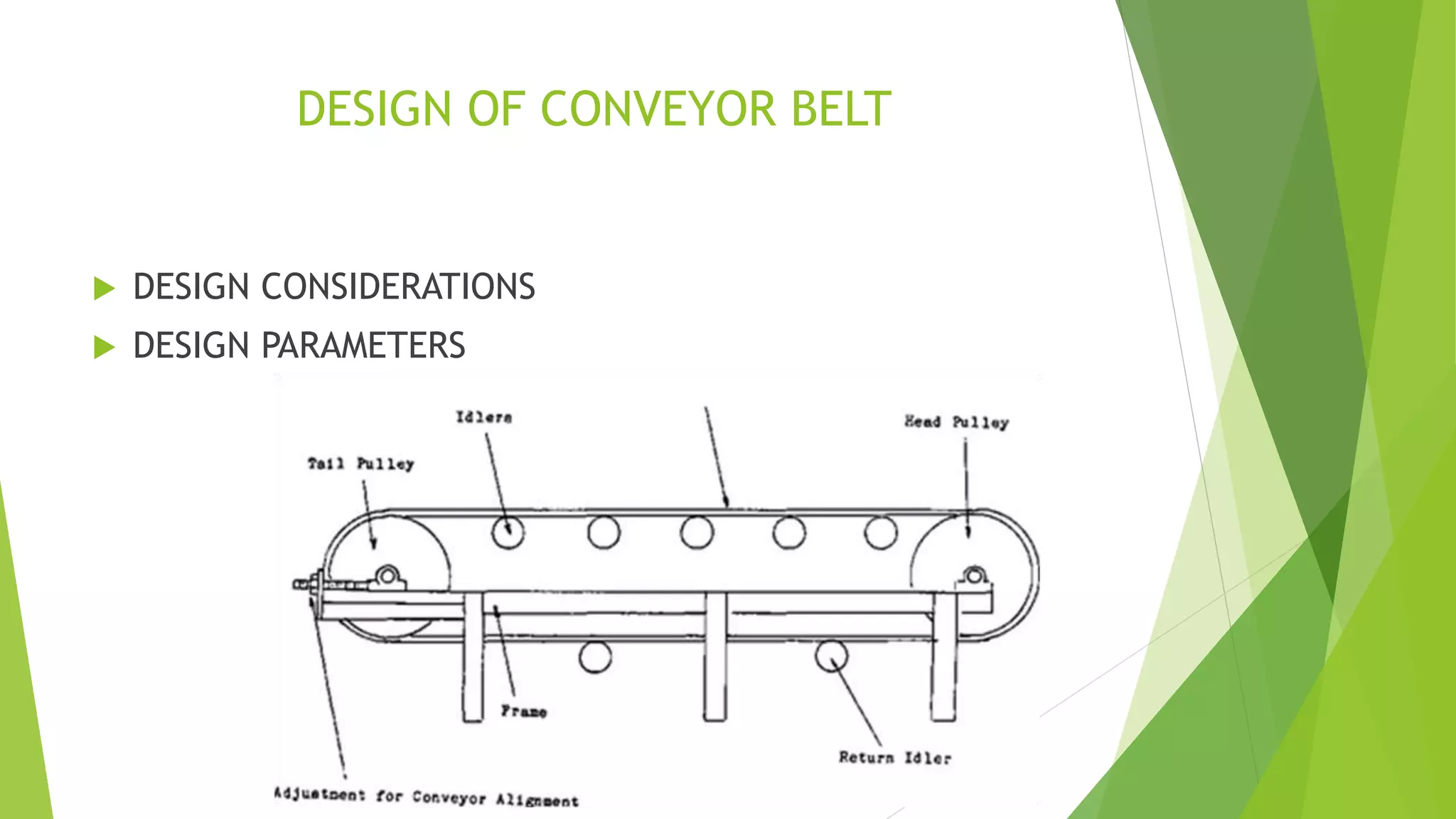

The document describes the design of a belt conveyor system. It discusses key considerations for the design such as ensuring continuous material flow, standardization, and minimizing the ratio of non-payload weight to payload weight. It also outlines important design parameters that must be determined like belt dimensions and speed, roller diameter, belt power and tension, idler spacing, pulley diameter, motor selection, shaft design, and control systems. The design aims to provide efficient transportation of materials while allowing for flexibility and automation with low costs.