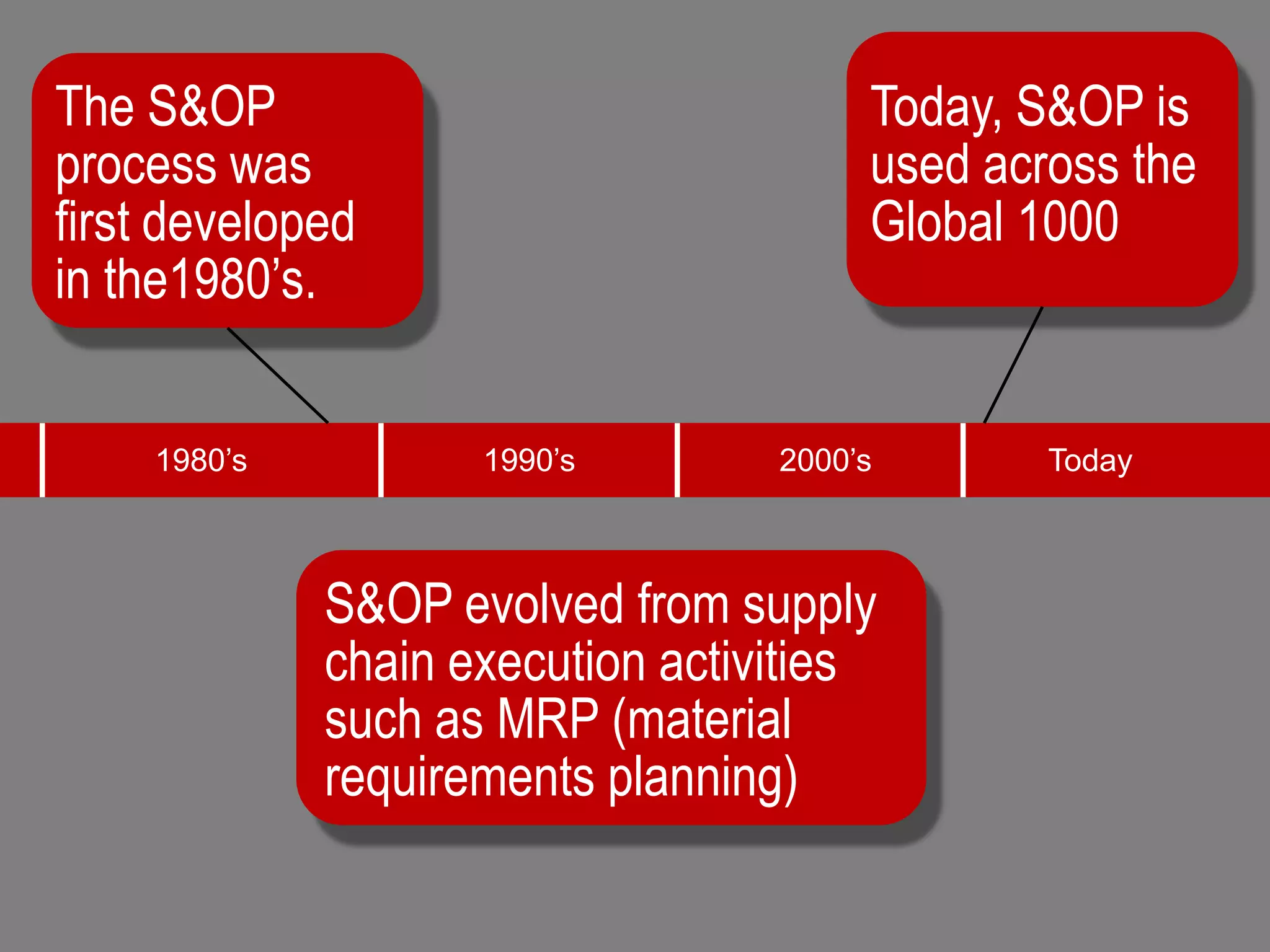

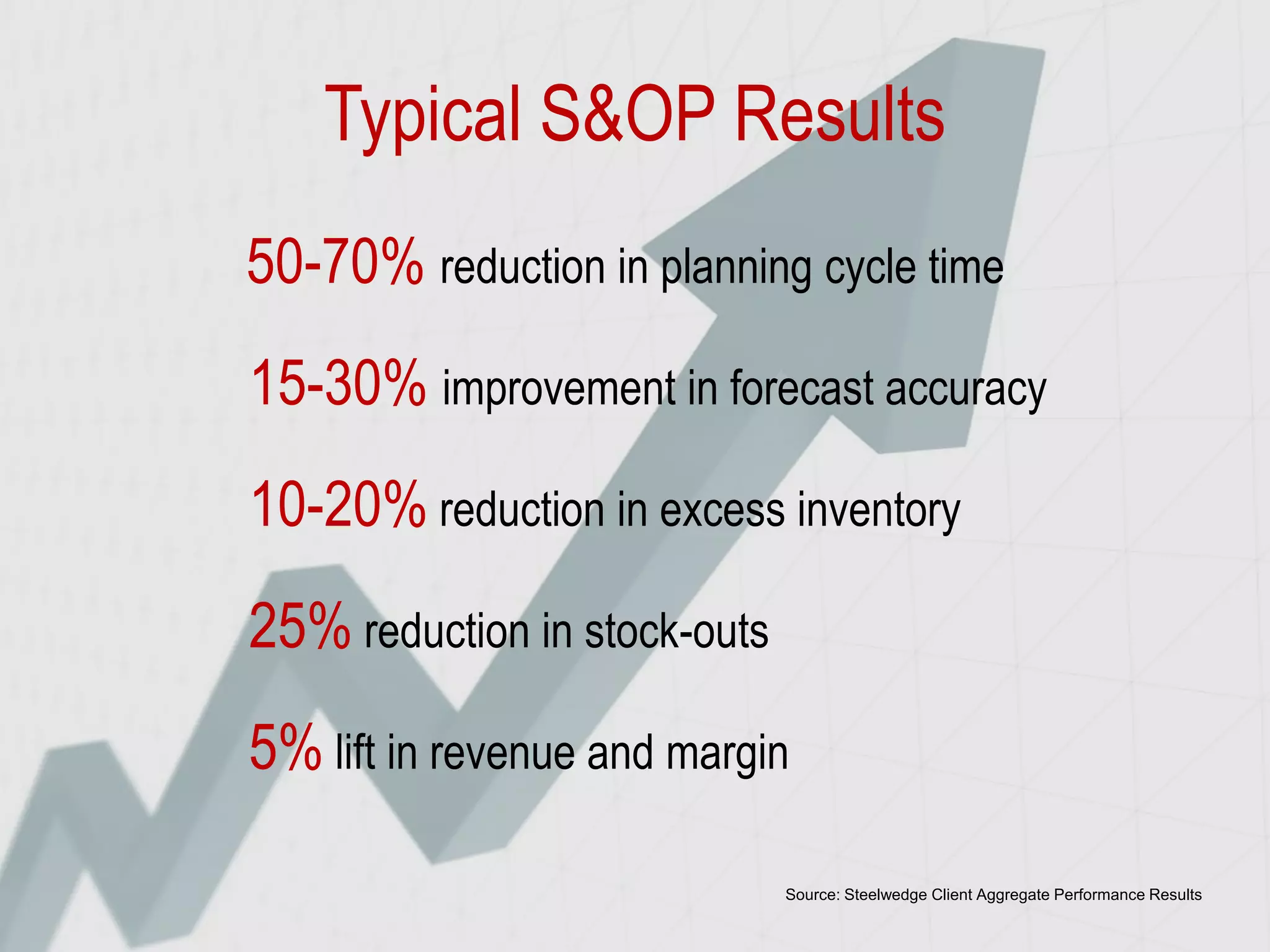

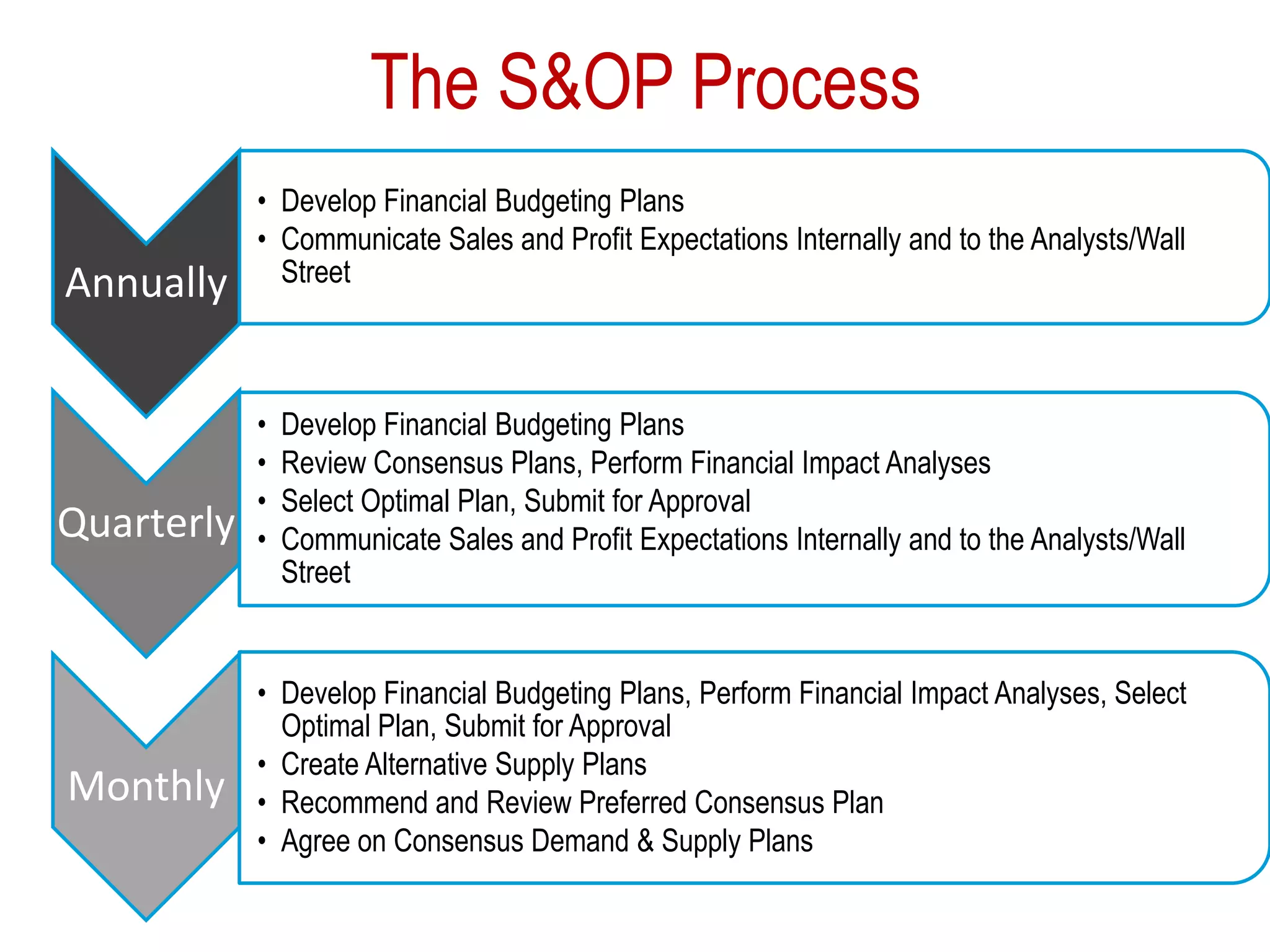

