rotor: steel or stainless steel Fixed rotor speed Variable rotor speed Capacity Drop Through EXISTE SUR MESURE 17 Models 150² 200² 250² 300² 2,2 Section de la bride en mm. 200 x 200 300 x 300 0 0 6 12 18 24 30 36 42 48 200 400 600 800 5 10 15 20 25 30 35 DEBIT (m³/heure) DÉBIT (litre/min) 150² 200² 250² 300² VITESSEDEROTATION(tour/min) - zation Adjustable rotor vane tips Motoreductor Rotor d bl I Rotary airlock valves are used for the dosing, feeding or the discharge of fine-grained and powdered materials or granulates contained in silos, hoppers, pneumatic conveying installations, filters or even cyclones. RotaryValves 16 www.palamaticprocess.com/powder-machine/gra it -rotar - al e Downloadable videos & plans on our website

- 11. I ² I ² I ² I ² Drop Through Rotary Airlock Feeder 1918Layouts are downloadable on www.palamaticprocess.com 10 rounds/min. 20 rounds/min. 30 rounds/min. Load Torque (kg) Load Torque (kg) rate Load Torque (kg) 9.9 360 22.8 300 10 rounds/min. 20 rounds/min. 30 rounds/min. Load Torque (kg) Load Torque (kg) rate Load Torque (kg) 2.8 0.37 88 73 6,3 73 10 rounds/min. 20 rounds/min. 30 rounds/min. Load Torque (kg) Load Torque (kg) Load Torque (kg) 0.37 73 2.6 10 rounds/min. 20 rounds/min. 30 rounds/min. Load Torque (kg) Load Torque (kg) Load Torque (kg) 300 457.14 206.55 350 265 220 265 150 120 150 150 225 150 120 225 265 2020 72.572.5 425.07 340.51 150 280 320 280 521.7 320 47.25154.45 150 278.13146.93 375 180 250 97.5 551233362 595 363.5187.5 97.5 97.597.5180 250 391 360 375 220 278430 364 440 300 13090 90 9090130 300 440 130 130 15 455 420 www.palamaticprocess.com/powder-machine/gra it -rotar - al e Downloadable videos & plans on our website

- 12. Drop Through Rotary Airlock Feeder I F Application under cyclone F Application under hopper F Application under silo F Application under the pneumatic conveying feeding system to load the material into the piping F Application under the filling stations to dose the productF Application under filter to insure the sealing and evacuation of fine particles 2120 www.palamaticprocess.com/powder-machine/gra it -rotar - al e Downloadable videos & plans on our website

- 13. Capacity: Objectives: powders dosing to feed the pneumatic conveying F Surface treatment of the rotor: chromium and nickel plating, tefloning F Cast iron body or stainless F Advantages F Motorisations: direct by gear, coaxial variator with chain transmission or without motori- sation (bare shaft) I Manufacturing materials: cast iron body or stainlss steel Surface treatment of the rotor: nickel plating, tefloning, hardened vanes Motorisation: direct or chain sprocket Rotor: steel or stainless steel Fixed rotor speed Variable rotor speed Capacity EXISTE SUR MESURE 23 Rotary Airlock Feeder Mesh screen hopper Rotary valve lowing pomp Conveying pipeline transfer F ATEX version for a high explosion resistance and at the passage of flame I 22 Blow Through 0 0 9 18 27 36 45 54 63 72 300 600 900 1200 10 20 35 DEBIT (m³/heure) DÉBIT (litre/min) ERL05 ERL10 ERL15 ERL20 ERL35 VITESSEDEROTATION(tour/min) Models 9 20 38 0,7 0,7 0,7 0,7 0,7 Service temperature a hopper or a bin into a pneumatic conveying line and to restrict or prevent conveying air from blowing up into the hopper or bin. RotaryValves www.palamaticprocess.com/powder-machine/powder-dosing/rotar - al e/ low-thro gh Downloadable videos & plans on our website

