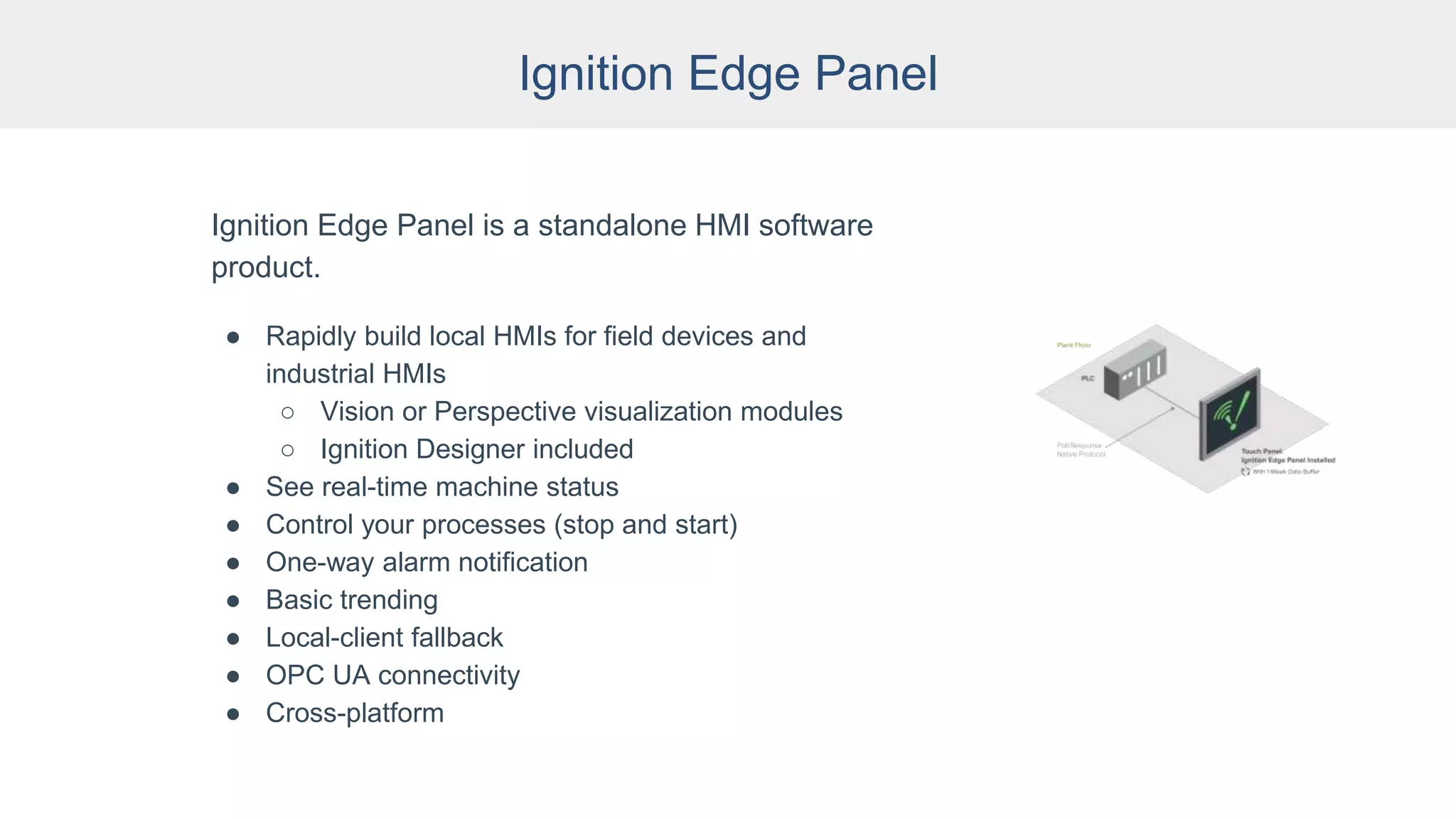

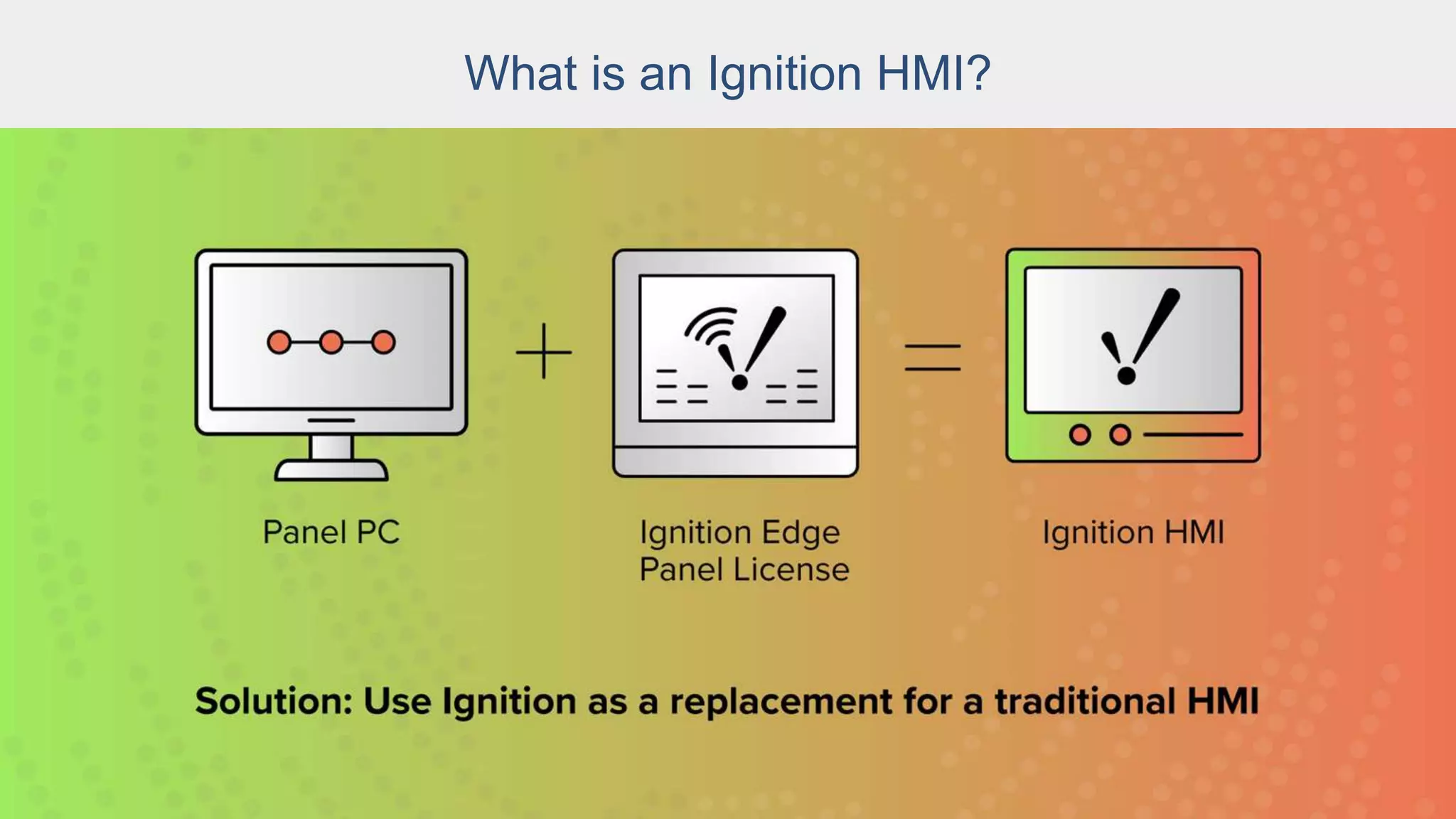

