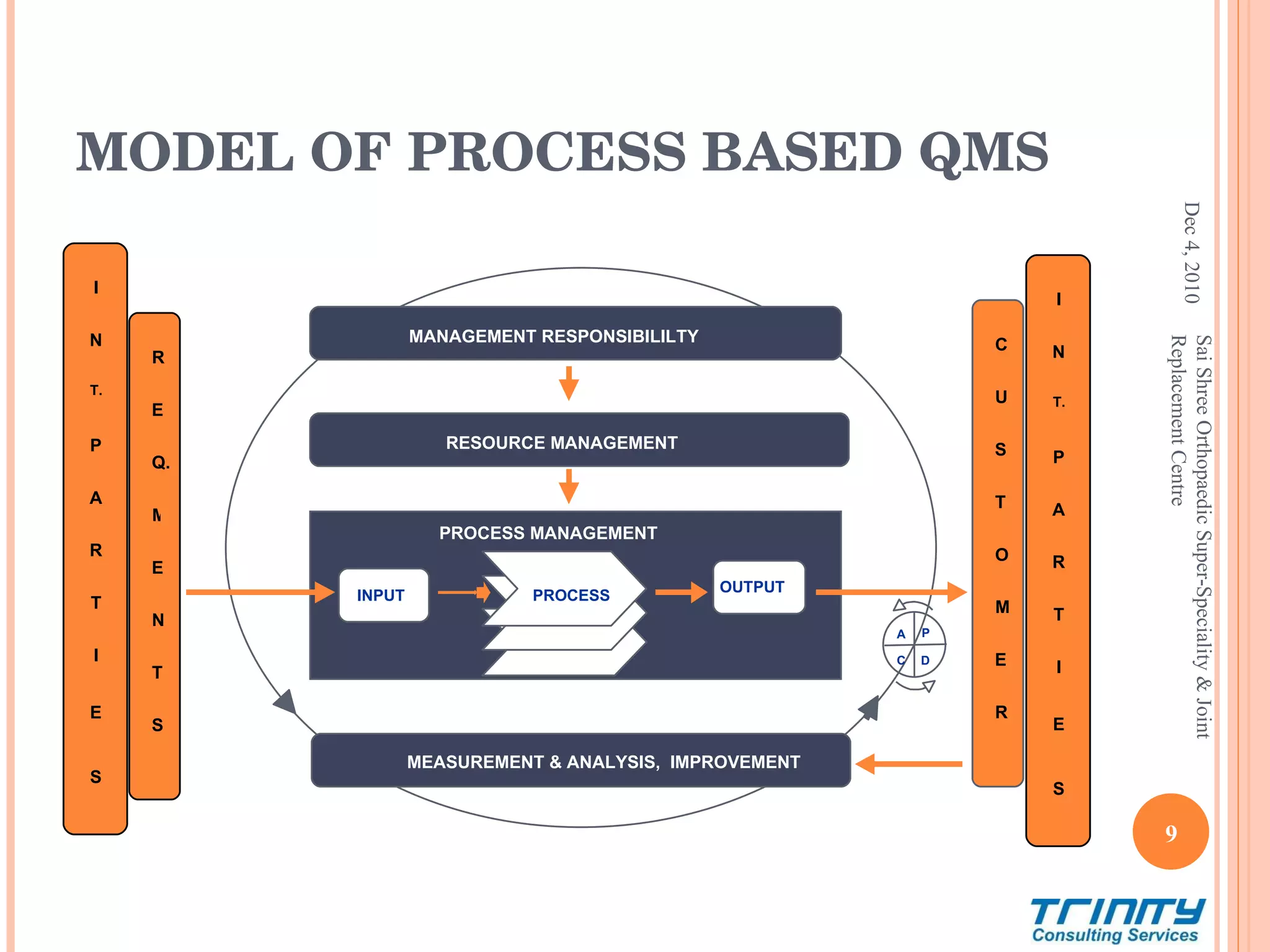

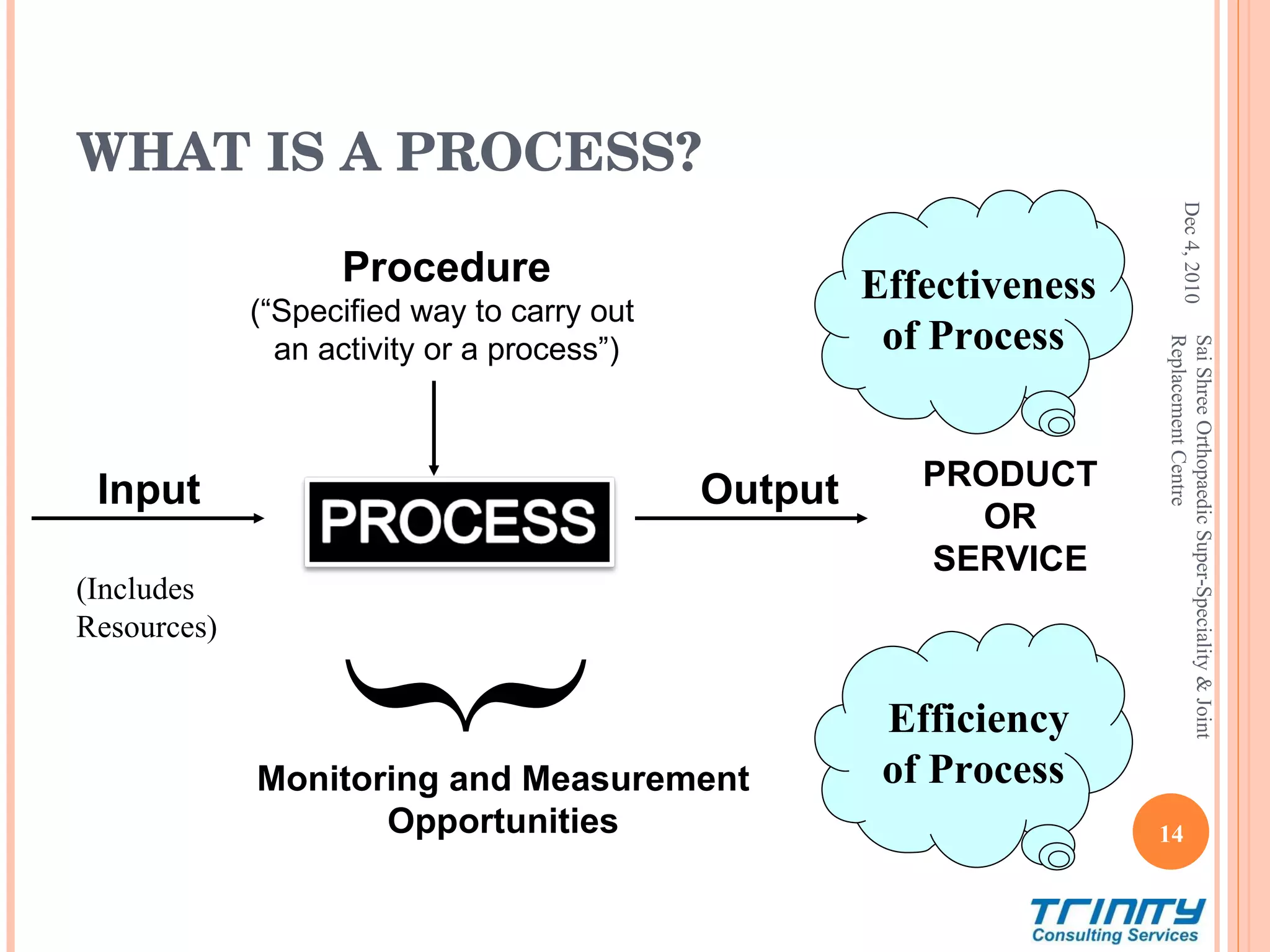

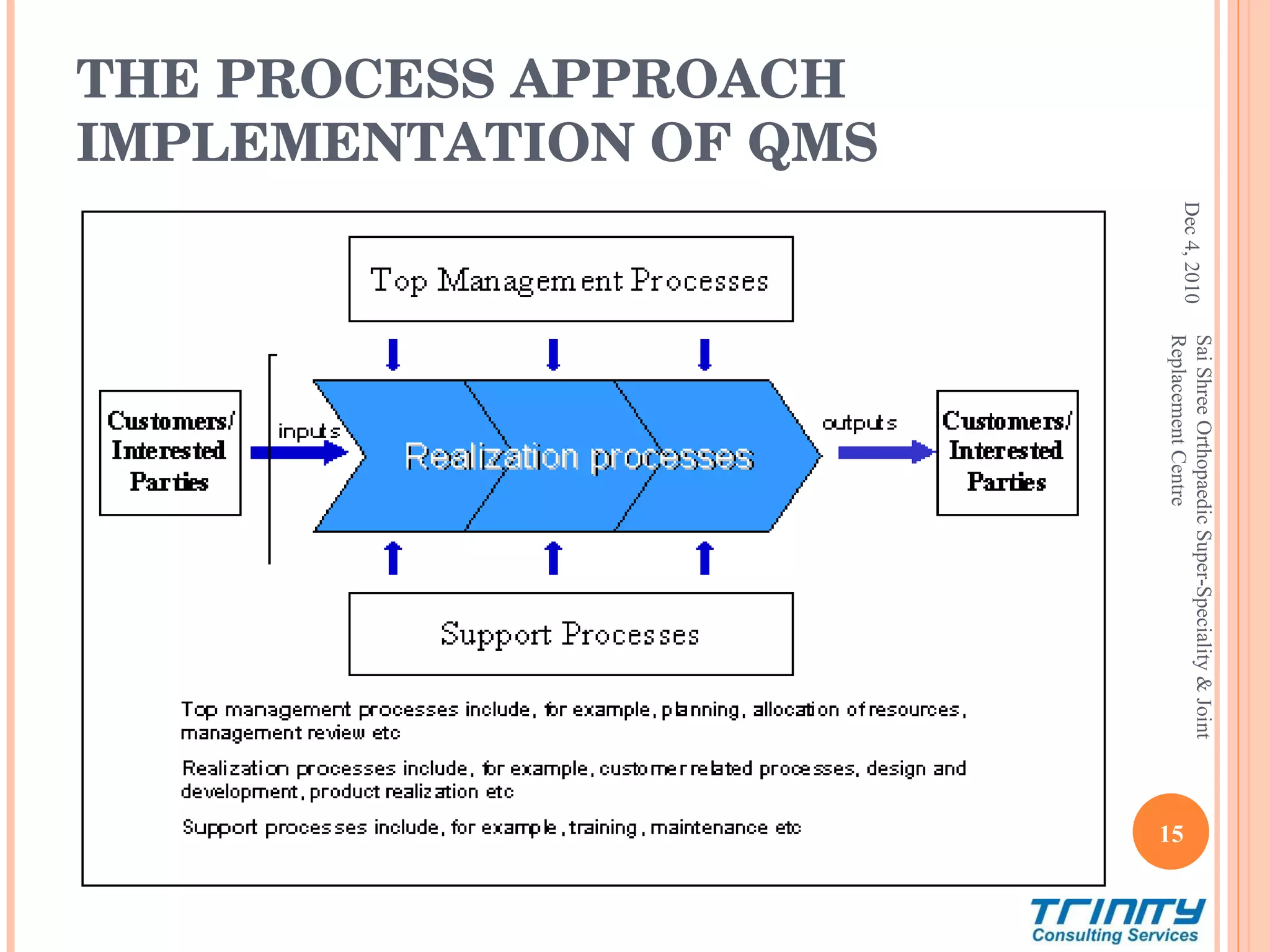

