Report

Share

Download to read offline

Recommended

More Related Content

What's hot

What's hot (19)

Siemens s7 300-400-s7 graph for s7-300 400 programming sequential control sys...

Siemens s7 300-400-s7 graph for s7-300 400 programming sequential control sys...

Top Ten Programming Mistakes by People New to Siemens

Top Ten Programming Mistakes by People New to Siemens

Viewers also liked

Viewers also liked (9)

treinamentos em automacao e solucoes industriais s7 tia 2 simatic s7 porgama...

treinamentos em automacao e solucoes industriais s7 tia 2 simatic s7 porgama...

Similar to 04 conexão logo! 0 ba7 com ihm

Similar to 04 conexão logo! 0 ba7 com ihm (20)

First fare 2010 lab-view creating custom dashboards

First fare 2010 lab-view creating custom dashboards

ABC Consolidated Financial InfoABC Companys current financial inf.docx

ABC Consolidated Financial InfoABC Companys current financial inf.docx

Line Graph Analysis using R Script for Intel Edison - IoT Foundation Data - N...

Line Graph Analysis using R Script for Intel Edison - IoT Foundation Data - N...

More from confidencial

More from confidencial (20)

03 requirements and functional process description v1.00_en

03 requirements and functional process description v1.00_en

01tiaportal handson-basicov11v2-140421084257-phpapp01

01tiaportal handson-basicov11v2-140421084257-phpapp01

Sitrains7 1200pwmpid-150301123045-conversion-gate01

Sitrains7 1200pwmpid-150301123045-conversion-gate01

Recently uploaded

Call girls in delhi ✔️✔️🔝 9953056974 🔝✔️✔️Welcome To Vip Escort Services In Delhi [ ]Noida Gurgaon 24/7 Open Sex Escort Services With Happy Ending ServiCe Done By Most Attractive Charming Soft Spoken Bold Beautiful Full Cooperative Independent Escort Girls ServiCe In All-Star Hotel And Home Service In All Over Delhi, Noida, Gurgaon, Faridabad, Ghaziabad, Greater Noida,

• IN CALL AND OUT CALL SERVICE IN DELHI NCR

• 3* 5* 7* HOTELS SERVICE IN DELHI NCR

• 24 HOURS AVAILABLE IN DELHI NCR

• INDIAN, RUSSIAN, PUNJABI, KASHMIRI ESCORTS

• REAL MODELS, COLLEGE GIRLS, HOUSE WIFE, ALSO AVAILABLE

• SHORT TIME AND FULL TIME SERVICE AVAILABLE

• HYGIENIC FULL AC NEAT AND CLEAN ROOMS AVAIL. IN HOTEL 24 HOURS

• DAILY NEW ESCORTS STAFF AVAILABLE

• MINIMUM TO MAXIMUM RANGE AVAILABLE.

Call Girls in Delhi & Independent Escort Service –

CALL GIRLS SERVICE DELHI NCR

Vip call girls in Delhi

Call Girls in Delhi, Call Girl Service 24×7 open

Call Girls in Delhi Best Delhi Escorts in Delhi

Low Rate Call Girls In Saket Delhi

X~CALL GIRLS IN Ramesh Nagar Metro

best Delhi call girls and Delhi escort service.

CALL GIRLS SERVICE IN ALL DELHI …

(Delhi) Call Girls in (Chanakyapuri)

Hot And Sexy Independent Model Escort Service In Delhi Unlimited Enjoy Genuine 100% Profiles And Trusted Door Step Call Girls Feel Free To Call Us Female Service Hot Busty & Sexy Party Girls Available For Complete Enjoyment. We Guarantee Full Satisfaction & In Case Of Any Unhappy Experience, We Would Refund Your Fees, Without Any Questions Asked. Feel Free To Call Us Female Service Provider Hours Opens Thanks.

Delhi Escorts Services 100% secure Services.Incall_OutCall Available and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services all over Delhi NCR.

Delhi All Hotel Services available 3* 4* 5* Call Call

Delhi Escorts Services And Delhi Call Girl Agency 100% secure Services in my agency. Incall and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services my agency in all over New Delhi

Delhi All Hotel Services available my agency

SERVICES [✓✓✓]

Housewife

College Girl

VIP Escort

Independent Girl

Aunty

Without a Condom sucking )?

Sexy Aunty.DSL (Dick Sucking Lips)?

DT (Dining at the Toes English Spanking)

Doggie (Sex style from no behind)??