- 14. 25 10 rounds/min. 20 rounds/min. 30 rounds/min. Load Torque Load Torque Load Torque 3 0.37 300 6 232 9 10 rounds/min. 20 rounds/min. 30 rounds/min. Load Torque Load Torque Load Torque 0,37 300 232 10 rounds/min. 20 rounds/min. 30 rounds/min. Load Torque Load Torque Load Torque 328 308 Blow Through Rotary Airlock Feeder 24 I I I Layouts are downloadable on www.palamaticprocess.com Inlet product flange Connection at the conveying pipeline Rotor Motor shaft coupling 184 Ø260 481 150 122 8282 170 124 105 234 258 501 335 150 62 357 150110 130 Ø54 238375.5530 571.5 G 3/4G 3/4 373 198.5 373.5 Ø64 156.5 30 14 1414172 135 339 32.532.5 14 270 135135 30 222177 399 1941414 3737148 428 630 342 16 155 155 16 3333 276342 165 111 111 www.palamaticprocess.com/powder-machine/powder-dosing/rotar - al e/ low-thro gh Downloadable videos & plans on our website

- 15. I The blow through rotary airlock feeders are designed to suit to pneumatic conveying processes. They can be mounted inline into a pneumatic conveying line. Blow Through Rotary Airlock Feeder 10 rounds/min. 20 rounds/min. 30 rounds/min. Load Torque Load Torque Load Torque 328 36 308 10 rounds/min. 20 rounds/min. 30 rounds/min. Load Torque Load Torque Load Torque 22.8 929 633 2.2 630 I I 2726Plans téléchargeables sur www.palamaticprocess.fr 278 196 447 199248 4141 45.5 19 19 195195428 717.5 428428190 139 139 428 428 33745.5 352 585 180 180 180 470 736 406 240 300 352 SURPRESSEUR TUYAUTERIE DE TRANSFERT for the industries. The added value of those rotary valves is to transfer sticky materials. The air conveying flow, through the rotary valve, ensures the cleaning of the rotor by taking off particles sticked on the walls. www.palamaticprocess.com/powder-machine/powder-dosing/rotar - al e/ low-thro gh Downloadable videos & plans on our website

- 16. OPTIONS F F The design respects highly the granular materials. For a more accurate feeding and the maintaining of a high rotation speed. The precision shims are fixed directly onto the roto and reduce the rotay airlock valve displacement by a fine feeding or the maintaining of high rotation speed. F F For a sanitary using in the food and pharmaceutical industries. The rotary valve gets a rotor which can be easily dismantled in few minutes for controlling and cleaning the inside parts. The extraction mecanism of the moving parts is more secured for the operator and offers a better flexibility for the cleaning and maintenance of the installation between various productions. These stainless steel rotary valves can be dismantled easily as well as keeping the highest standards of hygiene. To facilitate the material introduction in the conveying pipeline. The gear box is setting up under the rotary arirlock valve to introduce the material in the pneumatic conveying pipeline. Drop Through and Blow Through Rotary Airlock Valves 28 F F To seal the rotary valve. A air flow is injected to avoid that fines particles come inside the sealing system through the cable gland. To ensure a rotary airlock valve with large displacement. The overfill controller has been specially designed for revolving materials or for applications needing a rotary airlock valve with large displacement. F F Adjustment of the rotor vane depending on the properties of each material. rotary valves suitable at the material, by adjusting vanes. To evacuate the air. The degassing box is designed for pneumatic conveying applications to ensure the blower air evacuation retur- ning by the rotary airlock valve. F F Manufacturing material adapted to your needs and expectations. Three different configurations are available: steel design, stainless steel body and cast iron flange or even the full cast iron design. The aluminium configuration is anodised. To eliminate sticky materials from the rotary airlock valve body. The rotor with scraper vanes helps to get a very strong sealing and a full cleaning of the rotary airlock valve body for very sticky materials. F F Deaeration system of the body to avoid the pressure return. The degassing chambers are specially designed for being used in pneumatic conveying systems. It permits to avoid the pressure return into the piping and the hopper from where the product is extracted. The box indicates the number of rotor rotations. The box is an indicator to check the airlock valve rotation speed and identifies any problems if the velocity is too low. r engineering of ce is at o r disposal for an speci c options. 29www.palamaticprocess.com/powder-machine/powder-dosing/rotar - al e Downloadable videos & plans on our website

