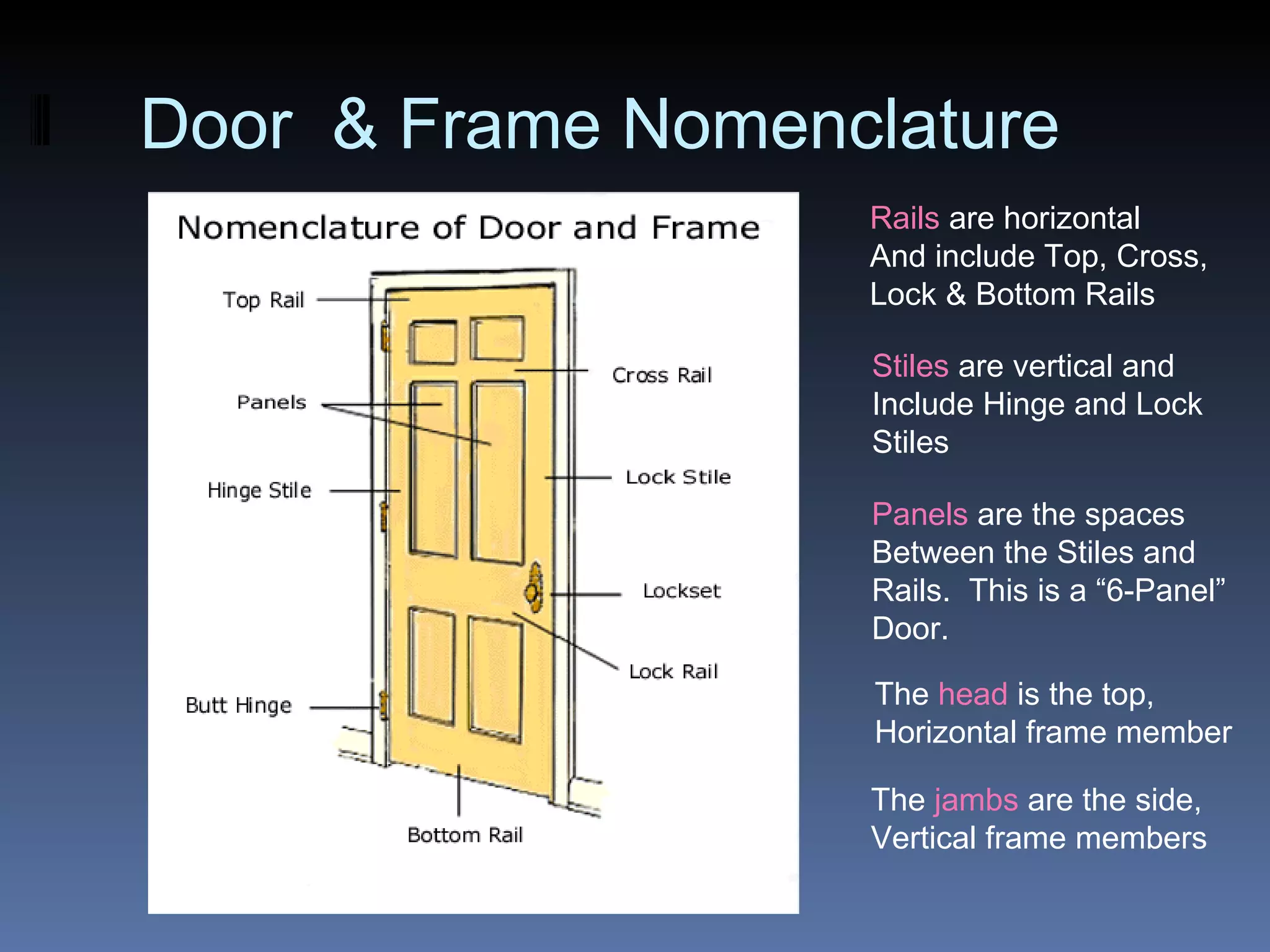

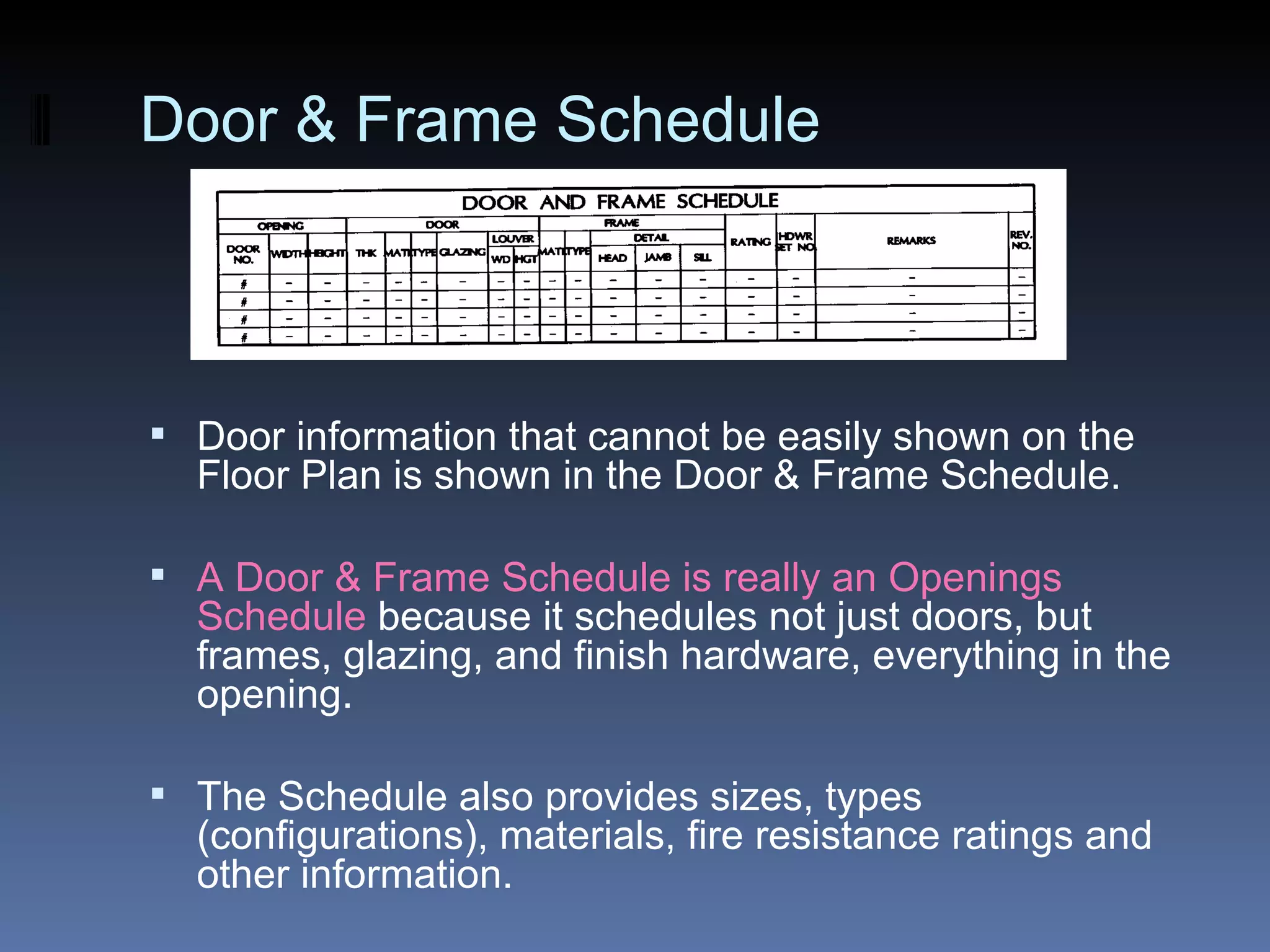

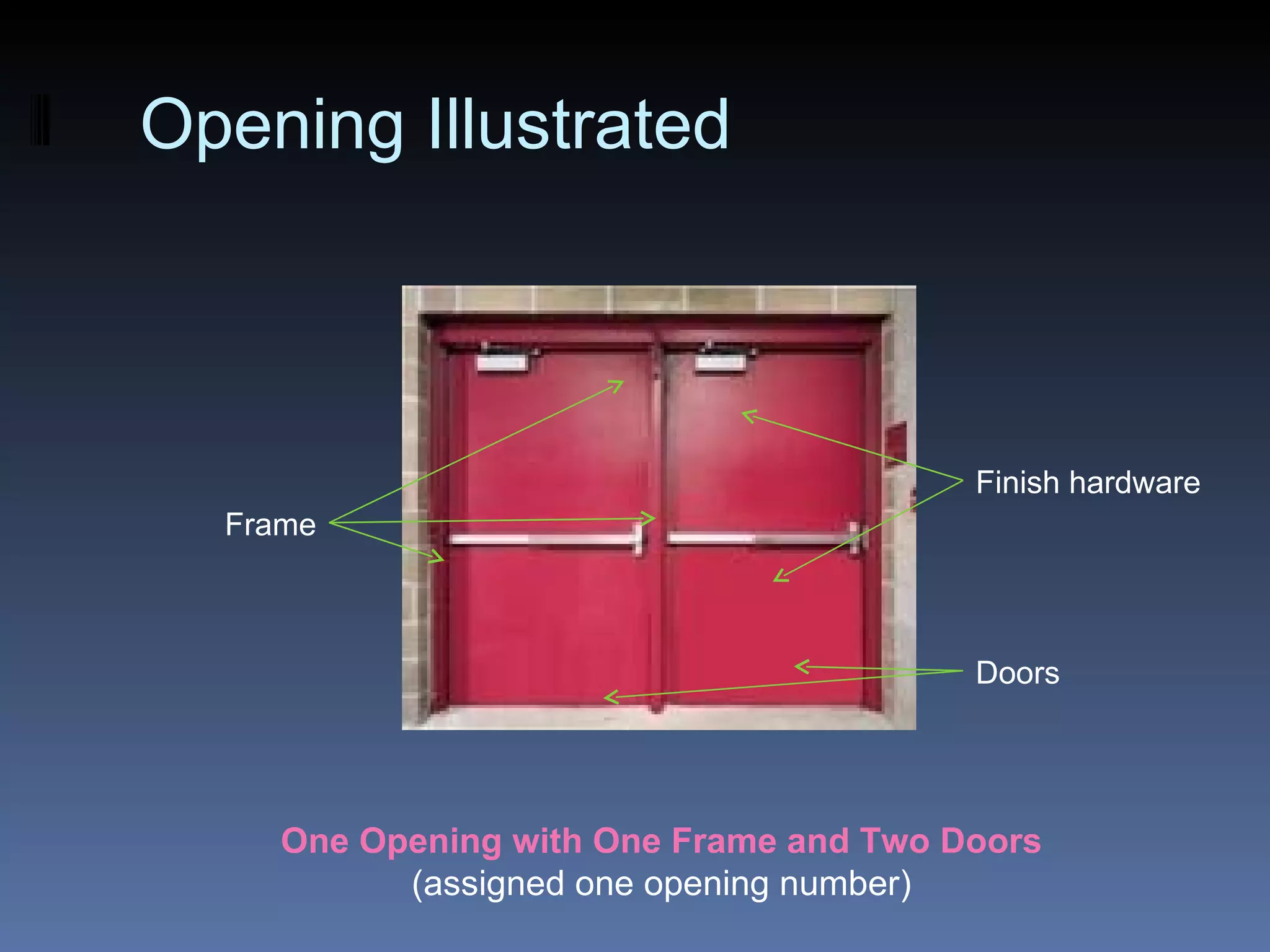

