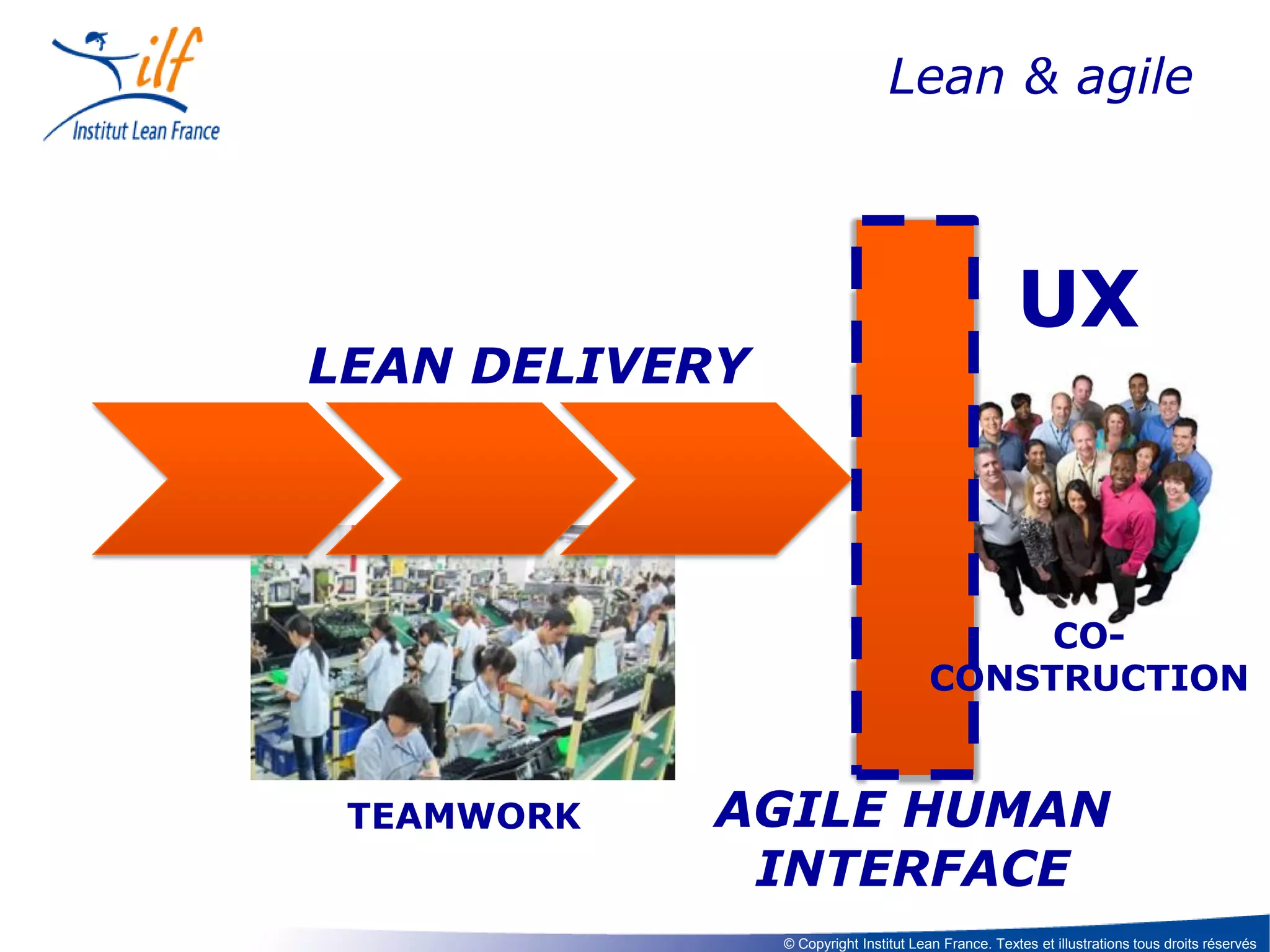

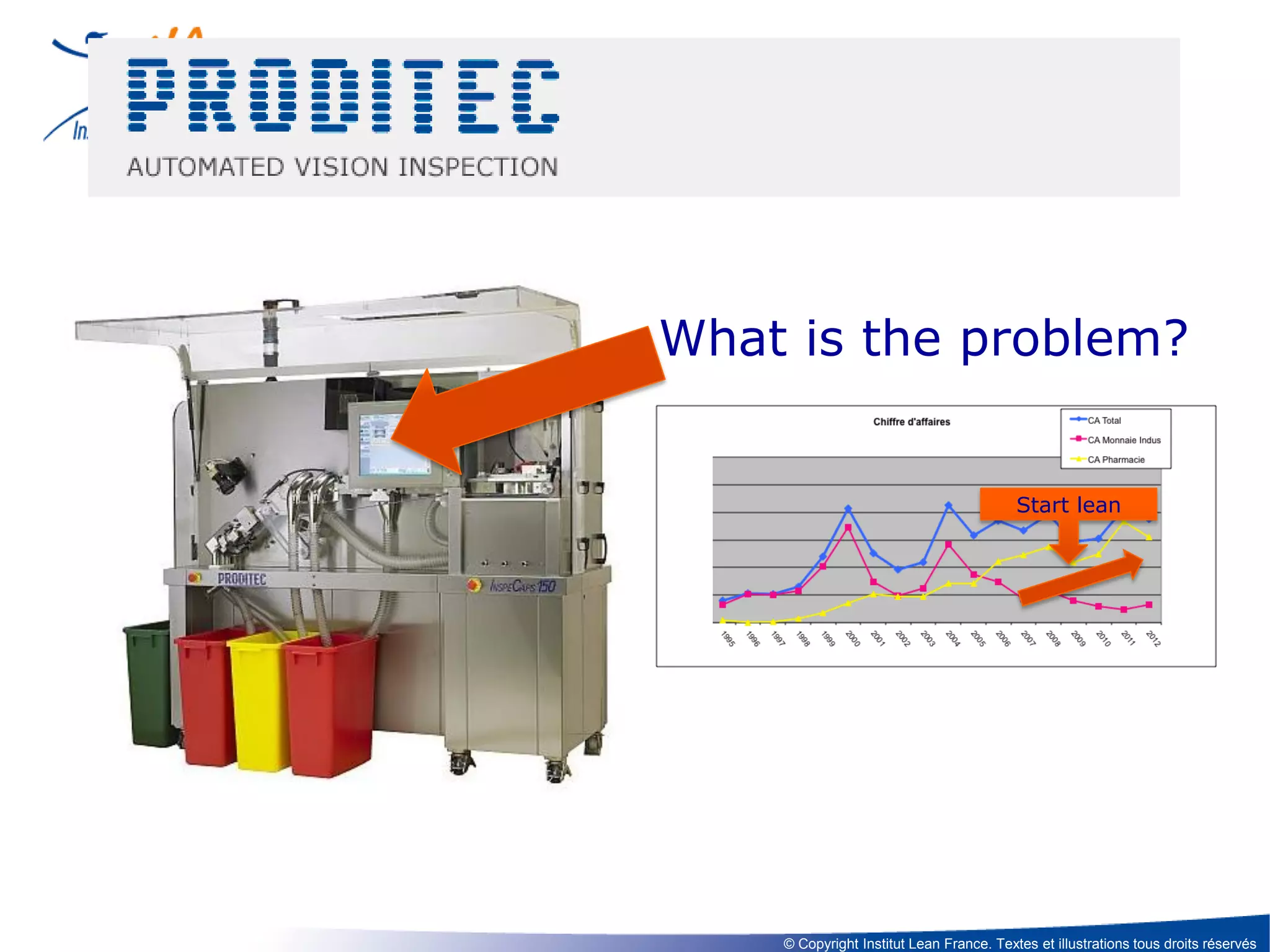

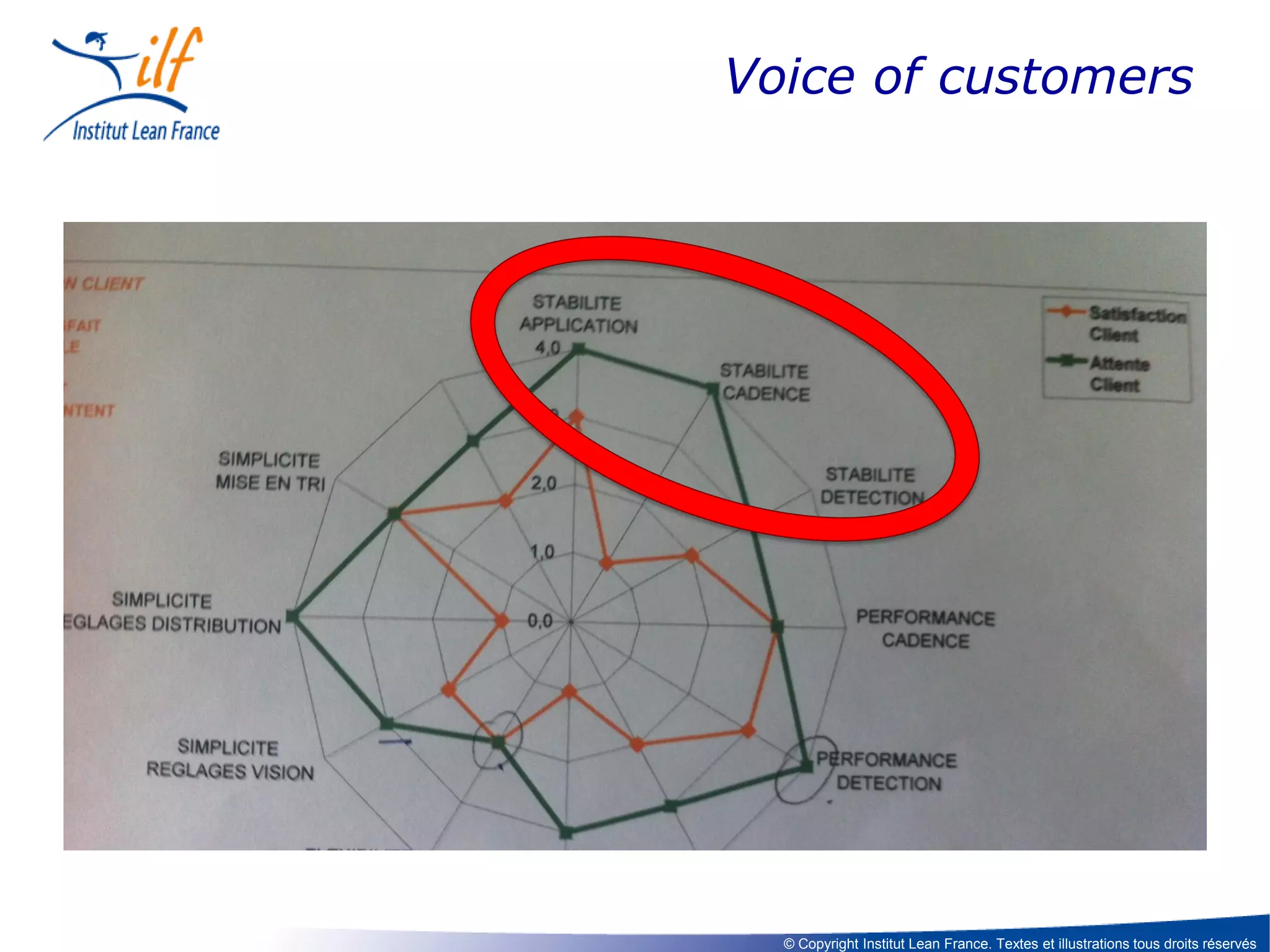

