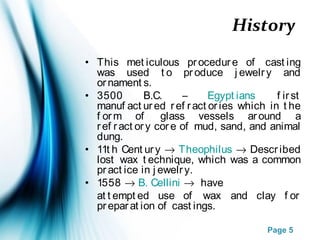

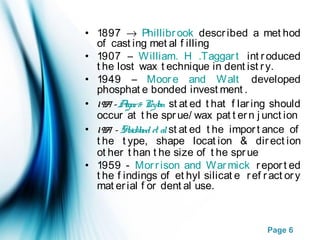

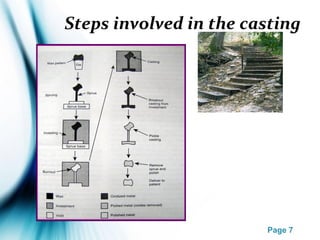

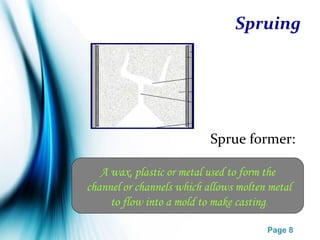

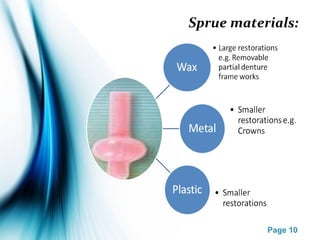

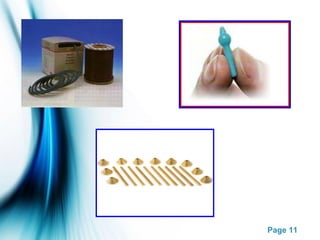

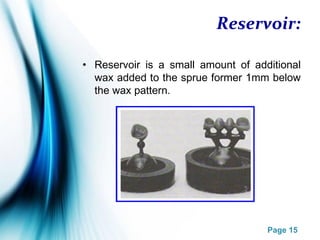

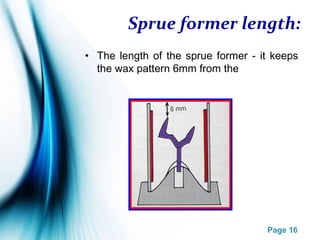

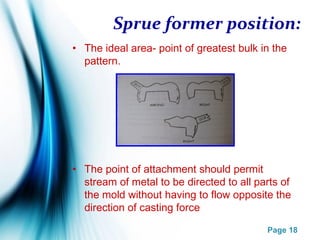

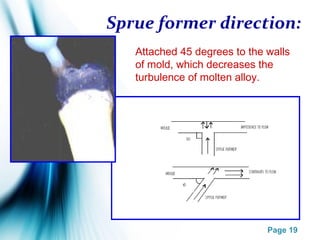

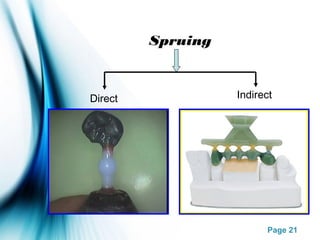

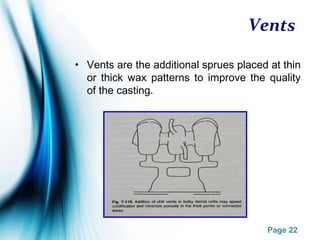

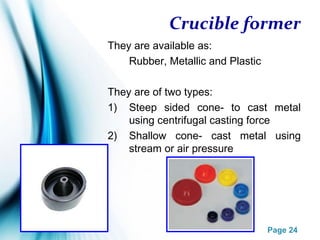

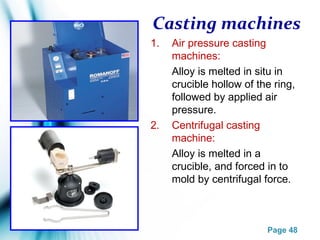

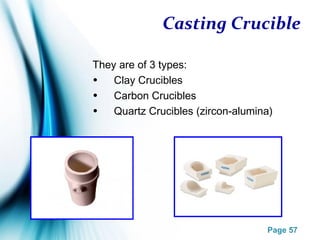

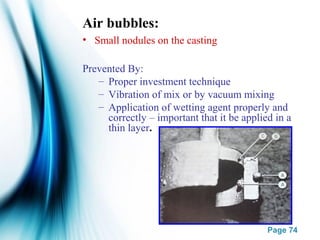

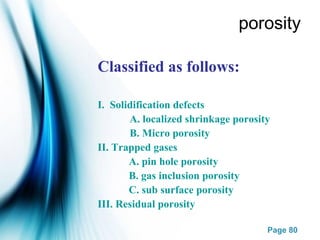

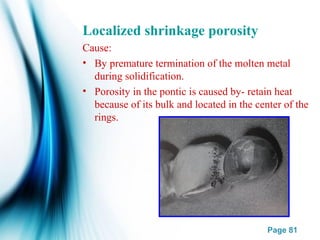

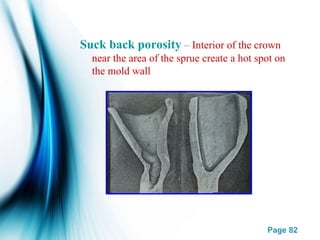

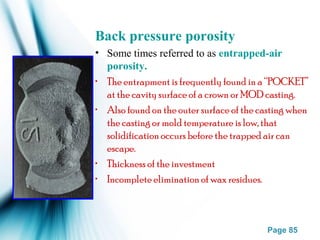

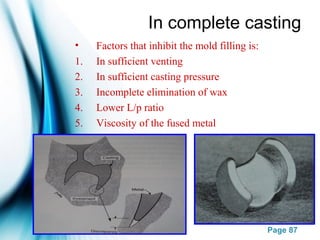

This document provides information about dental casting procedures and defects. It discusses the history of casting, outlines the main steps including spruing, investing, burnout and casting. Spruing involves attaching a sprue former made of wax, plastic or metal to direct molten metal into the mold. Investing is the process of enveloping the wax pattern with investment material. Burnout involves slowly heating the mold to eliminate wax. Casting involves melting dental alloys and directing the molten metal into the mold using various casting machines and techniques. The document also discusses potential casting defects.