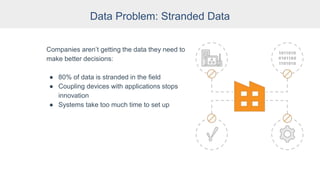

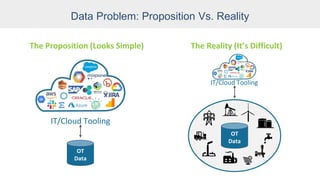

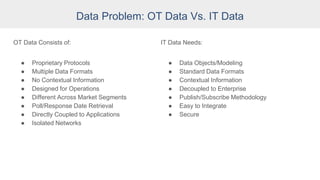

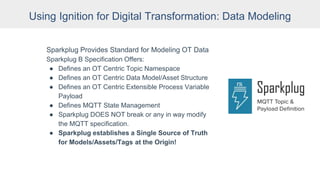

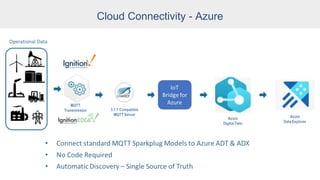

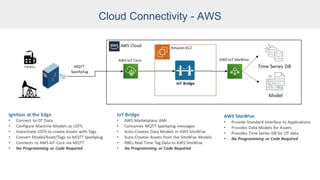

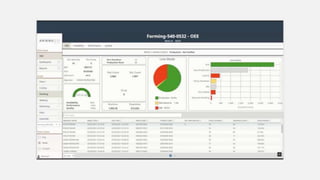

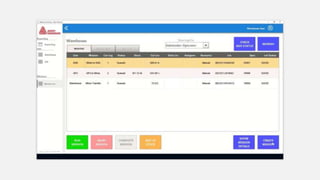

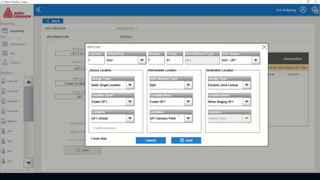

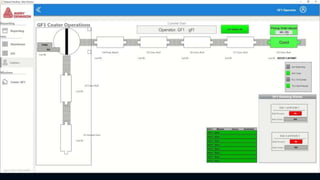

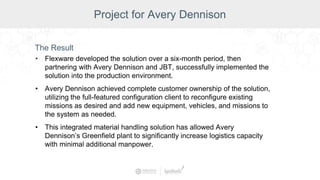

This document summarizes a presentation on using Ignition software for digital transformation. It discusses what digital transformation really means, common data problems companies face, and how Ignition can help by connecting operational technology (OT) data to information technology (IT) systems. Specific capabilities of Ignition mentioned include data collection, modeling, publication, applications, analytics, and machine learning. Success stories are provided of companies like Avery Dennison that have used Ignition for digital transformation projects. Benefits highlighted include security, training resources, and how Ignition can connect processes, solve data problems and access more OT data.