Dnyanesh Bangale's Professional Profile

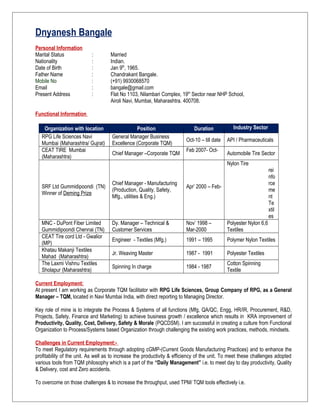

- 1. Dnyanesh Bangale Personal Information Marital Status : Married Nationality : Indian. Date of Birth : Jan 9th , 1965. Father Name : Chandrakant Bangale. Mobile No : (+91) 9930068570 Email : bangale@gmail.com Present Address : Flat No 1103, Nilambari Complex, 19th Sector near NHP School, Airoli Navi, Mumbai, Maharashtra. 400708. Functional Information Organization with location Position Duration Industry Sector RPG Life Sciences Navi Mumbai (Maharashtra/ Gujrat) General Manager Business Excellence (Corporate TQM) Oct-10 – till date API / Pharmaceuticals CEAT TIRE Mumbai (Maharashtra) Chief Manager –Corporate TQM Feb 2007- Oct- Automobile Tire Sector SRF Ltd Gummidipoondi (TN) Winner of Deming Prize Chief Manager - Manufacturing (Production, Quality, Safety, Mfg., utilities & Eng.) Apr’ 2000 – Feb- Nylon Tire rei nfo rce me nt Te xtil es MNC - DuPont Fiber Limited Gummidipoondi Chennai (TN) Dy. Manager – Technical & Customer Services Nov’ 1998 – Mar-2000 Polyester Nylon 6,6 Textiles CEAT Tire cord Ltd - Gwalior (MP) Engineer - Textiles (Mfg.) 1991 – 1995 Polymer Nylon Textiles Khatau Makanji Textiles Mahad (Maharashtra) Jr. Weaving Master 1987 - 1991 Polyester Textiles The Laxmi Vishnu Textiles Sholapur (Maharashtra) Spinning In charge 1984 - 1987 Cotton Spinning Textile Current Employment: At present I am working as Corporate TQM facilitator with RPG Life Sciences, Group Company of RPG, as a General Manager – TQM, located in Navi Mumbai India, with direct reporting to Managing Director. Key role of mine is to integrate the Process & Systems of all functions (Mfg, QA/QC, Engg, HR/IR, Procurement, R&D, Projects, Safety, Finance and Marketing) to achieve business growth / excellence which results in KRA improvement of Productivity, Quality, Cost, Delivery, Safety & Morale (PQCDSM). I am successful in creating a culture from Functional Organization to Process/Systems based Organization through challenging the existing work practices, methods, mindsets. Challenges in Current Employment:- To meet Regulatory requirements through adopting cGMP-(Current Goods Manufacturing Practices) and to enhance the profitability of the unit. As well as to increase the productivity & efficiency of the unit. To meet these challenges adopted various tools from TQM philosophy which is a part of the “Daily Management” i.e. to meet day to day productivity, Quality & Delivery, cost and Zero accidents. To overcome on those challenges & to increase the throughput, used TPM/ TQM tools effectively i.e.

- 2. • Productivity Improvement :- o Autonomous Maintenance- Operator based maintenance to increase the production efficiency o Planned Maintenance – Special maintenance by Engg to improve the MTBF (Mean Time Between Failure) & MTTR (Mean time to Repair) i.e. efficiency in the engineering function. o Increased in operational efficiency through lean management an effective tool from TQM • Quality Improvement :- o Effective execution of ICH Q8 & Q9 Guidelines i.e. Implemented various projects under Statistical process control to “meet Quality Beat Cost” o 24 X 7 Auditable plant through “Plant 5-S - A basic discipline for housekeeping” • Cost Improvement :- o Value Stream mapping (VSM) - Improve bottom line by eliminating through lean i.e. eliminate Non Value Adding Activities. ) etc. • Safety Improvement o Complete Visual plant on safety front with special safety orientation gallery for every new comer • Morale Improvement :- o People involvement across the organization through “Kaizen” i.e. Big results through small improvement, o Initiation of Quality Circles for improvement at shop floor through worker involvement o And Cross functional involvement at officer level for breakthrough results. MY CONTRIBUTION & LEARNING’S FROM PAST EMPLOYEEMENT: CEAT LIMITED – MUMBAI • CEAT Limited, multi locational (India & Srilanka) vehicle Tire manufacturing company in auto ancillary field who manufacturing and catering varieties of tire worldwide through distribution network. • I was leader with direct reporting to MD for creating cohesiveness in all functions towards company’s bottom line. • To ensure the transformation of functional culture to TQM culture. My Value addition in CEAT Tire was creating customer centric culture through converting customer’s voice, (requirements, needs,) in processes & systems. This results in many visible changes in short span of time in PQCDSM (Productivity, Quality, Cost, Delivery, Safety & employee Morale) which was appreciated & believed by the customer & management. SRF LIMITED formerly known as DUPONT India Limited Gummidipoondi • A key driver for getting “Deming Prize to SRF limited in 2004, “First Deming Prize Winning Company for Nylon reinforcement solution provider to Tire Industry” at Gummidipoondi. It was helped in systemizing the processes & practices for its effectivity & efficiency in Manufacturing including Quality, Safety, and Engineering & Customer services. DUPONT India Limited Gummidipoondi • During DuPont time, I established technology to convert delicate fiber of 840/2 in tire cord at DuPont-China. As well as completed flawless Transfer of “Tire cord technology” from Japan. • Being a ULT Member (Unit Leadership Member), I was responsible & accountable for Entire Manufacturing consist of Production, Quality, Engineering (Elect, Mech., & utility) and Safety to deliver following KRA’s • Executing “Policy Deployment” through Annual planning cycle which interns in to the budget. • Special Cost Reduction & Quality Improvement programs for unit • Creation of TQM culture in Mfg. area i.e. Quality, Safety, Productivity and Maintenance & Utility. Through “5-S, KAIZEN, Quality circles (for workmen involvement), Problem Solving Process (for senior management), Autonomous Maintenance, Planned Maintenance, Value Stream Mapping (VSM), Customer Red Book, etc. • Creating Manufacturing floor without Supervisor. • Vendor development under quality management. • Could established a slogan of Shop Floor to Top Floor.

