Condition Monitoring (PdM) Maturity Matrix - Know Best Practices

•

8 likes•4,802 views

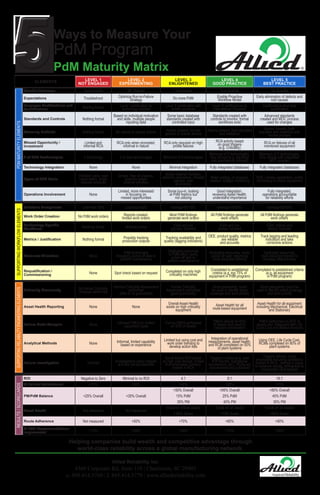

Use the PdM Maturity Maturity Matrix to identify gaps and maturity of the your current PdM Program. Most companies use a few types of PdM Technology however few maintenance organizations are focused on early detection of specific failure modes and responding by writing a work order, planning and scheduling work to eliminate the defect before the equipment fails. Balancing PM and PdM is not an easy task however it can be achieved through a disciplined maintenance process.

Report

Share

Report

Share

Download to read offline

Recommended

Recommended

More Related Content

What's hot

What's hot (20)

Best Practices in Maintenance Planning And Scheduling

Best Practices in Maintenance Planning And Scheduling

8 Steps To Success In Maintenance Planning And Scheduling

8 Steps To Success In Maintenance Planning And Scheduling

Maintenance Planning and Scheduling Maturity Matrix #1

Maintenance Planning and Scheduling Maturity Matrix #1

Total Productive Maintenance (TPM) for EVERTS 20Aug2018

Total Productive Maintenance (TPM) for EVERTS 20Aug2018

Day in the Life of a Proactive Maintenance Planner

Day in the Life of a Proactive Maintenance Planner

Viewers also liked

Viewers also liked (19)

RAMS 2013 Calculating roi when implementing a dfr program by mike silverman

RAMS 2013 Calculating roi when implementing a dfr program by mike silverman

Addressing sustainable development guidelines cps es efficient_carbon

Addressing sustainable development guidelines cps es efficient_carbon

Condition-Based Maintenance: 10 Steps Towards Continuous Improvement

Condition-Based Maintenance: 10 Steps Towards Continuous Improvement

Why should you use repeatable maintenance procedures?

Why should you use repeatable maintenance procedures?

Similar to Condition Monitoring (PdM) Maturity Matrix - Know Best Practices

Similar to Condition Monitoring (PdM) Maturity Matrix - Know Best Practices (20)

Use the Windshield, Not the Mirror Predictive Metrics that Drive Successful ...

Use the Windshield, Not the Mirror Predictive Metrics that Drive Successful ...

More from Ricky Smith CMRP, CMRT

More from Ricky Smith CMRP, CMRT (20)

Day in the Life (DILO) of a Proactive Maintenance Manager

Day in the Life (DILO) of a Proactive Maintenance Manager

Day in the life of a Proactive Maintenance Supervisor

Day in the life of a Proactive Maintenance Supervisor

How to know if your maintenance planning and scheduling is not effective

How to know if your maintenance planning and scheduling is not effective

Day in the life of a Proactive Maintenance Supervisor

Day in the life of a Proactive Maintenance Supervisor

Day in the Life of a Proactive Maintenance Technician Article

Day in the Life of a Proactive Maintenance Technician Article

Tool Box Talk - Maintenance Planning and Scheduling

Tool Box Talk - Maintenance Planning and Scheduling

Top 7 Reasons why Maintenance Work Orders are Closed Out Accurately

Top 7 Reasons why Maintenance Work Orders are Closed Out Accurately

Tool Box Talk - How to Stop Hydraulic Leaks and Why

Tool Box Talk - How to Stop Hydraulic Leaks and Why

PM Tool Box Talk 101 - Fundamentals of Preventive Maintenance

PM Tool Box Talk 101 - Fundamentals of Preventive Maintenance

How to Develop an Effective Maintenance Skills Training Program

How to Develop an Effective Maintenance Skills Training Program

PM Tool Box Talk 101 - Fundamentals of Preventive Maintenance

PM Tool Box Talk 101 - Fundamentals of Preventive Maintenance

Day in the Life of (DILO) of a Proactive Maintenance Technician

Day in the Life of (DILO) of a Proactive Maintenance Technician

Recently uploaded

God is a creative God Gen 1:1. All that He created was “good”, could also be translated “beautiful”. God created man in His own image Gen 1:27. Maths helps us discover the beauty that God has created in His world and, in turn, create beautiful designs to serve and enrich the lives of others.

