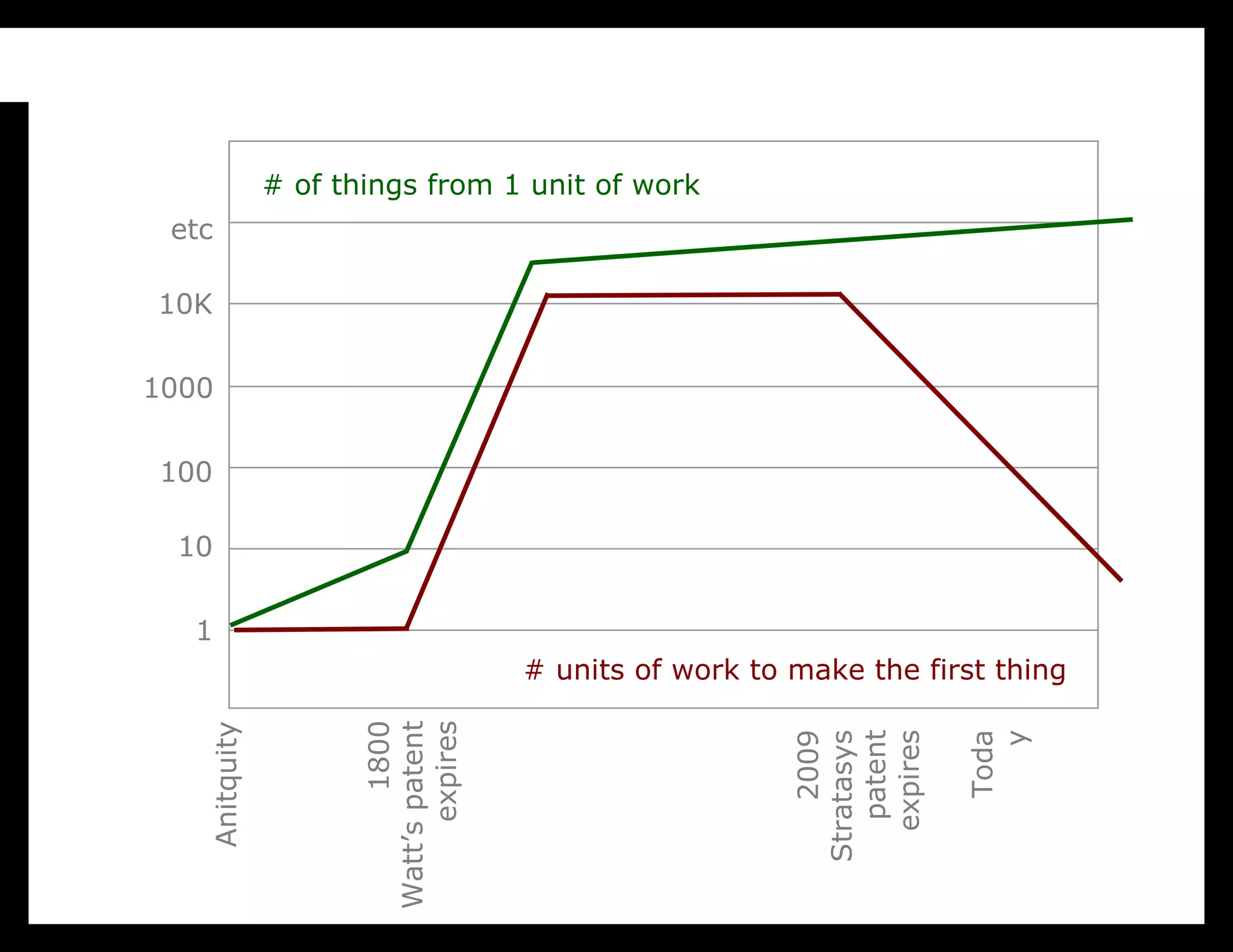

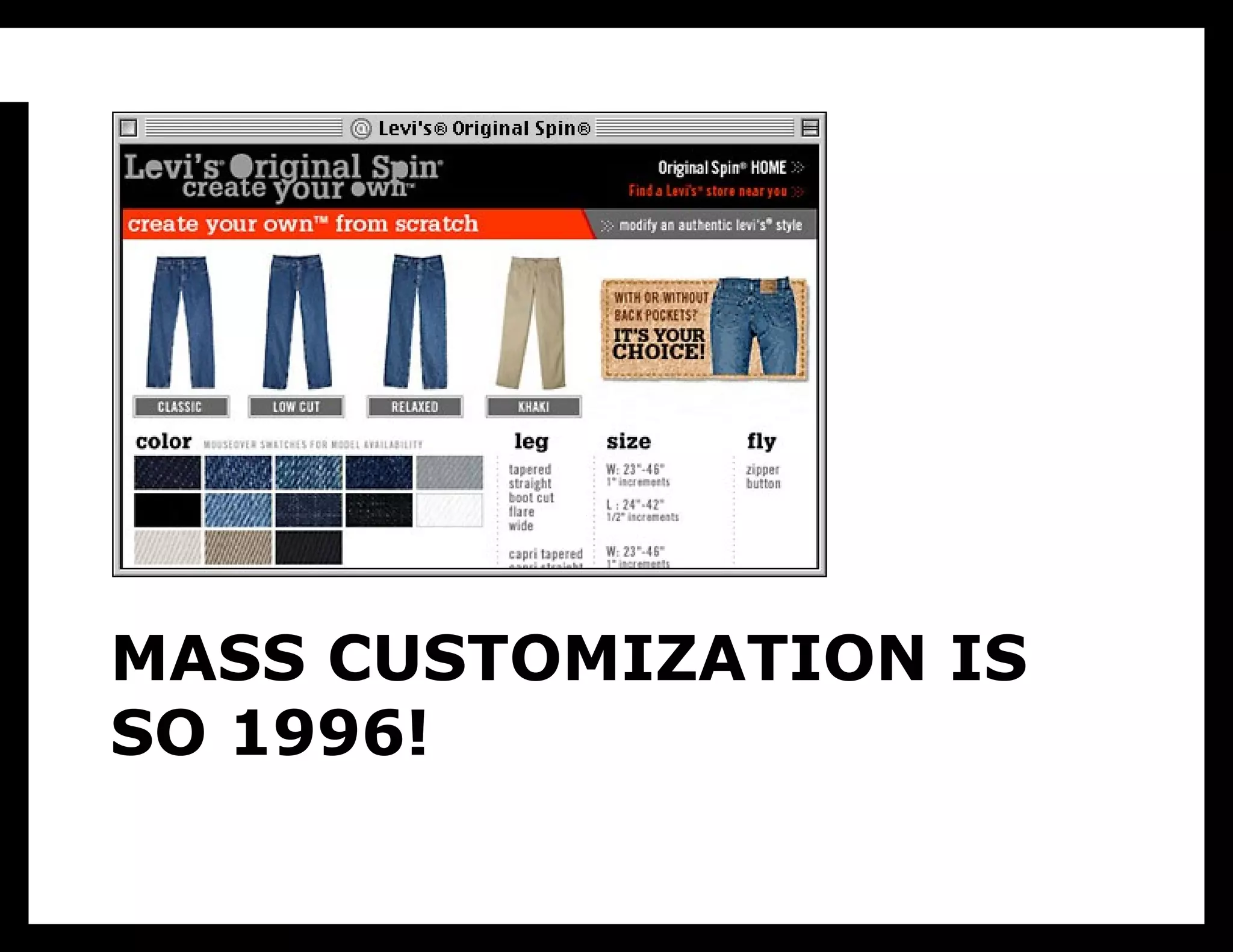

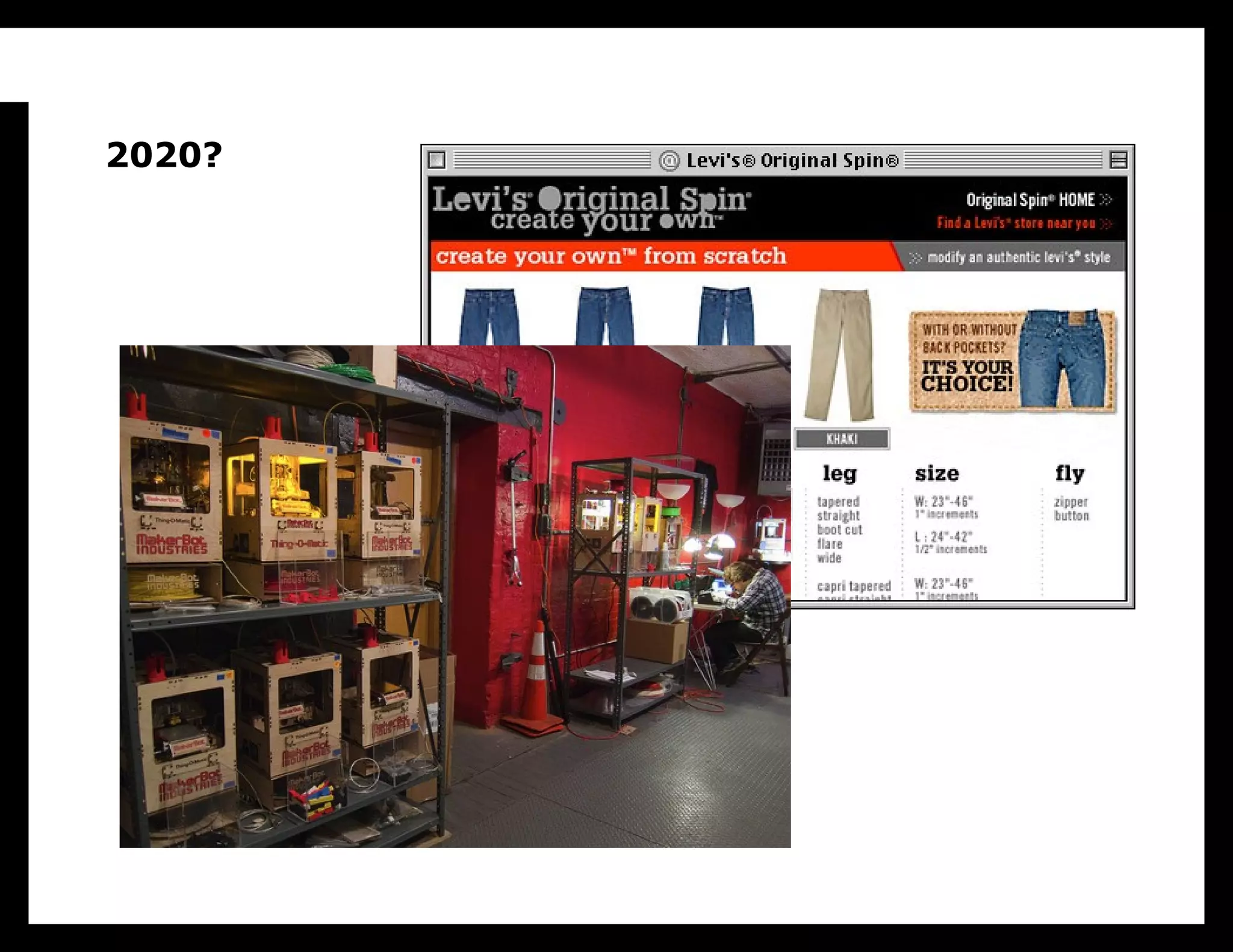