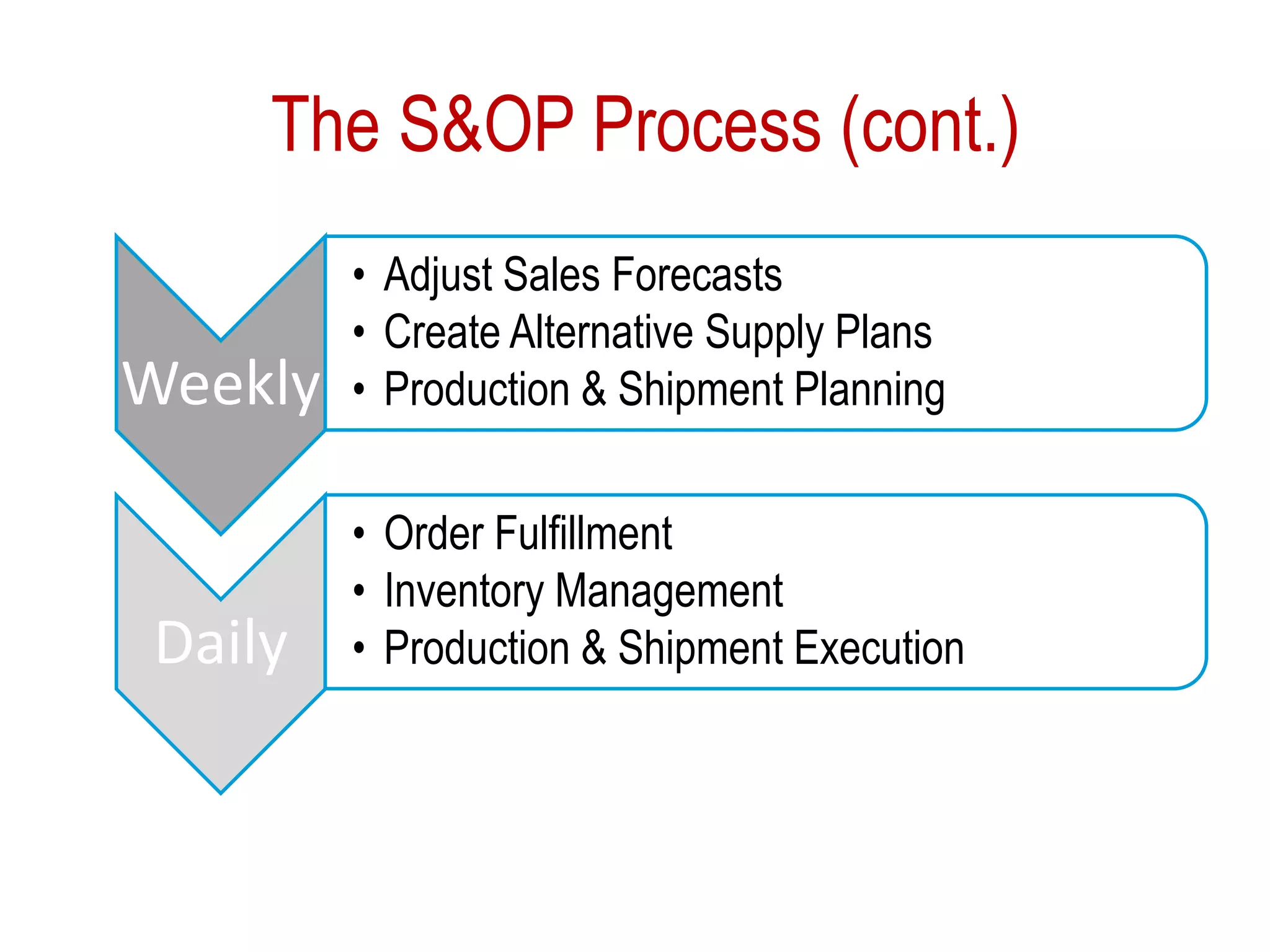

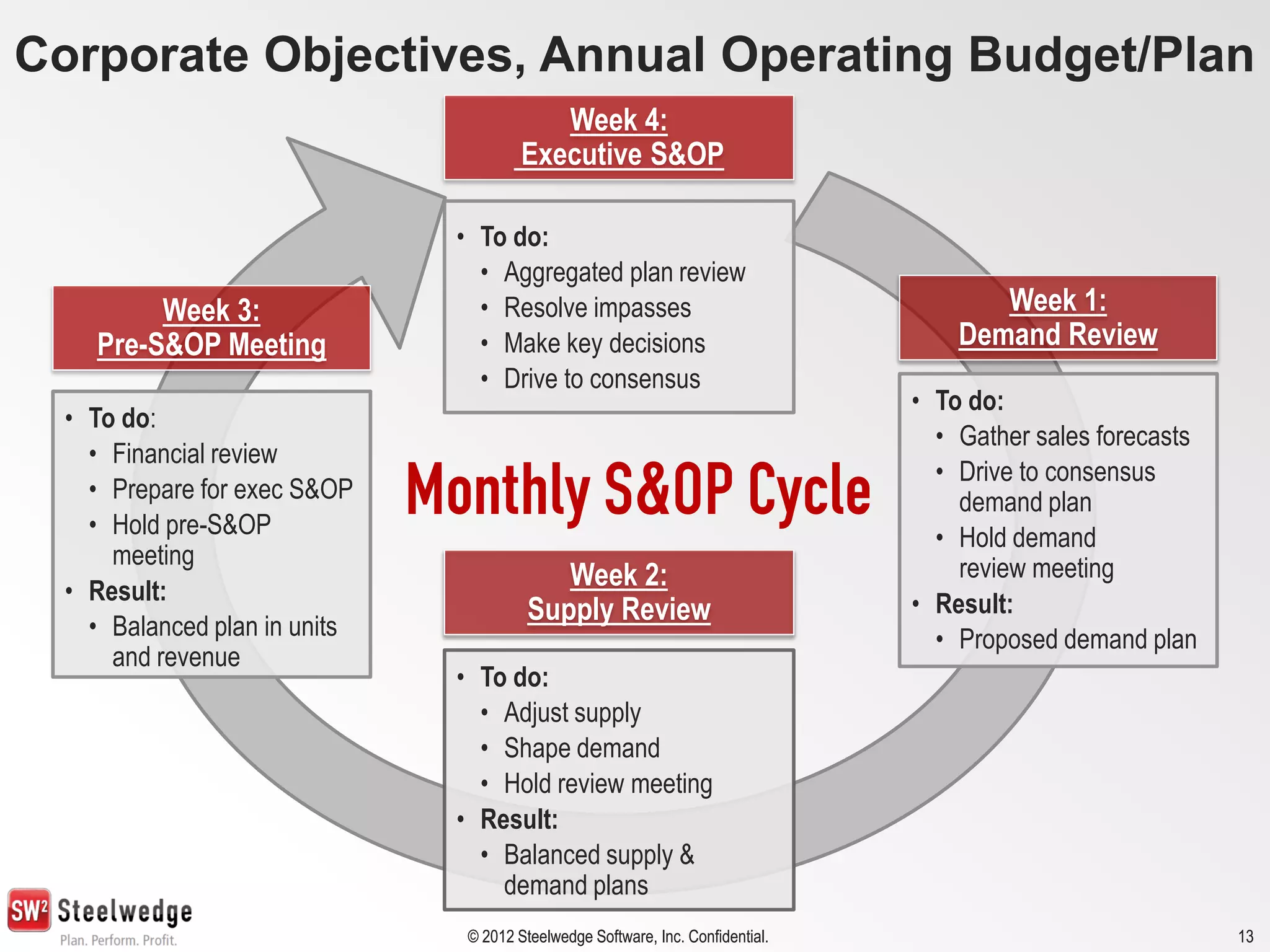

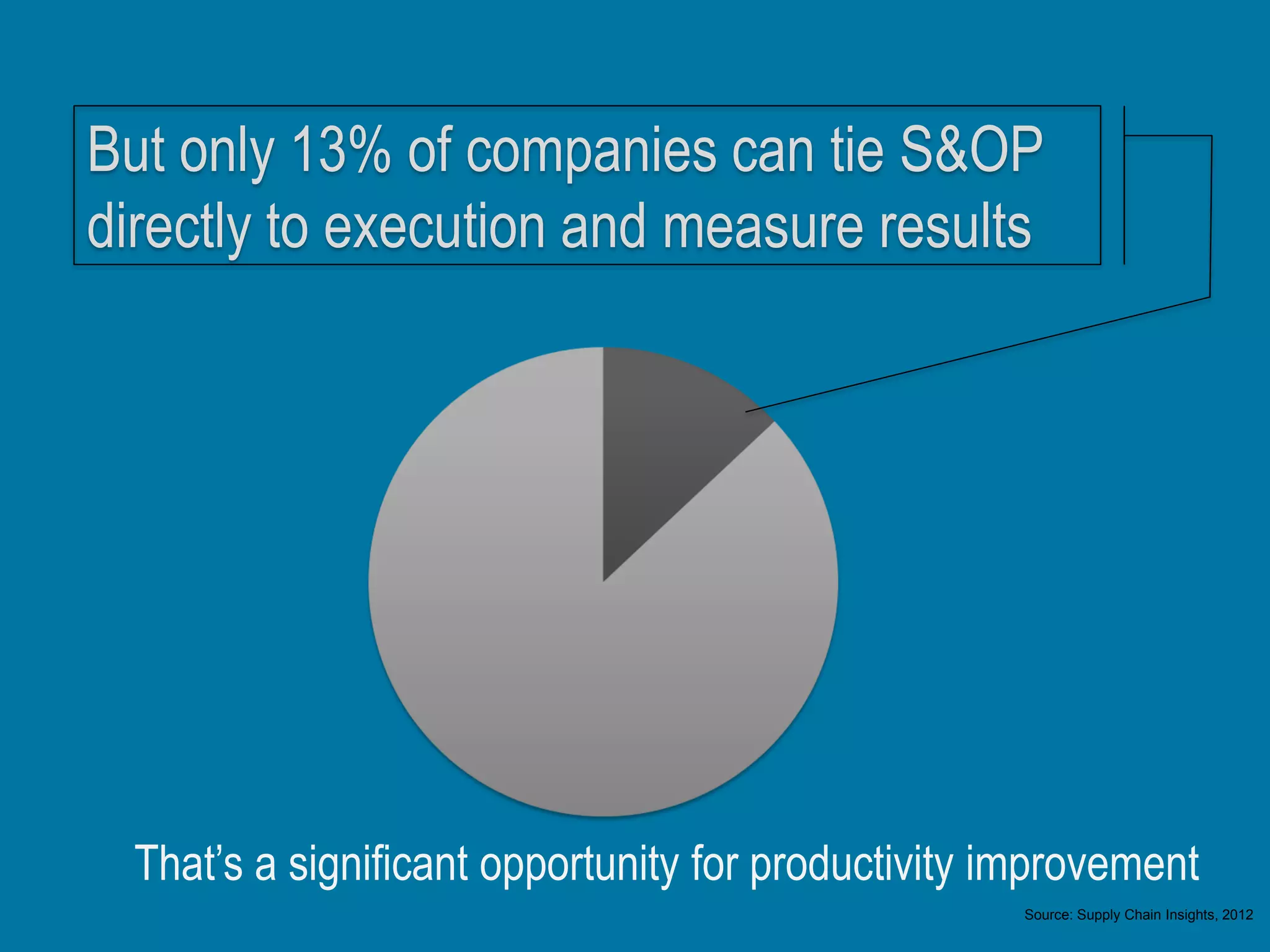