OutCall- All Over Delhi Noida Gurgaon 24/7

FOR APPOINTMENT Call/Whatsop / 9953056974Call Girls in Netaji Nagar, Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Netaji Nagar, Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service9953056974 Low Rate Call Girls In Saket, Delhi NCR

Process of Integration the Laser Scan Data into FEA Model and Level 3 Fitness-for-Service Assessment of Critical Assets in Refinery & Process IndustriesFEA Based Level 3 Assessment of Deformed Tanks with Fluid Induced Loads

FEA Based Level 3 Assessment of Deformed Tanks with Fluid Induced LoadsArindam Chakraborty, Ph.D., P.E. (CA, TX)

Call Girl Bhosari Indira Call Now: 8617697112 Bhosari Escorts Booking Contact Details WhatsApp Chat: +91-8617697112 Bhosari Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable. Independent Escorts Bhosari understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together. We provide –(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7

(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Model Call Girl Services in Delhi reach out to us at 🔝 9953056974 🔝✔️✔️

Our agency presents a selection of young, charming call girls available for bookings at Oyo Hotels. Experience high-class escort services at pocket-friendly rates, with our female escorts exuding both beauty and a delightful personality, ready to meet your desires. Whether it's Housewives, College girls, Russian girls, Muslim girls, or any other preference, we offer a diverse range of options to cater to your tastes.

We provide both in-call and out-call services for your convenience. Our in-call location in Delhi ensures cleanliness, hygiene, and 100% safety, while our out-call services offer doorstep delivery for added ease.

We value your time and money, hence we kindly request pic collectors, time-passers, and bargain hunters to refrain from contacting us.

Our services feature various packages at competitive rates:

One shot: ₹2000/in-call, ₹5000/out-call

Two shots with one girl: ₹3500/in-call, ₹6000/out-call

Body to body massage with sex: ₹3000/in-call

Full night for one person: ₹7000/in-call, ₹10000/out-call

Full night for more than 1 person: Contact us at 🔝 9953056974 🔝. for details

Operating 24/7, we serve various locations in Delhi, including Green Park, Lajpat Nagar, Saket, and Hauz Khas near metro stations.

For premium call girl services in Delhi 🔝 9953056974 🔝. Thank you for considering us!Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...9953056974 Low Rate Call Girls In Saket, Delhi NCR

Call girls in delhi ✔️✔️🔝 9953056974 🔝✔️✔️Welcome To Vip Escort Services In Delhi [ ]Noida Gurgaon 24/7 Open Sex Escort Services With Happy Ending ServiCe Done By Most Attractive Charming Soft Spoken Bold Beautiful Full Cooperative Independent Escort Girls ServiCe In All-Star Hotel And Home Service In All Over Delhi, Noida, Gurgaon, Faridabad, Ghaziabad, Greater Noida,

• IN CALL AND OUT CALL SERVICE IN DELHI NCR

• 3* 5* 7* HOTELS SERVICE IN DELHI NCR

• 24 HOURS AVAILABLE IN DELHI NCR

• INDIAN, RUSSIAN, PUNJABI, KASHMIRI ESCORTS

• REAL MODELS, COLLEGE GIRLS, HOUSE WIFE, ALSO AVAILABLE

• SHORT TIME AND FULL TIME SERVICE AVAILABLE

• HYGIENIC FULL AC NEAT AND CLEAN ROOMS AVAIL. IN HOTEL 24 HOURS

• DAILY NEW ESCORTS STAFF AVAILABLE

• MINIMUM TO MAXIMUM RANGE AVAILABLE.

Call Girls in Delhi & Independent Escort Service –

CALL GIRLS SERVICE DELHI NCR

Vip call girls in Delhi

Call Girls in Delhi, Call Girl Service 24×7 open

Call Girls in Delhi Best Delhi Escorts in Delhi

Low Rate Call Girls In Saket Delhi

X~CALL GIRLS IN Ramesh Nagar Metro

best Delhi call girls and Delhi escort service.

CALL GIRLS SERVICE IN ALL DELHI …

(Delhi) Call Girls in (Chanakyapuri)

Hot And Sexy Independent Model Escort Service In Delhi Unlimited Enjoy Genuine 100% Profiles And Trusted Door Step Call Girls Feel Free To Call Us Female Service Hot Busty & Sexy Party Girls Available For Complete Enjoyment. We Guarantee Full Satisfaction & In Case Of Any Unhappy Experience, We Would Refund Your Fees, Without Any Questions Asked. Feel Free To Call Us Female Service Provider Hours Opens Thanks.

Delhi Escorts Services 100% secure Services.Incall_OutCall Available and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services all over Delhi NCR.

Delhi All Hotel Services available 3* 4* 5* Call Call

Delhi Escorts Services And Delhi Call Girl Agency 100% secure Services in my agency. Incall and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services my agency in all over New Delhi

Delhi All Hotel Services available my agency

SERVICES [✓✓✓]

Housewife

College Girl

VIP Escort

Independent Girl

Aunty

Without a Condom sucking )?

Sexy Aunty.DSL (Dick Sucking Lips)?

