28 Edge protection to open edges, shafts and risers Risk Assessment Templates.docx

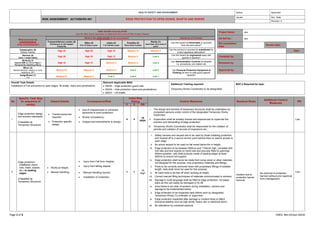

Project Name: xxx RA Ref No.: xxx RA compilation Date: Review date: Date: Compiled by: Reviewed by: Approved by: Overall Task Details Installation of Fall prevention to open edges, lift shafts, risers and penetrations; Relevant Applicable MAS: • 00235 – Edge protection guard rails • 00234 – Hole protection risers and penetrations; • 00233 – Lift shafts; Additional Training required: Temporary Works Coordinator to be designated NOC’s Required for task: RISK SCORE CALCULATOR Use the Risk Score Calculator to Determine the Level of Risk of each Hazard What would be the CONSEQUENCE of an occurrence be? What is the LIKELIHOOD of an occurrence? Hierarchy of Controls Frequent/Almost certain (5) Continuous or will happen frequently Often (4) 6 to 12 times a year Likely (3) 1 to 5 times a year Possible (2) Once every 5 years Rarely (1) Less than once every 5 years Can the hazard be Eliminated or removed from the work place? Catastrophic (5) Multiple Fatalities High 25 High 20 High 15 Medium 10 Medium 5 Can the product or process be substituted for a less hazardous alternative? Serious (4) Class 1 single fatality High 20 High 16 High 12 Medium 8 Low 4 Can the hazard be engineered away with guards or barriers? Moderate (3) Class2 (AWI or LTI) or Class 1 Permanently disabling effects High 15 High 12 Medium 9 Medium 6 Low 3 Can Administration Controls be adopted I.e. procedures, job rotation etc. Minor (2) Medical attention needed, no work restrictions. MTI Medium10 Medium 8 Medium 6 Low 4 Low 2 Can Personal Protective Equipment & Clothing be worn to safe guard against hazards? Insignificant (1) FAI Medium10 Medium 4 Low 3 Low 2 Low 1 No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR P S RR 1 Edge protection design and erection standards (Classified as Temporary Structure) • Trained personnel required; • Protection specific design; • Use of unsupervised or untrained personnel to erect protection; • Worker competency; • Unapproved amendments to design; 4 4 16 HIGH i. The design and erection of temporary structures shall be undertaken by competent persons under control of the designated Temporary Works Supervisor; ii. Supervision shall be suitably trained and experienced to supervise the erection and dismantling of edge protection; iii. Temporary Works Coordinator shall be responsible for the collation of permits and collation of records of inspections etc.; Low 2 Edge protection installation (hand rails, mesh, boards etc.) to leading edges (Classified as Temporary Structure) • Works at Height; • Manual Handling; • Injury from Fall from Heights; • Injury from falling objects; • Manual Handling injuries; • Installation of protection; 4 4 16 High i. Safety harness and lanyard are to be used by those installing protection and hooked off to a secure anchor point behind them to restrict access to open edge; ii.

Recommended

Recommended

More Related Content

Similar to 28 Edge protection to open edges, shafts and risers Risk Assessment Templates.docx

Similar to 28 Edge protection to open edges, shafts and risers Risk Assessment Templates.docx (20)

More from Dwarika Bhushan Sharma

More from Dwarika Bhushan Sharma (20)

Recently uploaded

Recently uploaded (20)

28 Edge protection to open edges, shafts and risers Risk Assessment Templates.docx

- 1. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 EDGE PROTECTION TO OPEN EDGES, SHAFTS AND RISERS Issued: Rev. Date: Revision: 0 Page 1 of 3 HSEQ -Rev-01(Jan-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR P S RR 1 Edge protection design and erection standards (Classified as Temporary Structure) Trained personnel required; Protection specific design; Use of unsupervised or untrained personnel to erect protection; Worker competency; Unapproved amendments to design; 4 4 16 HIGH i. The design and erection of temporary structures shall be undertaken by competent persons under control of the designated Temporary Works Supervisor; ii. Supervision shall be suitably trained and experienced to supervise the erection and dismantling of edge protection; iii. Temporary Works Coordinator shall be responsible for the collation of permits and collation of records of inspections etc.; Low 2 Edge protection installation (hand rails, mesh, boards etc.) to leading edges (Classified as Temporary Structure) Works at Height; Manual Handling; Injury from Fall from Heights; Injury from falling objects; Manual Handling injuries; Installation of protection; 4 4 16 High i. Safety harness and lanyard are to be used by those installing protection and hooked off to a secure anchor point behind them to restrict access to open edge; ii. No shock lanyard to be used on fall arrest below 6m in height; iii. Edge protection to be between 900mm and 1150mm high, complete with mid rails and kick boards on hand rails and securely fitted to openings. Where possible, rails shall protrude inside of leading edges at least 500mm to ensure full support; iv. Edge protection shall never be made from scrap wood or other materials not designed for the purpose, only proprietary materials and fittings; v. Posts to be correctly anchored down with proprietary fittings of suitable length, nails shall never be used for this purpose; vi. All hand tools to be tied off when working at height; vii. Correct manual lifting techniques of materials communicated to workers; viii. Signage in multi-language shall be fitted to edge protection, not paper signs as this can easily be damaged or fly off; ix. Area below to be clear of workers during installation, barriers and signage to be implemented below; x. Edge protection to be inspected daily before work by designated Temporary Works Co-ordinator or supervisor; xi. Edge protection inspected after damage or incident likely to affect structural stability such as high winds, heavy rain or electrical storm; xii. No alterations by untrained persons; Incident due to protection barrier removal No removal of protection barriers without prior approval from management. Low Project Name: xxx RA Ref No.: xxx RA compilation Date: Review date: Date: Compiled by: Reviewed by: Approved by: Overall Task Details Installation of Fall prevention to open edges, lift shafts, risers and penetrations; Relevant Applicable MAS: 00235 – Edge protection guard rails 00234 – Hole protection risers and penetrations; 00233 – Lift shafts; Additional Training required: Temporary Works Coordinator to be designated NOC’s Required for task: RISK SCORE CALCULATOR Use the Risk Score Calculator to Determine the Level of Risk of each Hazard What would be the CONSEQUENCE of an occurrence be? What is the LIKELIHOOD of an occurrence? Hierarchy of Controls Frequent/Almost certain (5) Continuous or will happen frequently Often (4) 6 to 12 times a year Likely (3) 1 to 5 times a year Possible (2) Once every 5 years Rarely (1) Less than once every 5 years Can the hazard be Eliminated or removed from the work place? Catastrophic (5) Multiple Fatalities High 25 High 20 High 15 Medium 10 Medium 5 Can the product or process be substituted for a less hazardous alternative? Serious (4) Class 1 single fatality High 20 High 16 High 12 Medium 8 Low 4 Can the hazard be engineered away with guards or barriers? Moderate (3) Class2 (AWI or LTI) or Class 1 Permanently disabling effects High 15 High 12 Medium 9 Medium 6 Low 3 Can Administration Controls be adopted I.e. procedures, job rotation etc. Minor (2) Medical attention needed, no work restrictions. MTI Medium10 Medium 8 Medium 6 Low 4 Low 2 Can Personal Protective Equipment & Clothing be worn to safe guard against hazards? Insignificant (1) FAI Medium10 Medium 4 Low 3 Low 2 Low 1

