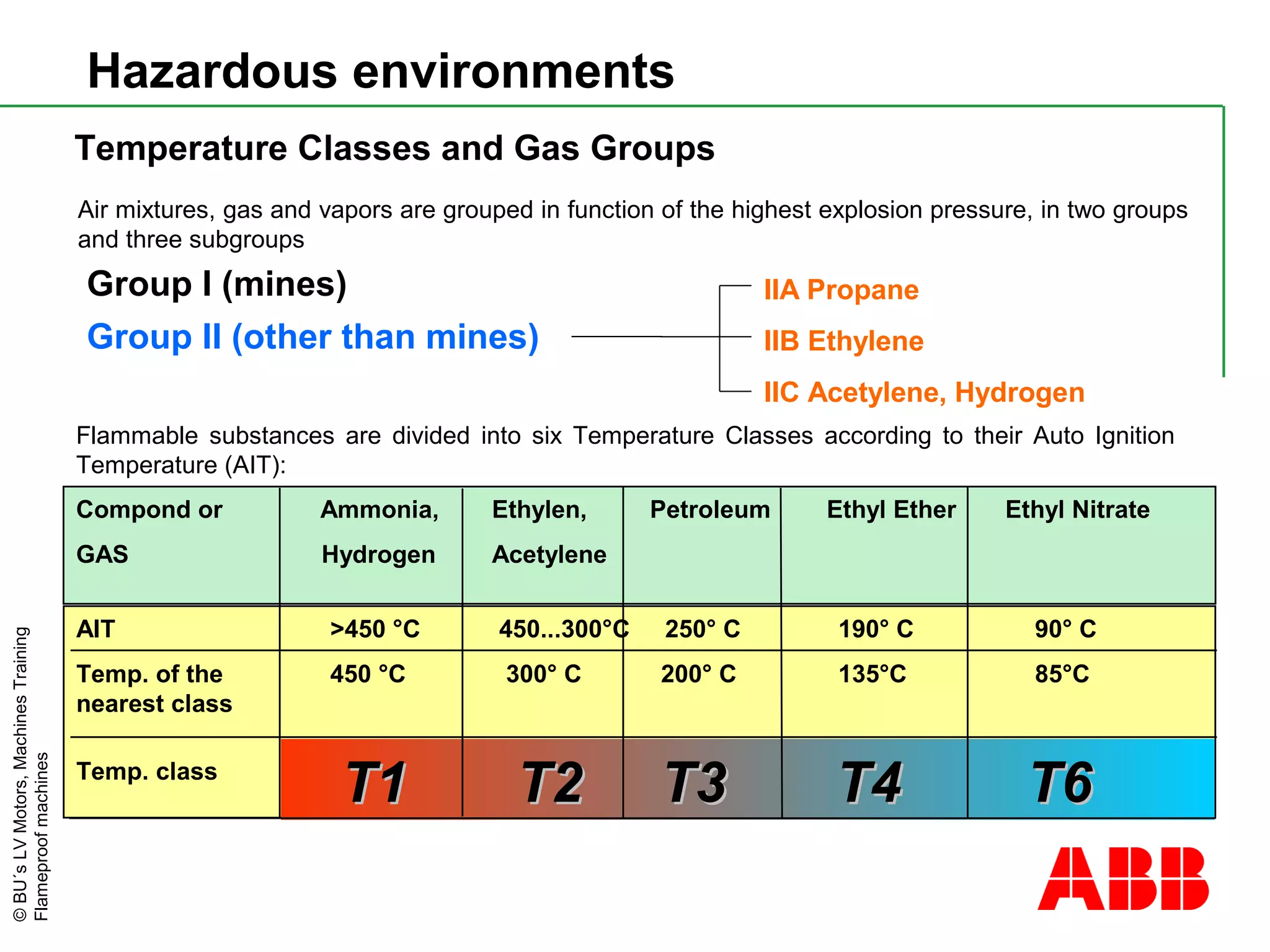

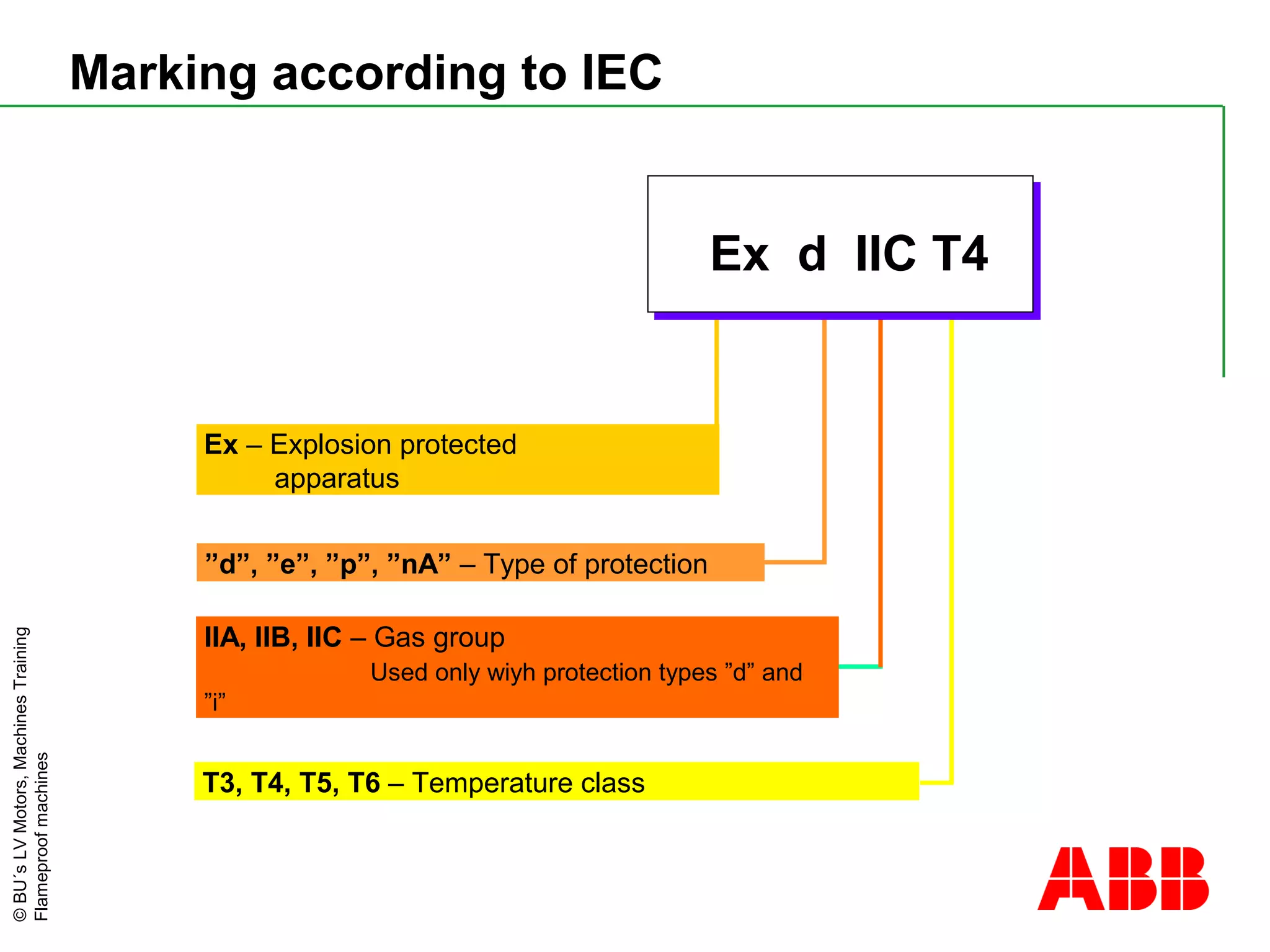

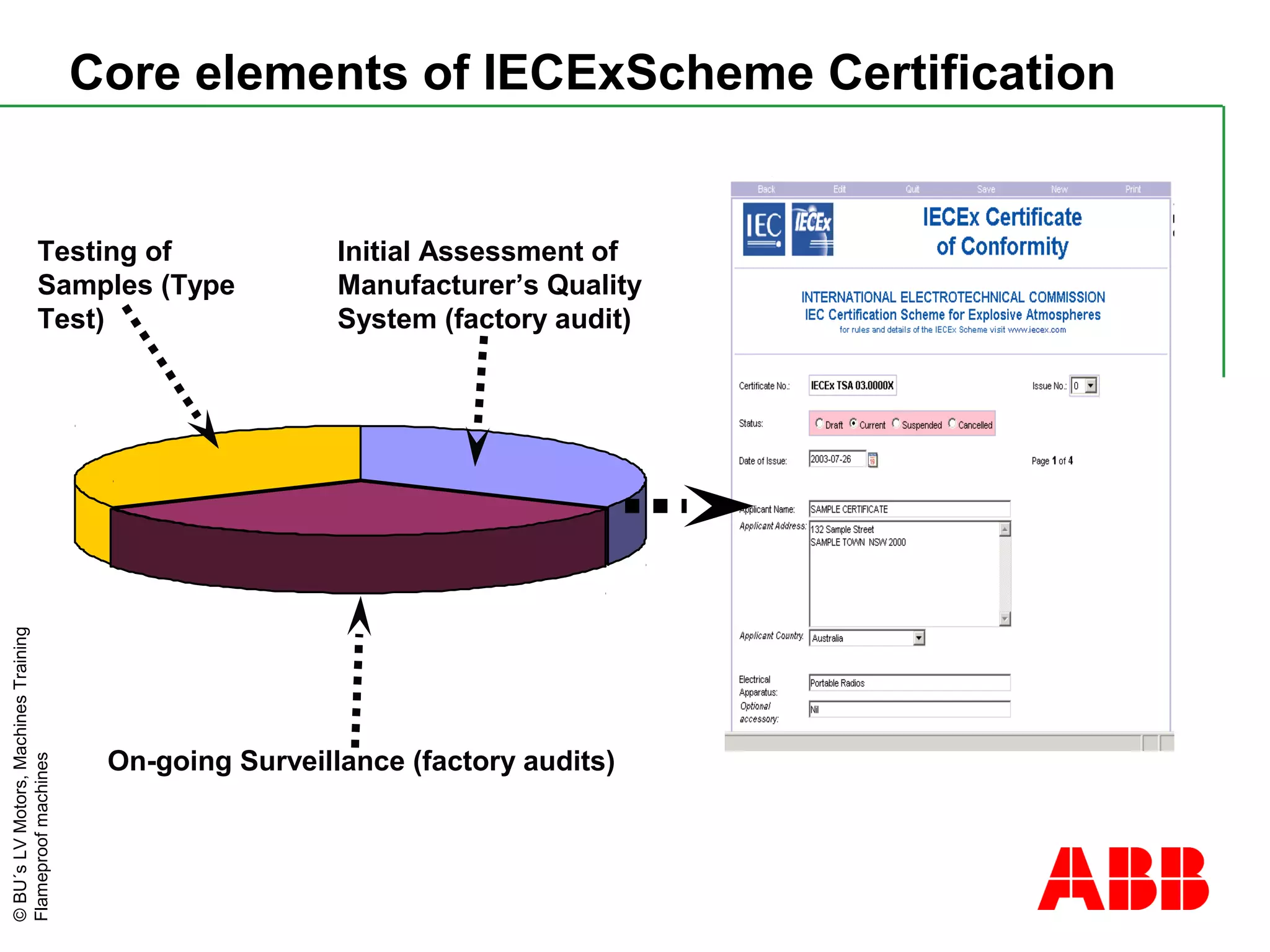