Explore beautiful and ugly buildings. Mathematics helps us create beautiful d...

Explore beautiful and ugly buildings. Mathematics helps us create beautiful d...christianmathematics

Making communications land - Are they received and understood as intended? webinar

Thursday 2 May 2024

A joint webinar created by the APM Enabling Change and APM People Interest Networks, this is the third of our three part series on Making Communications Land.

presented by

Ian Cribbes, Director, IMC&T Ltd

@cribbesheet

The link to the write up page and resources of this webinar:

https://www.apm.org.uk/news/making-communications-land-are-they-received-and-understood-as-intended-webinar/

Content description:

How do we ensure that what we have communicated was received and understood as we intended and how do we course correct if it has not.Making communications land - Are they received and understood as intended? we...

Making communications land - Are they received and understood as intended? we...Association for Project Management

Recently uploaded (20)

Vishram Singh - Textbook of Anatomy Upper Limb and Thorax.. Volume 1 (1).pdf

Vishram Singh - Textbook of Anatomy Upper Limb and Thorax.. Volume 1 (1).pdf

HMCS Max Bernays Pre-Deployment Brief (May 2024).pptx

HMCS Max Bernays Pre-Deployment Brief (May 2024).pptx

Micro-Scholarship, What it is, How can it help me.pdf

Micro-Scholarship, What it is, How can it help me.pdf

Explore beautiful and ugly buildings. Mathematics helps us create beautiful d...

Explore beautiful and ugly buildings. Mathematics helps us create beautiful d...

Kodo Millet PPT made by Ghanshyam bairwa college of Agriculture kumher bhara...

Kodo Millet PPT made by Ghanshyam bairwa college of Agriculture kumher bhara...

Fostering Friendships - Enhancing Social Bonds in the Classroom

Fostering Friendships - Enhancing Social Bonds in the Classroom

Making communications land - Are they received and understood as intended? we...

Making communications land - Are they received and understood as intended? we...

Basic Civil Engineering first year Notes- Chapter 4 Building.pptx

Basic Civil Engineering first year Notes- Chapter 4 Building.pptx

General Principles of Intellectual Property: Concepts of Intellectual Proper...

General Principles of Intellectual Property: Concepts of Intellectual Proper...

