Manufacturing Processes 40

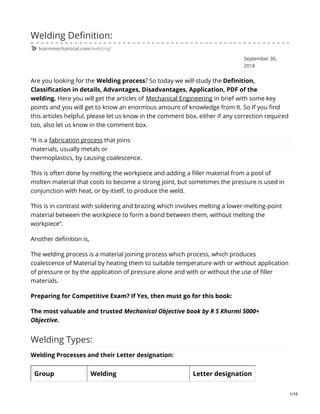

- 1. September 30, 2018 Welding Definition: learnmechanical.com/welding/ Are you looking for the Welding process? So today we will study the Definition, Classification in details, Advantages, Disadvantages, Application, PDF of the welding. Here you will get the articles of Mechanical Engineering in brief with some key points and you will get to know an enormous amount of knowledge from It. So If you find this articles helpful, please let us know in the comment box, either if any correction required too, also let us know in the comment box. “It is a fabrication process that joins materials, usually metals or thermoplastics, by causing coalescence. This is often done by melting the workpiece and adding a filler material from a pool of molten material that cools to become a strong joint, but sometimes the pressure is used in conjunction with heat, or by itself, to produce the weld. This is in contrast with soldering and brazing which involves melting a lower-melting-point material between the workpiece to form a bond between them, without melting the workpiece”. Another definition is, The welding process is a material joining process which process, which produces coalescence of Material by heating them to suitable temperature with or without application of pressure or by the application of pressure alone and with or without the use of filler materials. Preparing for Competitive Exam? If Yes, then must go for this book: The most valuable and trusted Mechanical Objective book by R S Khurmi 5000+ Objective. Welding Types: Welding Processes and their Letter designation: Group Welding Letter designation 1/15

- 2. Arc Carbon Arc Flux-cored Arc Gas Metal-Arc Gas Tungsten Arc Plasma Arc Shielded Metal Arc Stub Arc Submerged Arc Atomic hydrogen CAW FCAW GMAW GTAW PAW SMAW SW SAW AHW Oxyfuel Gas Oxyacetylene Oxyhydrogen Pressure gas OAW OHW PGW Resistance Flash High-frequency Resistance Percussion Projection Resistance-seam Resistance-spot Upset welding FW HFRW PEW RPW PEW RESW UW Solid-state and Cold Diffusion Explosion Forge Friction Hot pressure Roll Ultrasonic CW DFW EXW FOW FRW HPW ROW USW Another process Electron Beam Electroslag Induction Laser beam and Thermit welding EBW ESW IW LBW TW 2/15

- 3. The above table represents the classification of welding. I know there are a few types of welding you might not hear about it but don’t worry I will explain only those welding process which you have to study in details. If you want all the welding process in details just comment down I will provide you the link. So let’s start, Arc welding: The process in which used to join metal to metal by using electricity to create enough heat to melt metal, and the melted metals when the cool result in a binding of the metals. Or This is one of several fusion processes for joining metals. By applying intense heat, metal at the joint between two parts is melted and caused to intermix directly, or more commonly, with an intermediate molten filler metal. Upon cooling and solidification, a metallurgical bond is created. Since the joining is an intermixture of metals the final weldment potentially has the same strength properties as the metals of the parts. A problem that arises in arc welding is contamination of the metal with elements in the atmosphere (O, H, N, etc). There can also be a problem with the surface that is not clean. The solution to this Includes, Gas shields: An inert gas is blown into the weld zone to drive away other atmospheric gases. Flux: A material that is added to clean the surface this may also give off a gas to drive away unwanted gases. 3/15

- 4. Let’s understand by a circuit diagram: An AC or DC power sources, fitted with whatever controls may be needed, is connected by work cable to the workpiece and by an electrode cable to electrode holder of some type, which makes electrical contact with the welding electrode. An arc is created across the gap when the energized circuit and the electrode tip touches the workpiece and is withdrawn yet still within close contact. The arc produces a temperature of about 6500-degree centigrade at the tip. This heat melts both the base metal and the electrode producing a pool of molten metal sometimes called a creator. The creator solidifies behind the electrode as it is moved along the joint. This result is a fusion bond. Advantages: The process gives high deposition rates. Welding speed is high. Wire consumption is low. The consumption of electrical energy is low, as a maximum of 97 % of heat energy can be utilized. Any length can be welded without any interruption. 4/15

