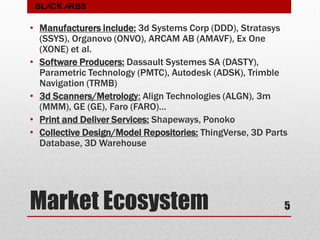

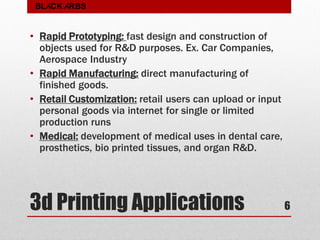

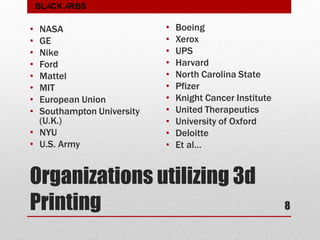

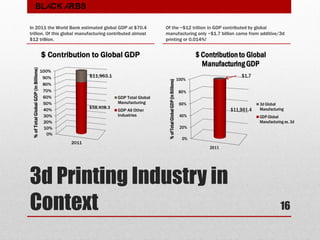

This document provides an overview of the 3D printing industry. It discusses the various 3D printing methods like stereolithography, fused deposition modeling, and selective laser sintering. It also outlines the market size, key players, and industries utilizing 3D printing. The 3D printing industry is still small relative to global manufacturing but is expected to grow significantly in the coming years as applications expand in areas like healthcare, consumer products, and industrial design.