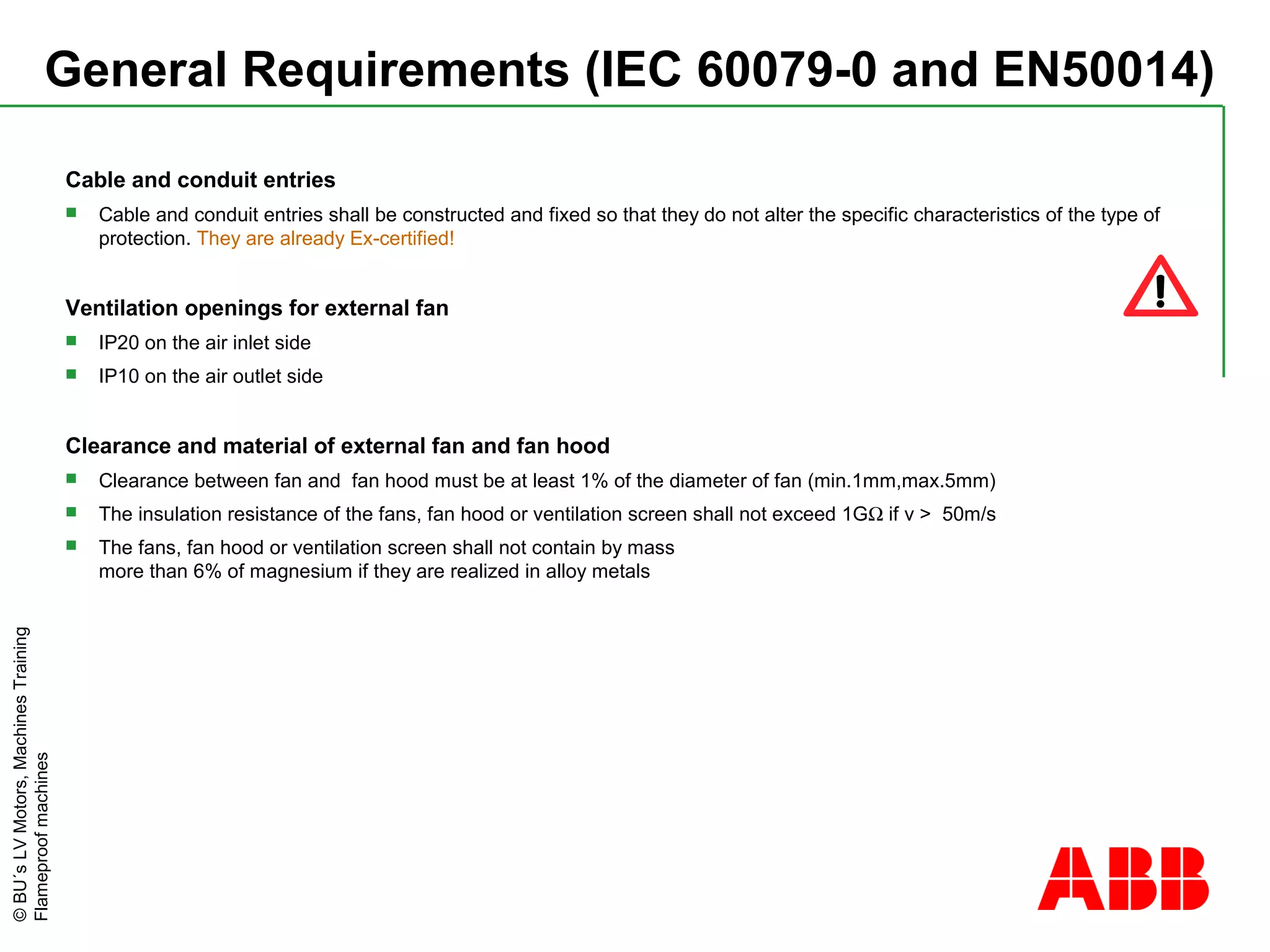

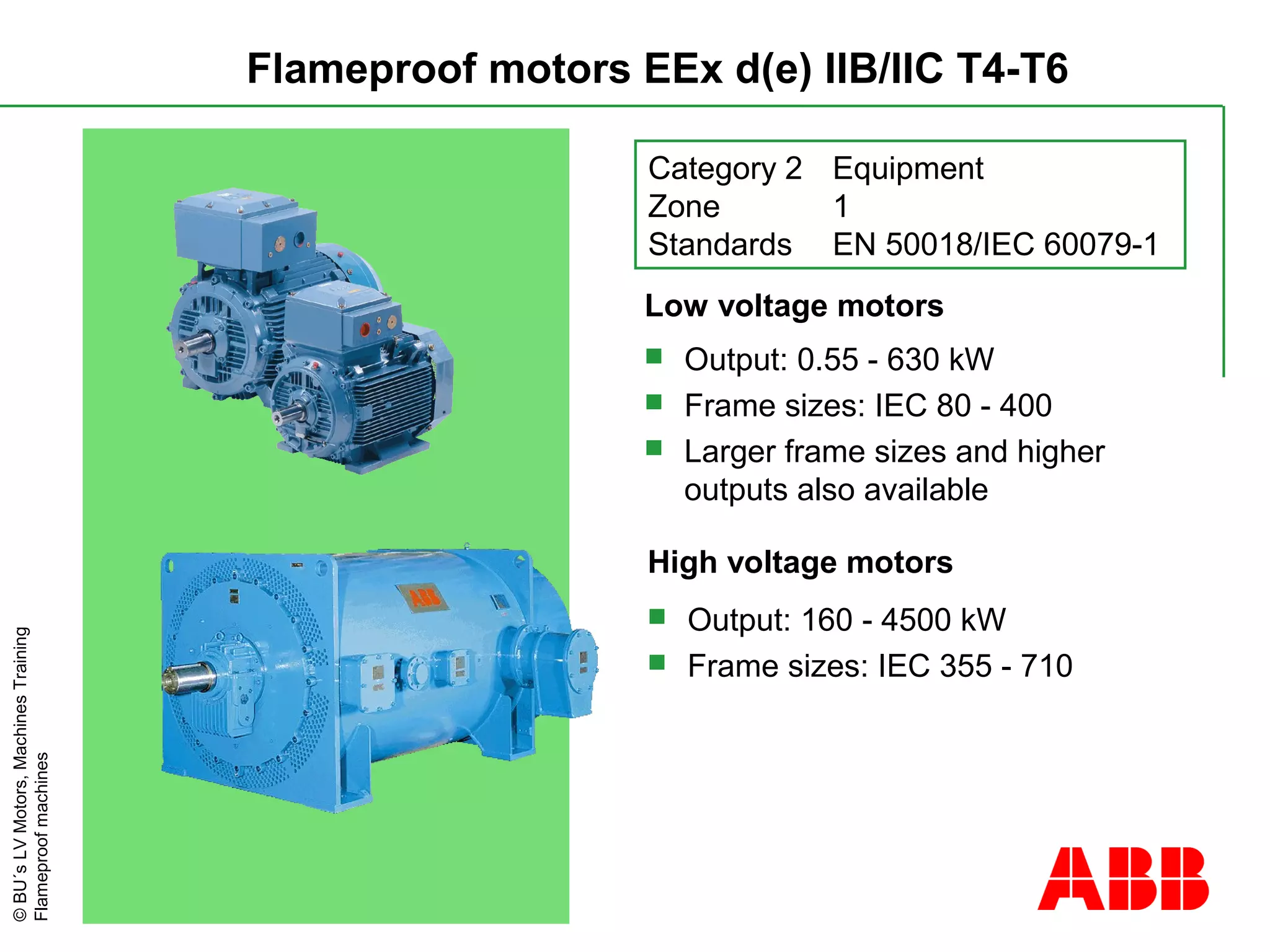

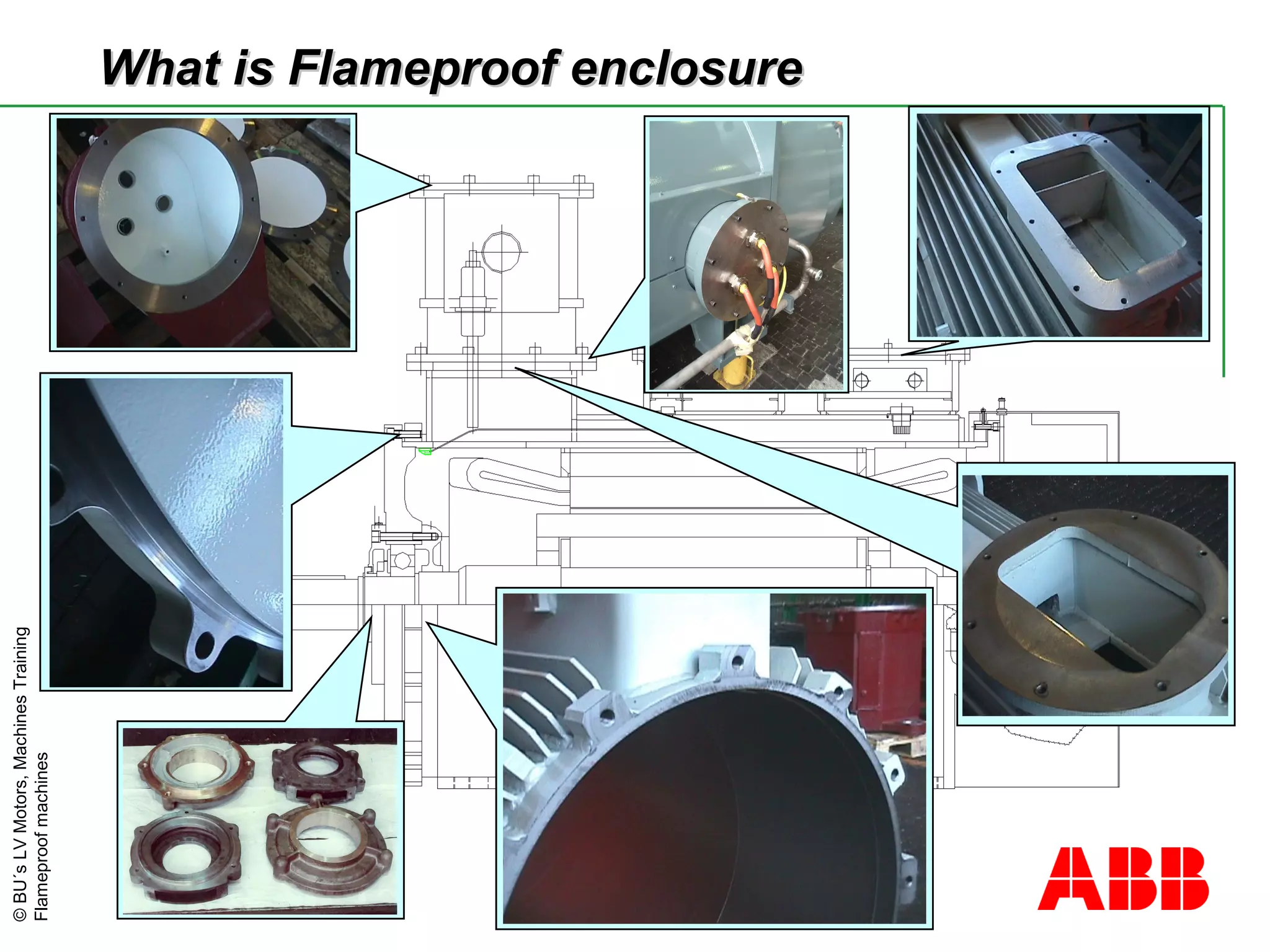