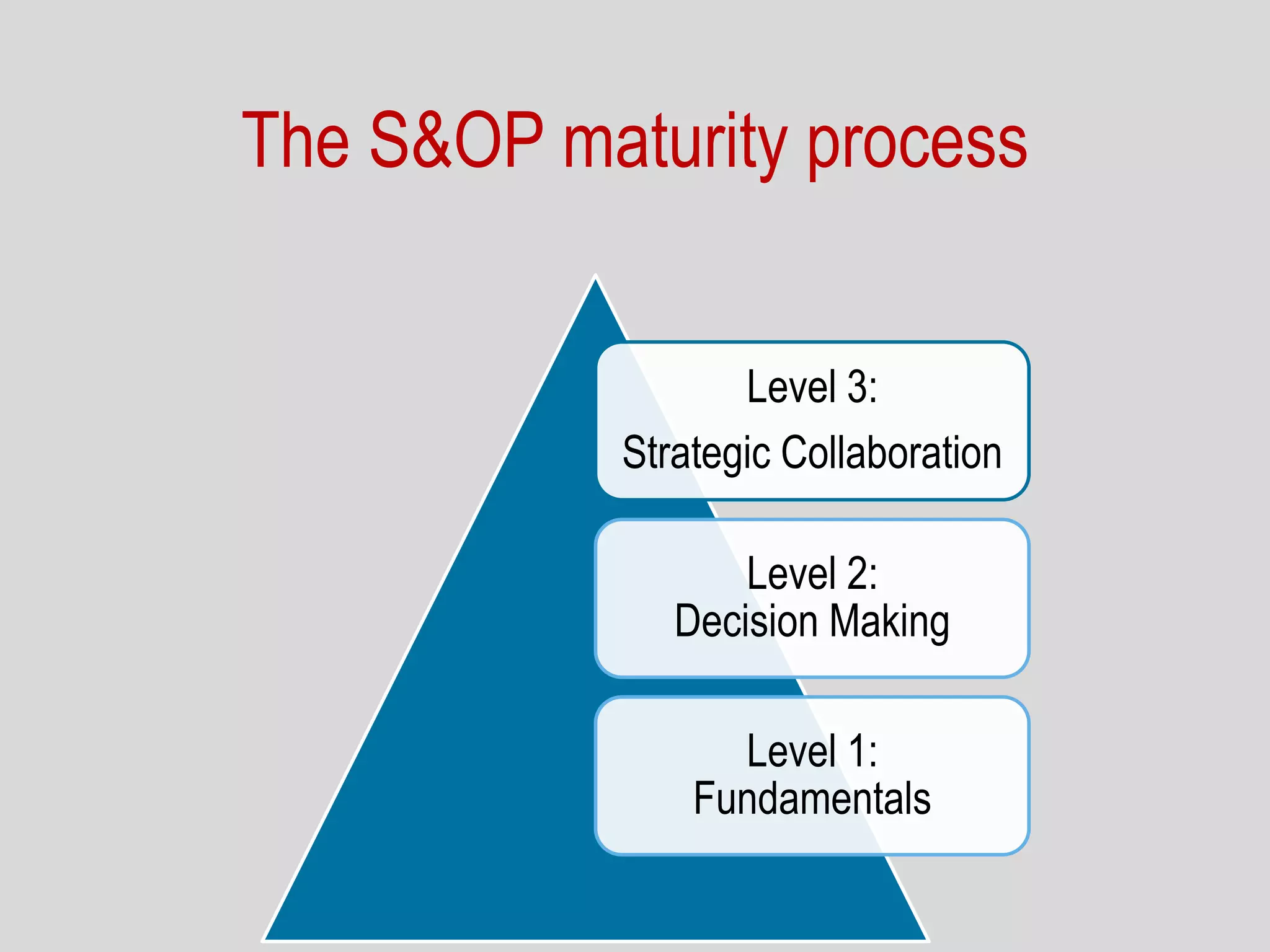

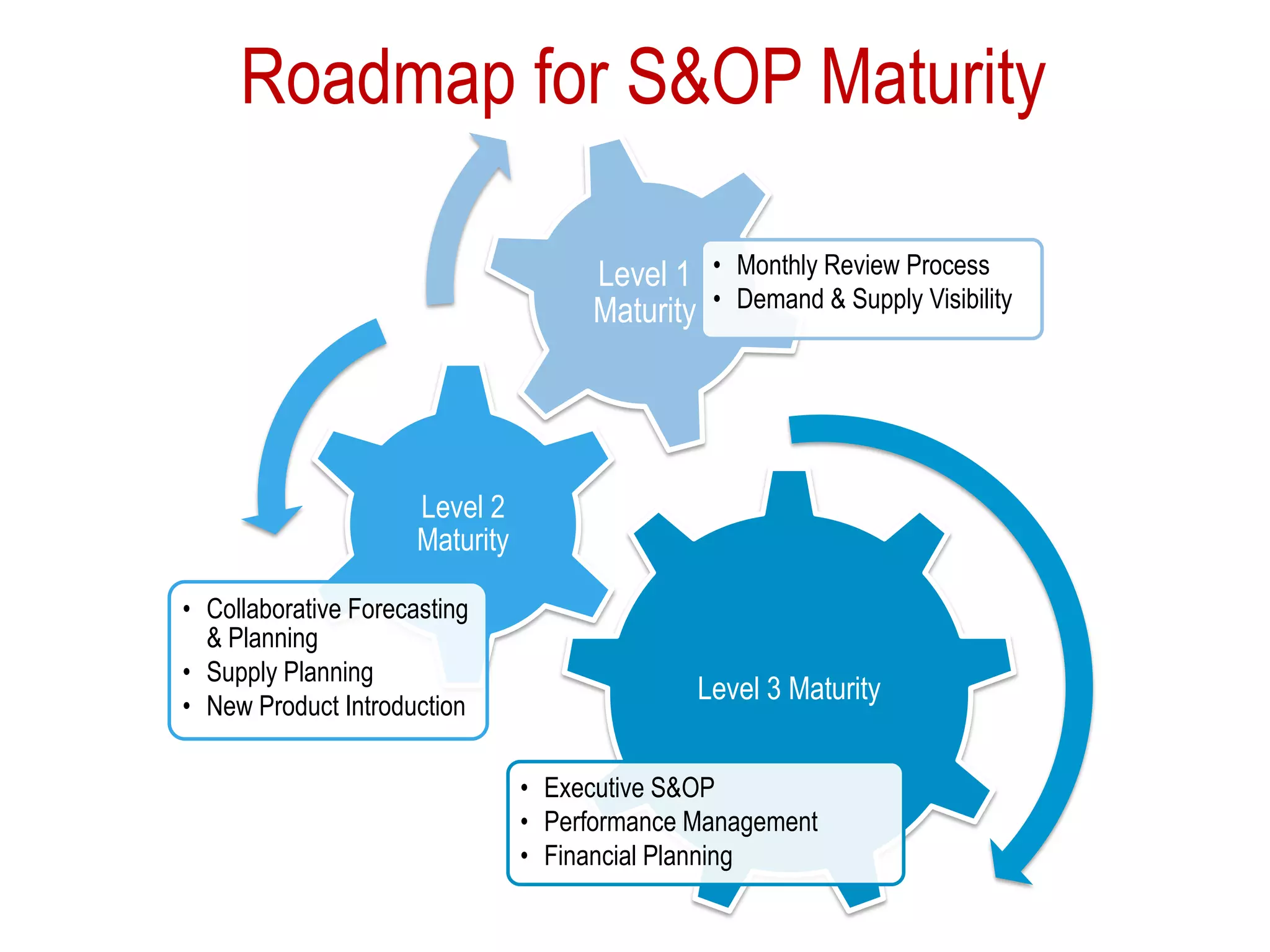

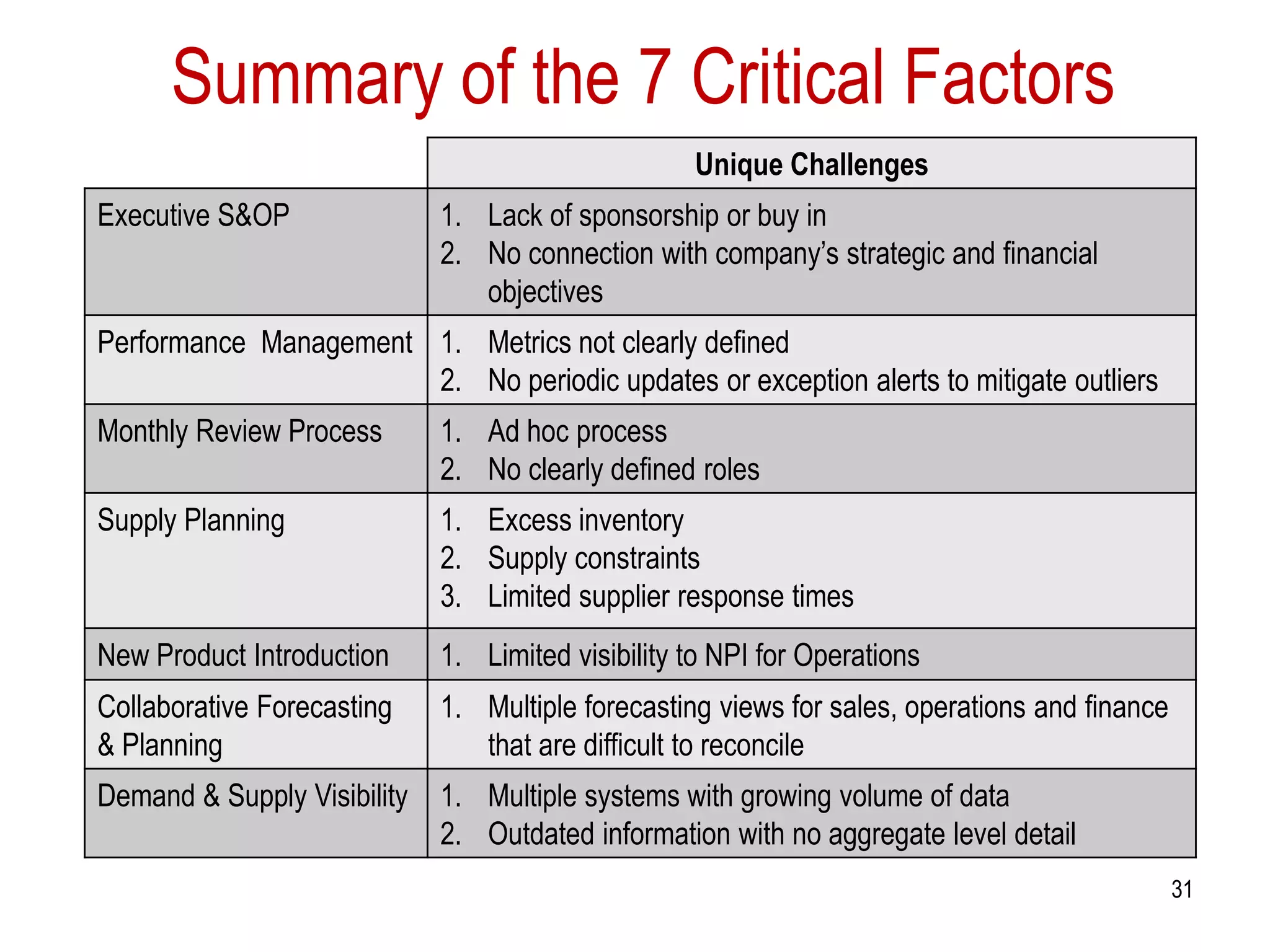