- 2. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 EDGE PROTECTION TO OPEN EDGES, SHAFTS AND RISERS Issued: Rev. Date: Revision: 0 Page 2 of 3 HSEQ -Rev-01(Jan-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR P S RR 3 Hole protection installation (hand rails, mesh, boards etc.) to risers and penetrations (Classified as Temporary Structure) Works at Height; Injury from Fall from Heights; Injury from falling objects; Working over other trades; Manual Handling injuries; Installation of protection; 4 4 16 HIGH As section 2, including; i. One trade MUST NOT work above another in a riser; ii. Working in a riser must be controlled by a permit system; iii. No lone working. There must be a minimum of two (2) persons; iv. Risers with a parapet or blockwork wall enclosed permanent solution in the design should be sequenced as early as possible to eliminate the need for temporary protection; v. Protective measures for openings shall only be removed when work is actually taking place in or around the opening; vi. Suitable alternative fall protection shall be provided during the installation, removal or work around removed covers; vii. Contractors working in the shaft will be responsible for maintaining the integrity of temporary edge protection; viii. Mandatory warning signs must be prominently displayed. Incident due to protection barrier removal No removal of protection barriers without prior approval from management. Low 4 Hole protection installation (hand rails, mesh, boards etc.) to lift shafts (Classified as Temporary Structure) Works at Height; Injury from Fall from Heights; Injury from falling objects; Working over other trades; Manual Handling injuries; Installation of protection; 4 4 16 HIGH As section 3, including: i. Lift shaft openings must be securely closed from floor level to ensure that no person or materials can fall into it; ii. The enclosure shall be tamper proof and will be installed upon striking of the formwork /completion of the shaft walls at each floor level; iii. There must be a permit system for removal and all works to be undertaken inside the shaft must be controlled under a permit to work system; iv. Lighting must be installed at every opening level; v. The lift shaft must have adequate signage identifying the lift shaft area and inherent dangers; vi. Where necessary, protection systems must be installed from fully boarded working platforms prior to installation of the lift car; vii. One trade MUST NOT work above another in a shaft and there must be a minimum of two (2) persons in a work group viii. Protective measures for all openings shall only be removed when work is actually taking place in and around the opening and effective safety measures are employed to prevent falls of those working on them; ix. During the installation of the lift equipment, the temporary protection is to remain in place until the permanent doors are installed and secured; Incident due to protection barrier removal No removal of protection barriers without prior approval from management. Low 5 Dismantling of edge protection Works at Height; Manual Handling; Worker competency; Injury from Fall from Heights; Injury from falling objects; Manual Handling injuries; Use of unsupervised or untrained personnel; 4 4 16 High i. A dismantling permit shall be produced before dismantling is undertaken, to ensure safe removal; ii. The edge protection shall be systematically removed and undertaken by competent persons wearing safety harness and lanyard as required; Workers not adhering to procedure; Supervision to constantly monitor workers; Low 6 Maintenance of edge protection Adverse weather; Edge protection erected for long periods; Damage due to incident or adverse weather; Incident due to removal of protection barriers; Unapproved amendments to design; 3 3 9 Med i. Edge protection shall checked after heavy rains, severe winds etc., for damage; ii. Implemented warning signage maintained; iii. All amendments authorized by Temporary Works Coordinator; Edge protection damaged by weather or collision Quarantine area until design checks undertaken and reviewed by TWC Low

- 3. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 EDGE PROTECTION TO OPEN EDGES, SHAFTS AND RISERS Issued: Rev. Date: Revision: 0 Page 3 of 3 HSEQ -Rev-01(Jan-2023)