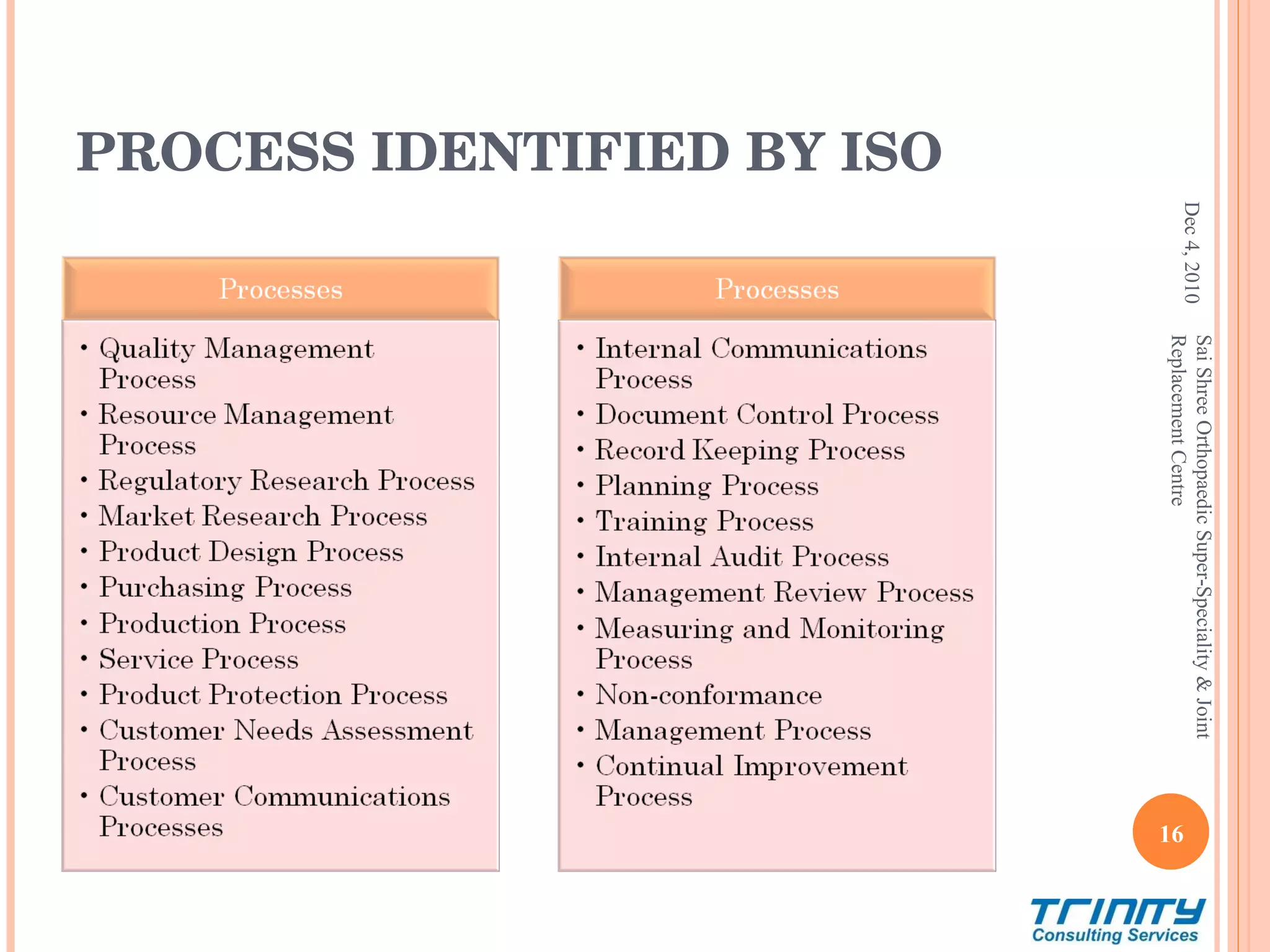

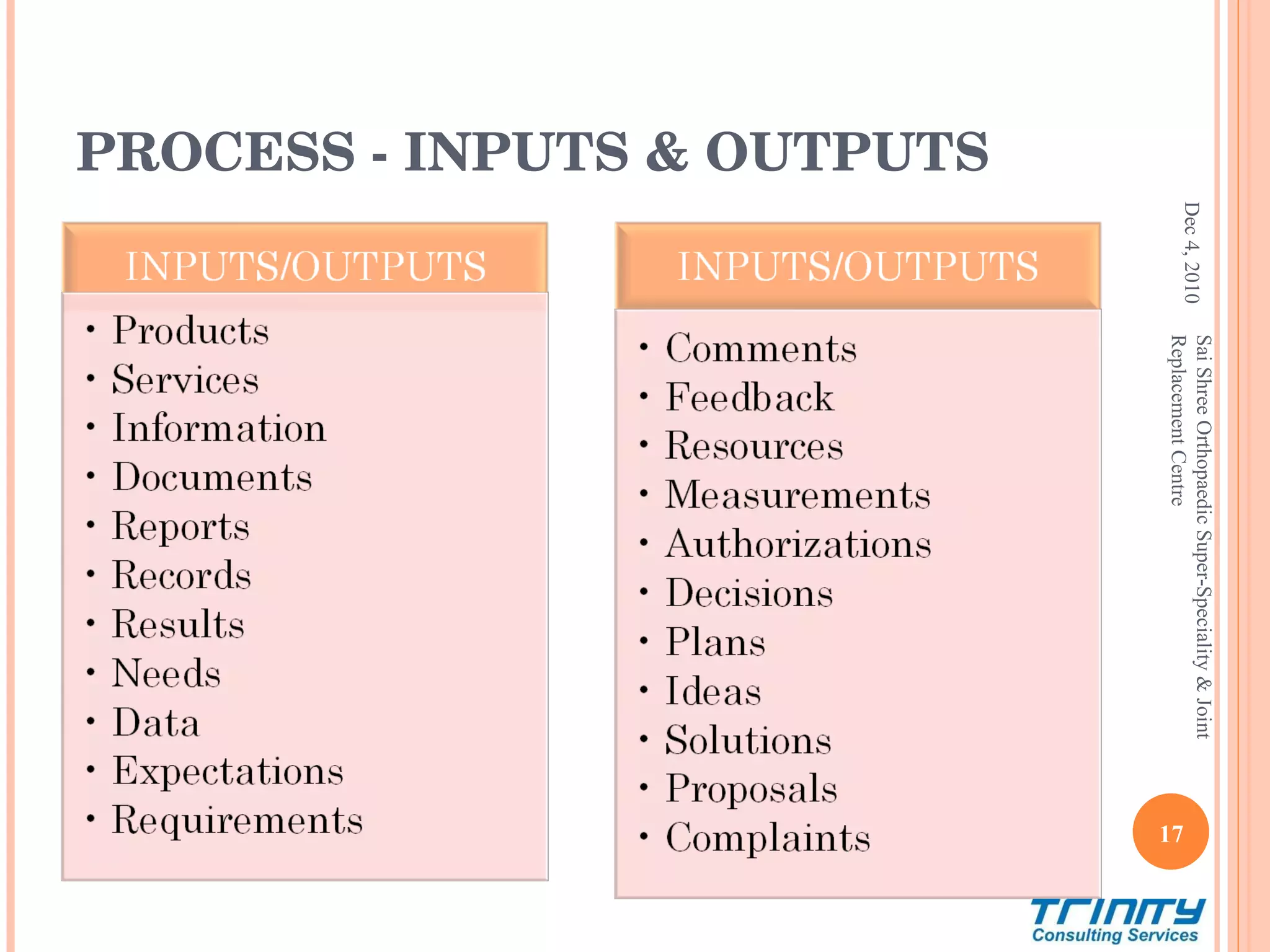