On National Teacher Day, meet the 2024-25 Kenan Fellows

On National Teacher Day, meet the 2024-25 Kenan Fellows

Condition Monitoring (PdM) Maturity Matrix - Know Best Practices

- 1. Ways to Measure Your PdM Program PdM Maturity Matrix ELEMENTS LEVEL 1 NOT ENGAGED LEVEL 2 EXPERIMENTING LEVEL 3 ENLIGHTENED LEVEL 4 GOOD PRACTICE LEVEL 5 BEST PRACTICE PdMMATURITYELEMENTS Quartile Coverage Spot checks 4th Quartile 3rd Quartile 2nd Quartile 1st Quartile Expectations Troubleshoot Optimize Run-to-Failure Strategy Do more PdM Enable Proactive Workflow Model Early elimination of defects and root causes Employee Certifications and Qualifications Nothing formal Level I certification by technology supplier Level II certification with written practices Level III certifications to International Standard Certifications plus task qualification Standards and Controls Nothing formal Based on individual motivation and skills, multiple people inputting data Some basic database standards created with controlled input Standards created with controls to monitor, formal workflows exist Advanced standards created and MOC process used for changes Alarming Methods Nothing formal No alarms to overall alarms Alarms present, but are generic or overall alarms Alarms present, both standard and statistical Alarms present, both standard and statistical with review process Missed Opportunity / Investment Limited and informal RCA RCA only when prompted, informal in nature RCA only required on high profile failures RCA activity based on good triggers (e.g. Criticality) RCA on failures of all monitored equipment # of PdM Technologies 1 technology 2 or less technologies Minimum of 3 technologies Minimum of 5 technologies, fully utilized (e.g. electrical and mechanical infrared) Minimum of 5 technologies, fully utilized with integrated NDT program Technology Integration None None Minimal integration Fully integrated (database) Fully integrated (database) Types of PdM Tools Vibration pens, spot radiometers, single channel analyzer Simple, free oil analysis, possible single channel vibration Single channel vibration, airborne ultrasonics, infrared camera, paid oil analysis Motor testing, oil analysis, medium voltage monitoring ODS / modal capabilities, online monitoring of critical equipment Operations Involvement None Limited, more interested in focusing on missed opportunities Some buy-in, looking at PdM metrics but not utilizing Good integration, reviewing Asset Health, understand importance Fully integrated, operations accountable for reliability efforts SupportingWorkflowElements Schedule Compliance Less than 50% Less than 60% Average 60-70% Average 70-80% Average 80-90% Work Order Creation No PdM work orders Reports created, limited work orders Most PdM findings generate work orders All PdM findings generate work orders All PdM findings generate work orders Technology Specific Workflows Northing formal Nothing formal Exist and are typically followed Exist and are always followed Exist, refined and always followed Metrics / Justification Nothing formal Possibly tracking production outputs Tracking availability and quality (lagging indicators) OEE, product quality, metrics are reliable and accurate Track lagging and leading indicators and take corrective actions Resource Allocation None PdM technicians frequently pulled off task to perform maintenance Dedicated resources to PdM effort, rarely pulled off task to perform maintenance Dedicated resources, never pulled off task, beginning multi-discipline training Dedicated resources, multi-discipline trained to increase effectiveness Requalification / Commissioning None Spot check based on request Completed on only high criticality machines Completed to established criteria (e.g. top 75% of equipment in PdM program) Completed to established criteria (e.g. all equipment in PdM program) SupportingReliabilityEngineeringElements Criticality Granularity No formal Criticality Analysis performed Informal Criticality Assessment performed (little or no granularity) Formal Criticality Assessment performed (good granularity) Good granularity, could be used to identify asset coverage and work priority Good granularity, could be used to identify asset coverage and work priority Asset Health Reporting None None Overall Asset Health exists on high criticality equipment Asset Health for all route-based equipment Asset Health for all equipment including Mechanical, Electrical and Stationary Failure Mode Analysis None Informal FMEA on limited equipment types Formal FMEA performed on 50% of assets FMEA utilized on 65% of assets and used for program optimization FMEA performed on 80% of assets and integrated with Life Cycle Cost and Weibull Analysis Analytical Methods None Informal, limited capability based on experience Limited but using cost and work order trending to develop action lists Integration of operational measurements, asset health, and RCM completed on 50% of plant systems Using OEE, Life Cycle Cost, RCMs completed on 80% of plant systems Failure Investigation Informal Investigations rarely happen and are not documented Some formal RCA based on high cost failures, limited # of employees formerly trained in RCA Triggers in place (e.g. cost, # of failures, operational involvement, etc.), RCAs are documented and published Triggers refined, many employees including operations trained in RCA, metrics in place to measure results, willingness to incorporate OEM experts Results/Scorecards ROI Negative to Zero Minimal to no ROI 4:1 8:1 16:1 % Failure Maintenance >70% >50% <40% <25% <15% PM/PdM Balance <25% Overall <35% Overall >50% Overall >65% Overall >80% Overall 15% PdM 25% PdM 45% PdM 35% PM 40% PM 35% PM Asset Health Not measured Not measured Exists on critical assets Exists on all assets Exists on all assets > 65% Green >75% Green >80% Green Route Adherence Not measured <50% >70% >85% >90% % PdM Recommendations Implemented <15% <30% >50% >75% >90% PDMMATURITYELEMENTSPDMMATURITYELEMENTSSUPPORTINGRELIABILITYENGINEERINGELEMENTSSUPPORTINGRELIABILITYENGINEERINGELEMENTSRESULTS/SCORECARDSRESULTS/SCORECARDS LEVEL 1 NOT ENGAGED LEVEL 1 NOT ENGAGED LEVEL 2 EXPERIMENTING LEVEL 2 EXPERIMENTING LEVEL 4 GOOD PRACTICE LEVEL 4 GOOD PRACTICE LEVEL 5 BEST PRACTICE LEVEL 5 BEST PRACTICE Allied Reliability Inc. 4360 Corporate Rd, Suite 110 | Charleston, SC 29405 o. 888.414.5760 | f. 843.414.5779 | www.alliedreliability.com Helping companies build wealth and competitive advantage through world-class reliability across a global manufacturing network.