- 17. Capacities: Objective: woods pellets and chippings dosing 30 F Rotors equipped with blades F Robust compact design for a longer life Advantages F Direct motorisation EXISTE SUR MESURE Wood Pellets and Chippings 31 I Service temperature with special version Rotor Certifications: the rotary valves are destinated to wood com- Rotary Valves Rotor chip breaker ody Motoreductor (high torque) Scraper (anvil blade) D GF E A D E F G Models A* D E* F* G Motor speed (rpm) Motor Power (kW) Dosing flow rate (l./t.) 220 20 2,2 30 280 237 20 30 - 360 792 20 30 2,2 - 226 20 2,2 30 3,0 - led discharging and feeding of wood pellets or chippings from silos, hoppers, pneumatic conveying systems, bag filter houses, or cyclones. RotaryValves www.palamaticprocess.com/powder-machine/gra it -rotar - al e Downloadable videos & plans on our website

- 18. 460 370 1025 1350 4895 Capacity: Objectives: regulate and dose the conveyed materials 32 fan ust valve Maintenance door Clean air outlet Unclogging set F Minimal air leakage F Flame barrier certification ATEX 20-21-22 F Standard flanges to make or square flanges Advantages F Flexible vanes in polyu- rethane I Certifications : Résistante : Raccordement par bride : Débit : Pression : Forme des brides : I . The rotary airlock valve has a large opening for the perfor- mance of th rotor getting 6 flexibles vanes made of polyure- thane and which are adjustable and interchangeable. . The standard rotary airlock valve is adapted to materials . The stators of those rotary airlock valves have been tested bars of internal shocks. EXISTE SUR MESURE 33 Rotary Valve Dust Collection uuuustustust vavavalvelvelve Ø A A E G F E SS RR C D ØC PCD ØB PCD ØB D D Models Tour A ØA ØC C X RR SS ERD 200 6 200 200 200 320 8xØ23 ERD 250 370 dust lock valve has a dedictaed design for filter applications. The standard inlet and outlet flanges are drilled in - ter flanges. This rotary valve es suitable for simple and undemanding industrial applications, where its main function is to be a airlock. RotaryValves www.palamaticprocess.com/powder-machine/powder-dosing/rotar - al e/d st-loc Downloadable videos & plans on our website

- 19. 35 the volume of fluids. Our valves guarantee an accurate sealing (under silo, hoppers, mechnical and pneumatical conveyors, weighing system, etc.) of the free-flowing powdery products or liquids in several idustries such as food, chemical, pharmaceutical, cosmetic or even building. F F The rotary valve has been designed to respect rigourous sanitary requirements and to be disassembled quickly by the operator. The rotary valves are suitable in pharmaceutical applications to cut off or control the products flow. They offer a continuous powders and granulates feeding as well as a uniform dosing. The butterfly valve is a system which moves the shutter by rotation around a perpendicular axis perpendicular to the direction of flow and, in open position, is les liquides non visqueux. The butterfly valve is used in automatic or manual ins- tallations with stainless steel. This equipment limits the loss-in-weight and offers a constant product flow rate. F The pinch valve fits perfectly in a conveying application by ensuring the regula- tion and dosing of powdery products without any loss of pressure. This pinch valve enables the free flowing of the material. The oval shape of the valve body guarantees an efficient and quick closing of the valve. The pinch valves are ideal to stop powders, grains, fibers and dense mixtures flow. F F The slide gate is one of the most effective ways to close a flow path in a material handling line. The slide gate valve is designed for a complete or relative seal and its control is perfectly linear. INDUSTRIAL VALVES 34 EXAMPLES OF REALIZATIONS Rotary valves F Under silo, salt F Under hopper, food ingredientsF Under cyclone, resin transfer FF pipeline F www.youtube.com/user/Palamaticpro- cess F F F Under a dust collector r engineering of ce is at o r disposal for an speci c options. EXISTE SUR MESURE www.palamaticprocess.com/powder-machine/powder-dosing/ind strial- al es Downloadable videos & plans on our website