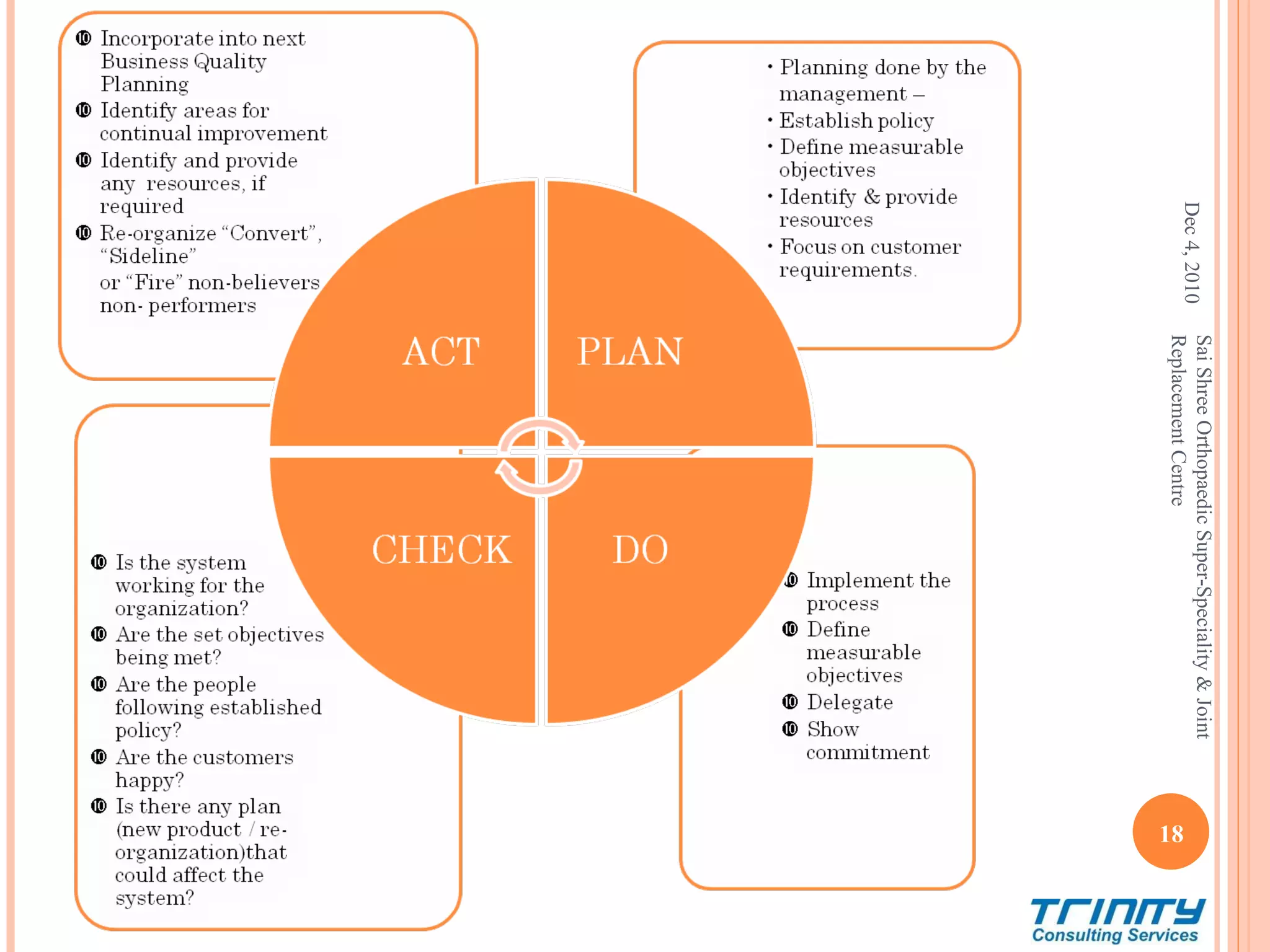

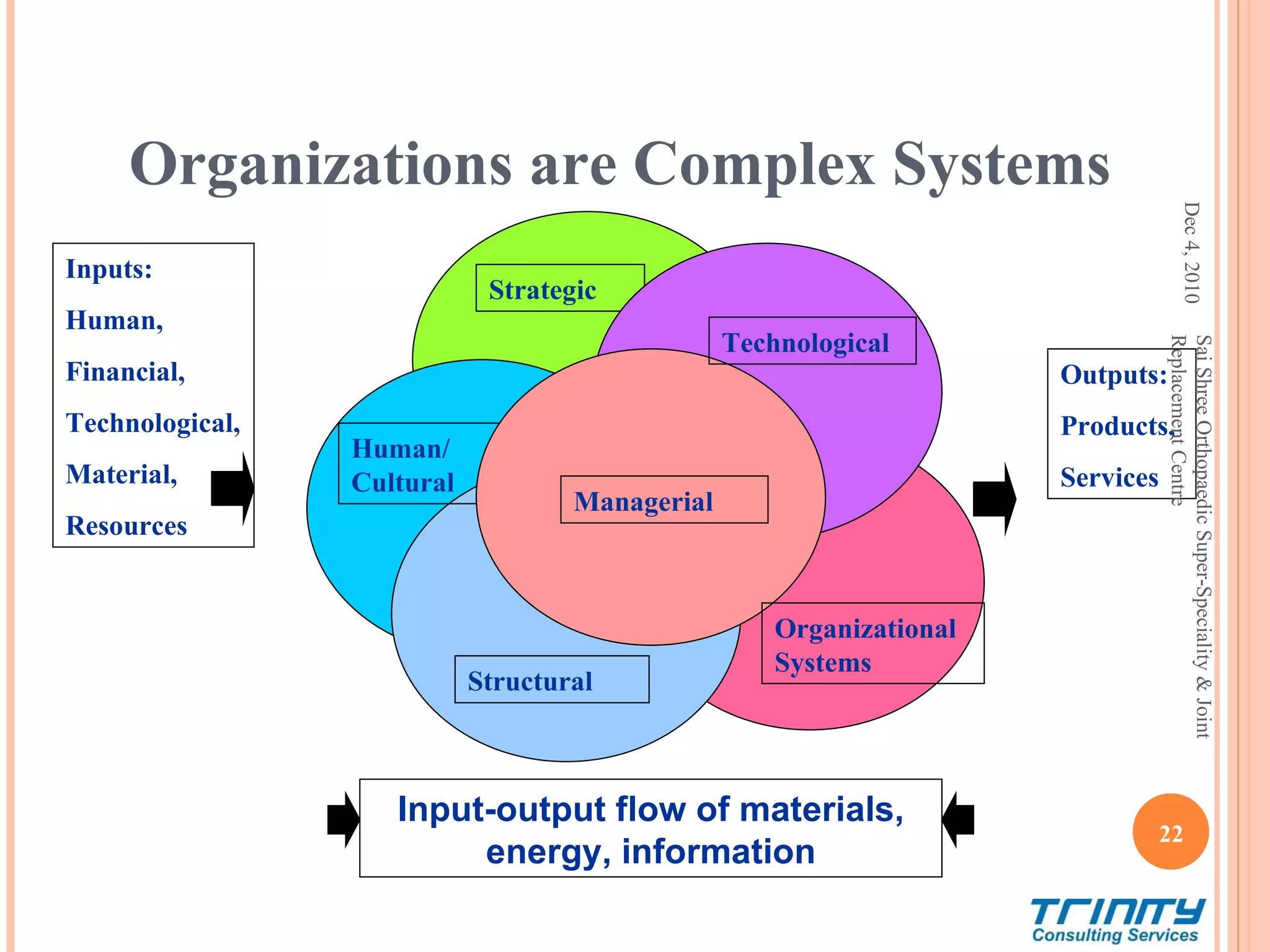

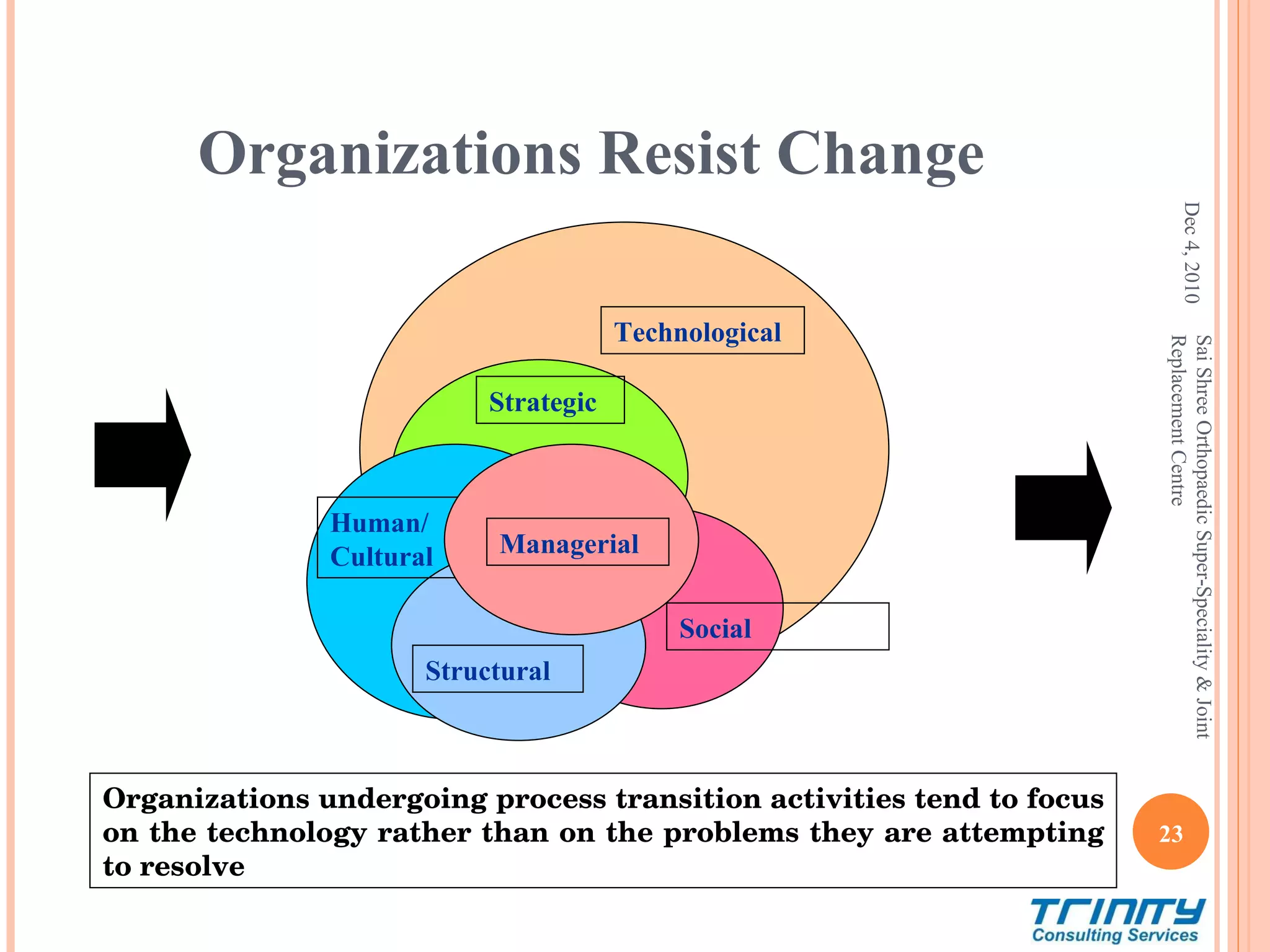