- 5. High-quality Welds are achieved with no fusion defects, no porosity and slag inclusions. Disadvantages: Arc is invisible, it can be controlled only by measuring arc voltage and current. It can be used only in the down hand welding position. Preparing for Competitive Exam? If Yes, then must go for this book: The most valuable and trusted Mechanical Objective book by R S Khurmi 5000+ Objective. Plasma Arc Welding: Plasma arc welding is a liquid state welding process in which, the metal to metal joint forms in a molten state. The hot ionized gases are known as Plasma. These hot ionized gases used to heat the work plates, and the joint is created due to fusion. Main Parts or component: 1. Filler Material 2. Power Supply 3. Plasma Console 4. Water re-circulator 5. Plasma Welding Torch 6. Torch Accessory Kit (Tips, ceramics, collets, electrodes set-up gages) Filler Material: In Plasma arc welding there is no filler material is used. If the filler material is used, then it is directly fed into the weld zone. Power Supply: PAW process needed a high power DC supply to generate the electric spark in between the tungsten electrode and welding plates. This welding can weld at low 2 amp and maximum current which it can handle is about 300 amp. It needs about 80volts for proper working. The power source consists of a transformer, rectifier and control console. Plasma torch: 5/15

- 6. This is the most important part of the PAW(Plasma Arc Welding) process. This torch is quite similar as used in TIG welding. PAW torches are water-cooled because the arc is contained inside the torch which produces high heat, so a water jacket is provided outside the torch. Working Diagram: In Plasma arc welding (PAW) is an arc welding process, a concentrated plasma arc is produced and directed towards the weld area. The arc is stable and reaches temperatures as high as 33,000°C. A plasma is an ionized very hot gas composed of nearly the same numbers of electrons and ions. The plasma starts between the tungsten electrode and the orifice by a low current pilot arc. What makes plasma-arc welding unlike other processes is that the plasma arc is concentrated because it is forced through a relatively small orifice. Operating currents usually are less than 100 A. When filler metal is used it is fed into the arc as is done in Gas Tungsten-arc Welding. Arc and weld-zone shielding are supplied by means of an outer shielding ring and the use of inert gases like argon, helium or mixtures. Advantages / Merits: 1. Torch design allows better control of the arc. 2. This method provides more freedom to observe and control the weld. 3. The higher the heat concentration and plasma jet allow faster travel speeds. 4. The high temperature and high heat concentration of plasma allow keyhole effect. 5. This provides complete penetration with single-pass welding of many joints. 6. Heat affected zone is smaller compared to GTAW(Gas tungsten arc welding). 7. It uses less current input as compared to another welding process. Disadvantages / Demerits: It produces wider welds and heat-affected zones compare to LBW and EBW. Plasma welding equipment is very costly. Hence it will have a higher startup cost. It requires training and specialization to perform plasma welding. It produces ultraviolet and infrared radiation. 6/15

- 7. The method produces higher noise on the order of about 100dB. The torch is bulky and hence manual welding is a bit difficult and requires training as mentioned. Application / Uses: This welding is used in marine and aerospace industries. This is used to weld pipes and tubes of stainless steel or titanium. It is mostly used in electronic industries. Also, this is used to repair tools, die, and mold. This is used for welding or coating on a turbine blade. Preparing for Competitive Exam? If Yes, then must go for this book: The most valuable and trusted Mechanical Objective book by R S Khurmi 5000+ Objective. Gas welding: Gas welding is a type of liquid state welding process, in which fuel gases burns to generate heat. This heat is used to melt interface surfaces of welding plates which are held together to form a joint. In this welding process, mostly oxy-acetylene gas is used as working fuel gas. This process can be done with or without the help of filler material. Main component or Equipment: Cylinders: Oxygen and acetylene are stored under pressure in a steel cylinder. They are seized by the amount of oxygen or acetylene that they hold. Cylinders should always be secured and used in the upright position. When a cylinder is not being used the valve cap should always be in place. Oxygen cylinders: 7/15

