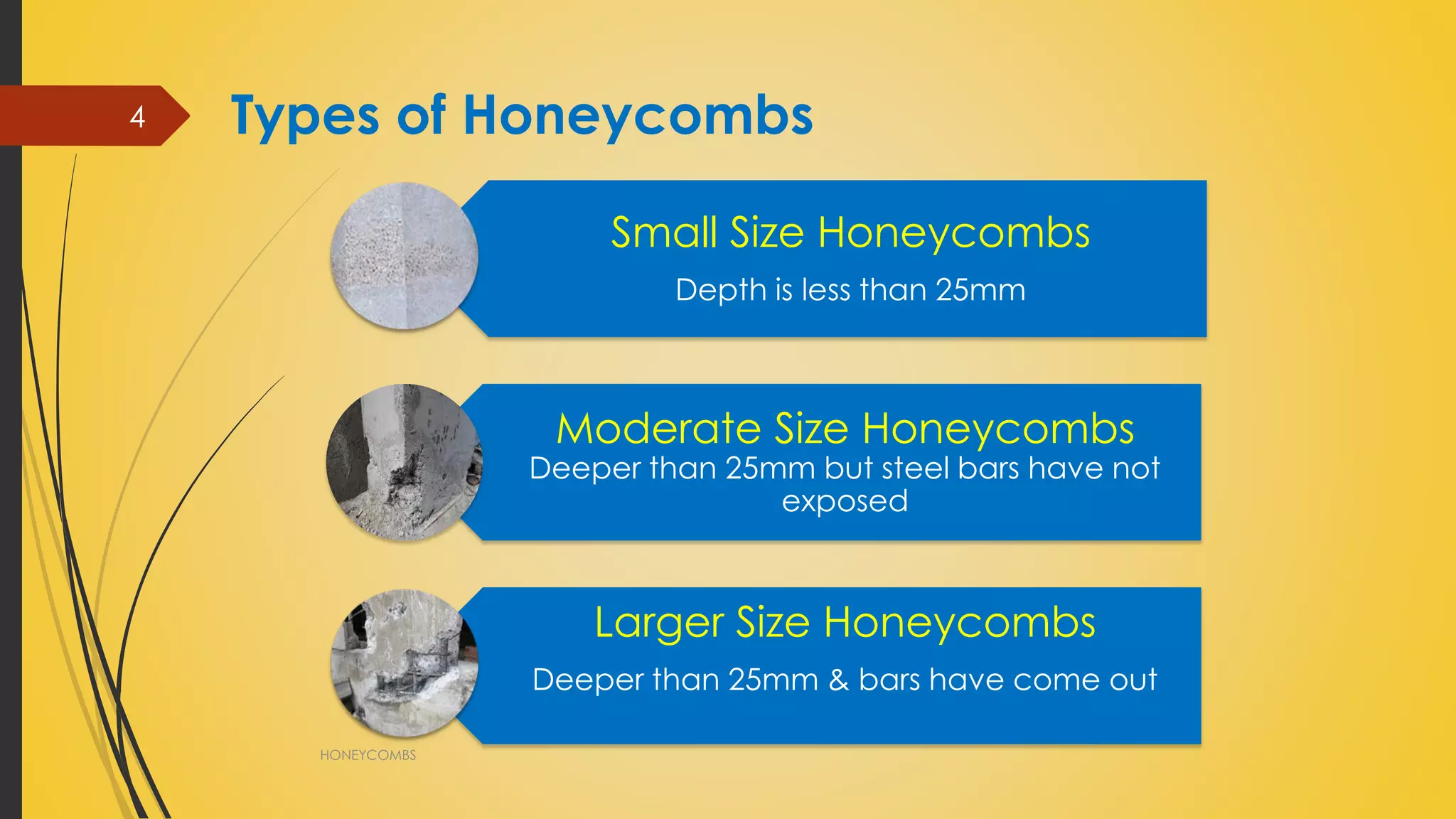

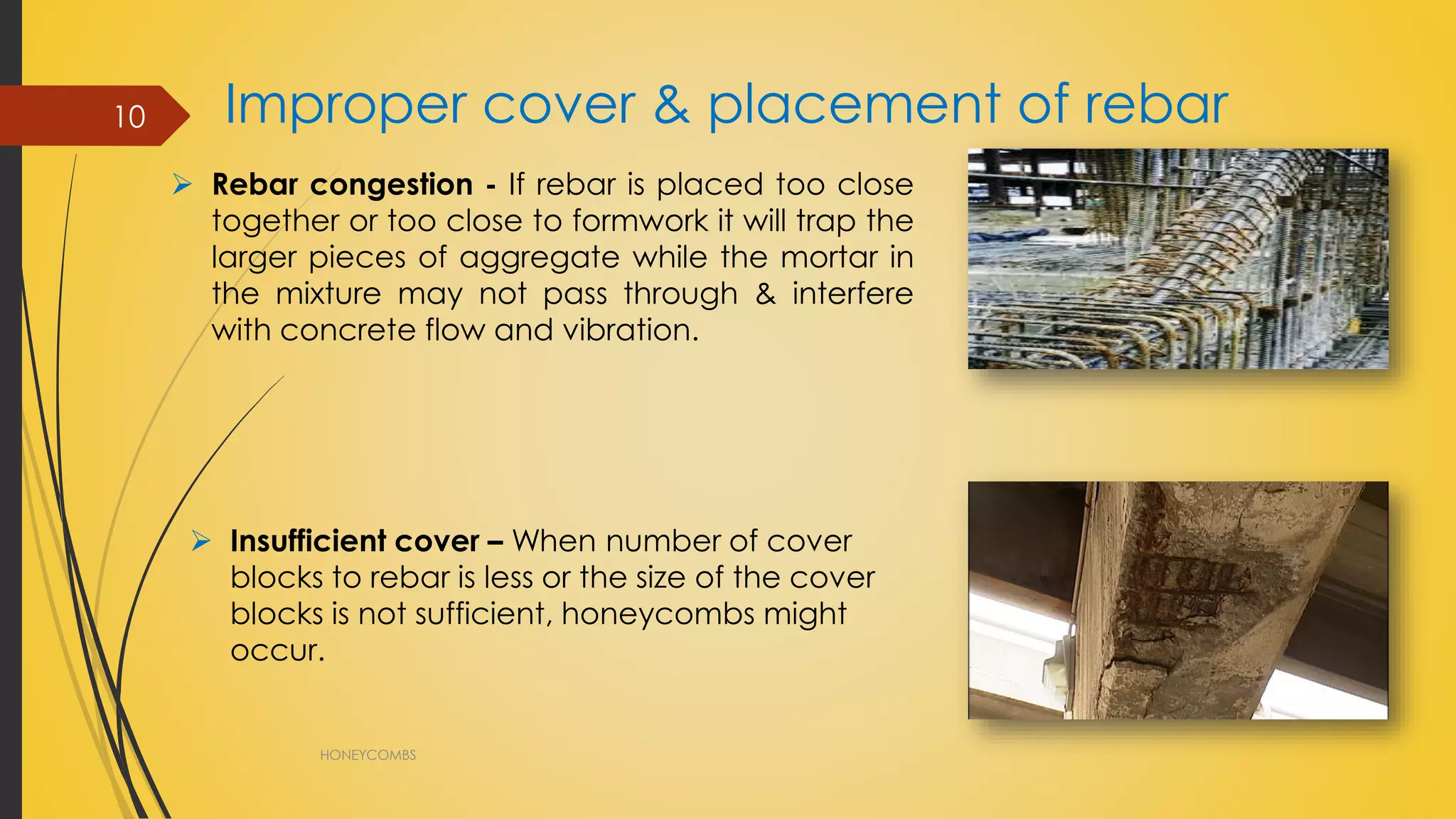

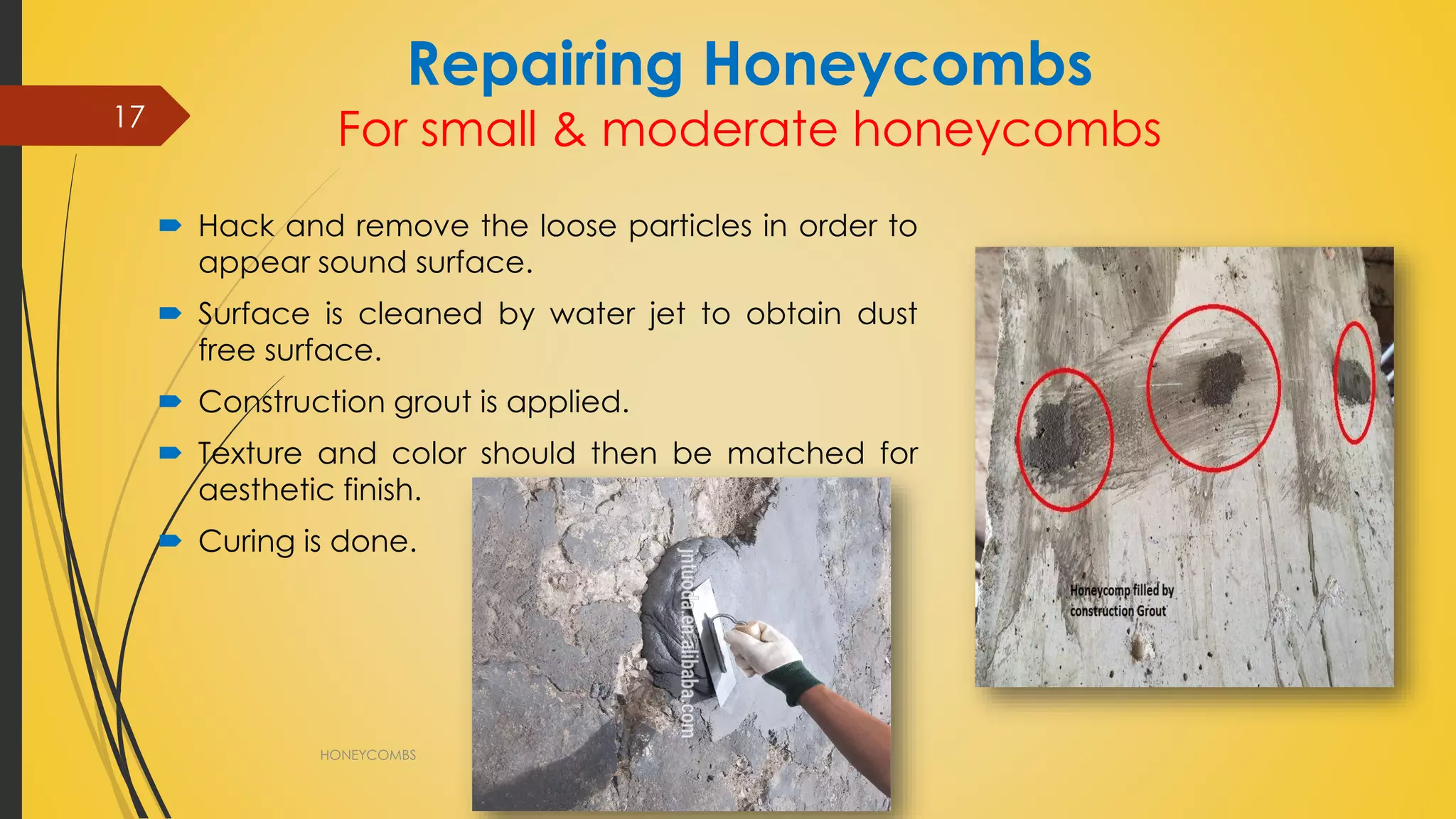

Honeycombs are hollow spaces in concrete caused when mortar fails to fill spaces between coarse aggregate. There are three types: small (<25mm deep), moderate (25-50mm deep), and large (>50mm deep exposing rebar). Honeycombs reduce durability and strength. They are caused by poor workability, improper compaction, rebar congestion, leaky formwork, and poor aggregate grading. To prevent honeycombs, proper mix design, placement, compaction, formwork, and cover are needed. Small and moderate honeycombs can be repaired by removing loose material, cleaning, applying grout, and curing. Large honeycombs require removing concrete to sound material and applying mort