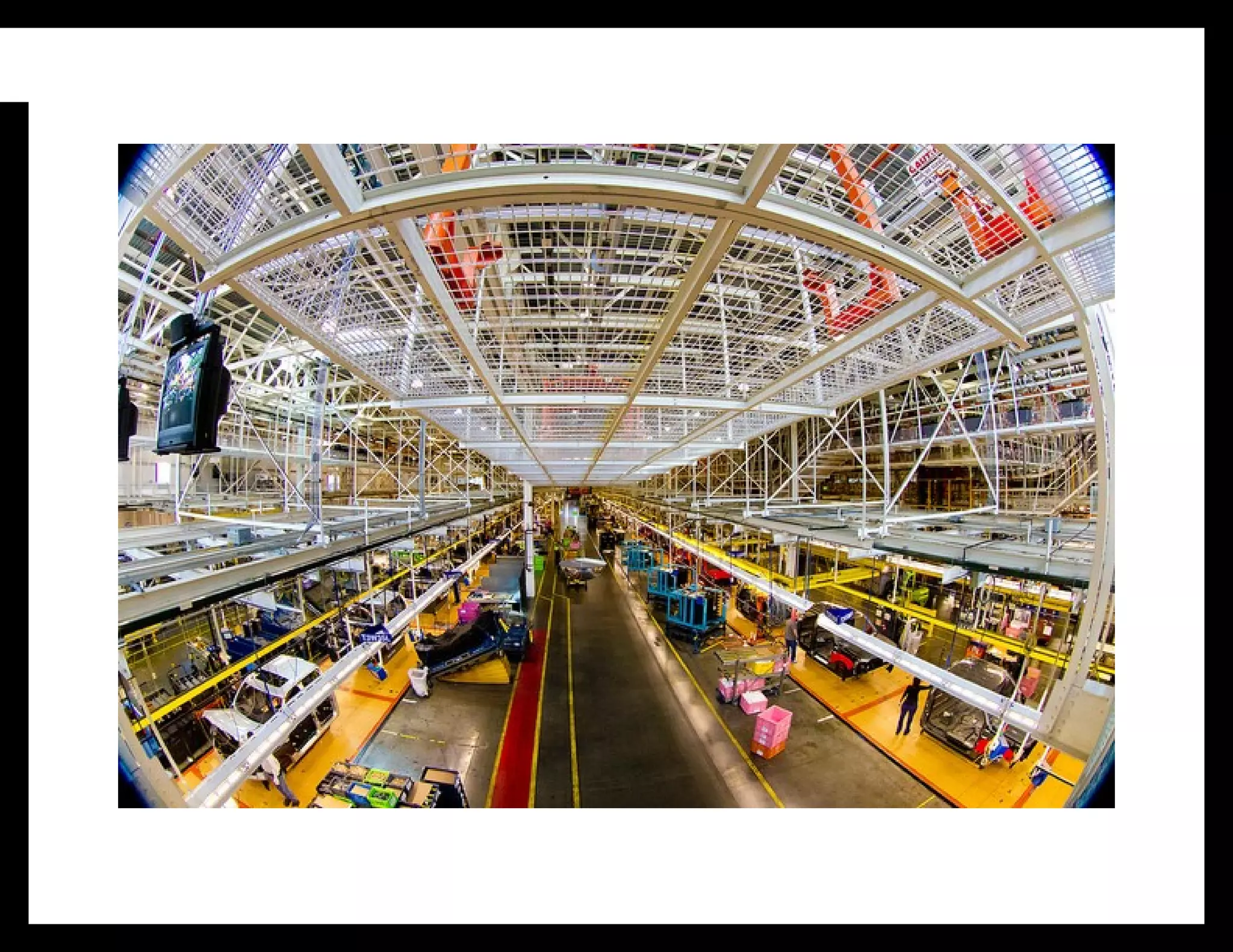

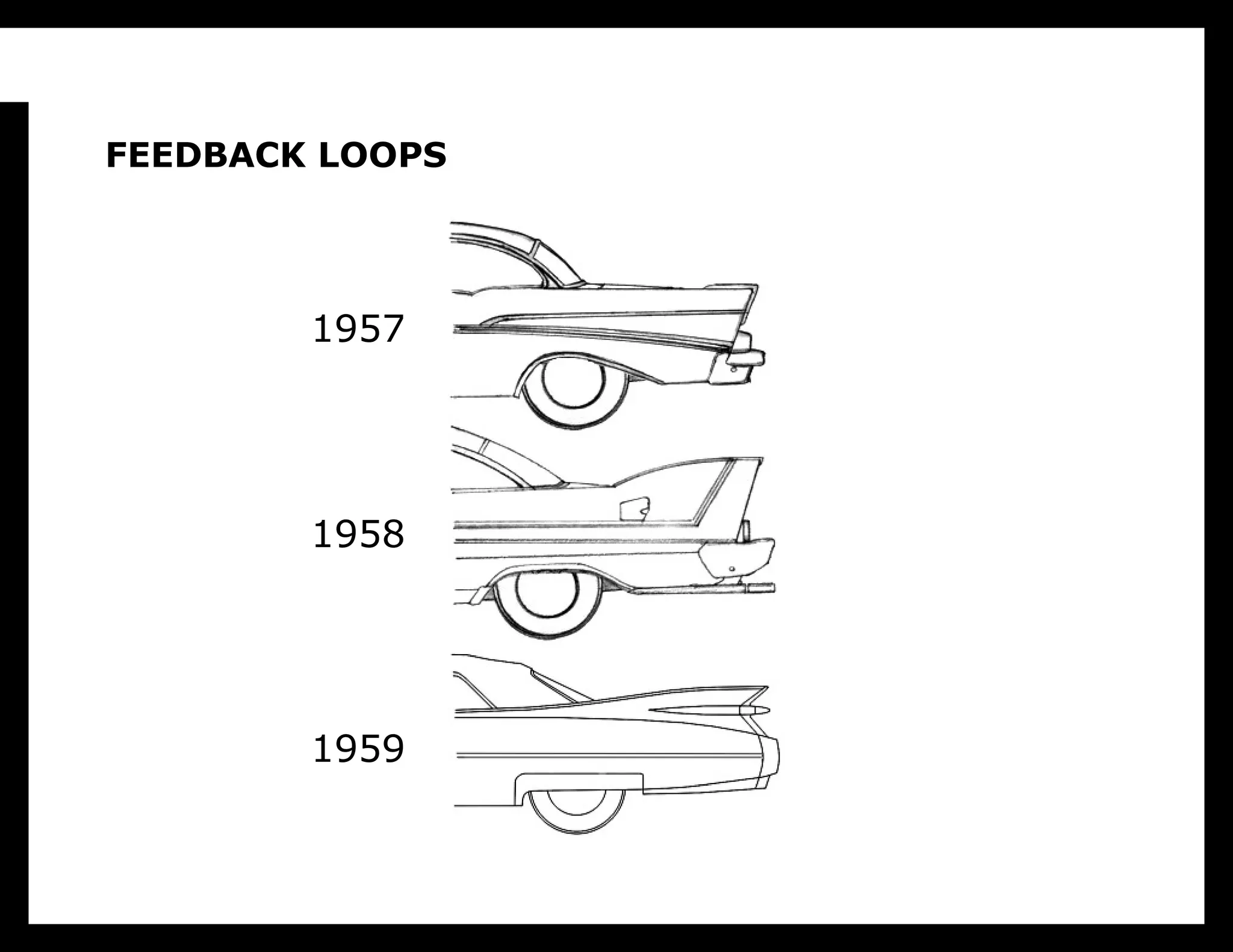

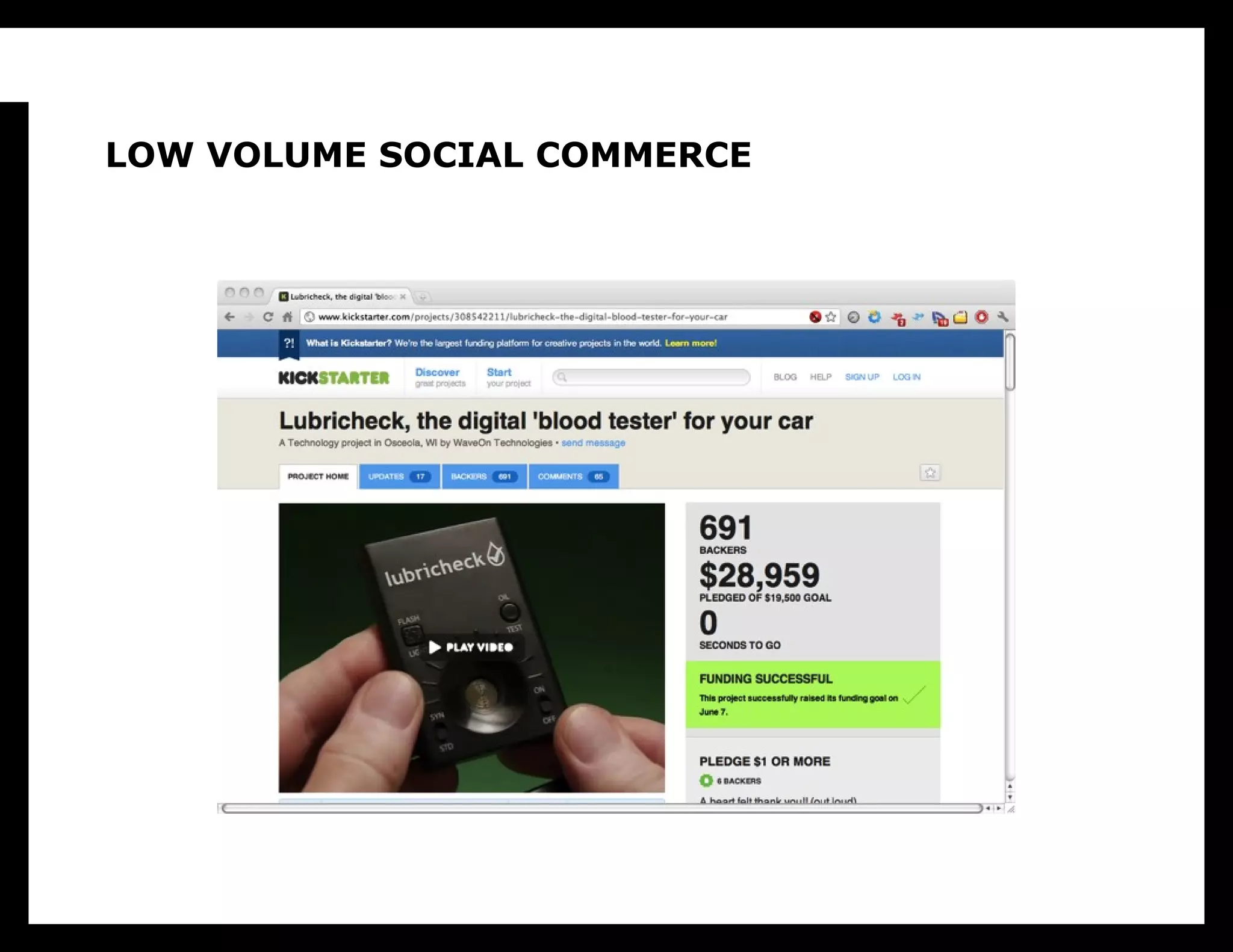