- 8. These cylinders are made of steel and are usually painted green. They contain compressed oxygen at presses that can be as high as 2200 PSI. All cylinders have valves and are fitted with a screw on steel cap that protects the cylinder valve when the cylinder is not in use. Acetylene cylinders: These cylinders contain acetylene under pressure are painted black made of steel and have cylinder valves. The cylinders contain a porous filler material which is fitted with acetone that allows the acetylene to be safely be contained in the cylinder at 250 PSI. Acetylene should never be used at a pressure that exceeds 15 PSI as it becomes highly unstable which depending upon the condition could cause it to decompose and explode. Pressure regulator: Both oxygen and fuel gases are filled in the cylinder at high pressure. These gases cannot use at this high pressure for welding works, So a pressure regulator is used between the flow. It supplies oxygen at a pressure about 70 – 130 Kn/m and gas at 7 – 103 Kn/m to the welding torch. Torches: The torch assembly consists of the handle Oxygen and fuel gas valves and the mixing chamber. Welding tips or cutting attachment can be used with the handle the allowing it to be used for welding, heating and cutting operations. Oxygen and fuel gas flow through tubes inside the handle which blend in the mixing chamber or tip. it is at the tip that the mixed gas is ignited. Goggles and Gloves: These two Goggles and Gloves are used for safety purpose. Goggles protect eyes and Gloves protects the hand from radiation and flame of fire. Types of Flames: 2 2 8/15

- 9. Neutral Flame: Welding is generally carried out using the neutral flame sitting which has equal quantities of oxygen and acetylene. Oxidizing Flame: The oxidizing flame is obtained by just increasing the oxygen flow rate. Carburising or Reducing Flame: The carburizing or reducing flame is achieved by increasing acetylene flow in relation to oxygen flow. Because steel melts at a temperature of 1500 degree centigrade the mixture of Oxygen and acetylene is used as it is the only gas combination with enough heat to weld Steel. However other gases such as propane hydrogen and coal gas can be used for joining lower melting point of metals and for brazing and silver soldering. Working: As the figure shows all the equipment are set carefully and now the gas cylinder and oxygen cylinder connected to the welding torch through pressure regulators. Now the regulate pressure of gas and oxygen supplied to the torch where they properly mixed. The flame is ignited by a striker. Take care the tip of a torch is pointing downward. Now the flame is controlled through valves situated in the welding torch. The flame is set at the natural flame or carburizing flame or oxidizing flame according to the welding condition. Now the welding torch moved along the line where joint to be created. This will melt the interface part and join them permanently. 3 Types of technique in gas welding: Leftward technique: 9/15

- 10. The leftward technique is used almost exclusively and is ideally suited for welding butt, fillet, and lap joints in sheet thickness up to approximately 5 mm. Rightward technique: The rightward technique finds an application on plate thickness above 5 mm for welding in the flat and horizontal-vertical position. All positional rightward technique: The all positional rightward method is a modification of the rightward technique and is ideally suited for welding steel plate and in particular pipework where positional welding (vertical and overhead) has to be carried out. Advantages: Process is versatile Adapted too many different jobs Equipment is relative to low cost Portable Self-sufficient Independent from the availability of external energy sources. Disadvantages: Welders skill required in manipulating the torch, the flame, and the filler Rod. Flux required for most materials other than low Carbon Steel. Reactive or refractory metals are unsuited to gas welding. Slow metal joining rate. Application: For joining thin materials. For joining most ferrous and nonferrous materials. Used in automatic and aircraft industries and sheet metal fabrication. 10/15

- 11. Tungsten Inert Gas Welding: Tungsten inert gas (TIG) is a type of arc welding that makes use of a tungsten electrode that is non-consumable in order to generate a weld. The weld spot is protected from contamination by helium, argon and other inert shielding gases. With this process, there is no longer a need for filler metal that is typically used in the process of arc welding. This process makes this kind of weld highly resistant to the effects of corrosion. This welding is also known as Gas tungsten arc welding (GTAW) Working Diagram: TIG welding uses the heat generated by an electric arc struck between a non-consumable tungsten electrode and the workpiece to fuse metal in the joint area, and it produces a molten weld pool. The arc area is shrouded in an inert or reducing gas shield to protect the weld pool and the non-consumable electrode. The process may be operated autogenously, that is without filler, or filler may be added by feeding a consumable wire or rod into the established weld pool. Tungsten Inert Gas produces very high-quality welds across a wide range of materials with thicknesses up to about 8 or 10mm Application: It is particularly well suited to the sheet material. It can be used with such a large variety of metals, the process can be applied to several industries and aid in the creation and repair of many items. This form of welding is common in the aerospace, automotive, repair, and art fields. 1. Aerospace –Aircraft, and spacecraft are constructed in part by means of TIG welding. 2. Automotive –Safe and secure construction is essential in the auto industry, as is making vehicles stand the test of time. 11/15