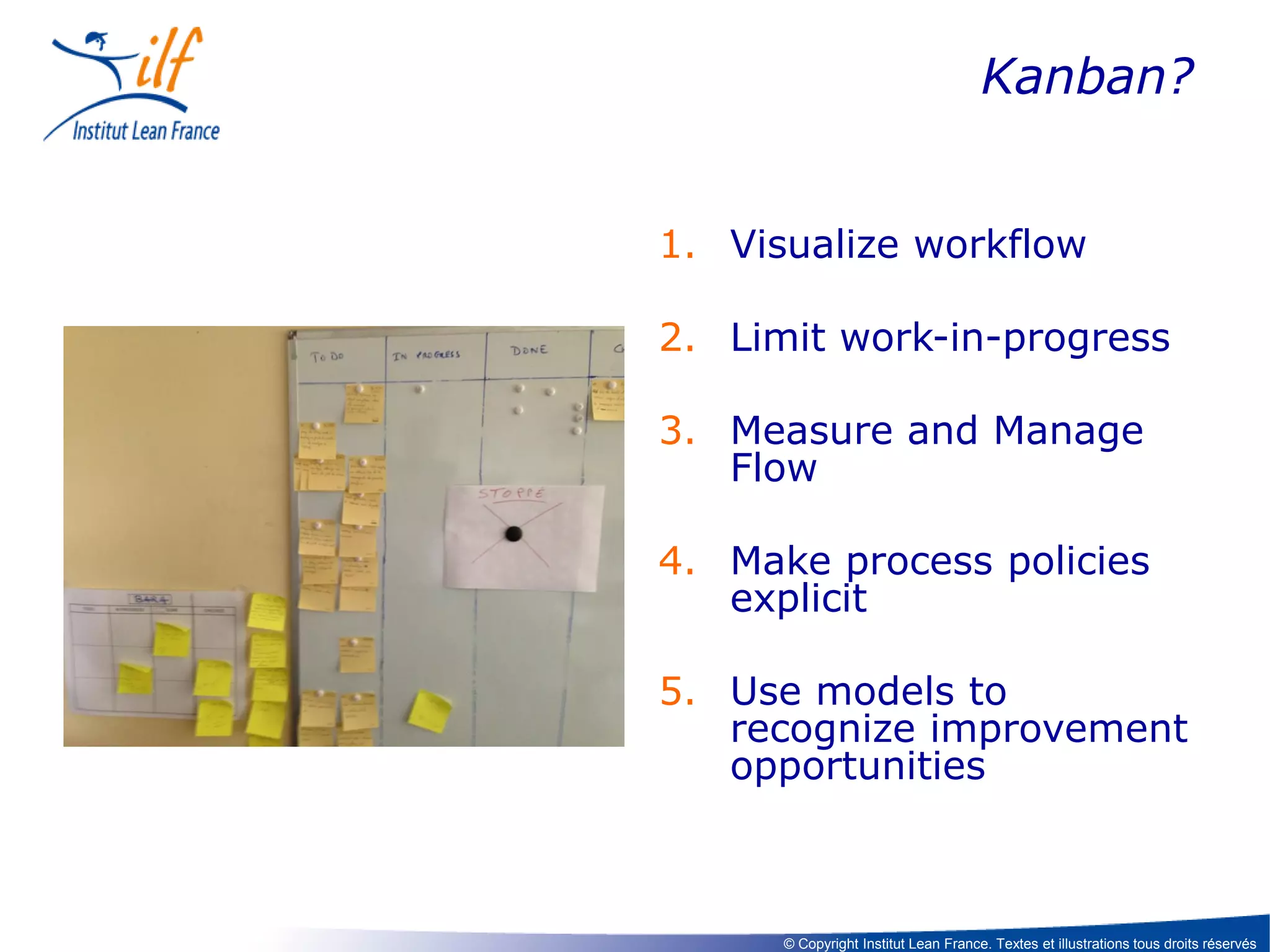

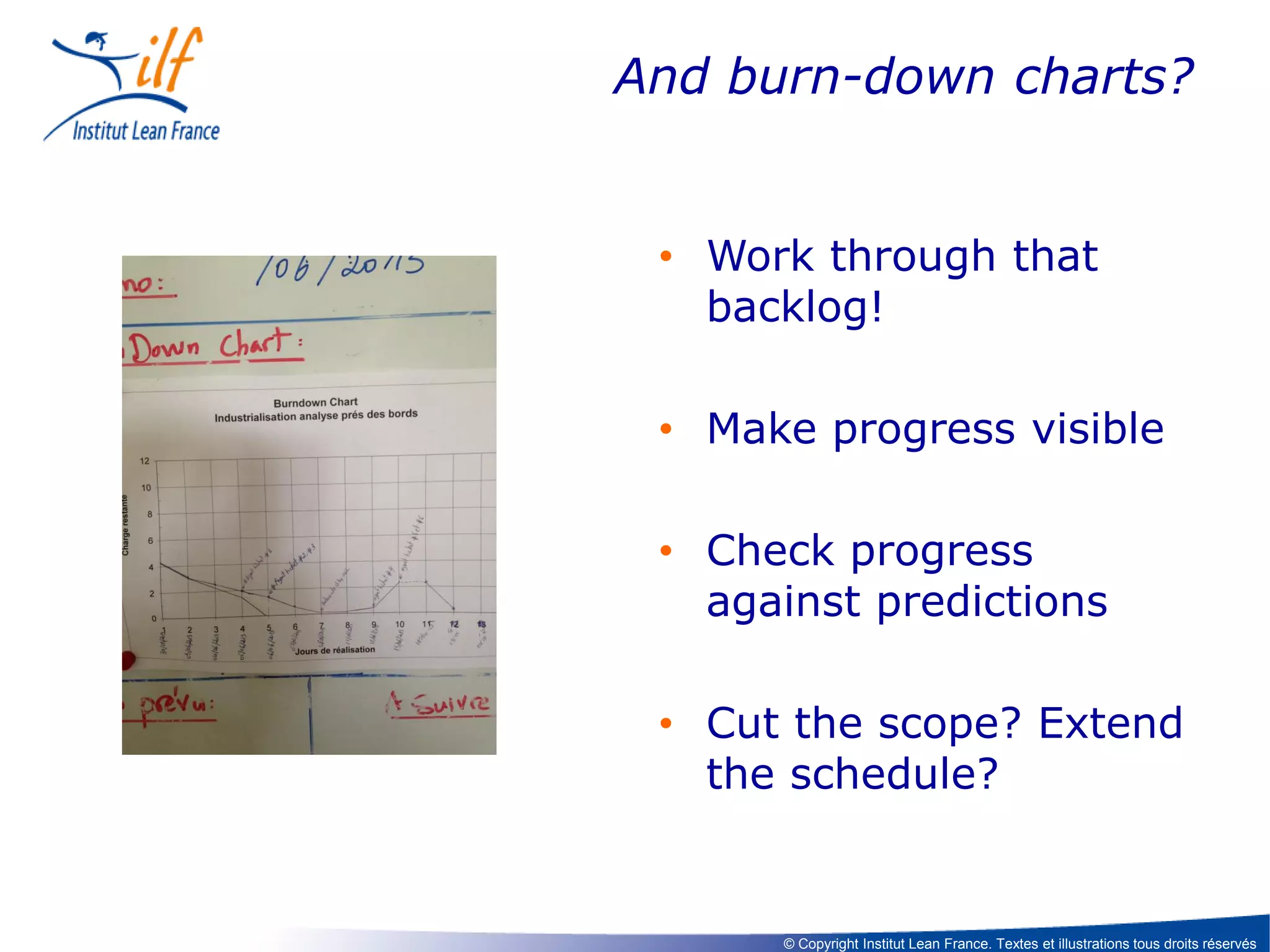

