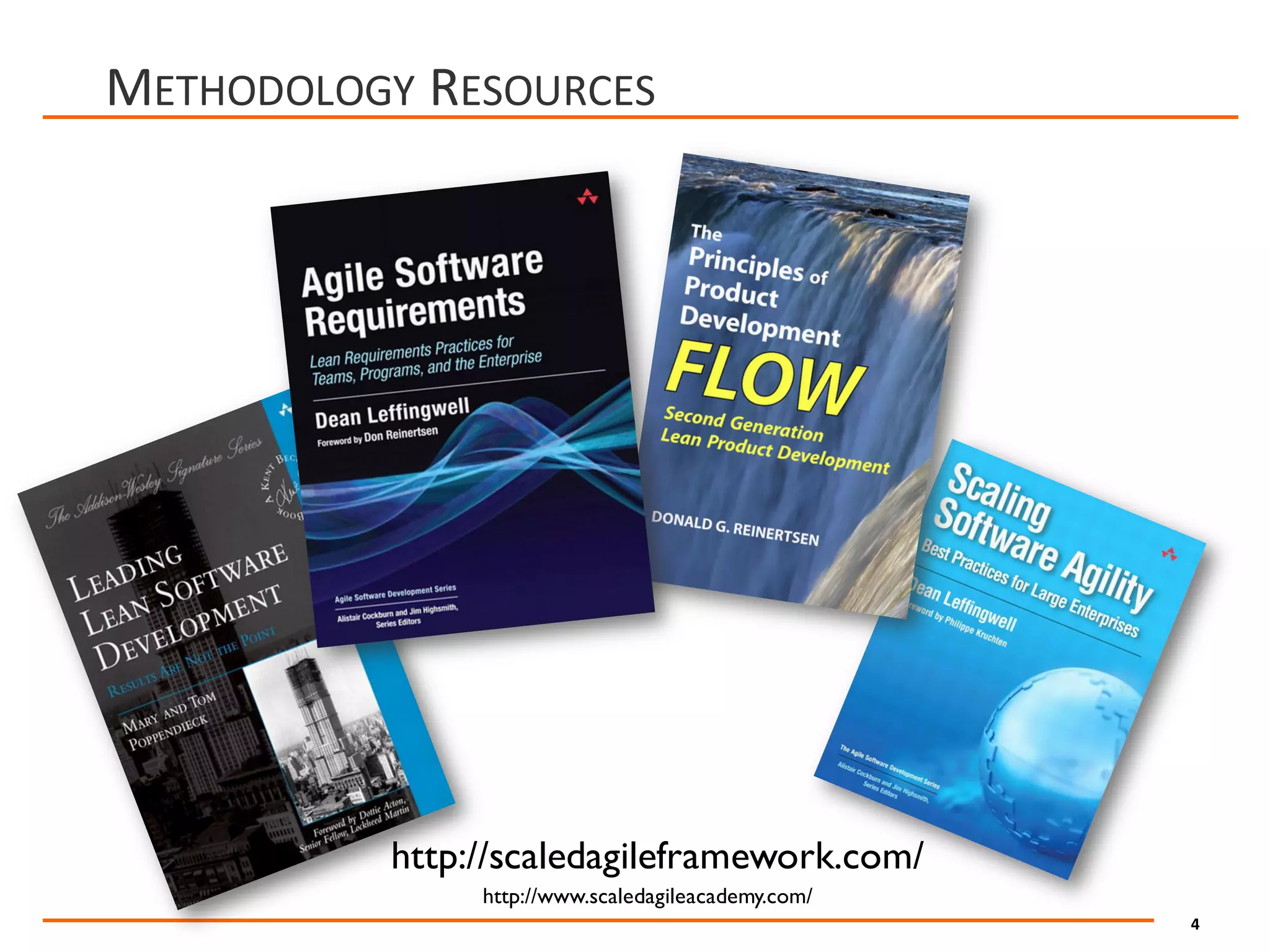

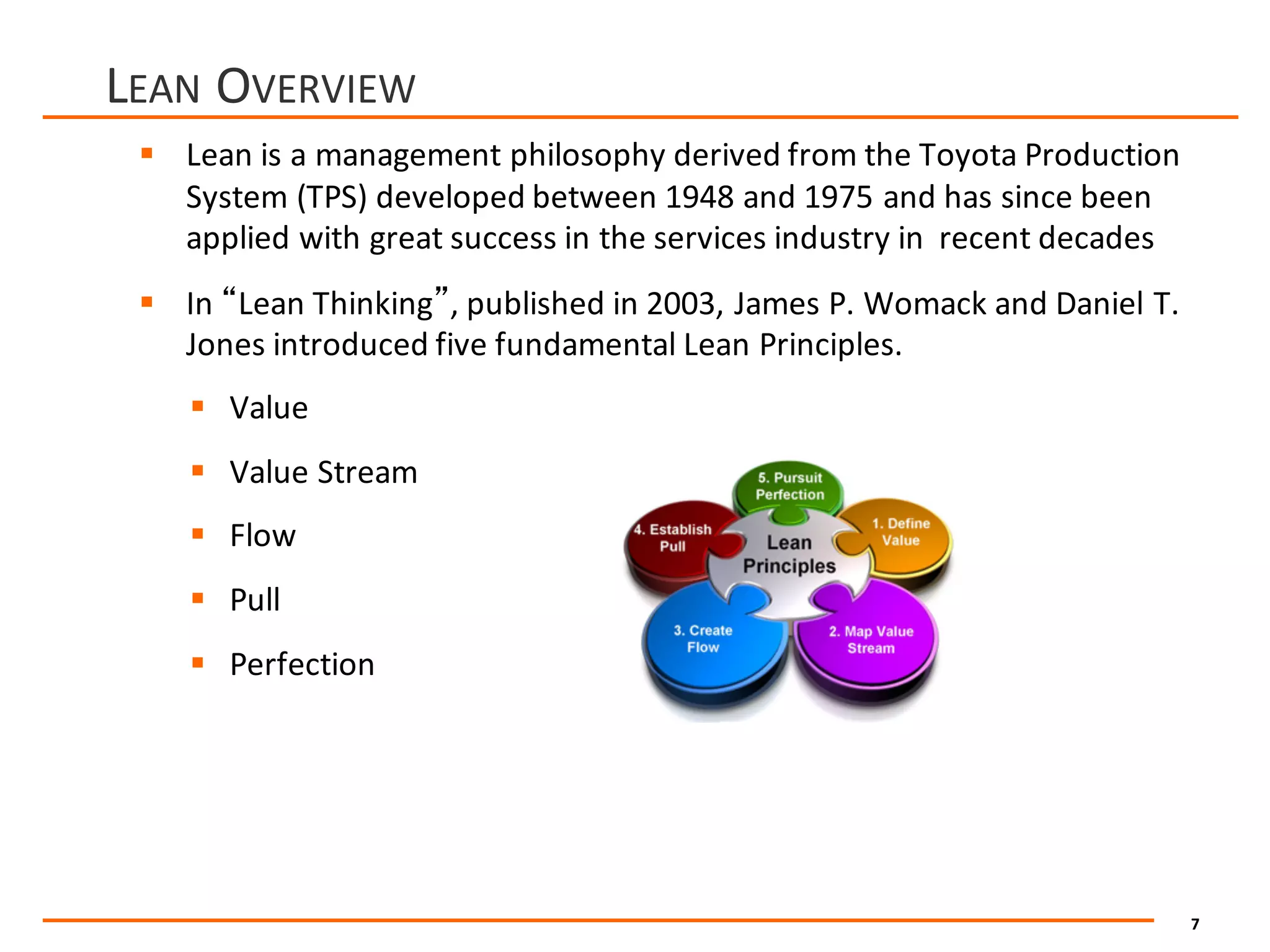

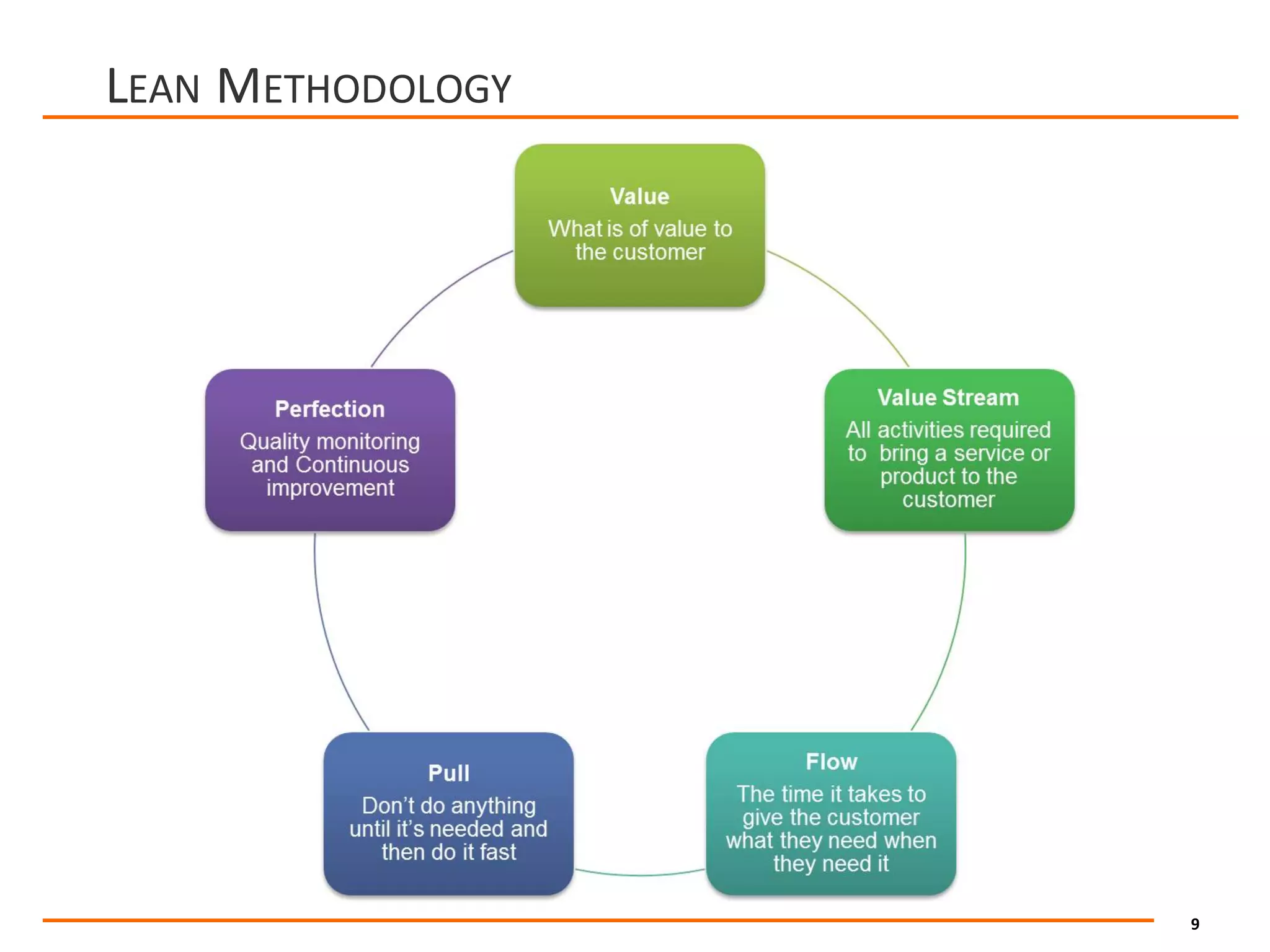

