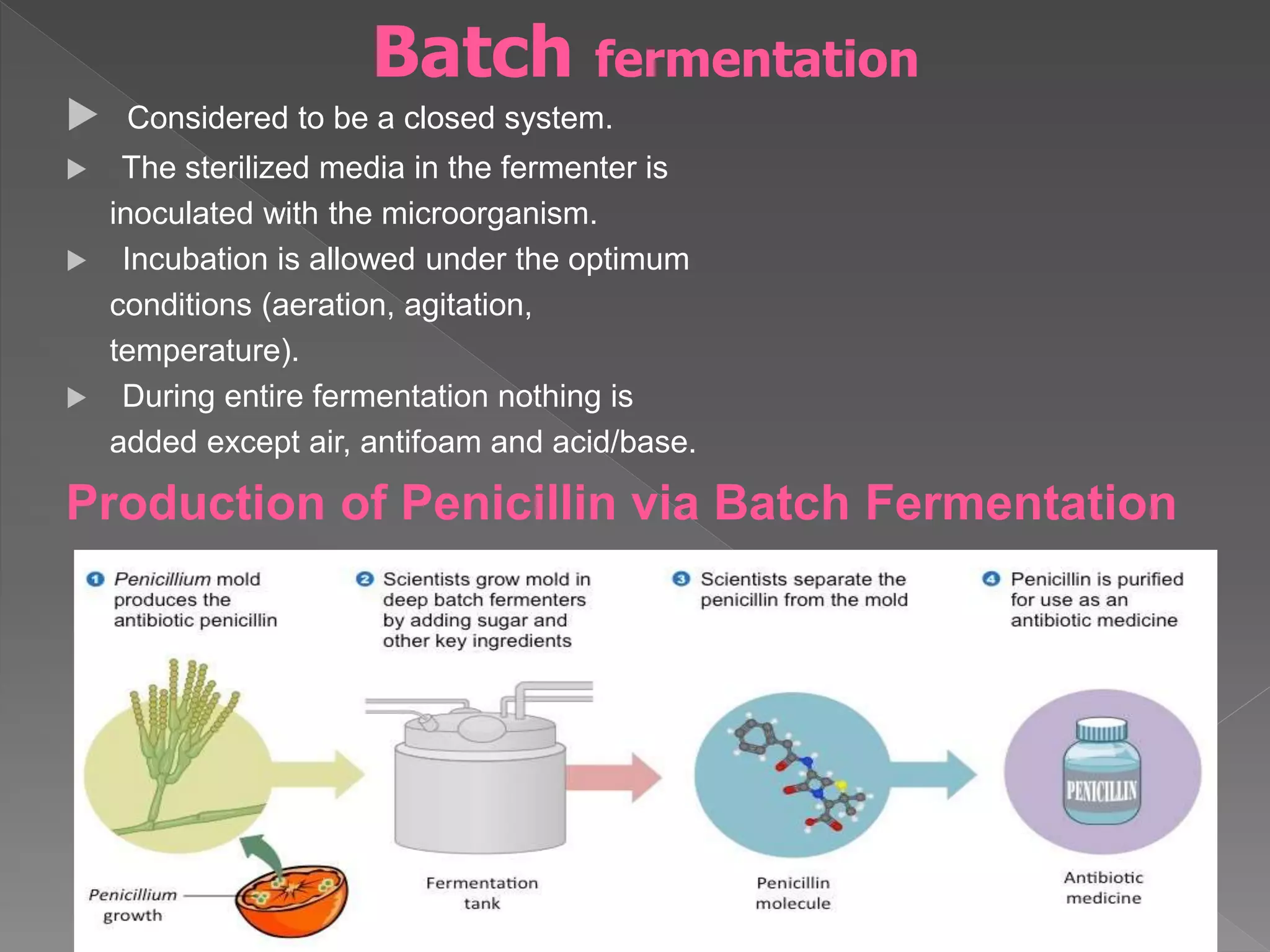

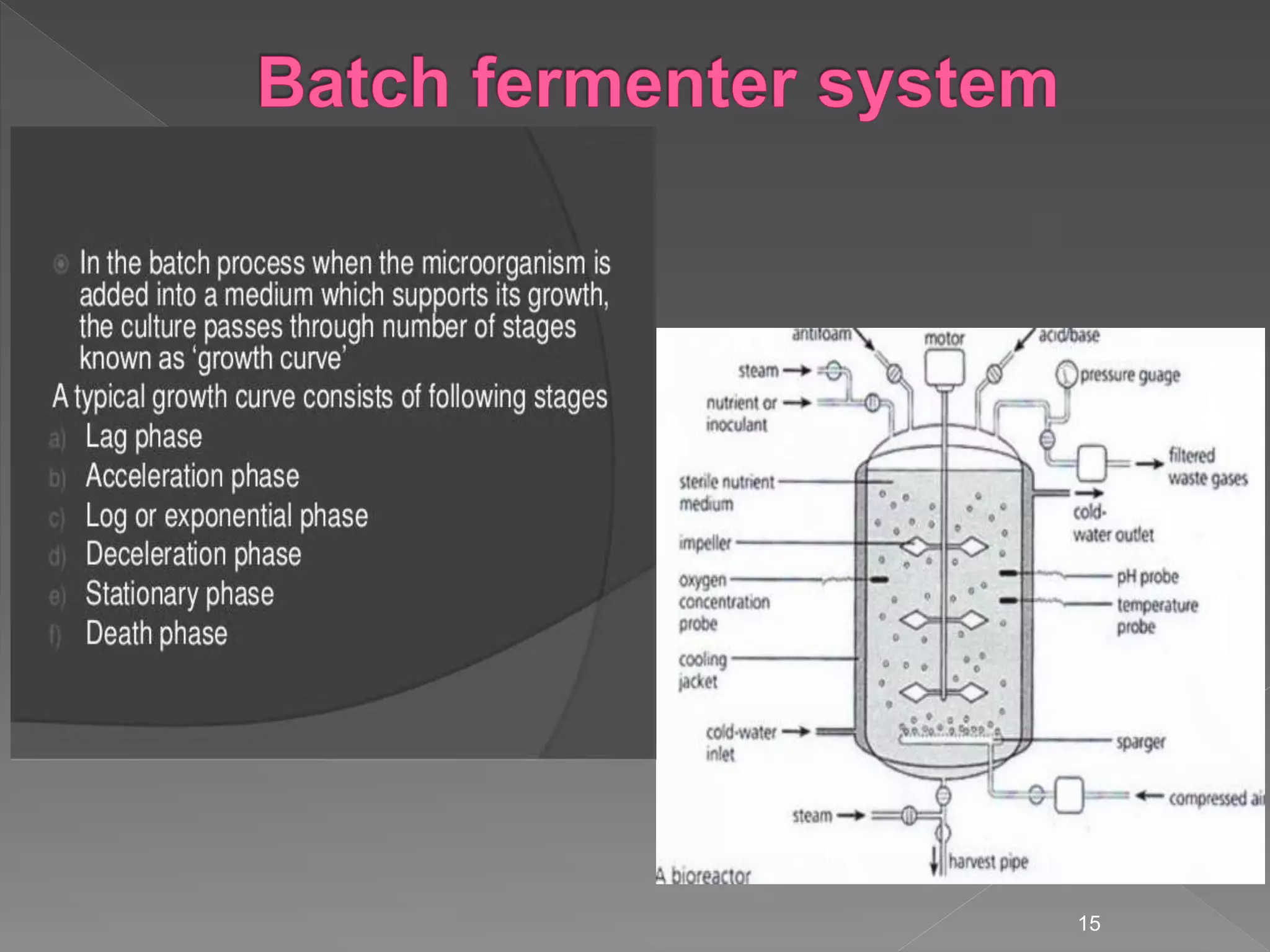

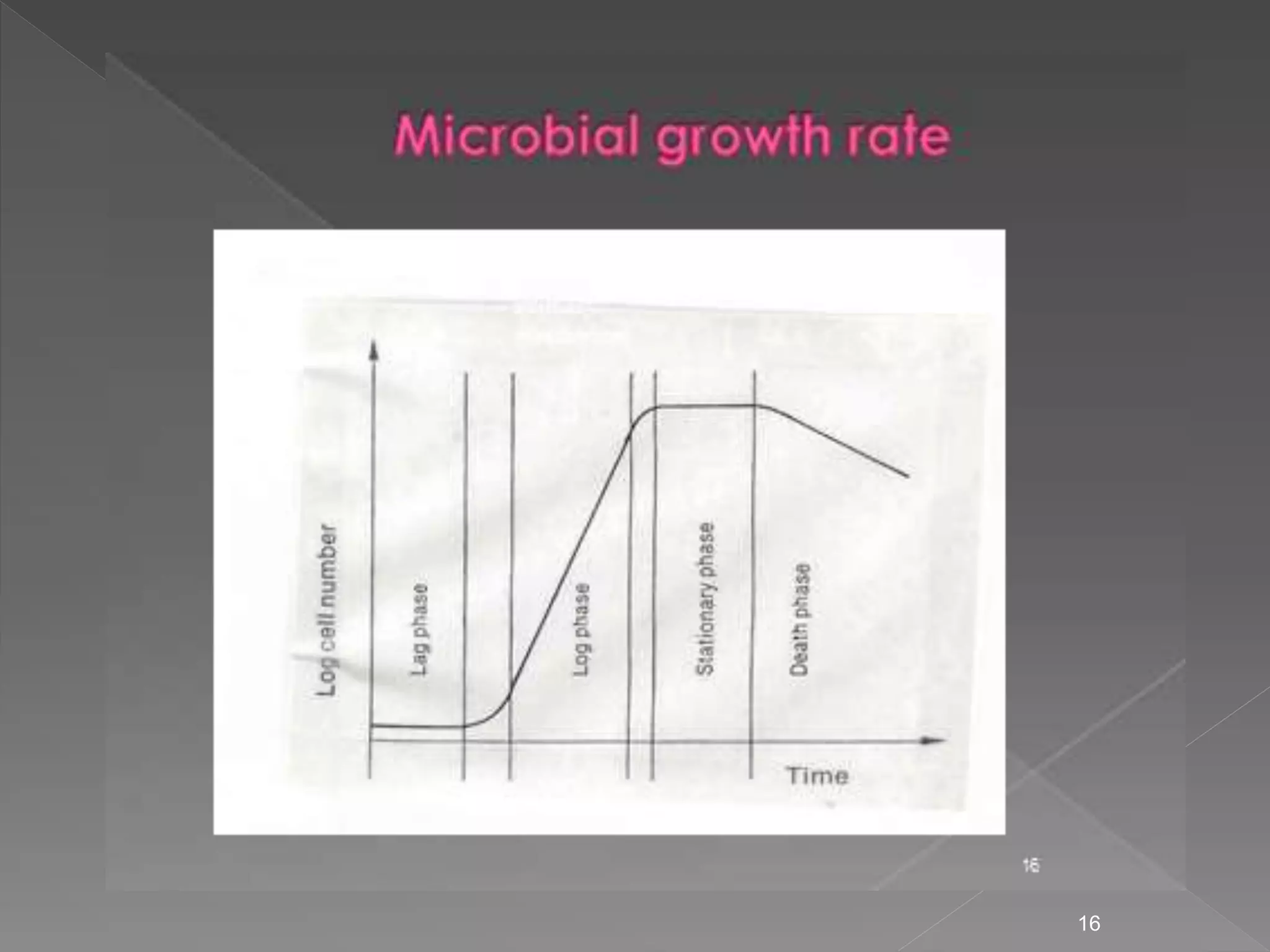