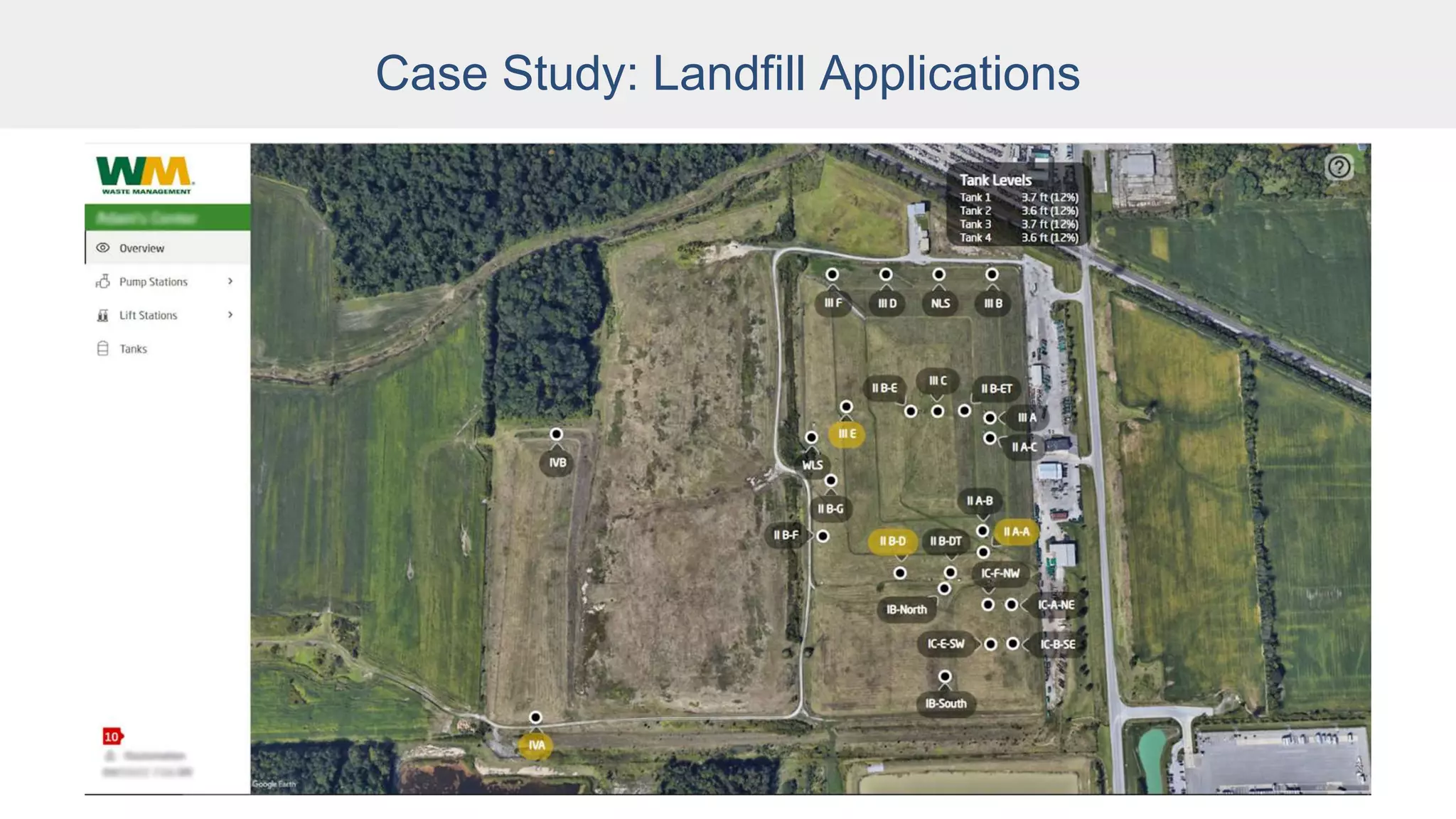

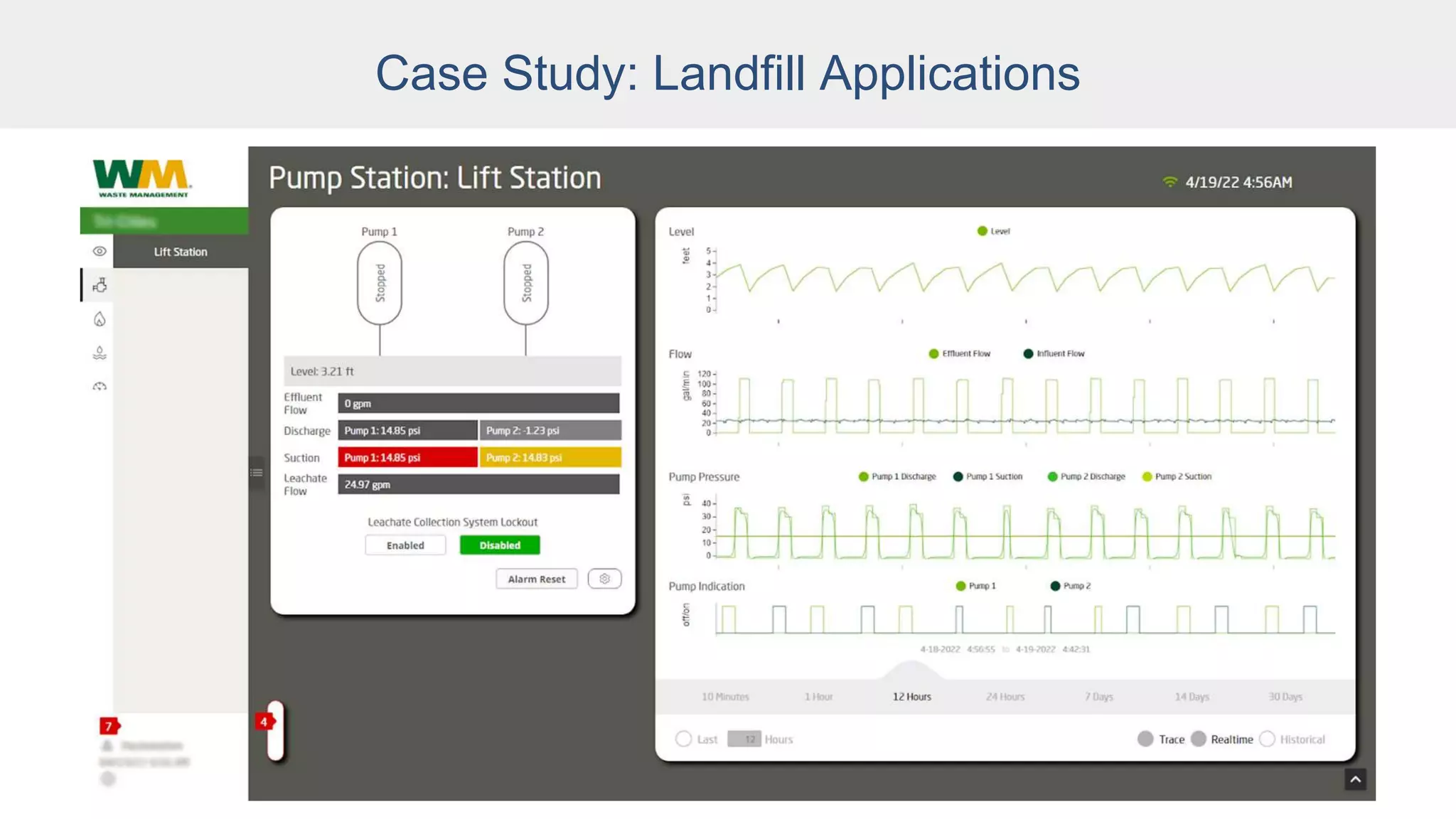

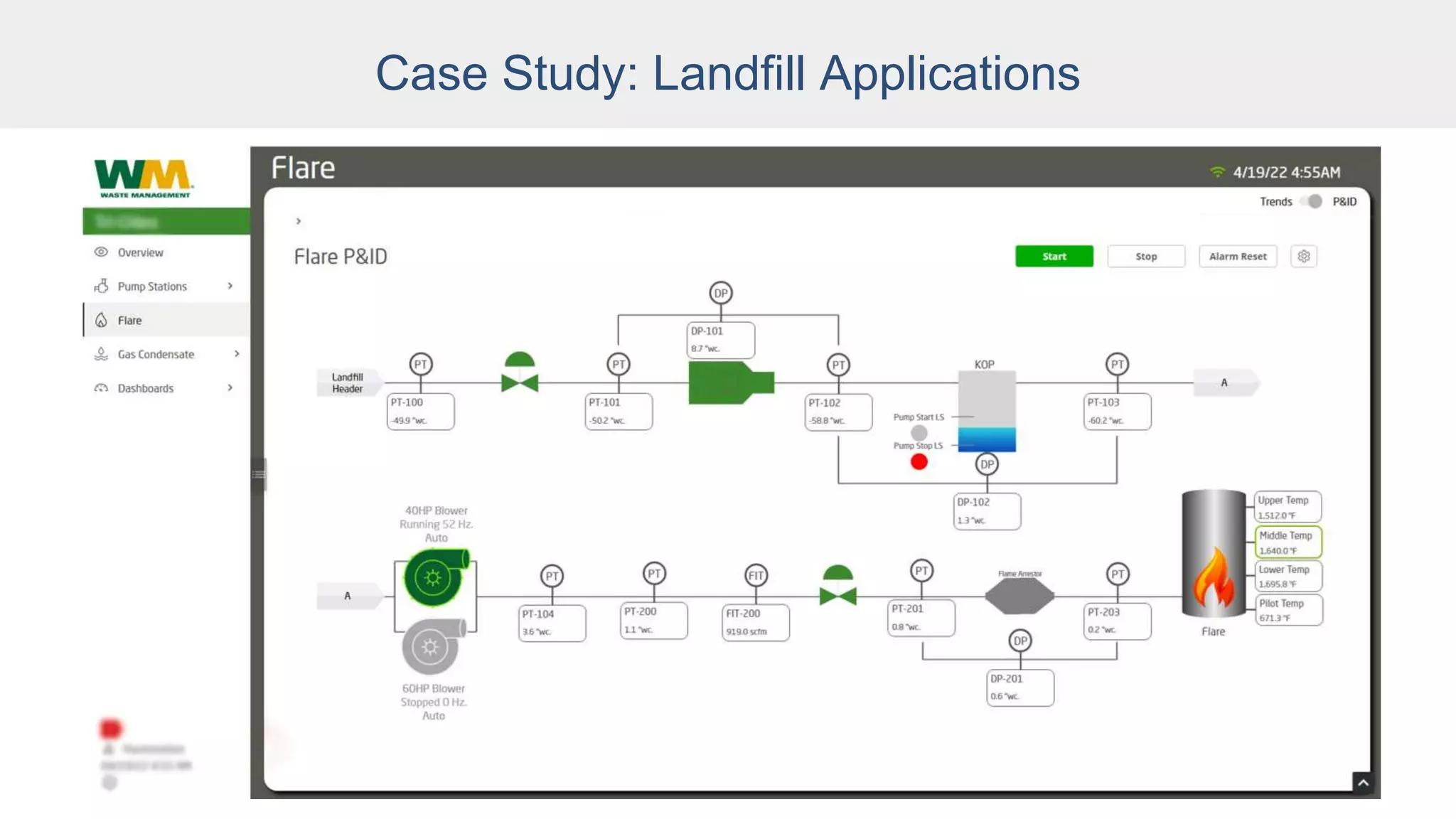