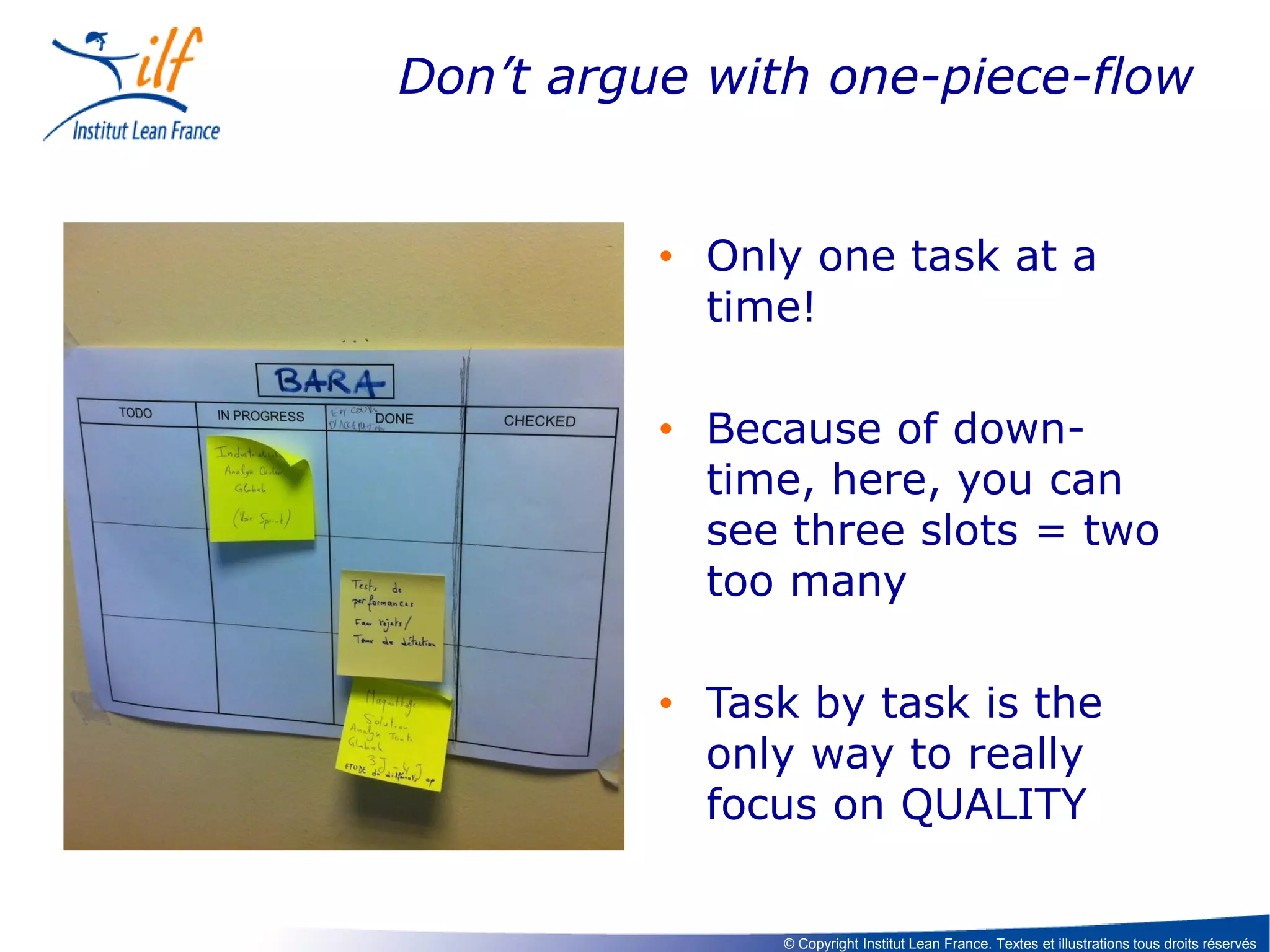

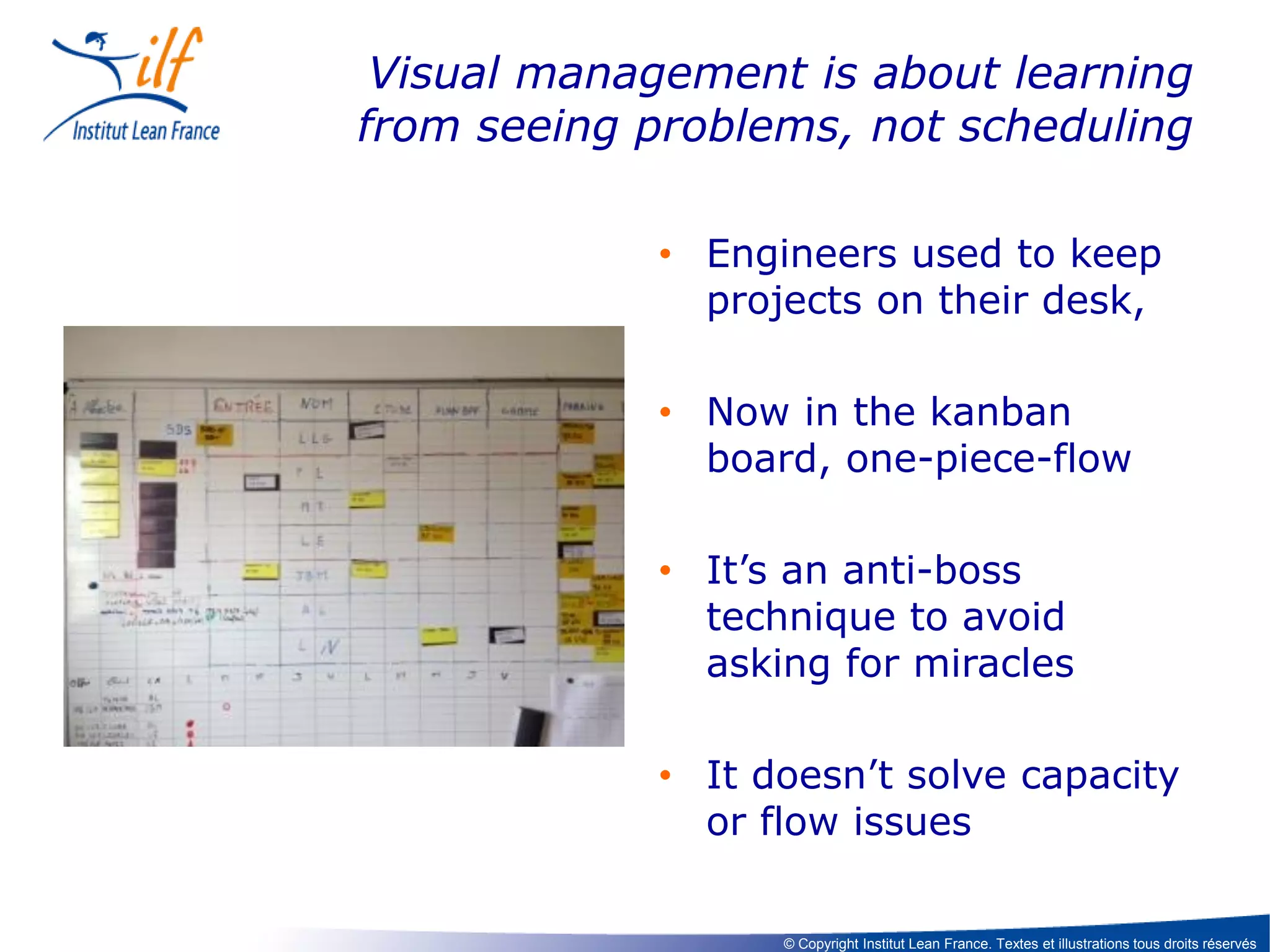

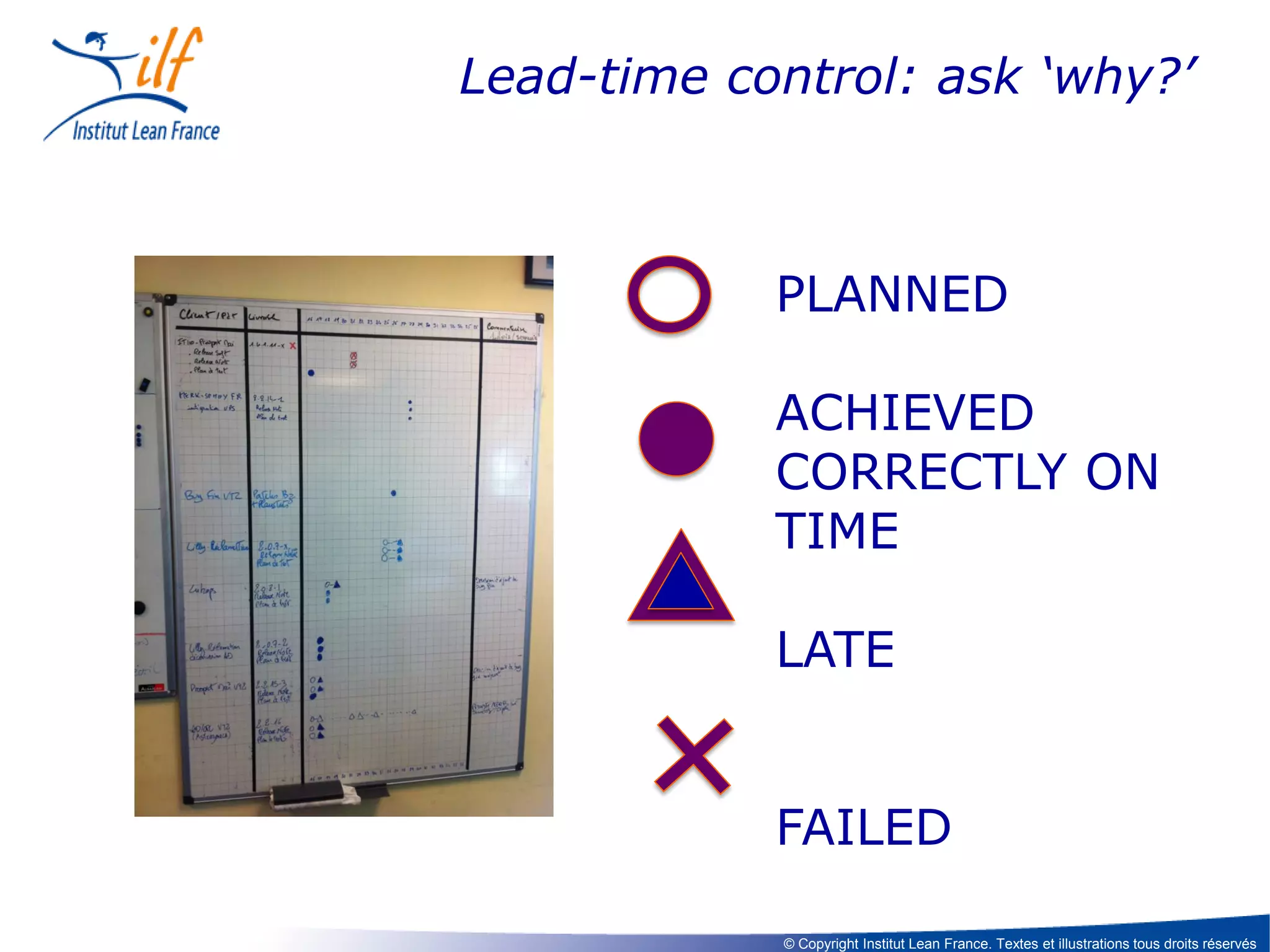