- 20. The butterfly valves are used to close tanks, hoppers and silos containing powder or granular materials. The butterfly valves are used in every installations needing to stop the materials flowing displaced by gravity or by pneumatic conveying. Objectives: discharge, sealing and closing Manual, pneumatic actuator, motoreductor F Shaft for actuator: manual; pneumatic; electric; option F Sealed closing at 6, 10, 16 bar F Flange connection tri clamp for pharmaceutical applications Advantages F Profiled valve for an opti- mized material flow EXISTE SUR MESURE 37 I Manufacturing: cast iron or stainless steel Diameter: Butterfly Valve Models ØA ØB ØC ØD E F G ØH N (holes) P (honings) ØR S T U V Z Kg 220 220 80 200 228 290 228 80 200 278 278 80 300 328 236 390 80 300 378 80 9 363 80 - 80 - 36 See all the option in page 39 Options Manual lever Interchangeable actuators ButterflyValve www.palamaticprocess.com/powder-machine/powder-dosing/ind strial- al es/ tter - al e Downloadable videos & plans on our website

- 21. OPTIONS Butterly Valve I Inflatable seat I 38 39 F The design respects at the maximum granular products. The butterfly valves are resistant to agressive cleaning agents and other chemical products. F For a sanitary using in food and pharmaceutical industries. There are a variety of actuators by which the valve can be operated: manual, electric, single or double acting pneumatic actuator. F Temperature of service over to 205°C. F The quality of the stainless steel (316 L) and the valve disc enable food and phar- maceutical applications. EPDM, viton, rubber. F Valve conception with flange. Tri-clamp system for applications where the valve dismantling is important for the cleaning operations. F mA Dosing specificity. 4-20mA 90° MODEMODE 4-20mA4-20mA 4-20mA4-20mA 90°90° r engineering of ce is at o r disposal for an speci c options. Some applications need significant sealing ac- tion under vaccum or pressure. The inflatable seat technology ensures this result. air pressure to expand the seal against the dics, providing an even-distribution for a bubble tight with the disc during valve opening and closing, there is minimal disc impingement. This is in contrast to conventional butterfly valves where disc impignement leads to shaving of the seat which decreases operational performance. This options increases the valve life and its efficiency. This technology feeds of the material and regulates the flow. I Motorized pneumatic valve operating mode: a pneumatic cylinder as a piston rack drives the valve shaft whose the movement is a quarter turn. A distributor sends a pneumatic signal alternatively in one of the two cylinder chambers to open or close the valve. Single acting: the pneumatic cylinder is equipped with piston compression springs. The pneumatic signal executes only one of the two mouvements of opening and closing, the second one being opered by the springs pressure. This type of operating mode helps to provide a safety position in case of lack of power. www.palamaticprocess.com/powder-machine/powder-dosing/ind strial- al es/ tter - al e Downloadable videos & plans on our website