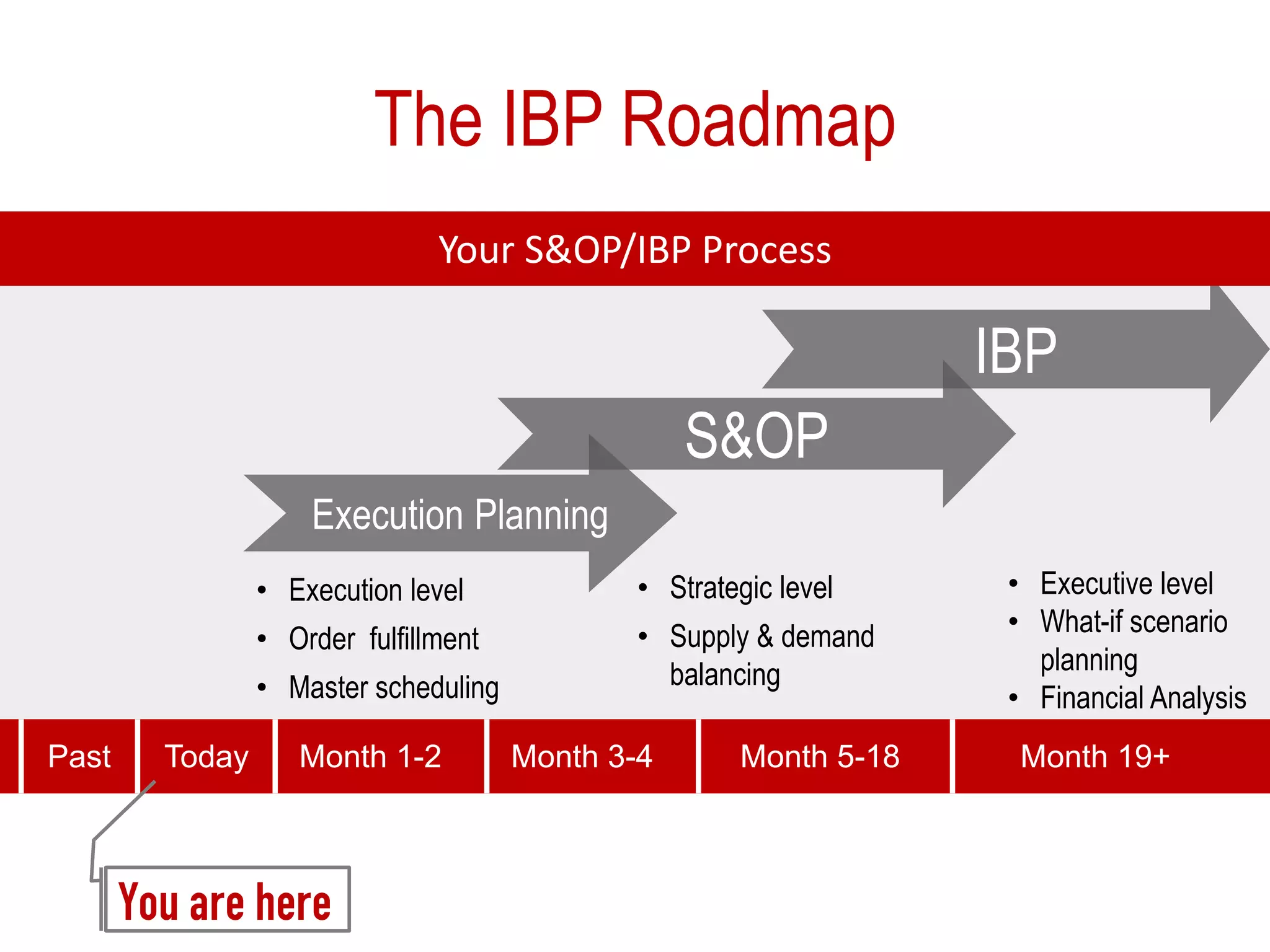

Sales and Operations Planning (S&OP) is an integrated business process designed to enhance collaboration and alignment across different company divisions, evolving since the 1980s from supply chain execution activities. The process aims to balance demand and supply, improve forecast accuracy, reduce excess inventory, and enhance overall business performance through structured monthly cycles and continuous improvement. S&OP is critical for strategic planning and involves collaboration, executive engagement, and effective performance management to achieve key business objectives.