DT (Dining at the Toes English Spanking)

Doggie (Sex style from no behind)??

OutCall- All Over Delhi Noida Gurgaon 24/7

FOR APPOINTMENT Call/Whatsop / 9953056974Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service9953056974 Low Rate Call Girls In Saket, Delhi NCR

Recently uploaded (20)

Double Revolving field theory-how the rotor develops torque

Double Revolving field theory-how the rotor develops torque

Intze Overhead Water Tank Design by Working Stress - IS Method.pdf

Intze Overhead Water Tank Design by Working Stress - IS Method.pdf

Call Girls in Netaji Nagar, Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Netaji Nagar, Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls Pimpri Chinchwad Call Me 7737669865 Budget Friendly No Advance Boo...

Call Girls Pimpri Chinchwad Call Me 7737669865 Budget Friendly No Advance Boo...

FEA Based Level 3 Assessment of Deformed Tanks with Fluid Induced Loads

FEA Based Level 3 Assessment of Deformed Tanks with Fluid Induced Loads

(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7

(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

Bhosari ( Call Girls ) Pune 6297143586 Hot Model With Sexy Bhabi Ready For ...

Bhosari ( Call Girls ) Pune 6297143586 Hot Model With Sexy Bhabi Ready For ...

Top Rated Call Girls In chittoor 📱 {7001035870} VIP Escorts chittoor

Top Rated Call Girls In chittoor 📱 {7001035870} VIP Escorts chittoor

Design For Accessibility: Getting it right from the start

Design For Accessibility: Getting it right from the start

Call Girls Walvekar Nagar Call Me 7737669865 Budget Friendly No Advance Booking

Call Girls Walvekar Nagar Call Me 7737669865 Budget Friendly No Advance Booking

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

04 conexão logo! 0 ba7 com ihm

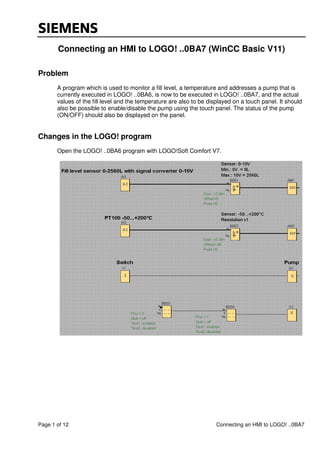

- 1. Page 1 of 12 Connecting an HMI to LOGO! ..0BA7 Connecting an HMI to LOGO! ..0BA7 (WinCC Basic V11) Problem A program which is used to monitor a fill level, a temperature and addresses a pump that is currently executed in LOGO! ..0BA6, is now to be executed in LOGO! ..0BA7, and the actual values of the fill level and the temperature are also to be displayed on a touch panel. It should also be possible to enable/disable the pump using the touch panel. The status of the pump (ON/OFF) should also be displayed on the panel. Changes in the LOGO! program Open the LOGO! ..0BA6 program with LOGO!Soft Comfort V7.

- 2. Page 2 of 12 Connecting an HMI to LOGO! ..0BA7 In the device selection ("Tools; Device selection") set the LOGO! ..0BA7 basic device. Configure an Ethernet connection between LOGO! ..0BA7 and the touch panel. Click on "Tools; Ethernet Connections…", assign the IP address as well as the subnet mask for the basic device; create a new connection with a right-click on the Ethernet connections under Peer-to-Peer connections.

- 3. Page 3 of 12 Connecting an HMI to LOGO! ..0BA7 Open the properties of the connection and configure it as seen in the following figure. To specify which data are to be made available to the HMI, open "Tools; Parameter VM Mapping…" and create a variable table. Notes: Information from the LOGO! program HMI address Parameter to be transferred is a value of a function (e.g. the amplified value of an analog amplifier) is a parameter of a function (e.g. the delay time of an on-delay) 3 21 1 3 2

- 4. Page 4 of 12 Connecting an HMI to LOGO! ..0BA7 A network input and an XOR have also been added in the program to implement a two-way circuit to turn the pump on and off. The variable V4.0 was set in the properties of the network input because the variable byte 4 is the next free byte in the LOGO! variable memory. Finally download the program with the configuration into the basic device.

- 5. Page 5 of 12 Connecting an HMI to LOGO! ..0BA7 Settings and configuration in WinCC Basic V11 Creating a new project Open WinCC Basic V11 and create a new project. Inserting a new device Then configure a new device. A KTP600 Basic PN is used in the example.