- 22. Diameter: Objectives: discharging, sealing and closing F For a constant dosing and a flow control F Double fully open solution and rotary valve DN50 or 80 F Tri-clamp flange for a quick mounting and removal of the valve Advantages F Implementation on a sacks conditioning skid EXISTE SUR MESURE 41 I Distribution Finishes Actuator: pneumatic until 6 bar Rotary Valve Models S I L M O 38 298 93 223 80 200 230 38 93 80 280 38 398 93 273 80 306 330 366 N O S S M G HI ND ND D1 D1 D2 D2 L S The rotary valve has been designed to cut off and control the free-flowing products in pharmaceutical industries. They enable a continuous feeding of powders and granulates with a uniform dosing. The valve is composed by two stopping elements. The butterfly is adapted to execute a coarse dosing while the little rotor realizes a fine dosing. The maximum accuracy achie- vables is around ± 20 grams. The valve can be combinated with dosing or weighing systems. This double valve can be supplied with a rubber seal between the vanes and the rotor to 40 The rotary valve has been designed to respect rigourous sanitary requi- rements and enables a quick disassembly by the operator. The rotary valves are particularly suitable in pharmaceutical industries to stop or control the products flow. These valves guarantee a continuous pow- ders and granulates feeding as well as an uniform dosing. RotaryValve www.palamaticprocess.com/powder-machine/powder-dosing/ind strial- al es/ tter - al e Downloadable videos & plans on our website

- 23. The pinch valves provide the ability to control the flow of a fluid through an simple to implement and with low maintenance time, these pinch valves are the ideal solution for liquid, gas or powder by ensuring the complete sealing of the tube by the opening and closing pinch. Our pinch valves can be adpated at several applications: acids, bases (phosphates, soda, ammonia ...), viscous or abrasive liquids, food liquids or powders. FDA manufacturing Objectives: complete shut off or flow control 12 models (Ø13 to Ø200) 42 F Sealed closure of the valve to stop the material flowing F Referral for the pneumatic conveying F Air consumption very low Advantages F Quick replacement of the pinch and the ring Available in version ATEX zone 22 EXISTE SUR MESURE 43 Pinch I Matériau du corps de la vanne: alliage en aluminium Matériaux des bouches de connexion: aluminium, acier car- Maximum operating pressure Pression de gonflage maximum: 6.0 bar Maximum pressure differential Options Pinch Valve AIR I Position N°1 : In the open position, the valve is at full bore with no flow restrictions thus making the valve an integral part of the pipelone. Position N°2 : air or liquid inside the pipe, the two pinchs vars queeze the sleeve shut on the centerline. This ensures that the product flow is completely sealed off tight. The pinch valves are the solution for isolating and regulating abrasive, corrosive and fibrous products such as granulates, powder, etc. Aluminium tip Aluminum, steel or stainless steel flange Aluminium body Rubber ØB ØA ØA J D N G F E C M ØA NL G M H Models A C L M Kg - - - - - - - 20 - - - - - - - 20 - - - - - - - 22 0,70 32 - - - - - - 70 - - 99 - 202 2,20 - - - - 230 80 200 270 - - 220 - - 7,60 - - - - 396 - - - - 200 - - - - 22,80 PinchValve www.palamaticprocess.com/powder-machine/powder-dosing/ind strial- al es/pich- al e Downloadable videos & plans on our website

- 24. The slide gate valves are commonly used to control flows with sus- pended solids. These valves are designed to shut off the bulk flow pro- duct thanks to the central blade seal which provides an excellent pro- duct retention. Our slide gate valves are mainly used in the chemical, food, energy or even water treatment industries. Objectives: extraction and dosing by gravity Handwheel or pneumatic 44 F Secured sealing without any additional mesurement thanks to the rubbers seal integrated in the polymere coating F Bi-directional knife gate valve appropriates for products with a solids concentration and for bulk materials F Uni-directional knife gate valve for liquids and solids F The valves bodies are totally coated with engineering poly- approved on demand) F High resistence to abrasion Advantages F Exchangeable actuators: manual, pneumatic or electome- canic EXISTE SUR MESURE 45 I Diameter Flanges finishes Sealing Temperature liquid and the materials) Manufacturing Actuator: hand wheel, ratchet lever, chain wheel, manual wheel reductor, pneumatic cylinder, electric servomotor, hydraulic cylin- der Pressure: Slide Gate Valve 11 10 12 8 2 3 4 1 5 7 6 9 Rubber seal Trim Cable gland Stem Arch2 3 7 8 9 6 I A B DEEE C ØF H Models AXA C Kg 2 93,3 3 220 3 22 270 23 3 30 320 89 900 370 SlideGateValve www.palamaticprocess.com/powder-machine/powder-dosing/ind strial- al es/slide- al e Downloadable videos & plans on our website