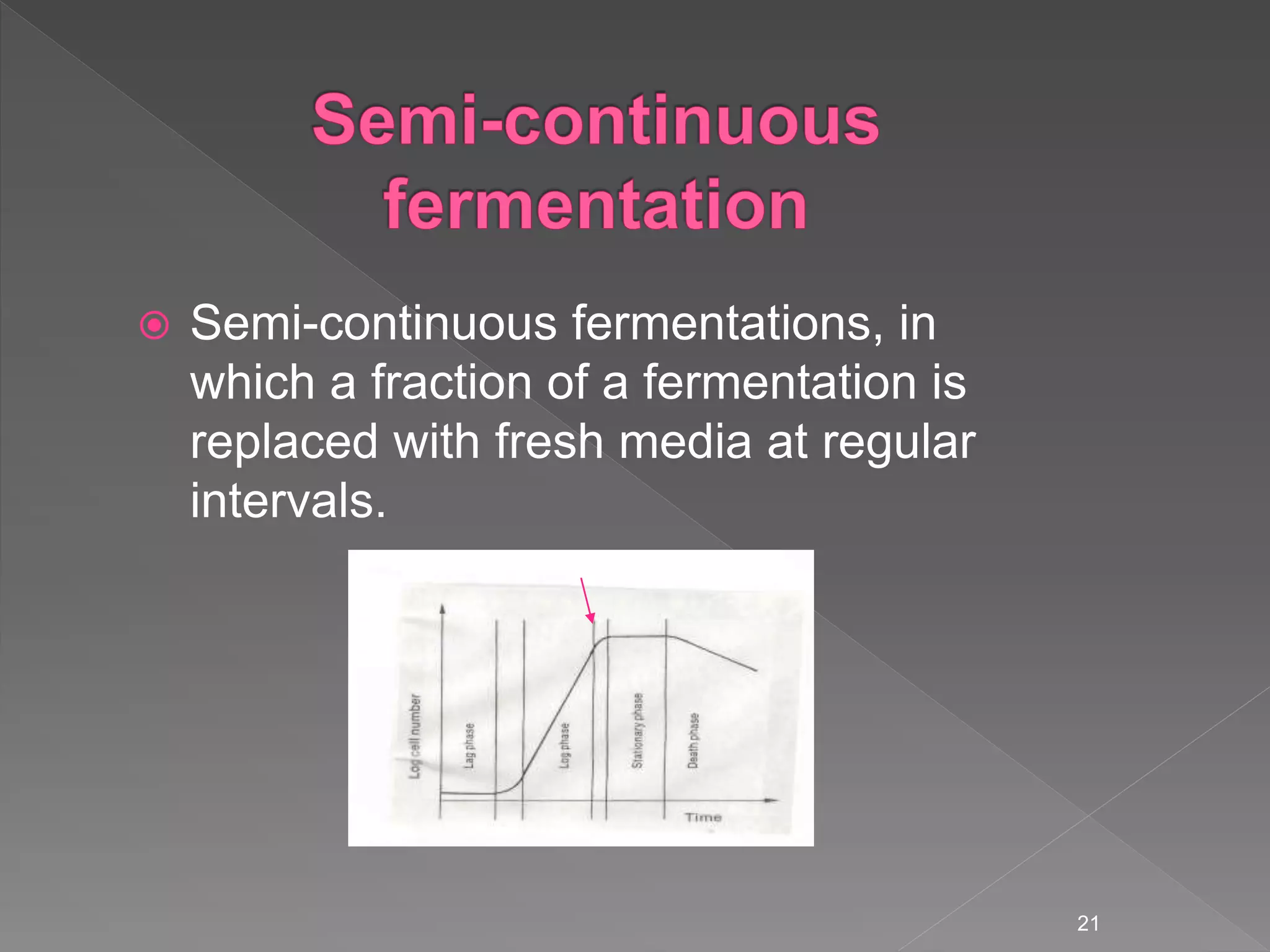

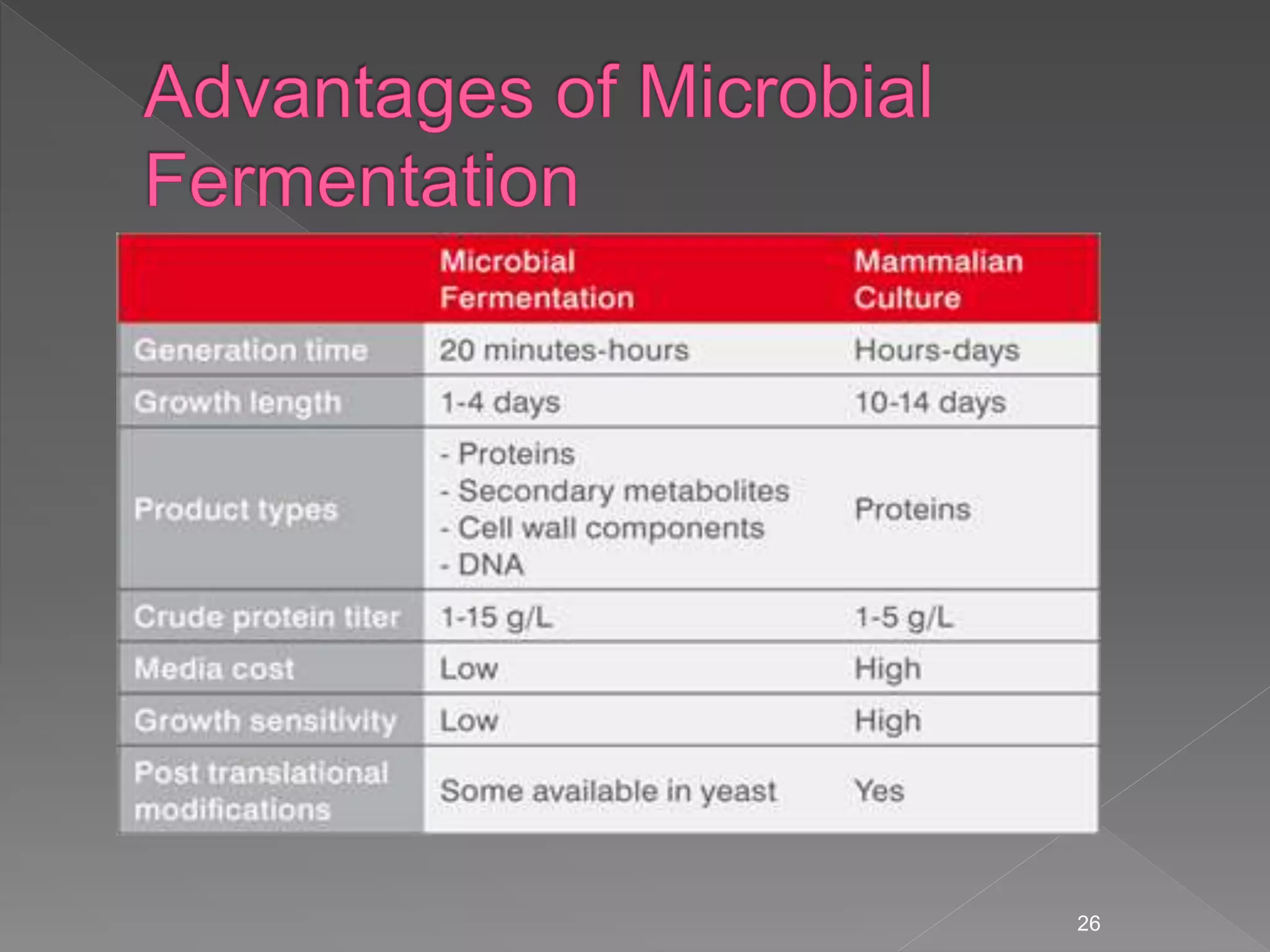

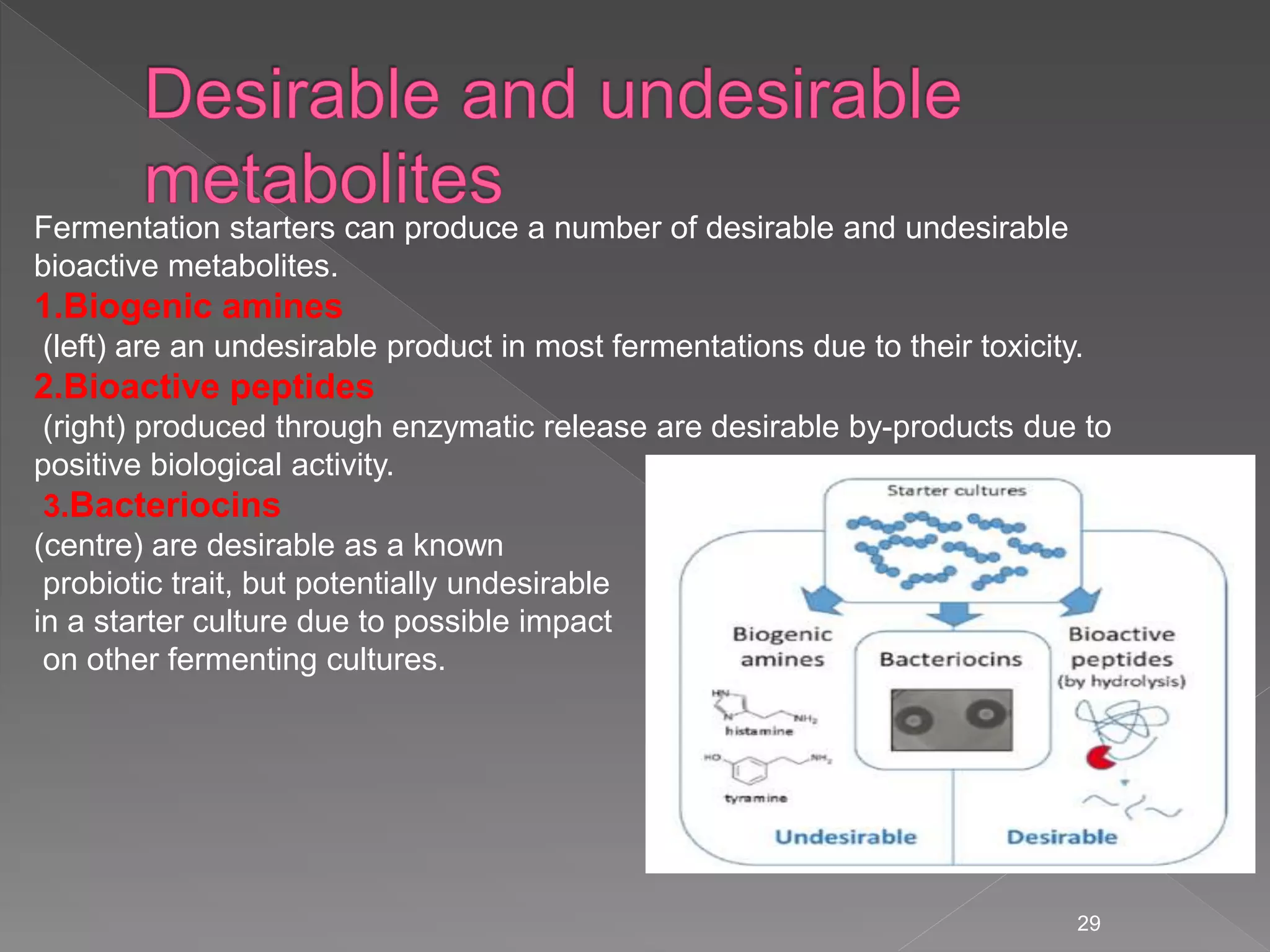

This document discusses different types of fermentation processes used in industry. It begins with an introduction and overview of fermentation media and microorganisms. It then describes the main types of fermentation processes - batch, fed-batch, and continuous fermentation - and factors that influence each type such as growth rate and flow rate. The document also covers solid state and submerged liquid fermentations. Important considerations for continuous fermentation are highlighted. Recent advances in fermentation technology are briefly mentioned at the end.