- 6. Page 6 of 12 Connecting an HMI to LOGO! ..0BA7 Creating a connection Open the Project view with a double-click on the device and configure the connection. Select the menu item "Connections" in the Project navigation to do so. Add a new connection with a double-click on "Add". Assign a name to the connection, enter the IP addresses of the HMI device and the controller and select the communication driver. Note: For communication with LOGO! ..0BA7, you must select the communication driver "SIMATIC S7 200". * The IP addresses must be set before directly on the devices. IP address of the HMI* IP address of LOGO!*

- 7. Page 7 of 12 Connecting an HMI to LOGO! ..0BA7 Creating tags Next open the folder "HMI tags" in the Project navigation. You can now add HMI tags in the "Default tag table" and specify their properties. Notes: The following table shows you to which data the HMI has read and write access: Read Write Inputs (I) x - Outputs (Q) x x Flags (M) x - Variables (V) x x It is theoretically possible to write inputs and bit memories. But this does not make a lot of sense, because LOGO! overwrites them in each cycle. Inputs, outputs and bit memories can be configured in WinCC Basic V11 with the following addresses: I Address Q Address M Address I1 I0.0 Q1 Q0.0 M1 M0.0 I2 I0.1 Q2 Q0.1 M2 M0.1 I3 I0.2 Q3 Q0.2 M3 M0.2 I4 I0.3 Q4 Q0.3 M4 M0.3 I5 I0.4 Q5 Q0.4 M5 M0.4 I6 I0.5 Q6 Q0.5 M6 M0.5 I7 I0.6 Q7 Q0.6 M7 M0.6 I8 I0.7 Q8 Q0.7 M8 M0.7 I9 I1.0 Q9 Q1.0 M9 F1.0 I10 I1.1 Q10 Q1.1 M10 F1.1 I11 I1.2 Q11 Q1.2 M11 M1.2 I12 I1.3 Q12 Q1.3 M12 M1.3 I13 I1.4 Q13 Q1.4 M13 M1.4 I14 I1.5 Q14 Q1.5 M14 M1.5 I15 I1.6 Q15 Q1.6 M15 M1.6 I16 I1.7 Q16 Q1.7 M16 M1.7 I17 I2.0 M17 M2.0 I18 I2.1 M18 M2.1 I19 I2.2 M19 M2.2 I20 I2.3 M20 M2.3 I21 I2.4 M21 M2.4 I22 I2.5 M22 M2.5 I23 I2.6 M23 M2.6 I24 I2.7 M24 M2.7 M25 M3.0 M26 M3.1 M27 M3.2

- 8. Page 8 of 12 Connecting an HMI to LOGO! ..0BA7 In WinCC flexible 2008, E and A is used for tag addresses instead of I and Q. Configuring screens To configure screens, open the "Screens" folder in the Project navigation. The root screen is automatically generated when you create the project as "Screen_1". Three screens (start screen, fill level and temperature) are created in the example. Add two more screens with a double-click. Open "Screen_1" and create three buttons in it. One for switching to "Screen_2", the other for switching to "Screen_3". Configure the third button to exit Runtime. To assign an event to a button, select the "Events" window under "Properties". Root screen with three buttons Properties of a button

- 9. Page 9 of 12 Connecting an HMI to LOGO! ..0BA7 Now open "Screen_2". This screen displays the fill level and the pump status and is also used to control the pump. That is why you enter a bar and two buttons as well as a circle into the screen. The bar is linked to the "Fill level" tag in the properties and the scale is adapted for reading the values. Button 1 is to be used to switch to the root screen. Configure this step in the properties of the button under "Events". The circle is used to show the status of the pump. The pump can be enabled/disabled with button 2. Screen 2 with a bar and a button Properties of the bar

- 10. Page 10 of 12 Connecting an HMI to LOGO! ..0BA7 Properties of the circle Properties of the button (Pump ON/OFF) Now open "Screen_3". This screen displays the temperature curve as well as the current temperature. Add a trend display, an I/O field and a button to the screen. The trend view and the I/O field are linked to the "Temperature" tag and the scale of the trend is adapted for reading the values. The mode of the I/O field is set to output. The button is to be used to switch to the root screen. Screen 3 with a trend display, an input/output field and a button

- 11. Page 11 of 12 Connecting an HMI to LOGO! ..0BA7 Properties of the I/O field Runtime settings Select the menu item "Runtime settings" in the Project navigation to edit the Runtime settings. Here you can make the general settings as well as settings for screens, keyboard, alarms, user administration and language & font.

- 12. Page 12 of 12 Connecting an HMI to LOGO! ..0BA7 Testing the configuration You can start testing your screens and settings during configuration. Open the shortcut menu with a right-click on your device. Select "Start simulation". You can also start simulation with a click on the icon in the toolbar. Another option for starting simulation is available in the menu bar. Here you open "Online; Simulation; Start". Note: If the controller is connected to the PC, you can use the process values from the controller for the simulation. You must, however, set the access point S7ONLINE under Control Panel; Setting PG/PC interface. You can also simulate the tags with the tag simulator. You open it with "Online; Simulation; With tag simulator" in the menu bar.