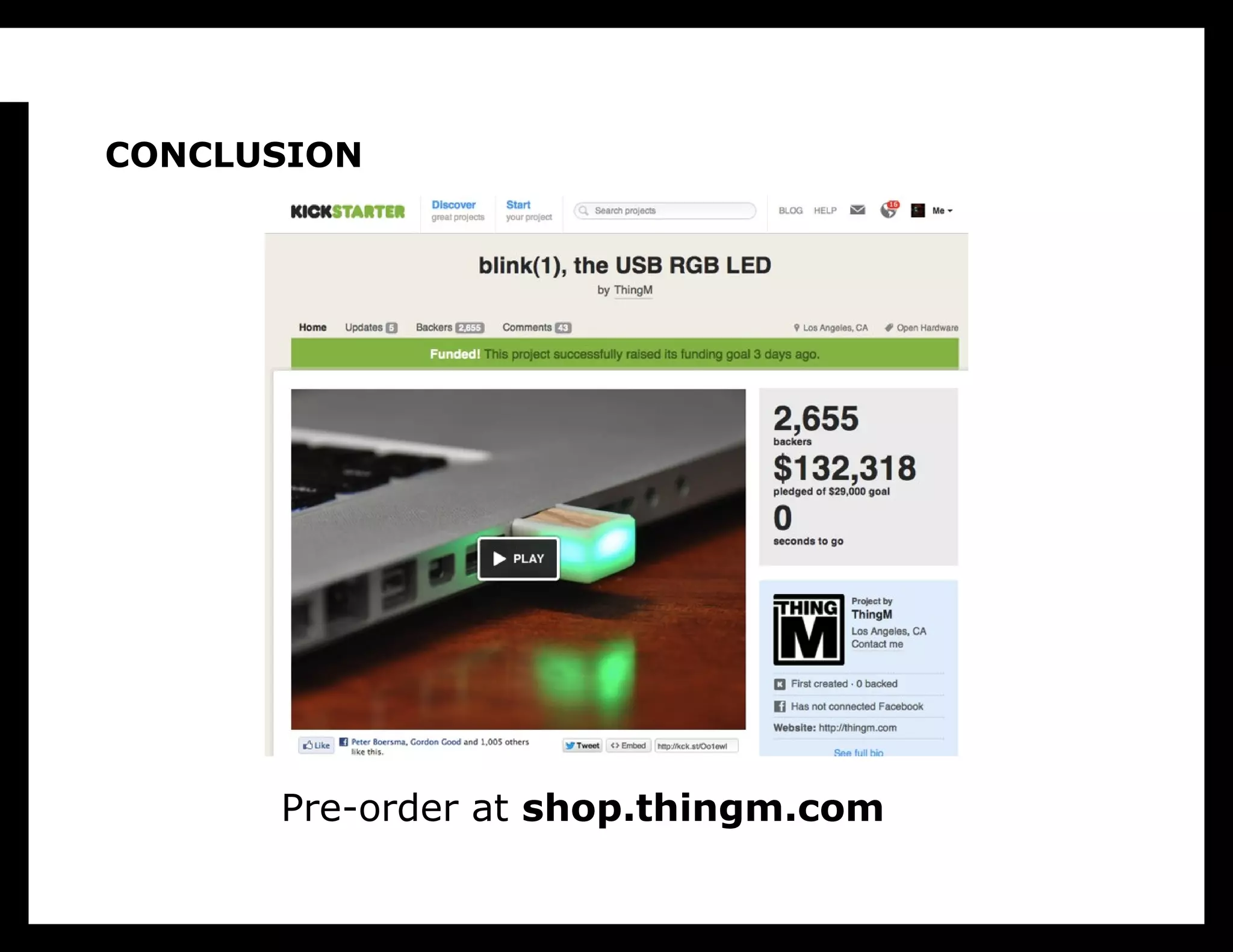

Mike Kuniavsky discusses the evolution of product development and manufacturing, emphasizing the shift towards localized production facilitated by advances in digital fabrication and analytics. He envisions a future where e-commerce platforms like Amazon will act as interfaces for nearby manufacturing processes, allowing for localized, bespoke creation of products. Kuniavsky highlights the importance of collaborative design tools and big data analytics in revolutionizing product creation and driving user-centered design.