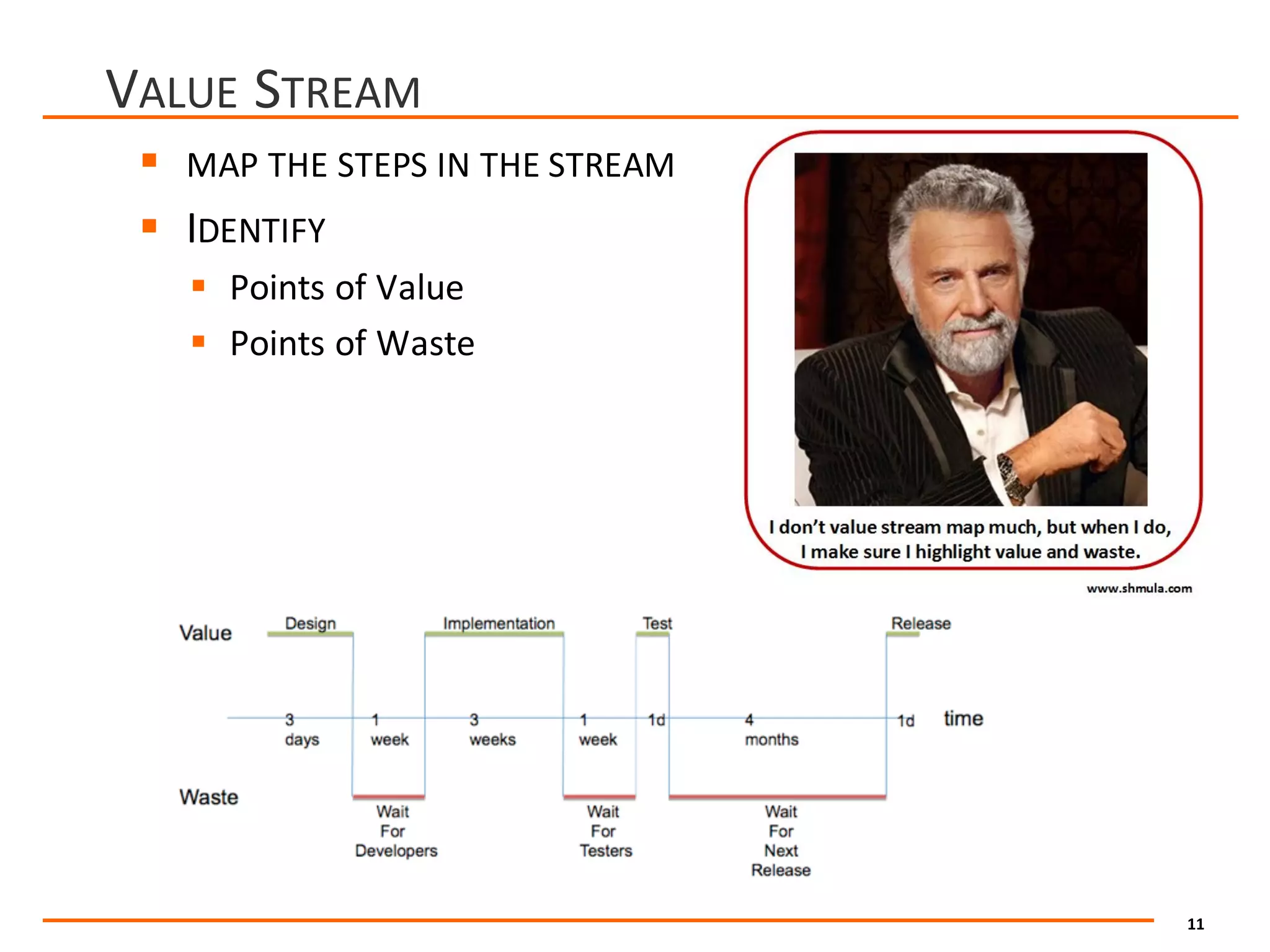

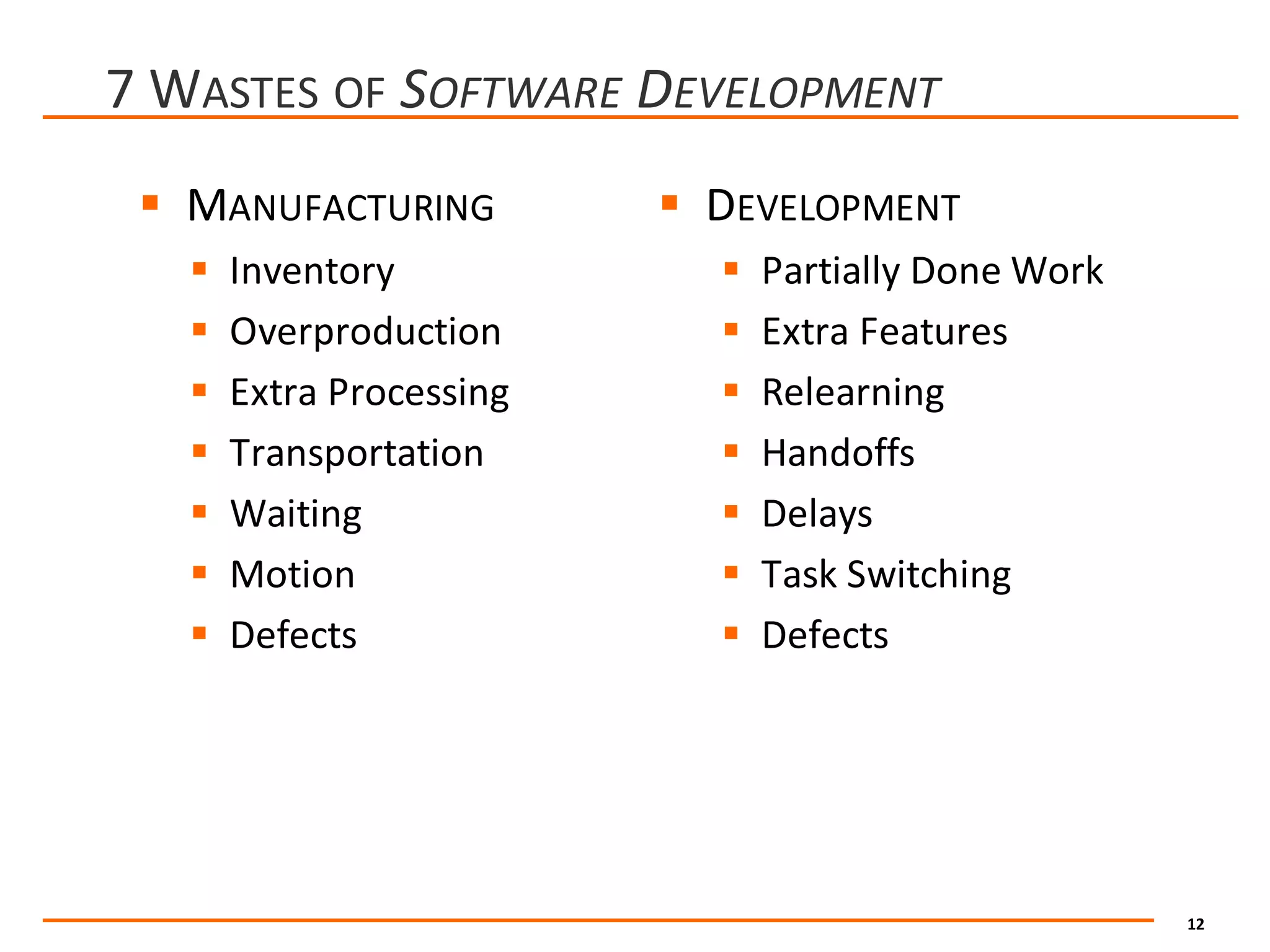

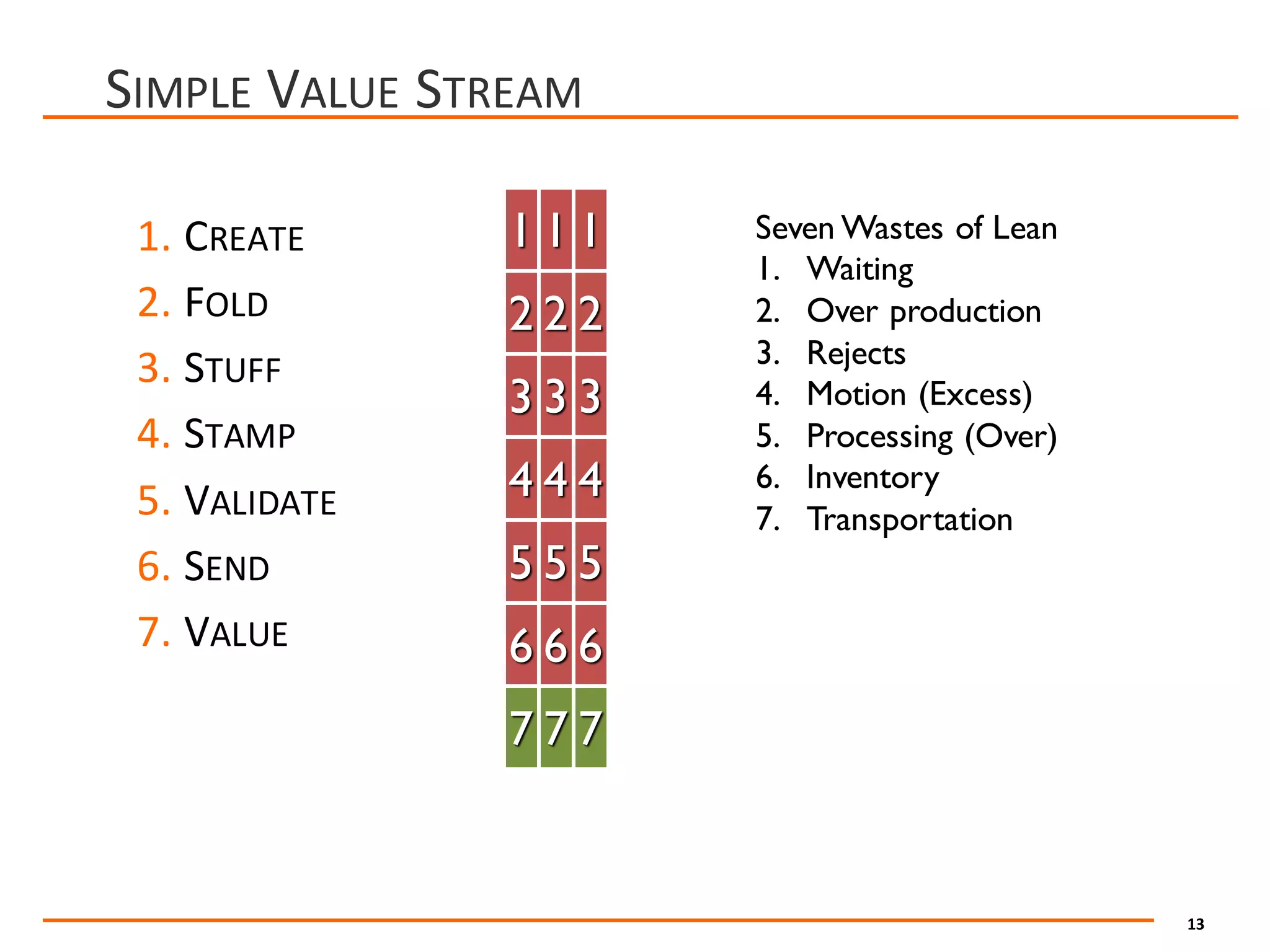

