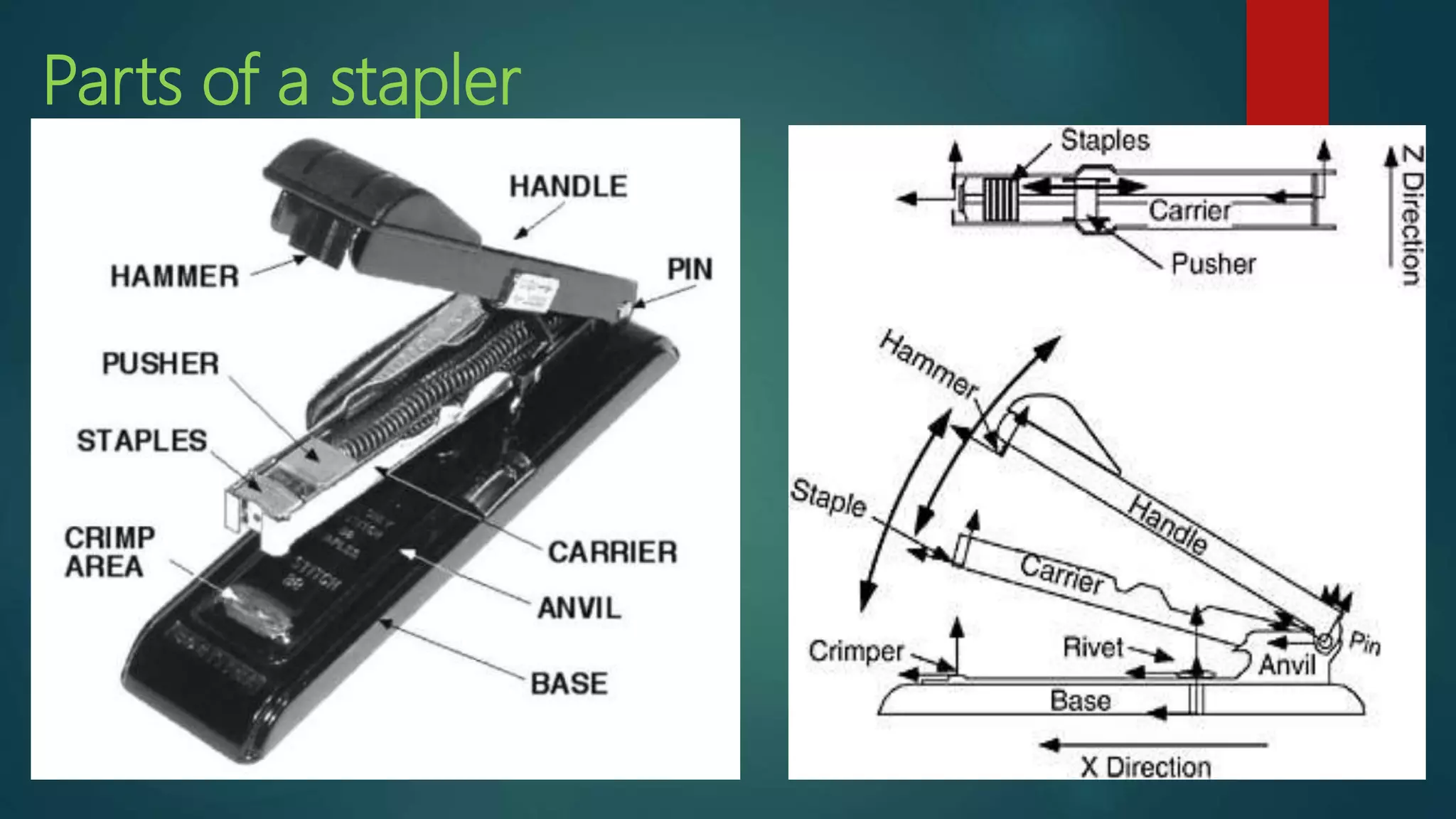

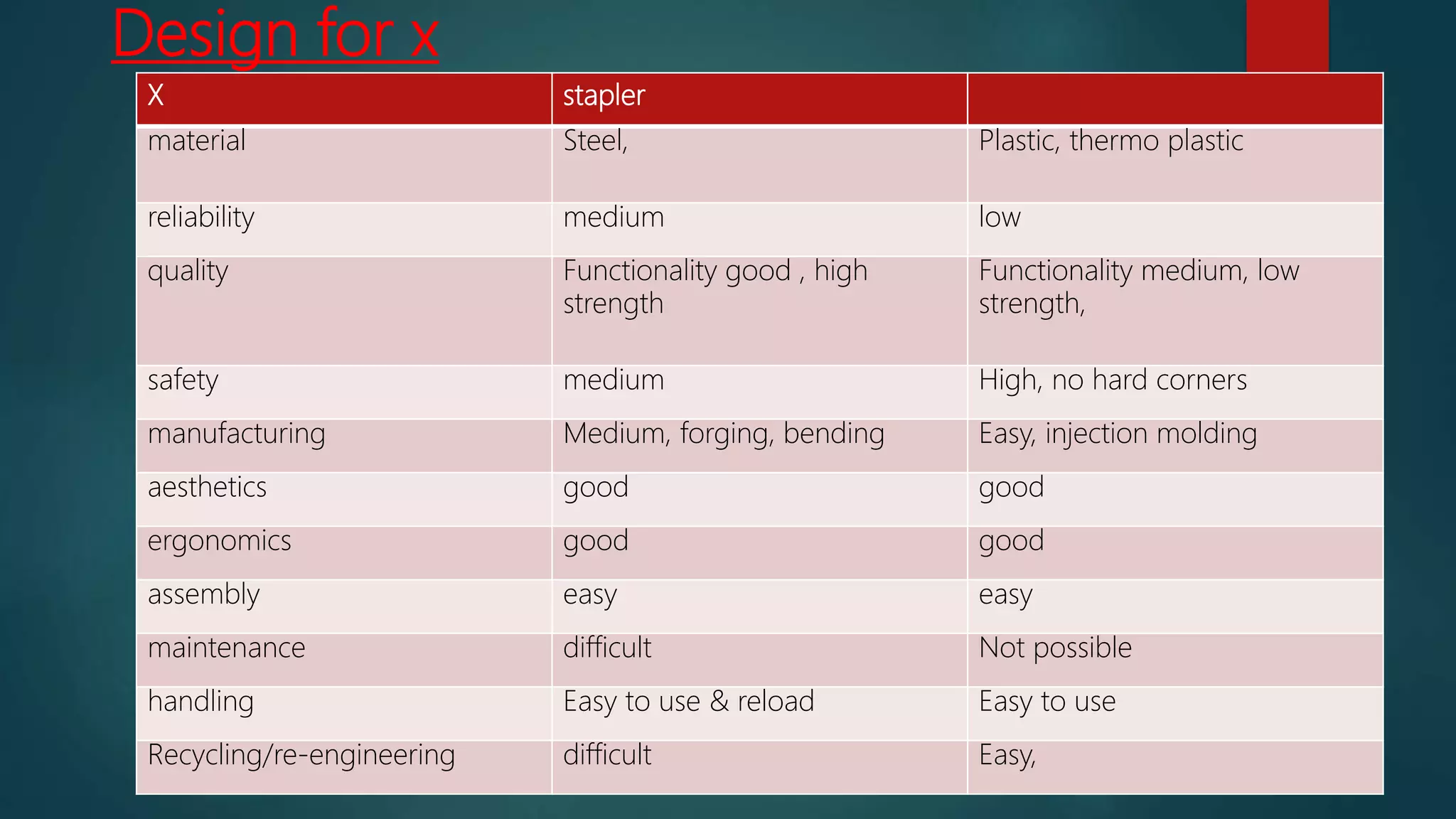

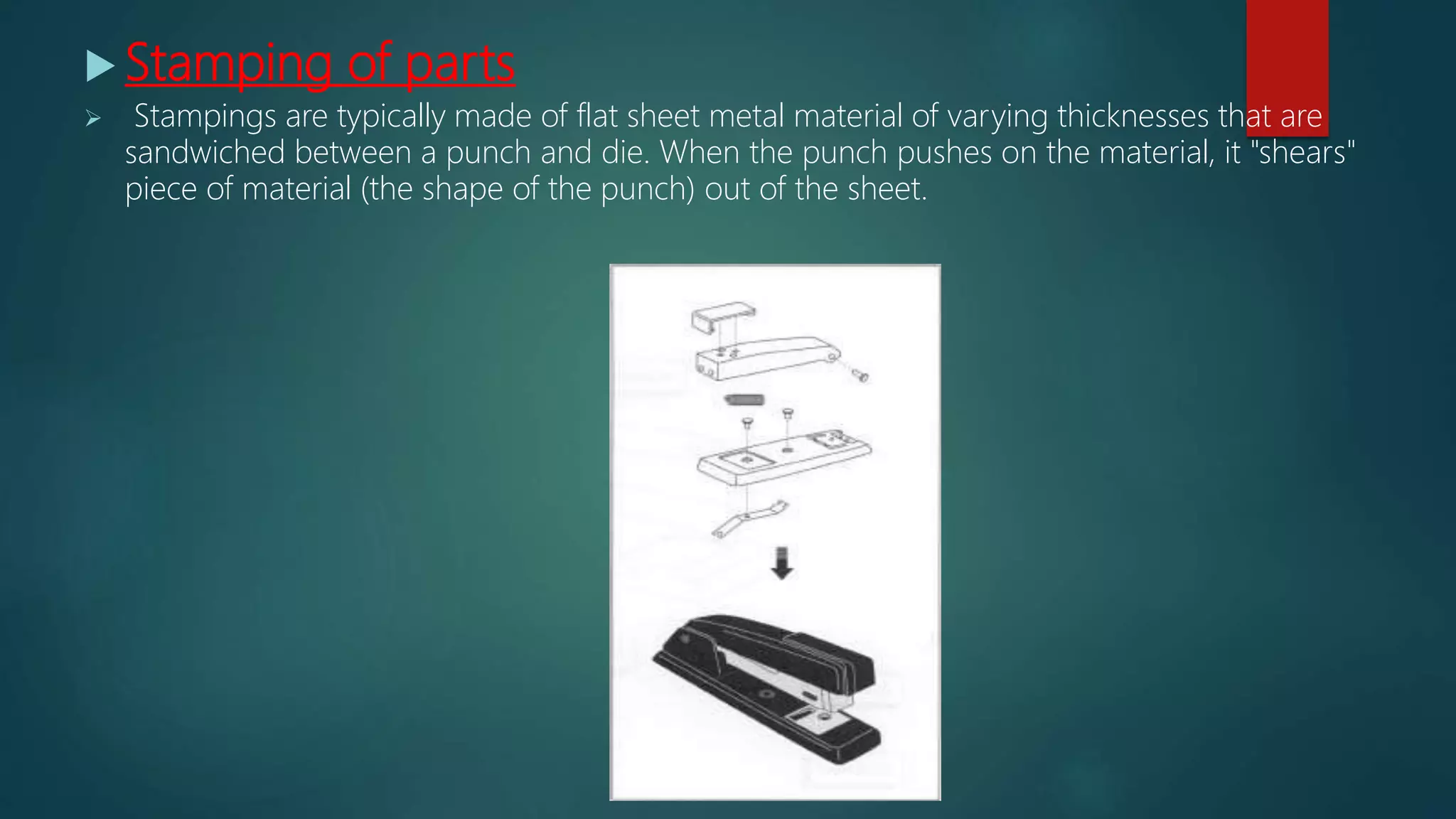

The document summarizes the key parts and manufacturing process of a typical stapler. It describes the main components like the base, anvil, and springs. It then explains how the parts like the springs and stampings are formed. The manufacturing process involves stamping metal parts, injection molding plastic parts, and assembling the subassemblies. Different types of staplers are mentioned for different applications. Design considerations for material selection, functionality, and ergonomics are also highlighted.