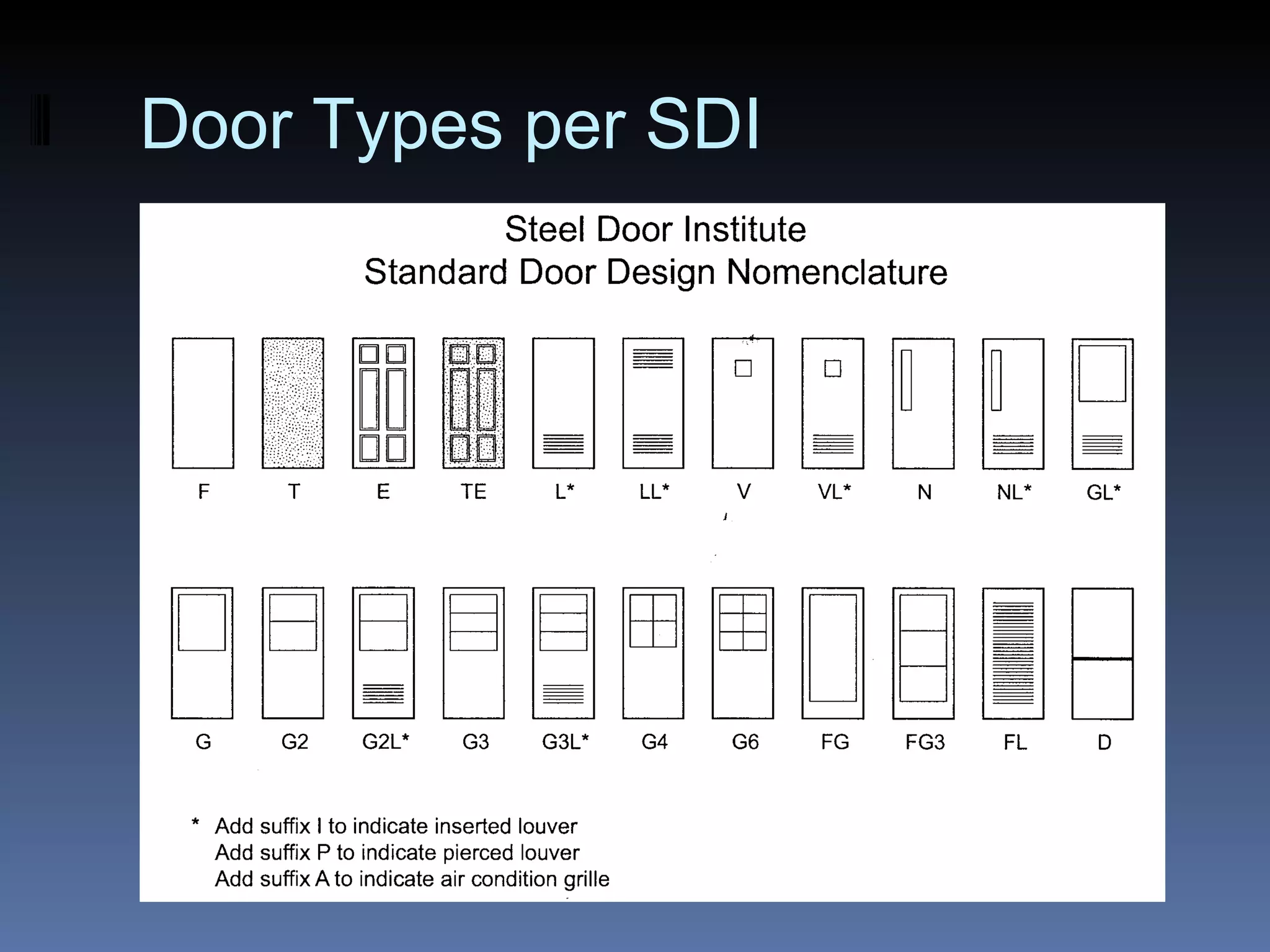

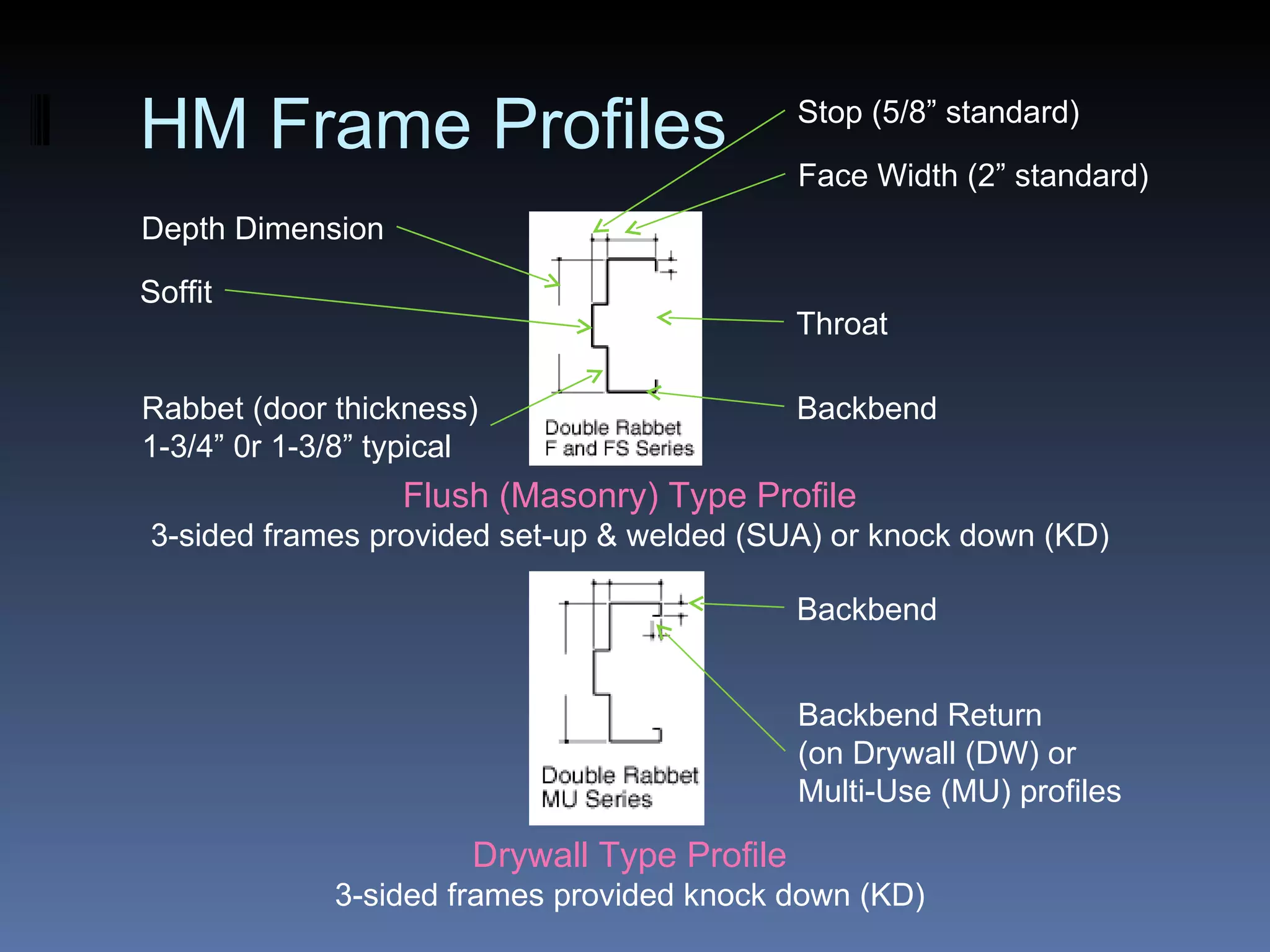

The document provides a comprehensive overview of doors, frames, glazing, and finish hardware in construction drawings, referencing specific sections of the Todd & Associates production manual. It details various types of doors and frames, their materials, and how to accurately represent them in floor plans and schedules. Additionally, it discusses the importance of fire ratings, hardware sets, and the organization of information to ensure clarity in construction documents.