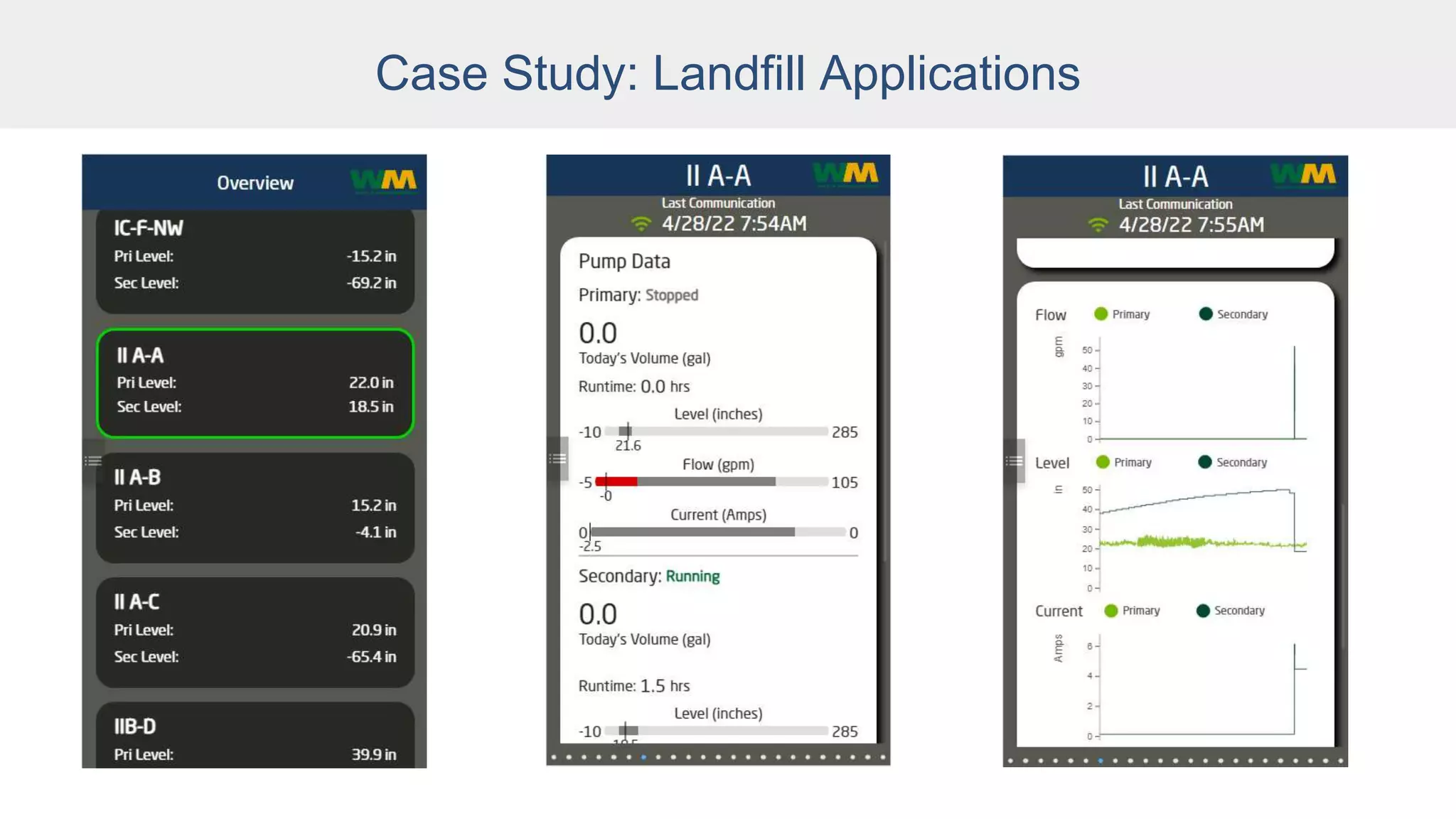

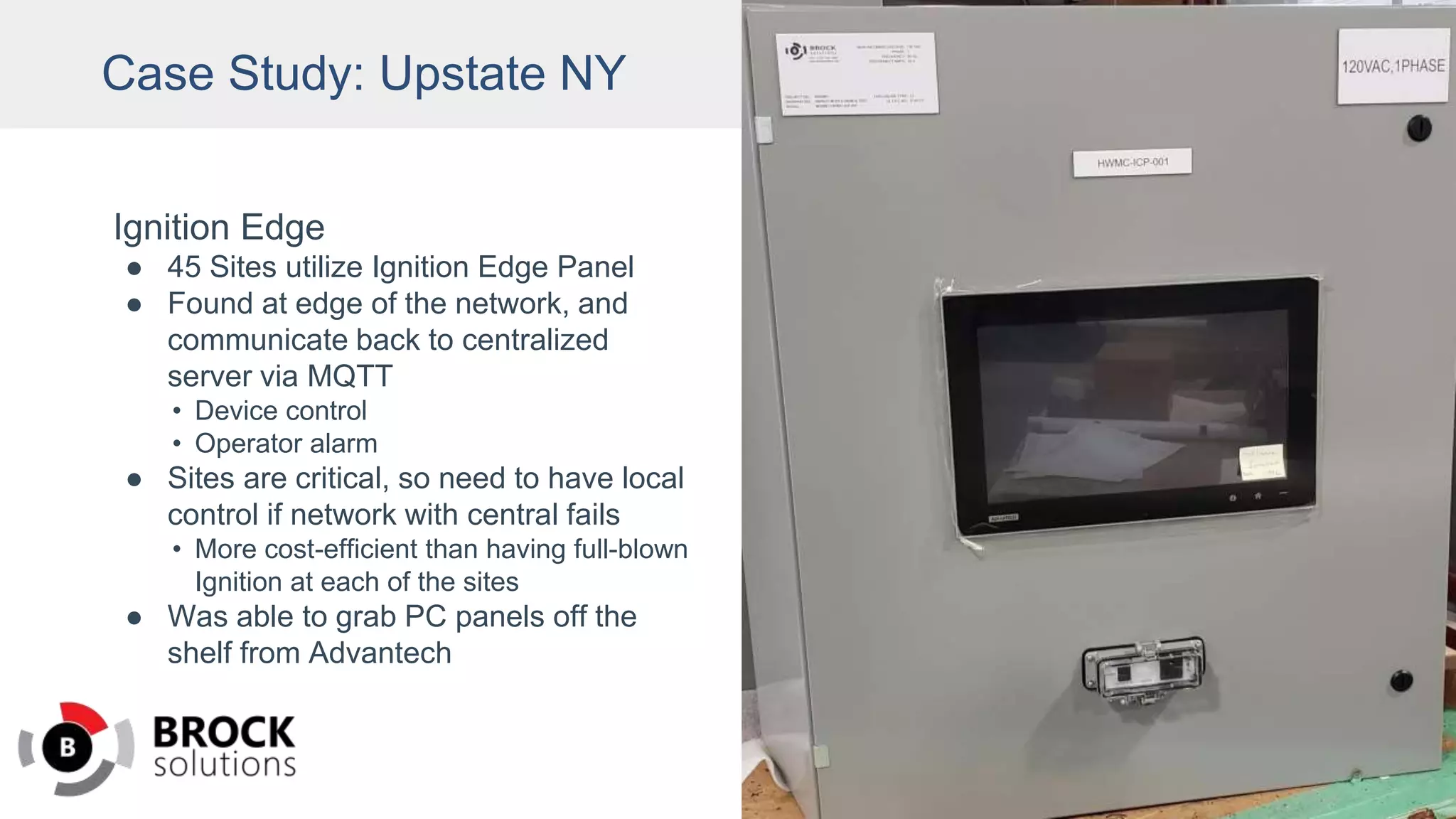

This document discusses HMIs and Ignition software's HMI capabilities. It provides an overview of what HMIs are used for in industrial settings. The Ignition Edge Panel is introduced as a standalone HMI software that can be installed on existing panel PCs or industrial PCs. Integrator case studies show how Ignition Edge Panel has been used for landfill and water SCADA applications.