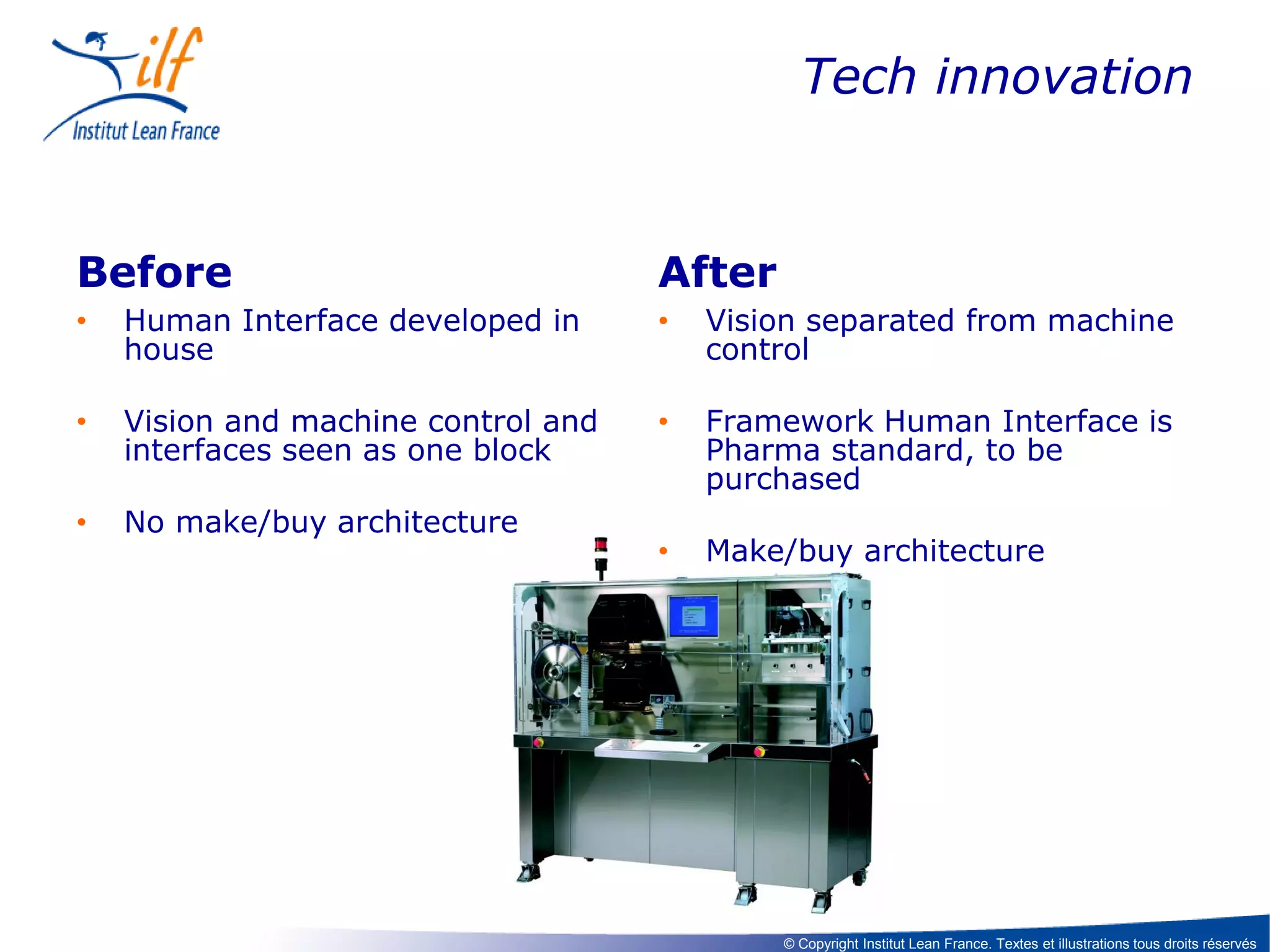

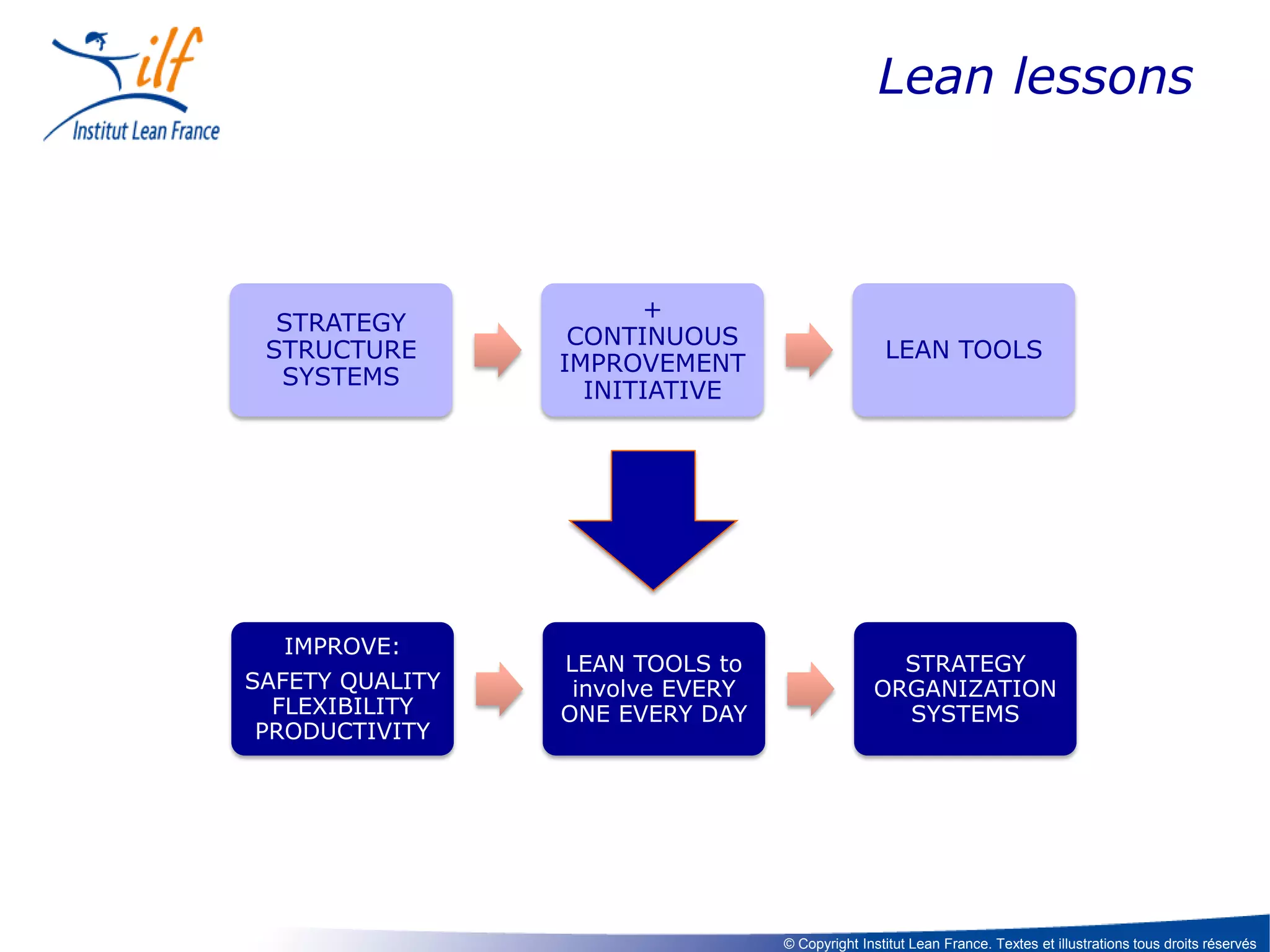

The document discusses the integration of lean and agile principles in software development, emphasizing the importance of built-in quality, continuous improvement, and team collaboration. It describes methods such as Kanban for visualizing workflows and managing tasks while encouraging problem-solving and learning among team members. The content also highlights the need for effective leadership and the development of standards to enhance productivity and meet customer needs.