- 25. DN 50-65 DN 80-200 DN 250 DN 300 DN 350 DN 400 DN 500-600 β° 2β° 2β° 2β° 2β° 2β° 2β° 2β°β° β° β° β° β° β° I I Slide Gate Valve 46 47 Models Ø flow area A ØB ØC D E N°E ØF Bolts G H Kg 2 200 93,3 3 3 22 300 23 3 30 89 900 Models A B C D E N°E ØF Bolts G H L M N N°N Kg 260 2 3 337 93,3 3 98 3 30 23,0 3 269 ØF ØB ØA C DEEED G DEEED H I I (for difficult materials) ØF M L G DEEED C DNNNDN B A H (mm.) Size A B C D E F G H J K L Air feeding Weight (kg) 90 86 202 299 90 227 ¼” 86 202 66 600 ¼” 80 3 80 86 202 88 623 ¼” 86 202 ¼” 86 709 698 ¼” 6 86 776 392 ¼” 200 8 200 60 888 ” 27 68 307 307 ” 38 300 300 78 ” 80 880 783 ” 80 977 880 ” 20 90 262 ” 600 600 682 262 682 ” 80 200 300 600 Ø external flange (mm.) 200 220 670 780 Ø bolts (mm.) 620 725 Front dimensions (mm.) 60 68 78 80 80 90 100 Number through-holes - - 6 6 6 8 8 Number tapped holes 6 8 12 Bolts size M20 M20 M20 M20 M20 M27 ß° 9 9 Screw size (mm.) 20 24 FG D C A H E JB K L Layouts are downloadable on www.palamaticprocess.com www.palamaticprocess.com/powder-machine/powder-dosing/ind strial- al es/slide- al e Downloadable videos & plans on our website

- 26. 48 EXAMPLES OF REALIZATIONS Valves F FF F Chemical productsF F www.youtube.com/ F F Cut off valve F Spices AUTOMATION & ELECTRICITY Equipment and programs: - As the designer of specific equipments, associates pro- production control is as important as the result. That is why automation and IT engineers of review the raw material feeding, the batches traceability, operators identification and dosings database. Thanks to continuous exchanges, during the step of project realization, between production team and our engineering office, screens of packaging lines control offer ergonomic and easy use with unique personalization. 49 www.palamaticprocess.fr/machines-industrielles/automatisme-pal-touch Downloadable videos & plans on our website ® ur engineering of ce is at our disposal for an options.www.palamaticprocess.fr/machines-industrielles/dosage/ annes Vidéos & plans téléchargeables en ligne

- 27. FILLING SOLUTIONS FOR BIG BAG AND OCTABIN To fill EMPTYING SOLUTIONS FOR BIG BAG AND OCTABIN To empty, compact and massage SACK SOLUTIONS To empty, compact, handle, fill CARDBOARD AND DRUM SOLUTIONS To fill, condition, empty PNEUMATIC TRANSFER EQUIPMENT Vacuum, pressure MECHANICAL TRANSFER EQUIPMENT To transfer with screw, belt conveyor, bucket elevator, aeromecanic or vibratory conveyor CRUMBLING AND GRINDING EQUIPMENT To granulate, crumble, grind, pound, micronise, disagglomerate SIFTING EQUIPMENT To sift, segregate, sieve, protect CONTAINERS AND STORAGE SOLUTIONS To fill, charge, empty, contain DOSING EQUIPMENT To control, regulate, empty, extract MIXING EQUIPMENT To homogenise, incorporate, fluidify, stir, mix FLOW AND CONNECTION To vibrate, fluidise, unclog, drain, facilitate extraction, control the descent, prevent stacks and vaults, connect INDUSTRIAL DUST COLLECTING EQUIPMENT To filter, clean, confine, secure Our expertise: contact@palamatic.fr Service Commercial : +33 (0)2 22 93 63 08