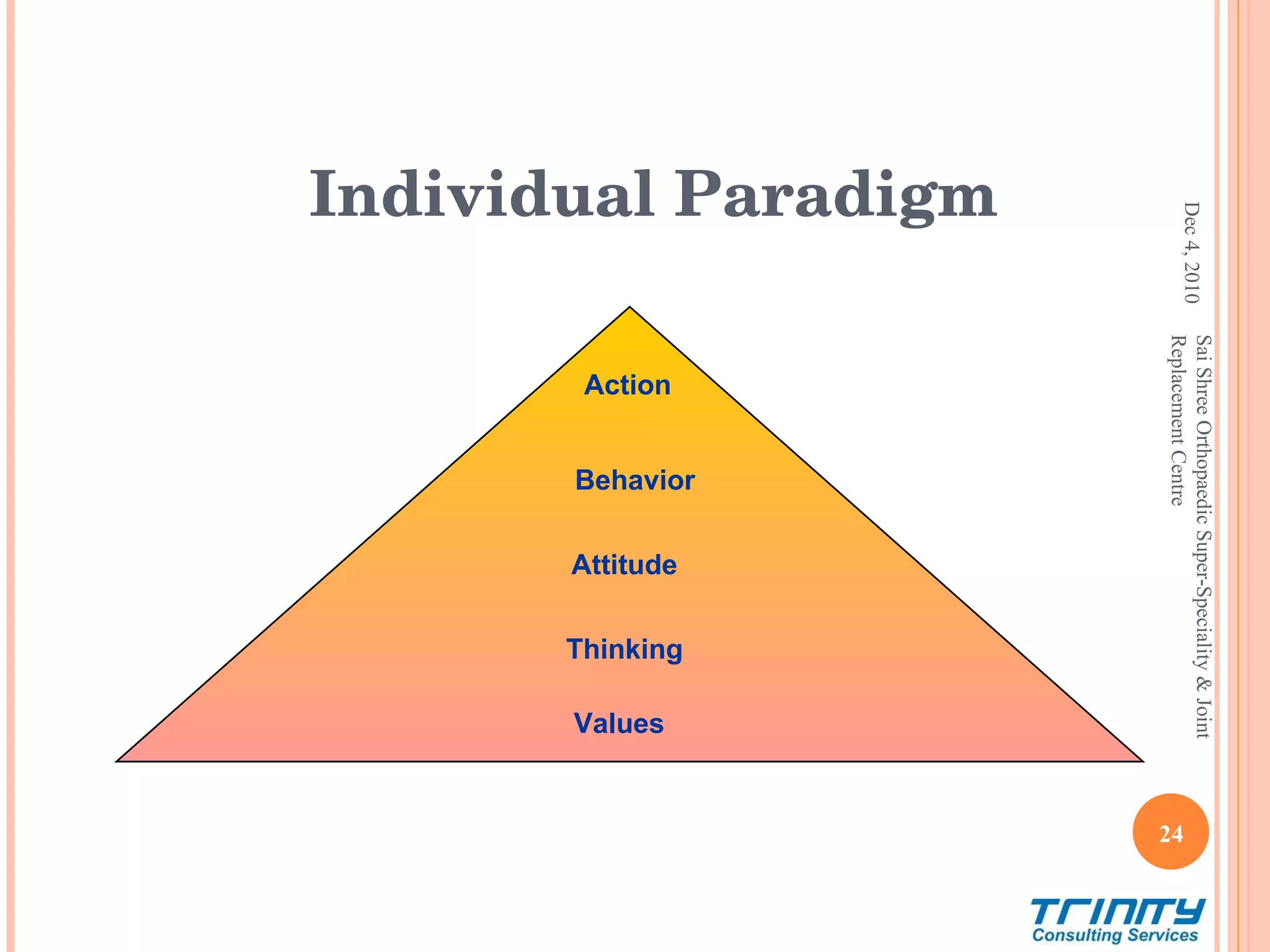

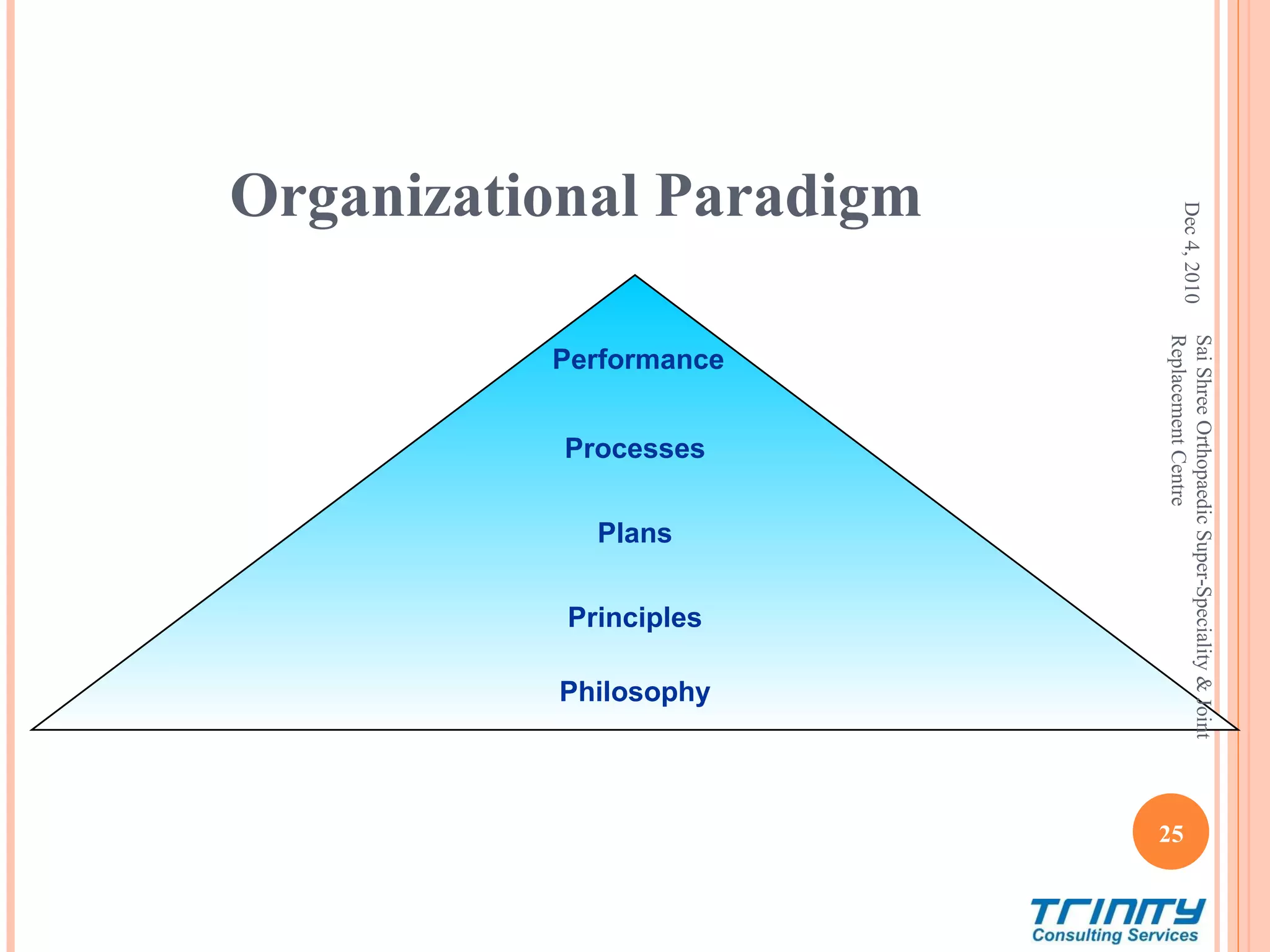