- 3. Few Achievement during DuPont & SRF LTD As a part of achievement, manufacturing unit under my leadership was appreciated by various senior authorities (CEO & MD) from DuPont and SRF with various awards. This indicate the measurement of Leadership success. • Achievement on Manufacturing (Quality, Production, Safety, & maintenance) front • Received “Deming quality award in 2004” for company & being a leader, major role was played by me • Received ISO 9001:2000 award from UL USA who certified company under my role as a MR. •Developed “Skill Block development” / Multiskilling for easy JOB ROTATION for workmen in all function •Few concepts initiated Mfg. like HPWS (high Performance work system) i.e. “No supervisor in department” in manufacturing. •Visual work place through 5-S, recognized by reputed organizations (CII, ABK AOTS Japan etc). • Achievements on Maintenance Front: • “ZERO” Breaks downs in utility (13 KT Plant capacity) i.e. Cooling Tower, Chillers, Air Compressors, Water treatment system, & Effluent treatment system to Fire Fighting system. • Various improvement projects for cost saving e.g. like local development of vendor etc. • Implementation AM & PM under TPM resulted easy & visual standards, procedures, checklists, & protocols.. • Initiated internal training program for all team members to ensure the smooth operation of the plant. • Developed the Matrixes for utility & maintenance, appreciated by External ISO auditors. • Ceat Ltd - Tire Cord Division (Taken over by SRF in 1995) Ltd. Gwalior • Worked from green project to Plant Operation by developing & Implementing systems for Nylon Tyre Cord Fabric for capacity of 6500 MT/Annum. • Responsible for production planning & as a coordinator with materials department for procurement of production accessories. • Was responsible for Installation, commissioning & start up having imported twisters (KAZI Make TO#3 Cablers) & Weaving M/C’s (Howa Hirano of Japan). Learning’s from Textile industry ( Khatau Mills & Laxmi Vishnu Textiles) • Understanding on green field projects, importance of planning & its execution • Was trained in both divisions of Textiles (i.e. spinning & weaving) as an initial exposure to the business. • Training importance from operational, functional & quality point of view. Languages Known • Mother Tong - Marathi • Others Regional - Hindi, Tamil (Understood) • Foreign - English, Educational Background • DTM :- Diploma In Textile Manufacturing. Passed in 1984 from Board of Technical form Mumbai with a rank. • DBM :- Diploma in Business Management. Passed in 1986 from Shivaji University Kolhapur with rank. • E-Commerce: - Done E-Com at TATA InfoTech. This course is for Internet & Web designing Technology, with Java, Advance Java & Java Script, OOP’s, Front Page, Multimedia, JSP etc. Additional Professional Qualifications: • Certified Lean Six Sigma Black Belt from Asian Institute of Quality, Pune, accredited by UK • Certified TPM (Total Productive Maintenance) Facilitator from JIPM - TPM Club of India • Certified TQM Facilitators in India (INFT) by AOTS Japan and TQM Facilitator by TQMI Delhi India • Certified SQC Trainer from TQMI India & N-7 QC tools i.e. advance quality tools from AOTS Japan • Certified 5-S Practitioner from the 5-S Institute Mumbai

- 4. • Certified CII Exim Bank Award assessor by CII institute of Quality Bangalore. • Certified Business Excellence Examiner from Ramkrishna Bajaj National Quality Award Mumbai. • Certified in Business Communication & Presentation Skill from IGE -USA • Certified Lead Auditor in ISO-9000:2000 & ISO-14000 (EMS) Norms by QCFI & TQMI • Specialized in developing “Skill Matrix” for workmen for multiskilling in the shop floor from DuPont. • Special hands-on TQM training from N. Ramnathan, TQM guru for India. My Contribution through TQM @ National Level • Conducting various training program on Quality Management at CII forum & world manufacturing conferences • Conducting Business Excellence assessment for Industry based on EFQM model & Malcom Baldrige model • Conducted various BE Assessment in RPG group companies as well as in industry through CII, RBNQA- Ramakrishna Bajaj National Quality Award, in various industry sectors like JSW- Steel, Ambuja Cement, Alliance Infrastructure, Harrison Malyalam -Tea & Rubber estate, Raychem and KEC international -Power transmission tower etc. • Member of CII Judge’s Panel for Kaizen at state & Region level • Member of ASQ Asian Society for Quality. Conducted ASQ conference in IIT Mumbai Hobbies & Interest • Playing a Musical Instrument “TABALA”. • Reading Books • Interested in Indoor Games. • Working & New Learning with Computers Salary Expectation Negotiable Dnyanesh Bangale Wednesday, June 29, 2016