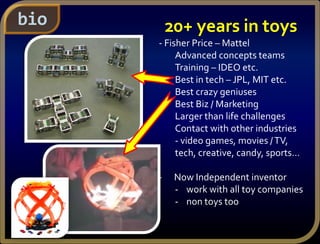

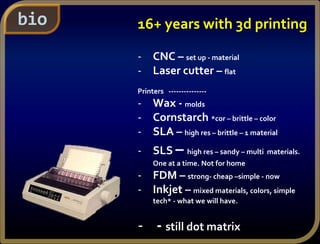

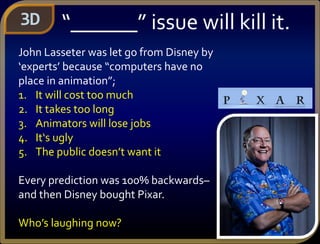

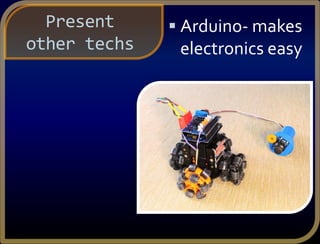

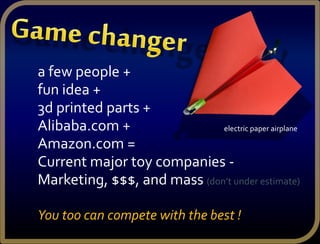

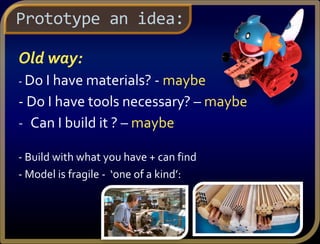

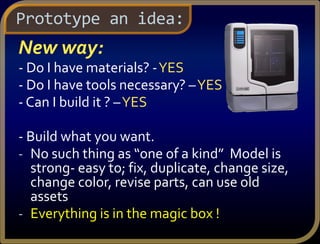

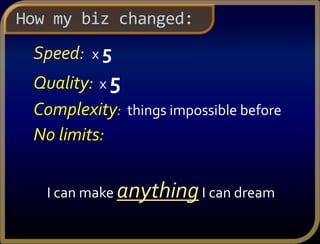

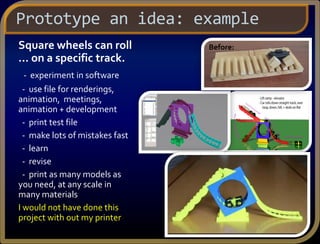

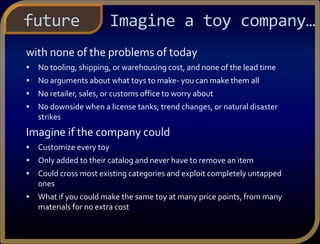

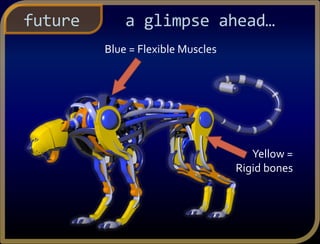

This document discusses the potential of 3D printing for toys and other industries. It begins with the speaker's background working with major toy companies and using 3D printing for over 16 years. The speaker discusses how 3D printing has changed prototyping by making it faster, higher quality and allowing for more complex designs. Examples are given of how current toy companies are using 3D printing. The future possibilities with 3D printing are explored, such as customizable toys and being able to experiment more easily. The document conveys an optimistic view of the opportunities 3D printing provides for inventors and American entrepreneurship.