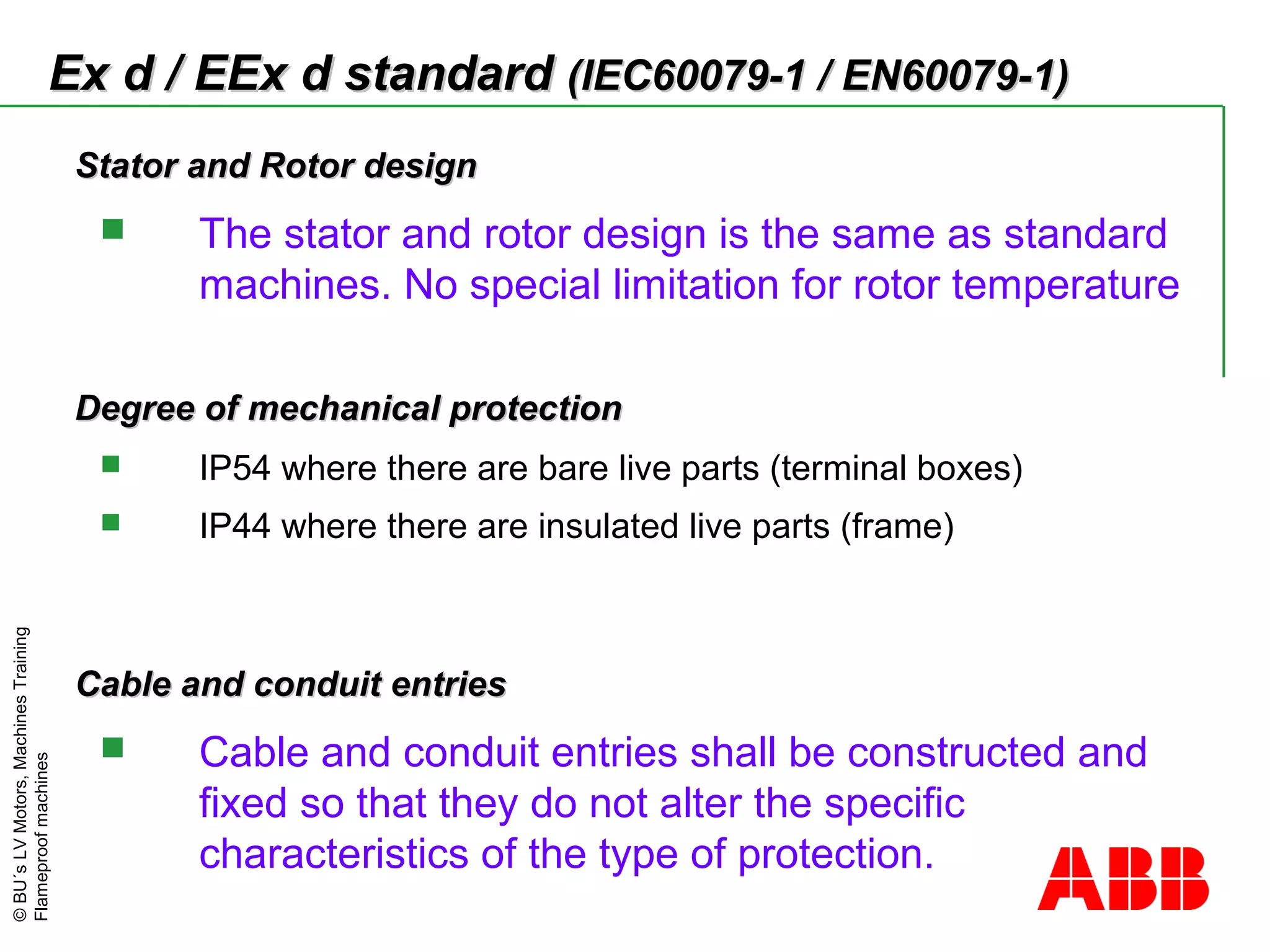

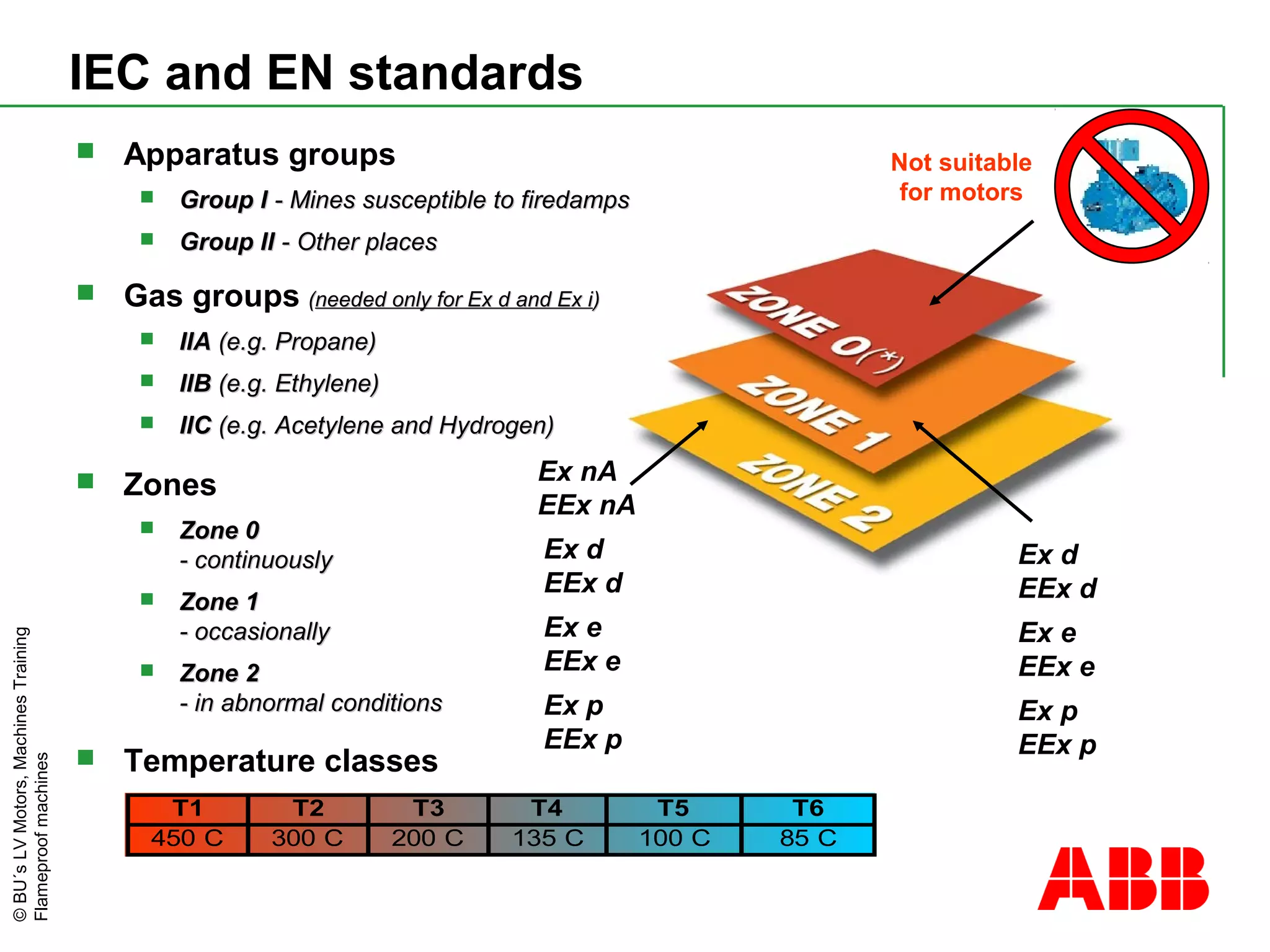

This document provides information on hazardous area classifications and explosion protection techniques for electrical equipment. It discusses the classification of hazardous environments into zones based on the likelihood of a flammable atmosphere occurring. It also covers gas and temperature group classifications. The main explosion protection techniques for electrical machines discussed are pressurized enclosures (Ex p), and flameproof enclosures (Ex d). Requirements for these techniques include enclosure design rules, temperature limits, purging for Ex p, and flamepath design for Ex d.