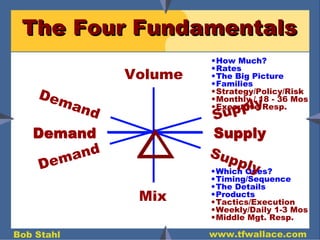

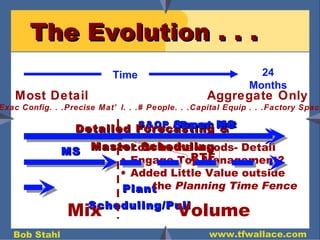

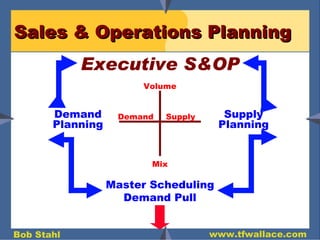

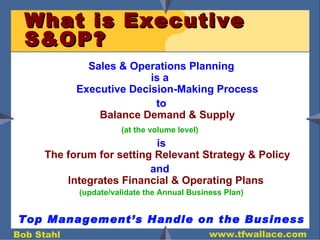

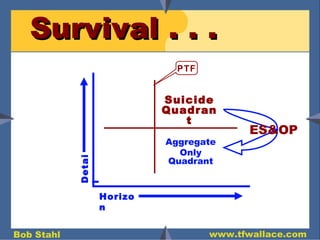

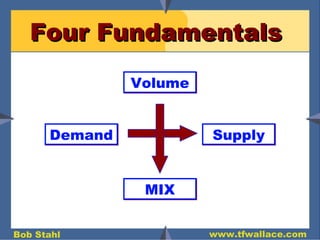

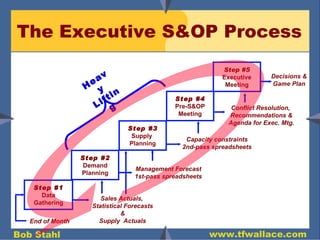

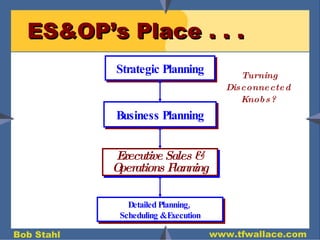

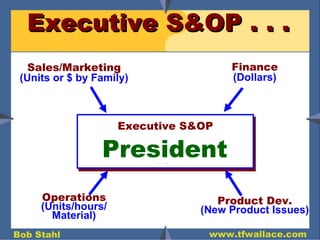

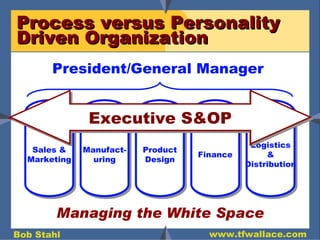

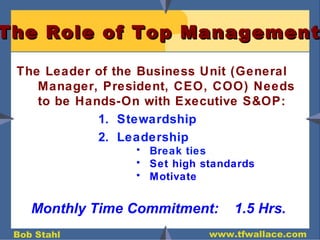

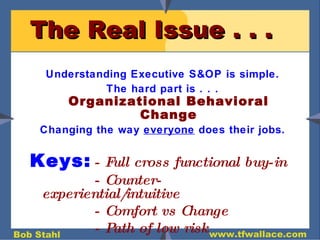

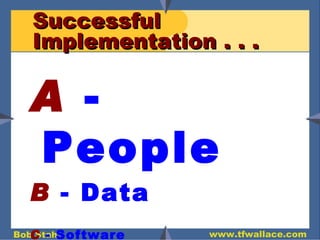

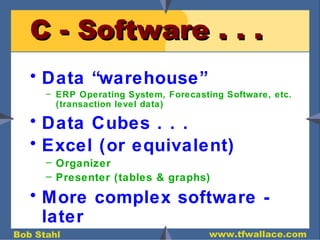

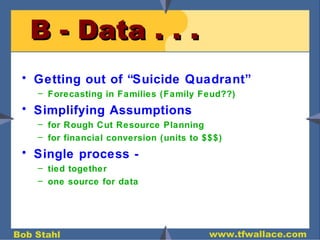

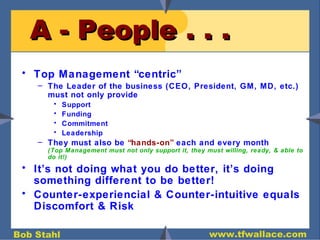

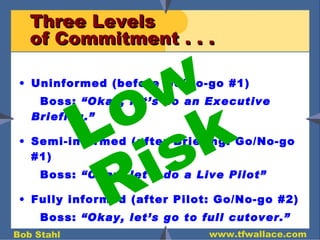

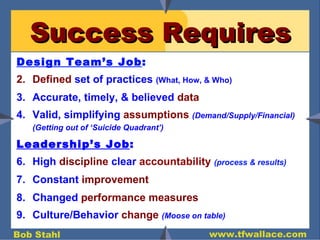

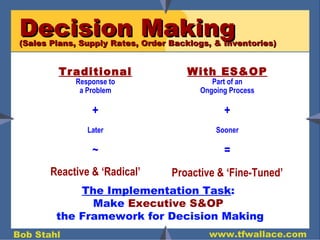

The document provides an overview of executive sales and operations planning (S&OP), including what it is, how to implement it successfully, and the benefits it provides. It discusses S&OP as a executive decision-making process to balance demand and supply. Successful implementation requires organizational change, data-driven decision making, and commitment from top management. When done properly, S&OP can lead to a simpler, better integrated process for strategic planning and decision making.

![Thanks & Good Luck ! 508/226-0477 [email_address] www.tfwallace.com Go to Web site : Copy of presentation Copy of Dubos Essay Copy of bi-monthly newsletter](https://image.slidesharecdn.com/nsmgpres-091116051411-phpapp01/85/Executive-S-OP-34-320.jpg)