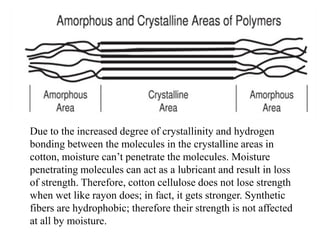

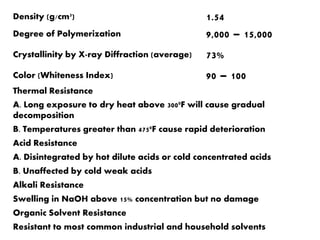

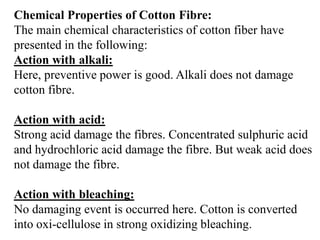

The document details the physical and chemical properties of cotton fiber, highlighting its durability, moisture retention, and comfort. Cotton fibers are absorbent, strong when wet, and can withstand various chemical treatments, but they are susceptible to sunlight and mildew. Additionally, it discusses critical metrics like tensile strength, elongation, and the impact of environmental factors on cotton's integrity.