- 12. 3. Repair –TIG may be used in a number of repair applications. From fixing a child’s toy, like a wagon or old-fashioned pedal car, to repairing aluminum tools, this welding method comes in handy. Advantages: TIG welding offers a solution for welding critical joints, and for situations where small or exceptionally precise welds are required. It can be performed with a wide variety of metals And, when done correctly, it produces a high-quality and high-purity weld compared with other joining processes, which is crucial in many applications. It can be done in both automatic and manual. Overall, it is one of the most efficient ways to join two metals. No slag is produced. TIG Welding can be done in any position. Resistance Welding: Resistance welding is one of the oldest of the electric welding process is used by industry today. The weld is made by the combination of the heat, pressure and time. All resistance welding spot welding, seam welding, projection welding, etc. are worked on the same principle of heat generation due to electric resistance. When a current passes through an electric resistance, it produces heat. This is the same principle which is used in the electric coil. The amount of heat produced depends on the resistance of the material, surface conditions, a current supplied, time duration of current supplied etc. This heat generation takes place due to the conversion of electric energy into thermal energy. The current is the same in the whole circuit. Heat is proportional to the product of resistance by the square of the current and by time. Therefor The heat generation equation is (H=I Rt).2 12/15

- 13. Where H=Heat generated in joules. I=Current in amperes. R=Resistance in omes. T=flow time of the current in seconds. The highest Heat is developed where the resistance is at its maximum, exactly where it is needed for this process. Equipment: The main requirement of the process is the low voltage and high current power supply. This is obtained by means of a step-down Transformer with a provision to have different tapping on the primary side, as required for different materials. The secondary windings are connected to the electrodes which are made of copper to reduce their electrical resistance. The time of the Electric Supply needs to be closely controlled so that the heat released is just enough to melt the joint and the subsequent fusion takes place due to the force (Forge welding) on the joint. The force required can be provided either mechanically, hydraulically or pneumatically as shown in the figure. To precisely control the time sophisticated electronic timers are available. The critical variable in the resistance welding process is the contact resistance between the two workpiece plates and their resistance themselves. The contact resistance is affected by the surface finish on the plate since the rougher surface has higher contact resistance. The contact resistance also will be affected by the cleanliness of the surface. Oxides or other contaminants if present, should be removed before attempting resistance welding. Defects: Cracks Electrode deposit on work Porosity or cavities Pinholes 13/15

- 14. The electrode indentation Improper weld penetration Advantages: Capable of a high degree of process control Capable of a high degree of mechanization Good Mechanical properties high-speed welding Easily automated Suitable for high rate production Economical Disadvantages: High equipment and tooling costs. Limitation of joint design requirements Initial equipment costs Lower tensile and fatigue strength Irregularly shaped welds Preparing for Competitive Exam? If Yes, then must go for this book: The most valuable and trusted Mechanical Objective book by R S Khurmi 5000+ Objective. Welding Advantages: 1. No problem of stress concentration 2. Strength is high 3. It has a good appearance 4. lighter 5. tight and leak proof 6. Production time is less 7. Cost of the welded joint is lower Welding Disadvantages: 1. Their capacity to damp vibrations is poor 14/15

- 15. 2. Parts manufactured by It are prone to thermal distortion due to the heat generated 3. Quality of parts manufactured depends on the skills of the operator Welding Application: 1. This welding is used in marine and aerospace industries. 2. This is used to weld pipes and tubes of stainless steel or titanium. 3. It is mostly used in electronic industries. 4. Also, this is used to repair tools, die, and mold. 5. This is used for welding or coating on a turbine blade. Welding PDF: Download PDF from Facebook or Telegram group. Join the Facebook group: Engramritkumar Facebook Connect Telegram group: Engramritkumar Telegram Join WhatsApp group: Engramritkumar WhatsApp Today we have learned about Definition, Classification in details, Advantages, Disadvantages, Application, and PDF. If I have missed something, kindly inform me through commenting. If you like this article, don’t forget to share it on social networks. Subscribe our website for more informative articles. Thanks for reading it. Thank you. 15/15