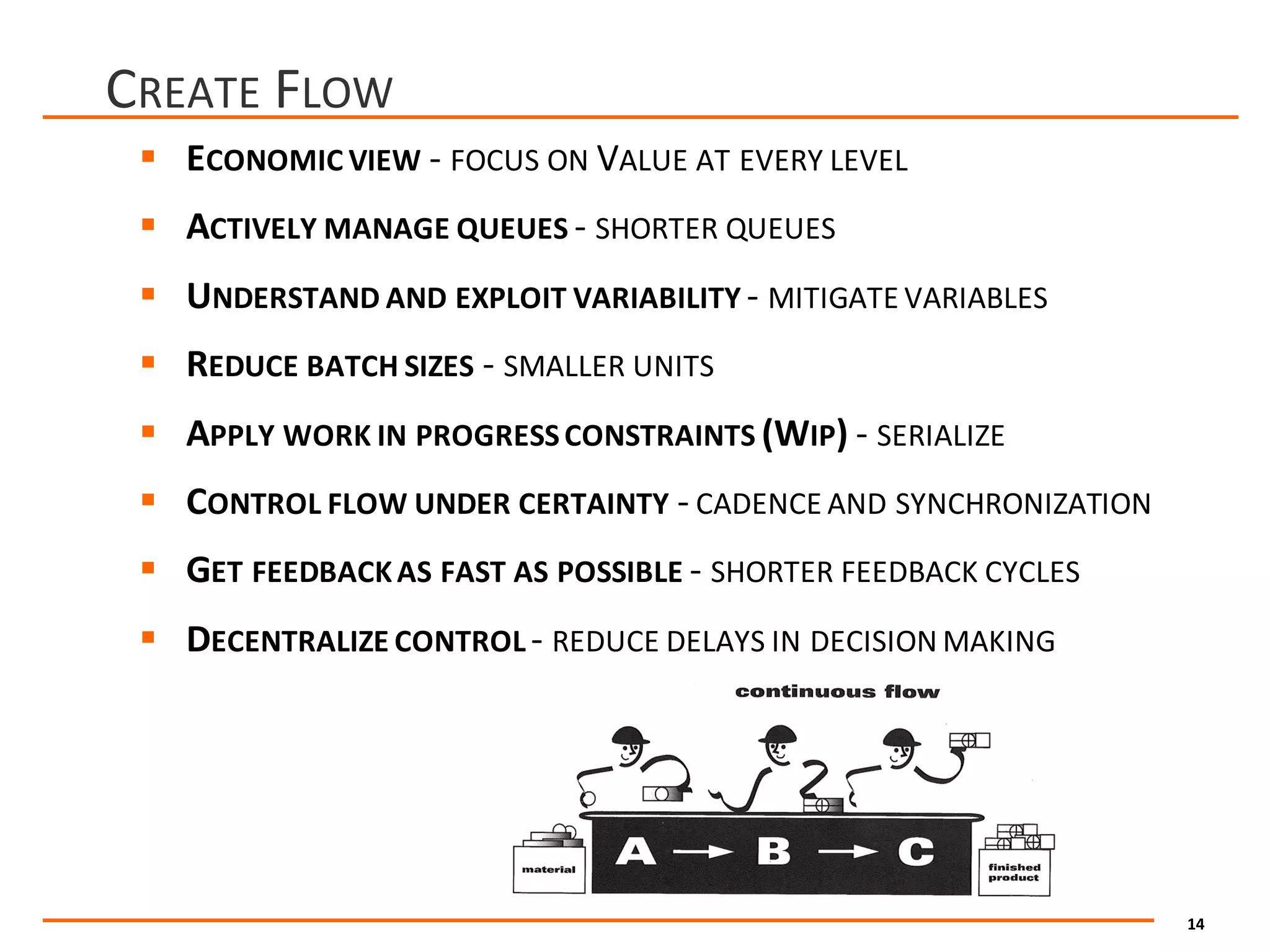

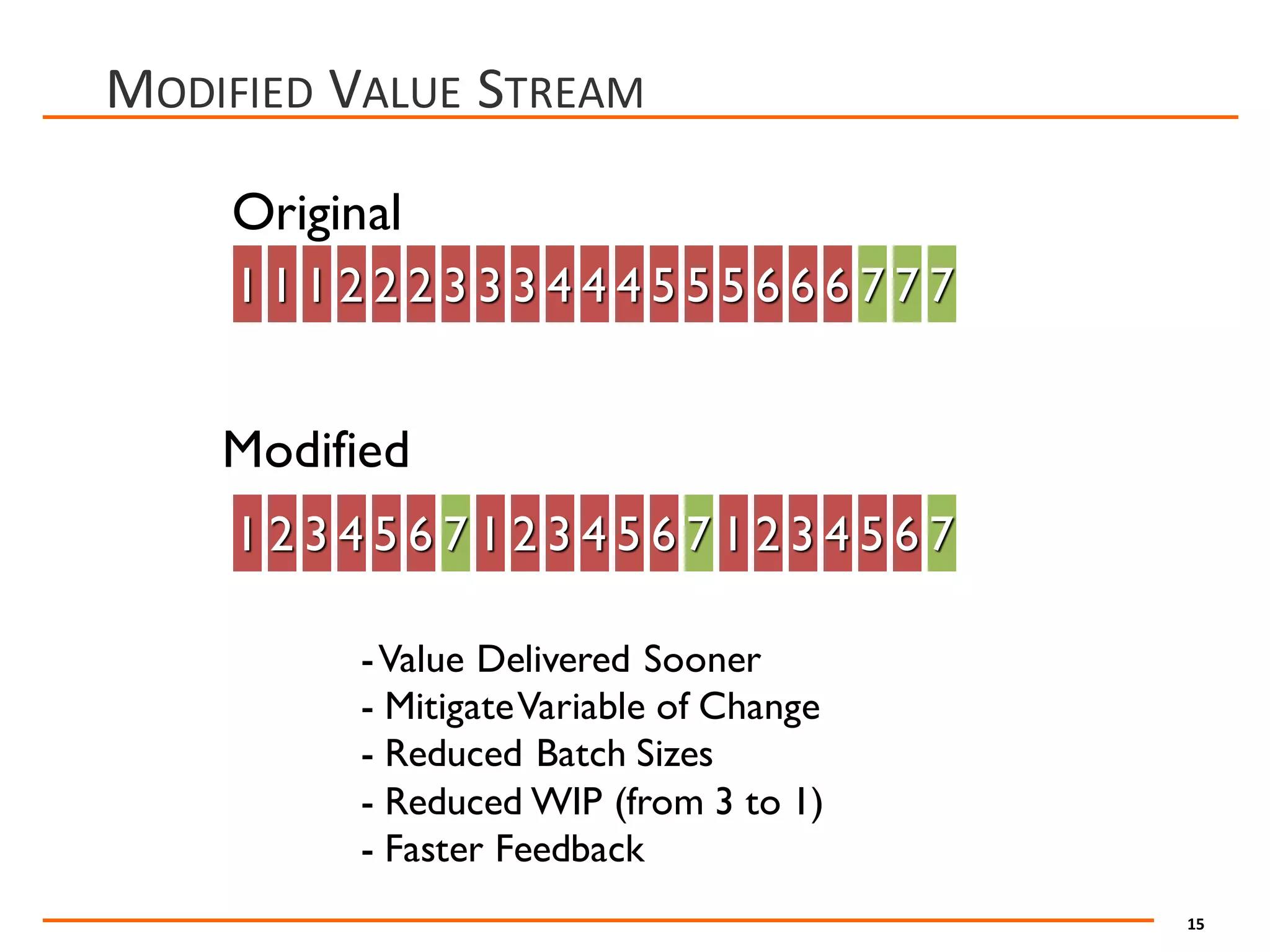

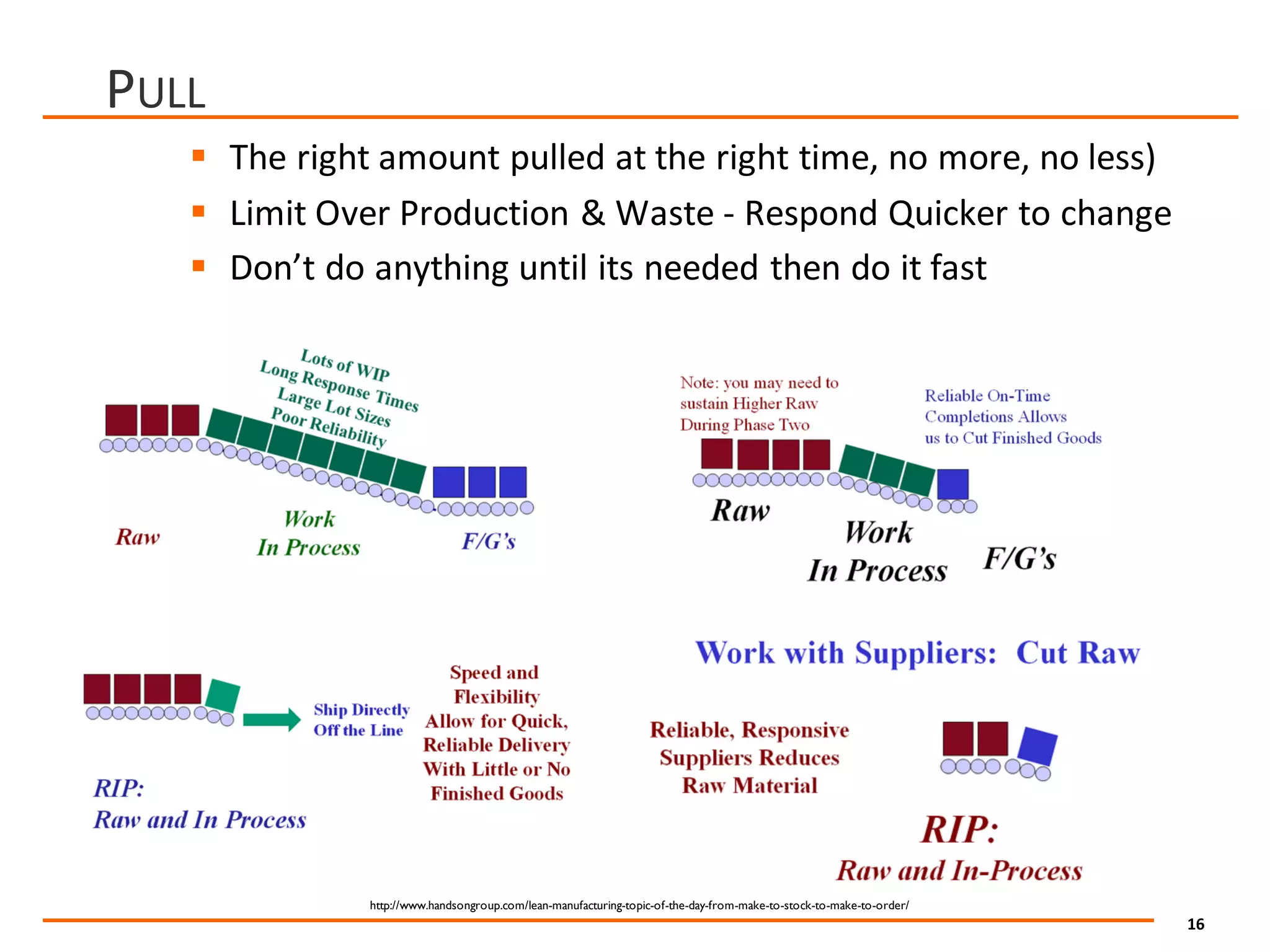