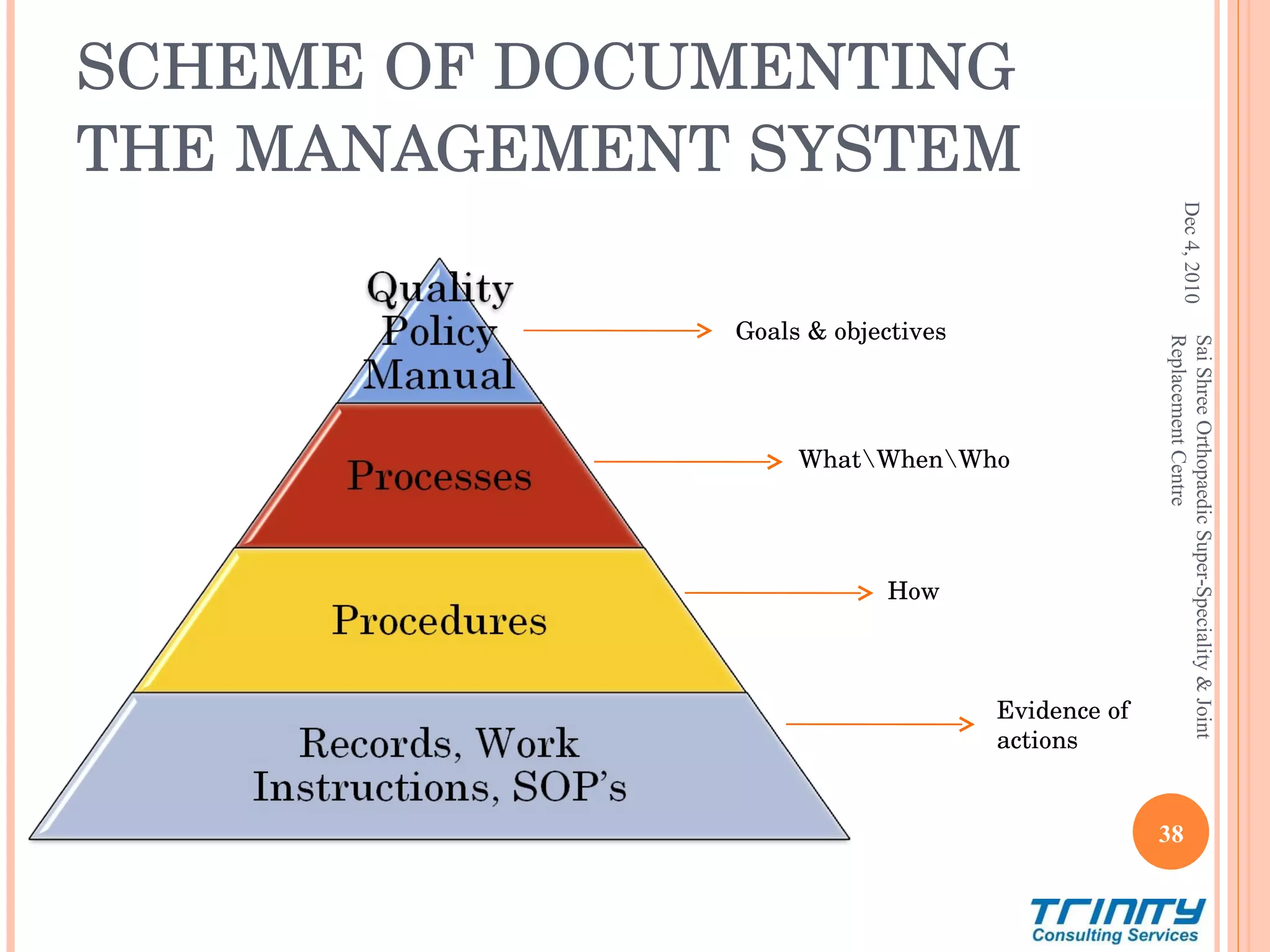

The document discusses ISO 9001:2008 and quality management systems. It explains that ISO 9001:2008 promotes a process approach and systems approach when developing, implementing, and improving quality management systems. An effective quality management system is achieved through identifying, managing, and improving interrelated processes and ensuring their interaction meets organizational objectives.