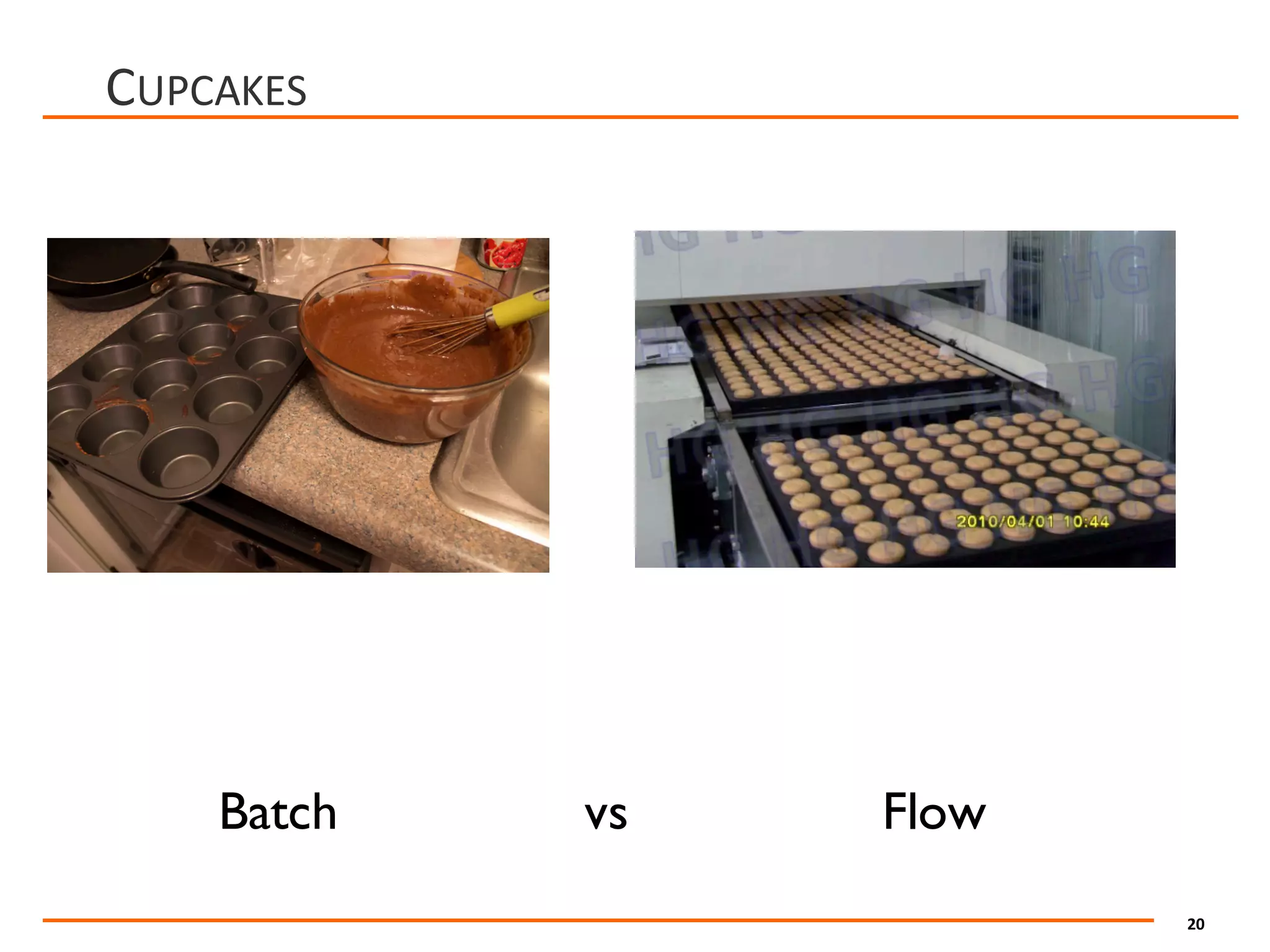

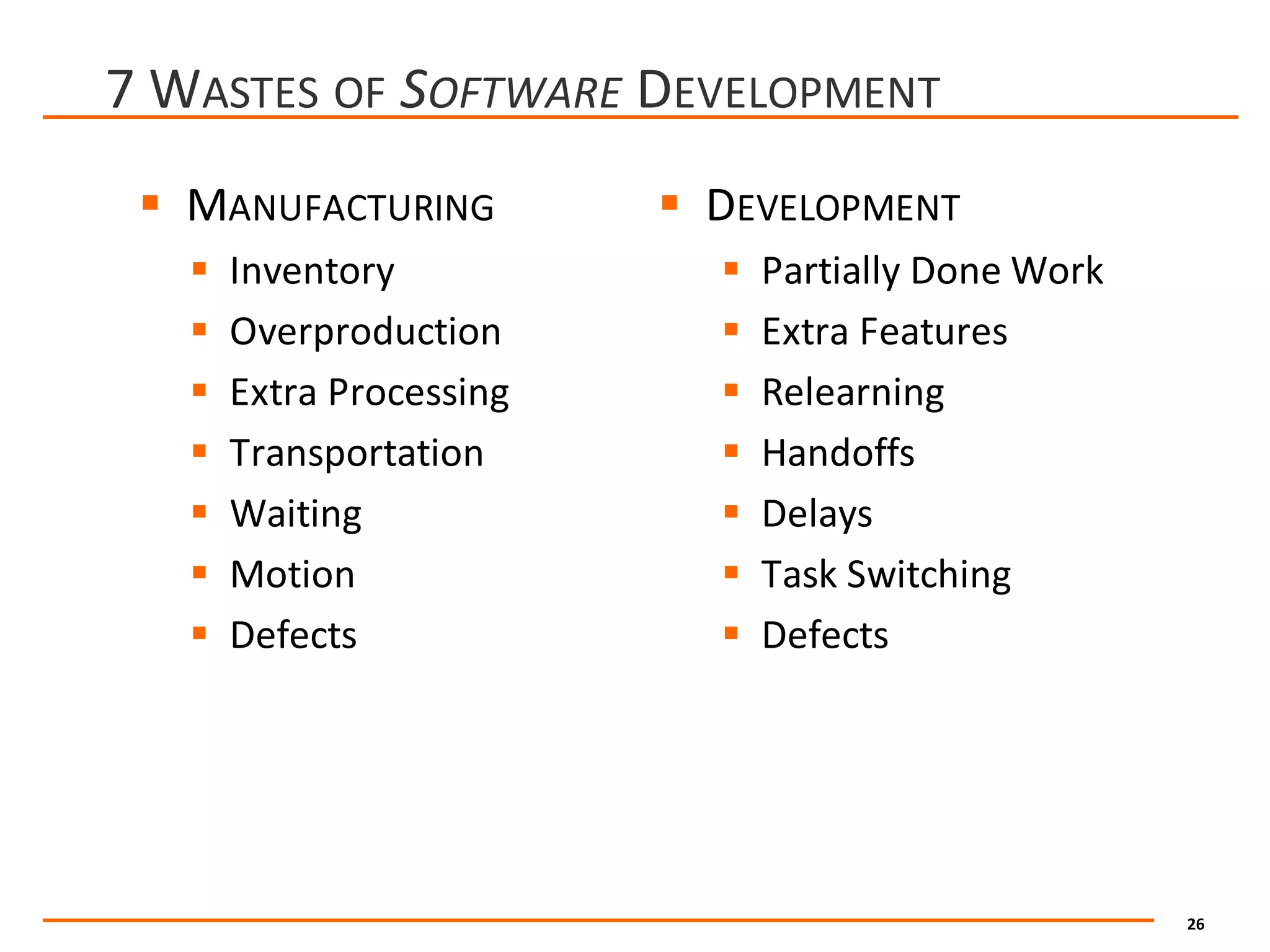

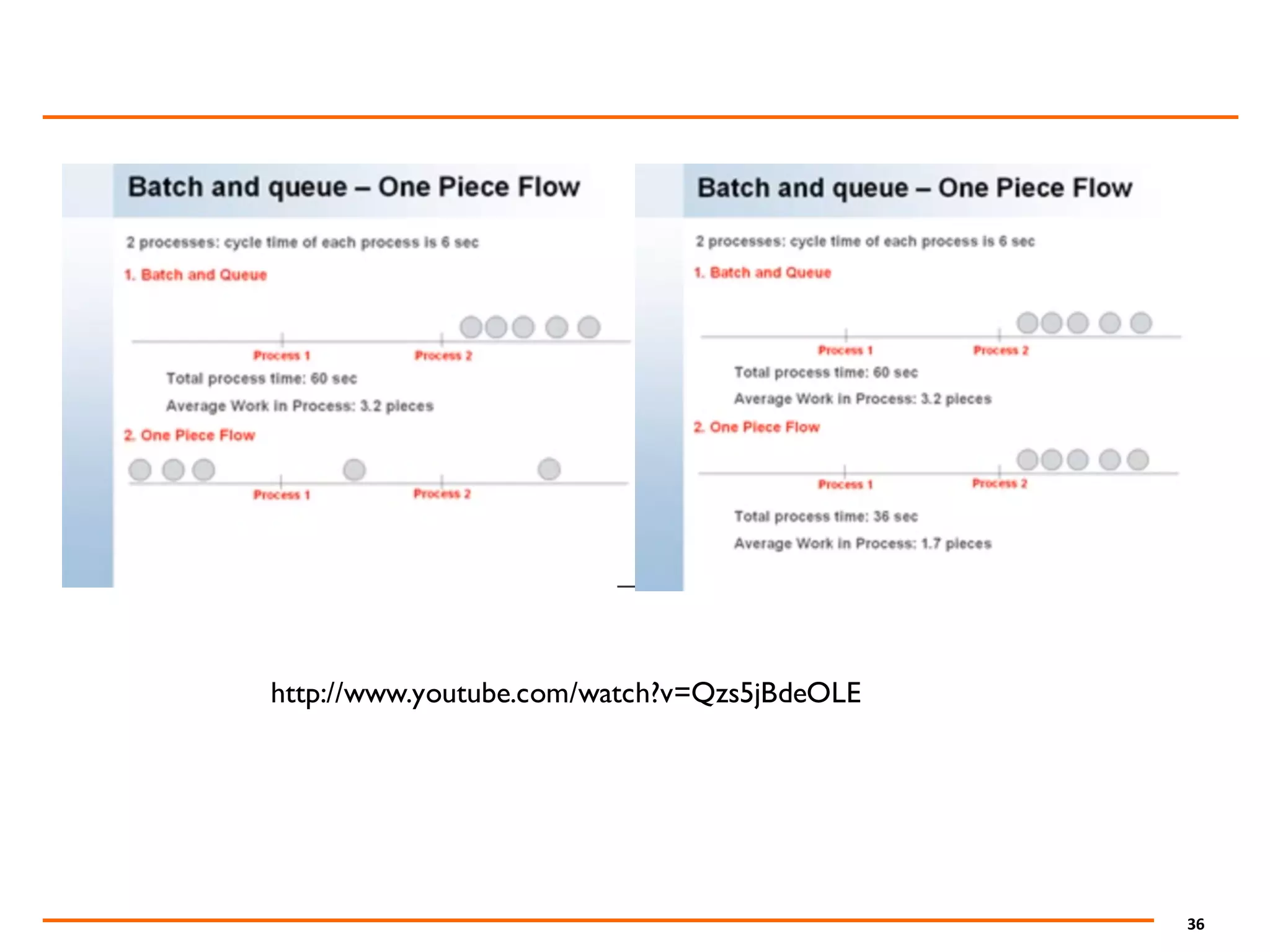

This document provides an overview of lean software development methodology. It discusses lean principles like value, value stream, flow, pull and perfection. It demonstrates these principles through examples like stuffing envelopes. The document outlines how to define value, map the value stream, eliminate waste, create flow, implement pull and continuous improvement. It provides real-world examples and discusses how to apply lean thinking in practice. Resources for further learning about scaled agile framework and focus areas are also included.