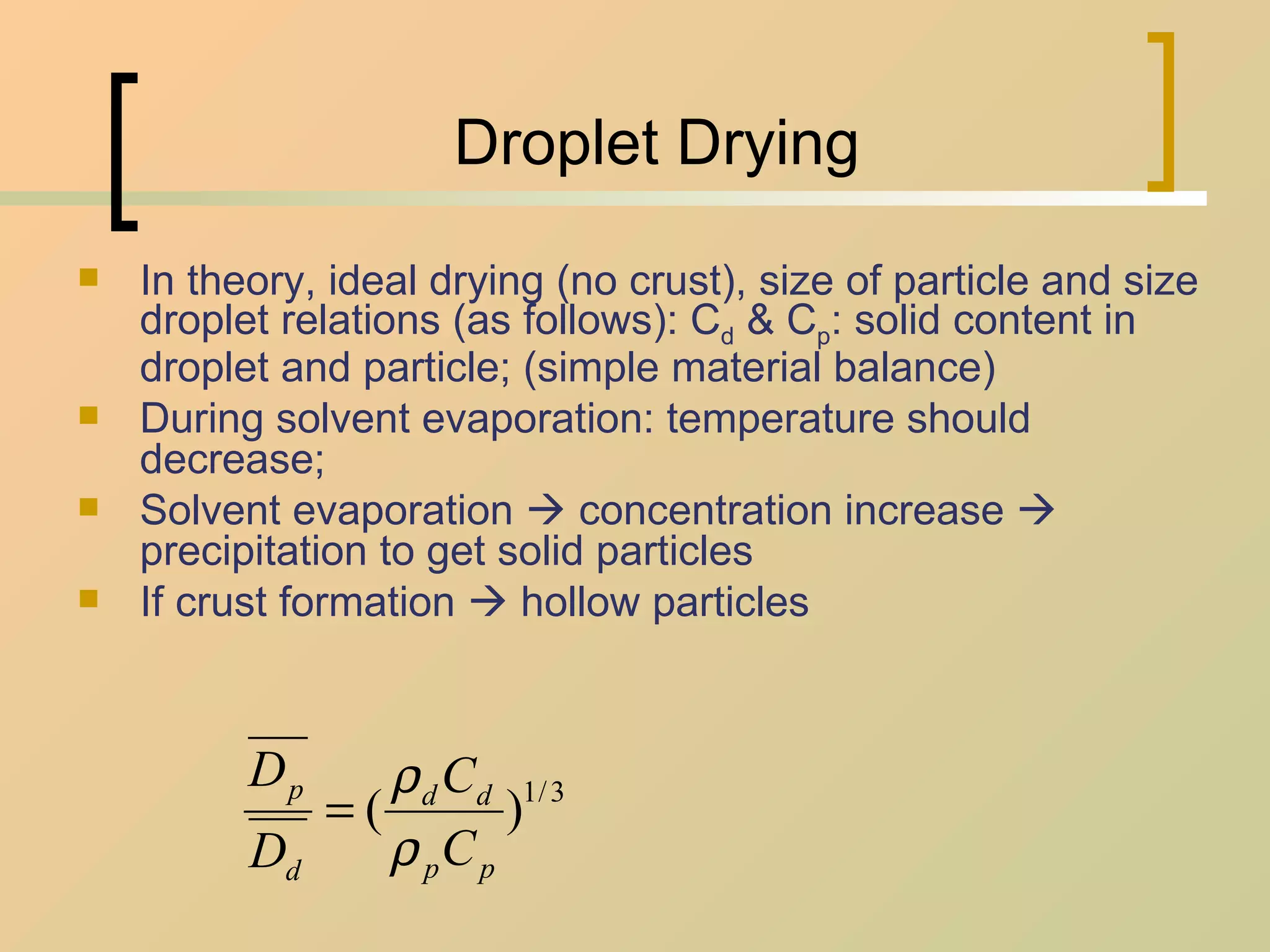

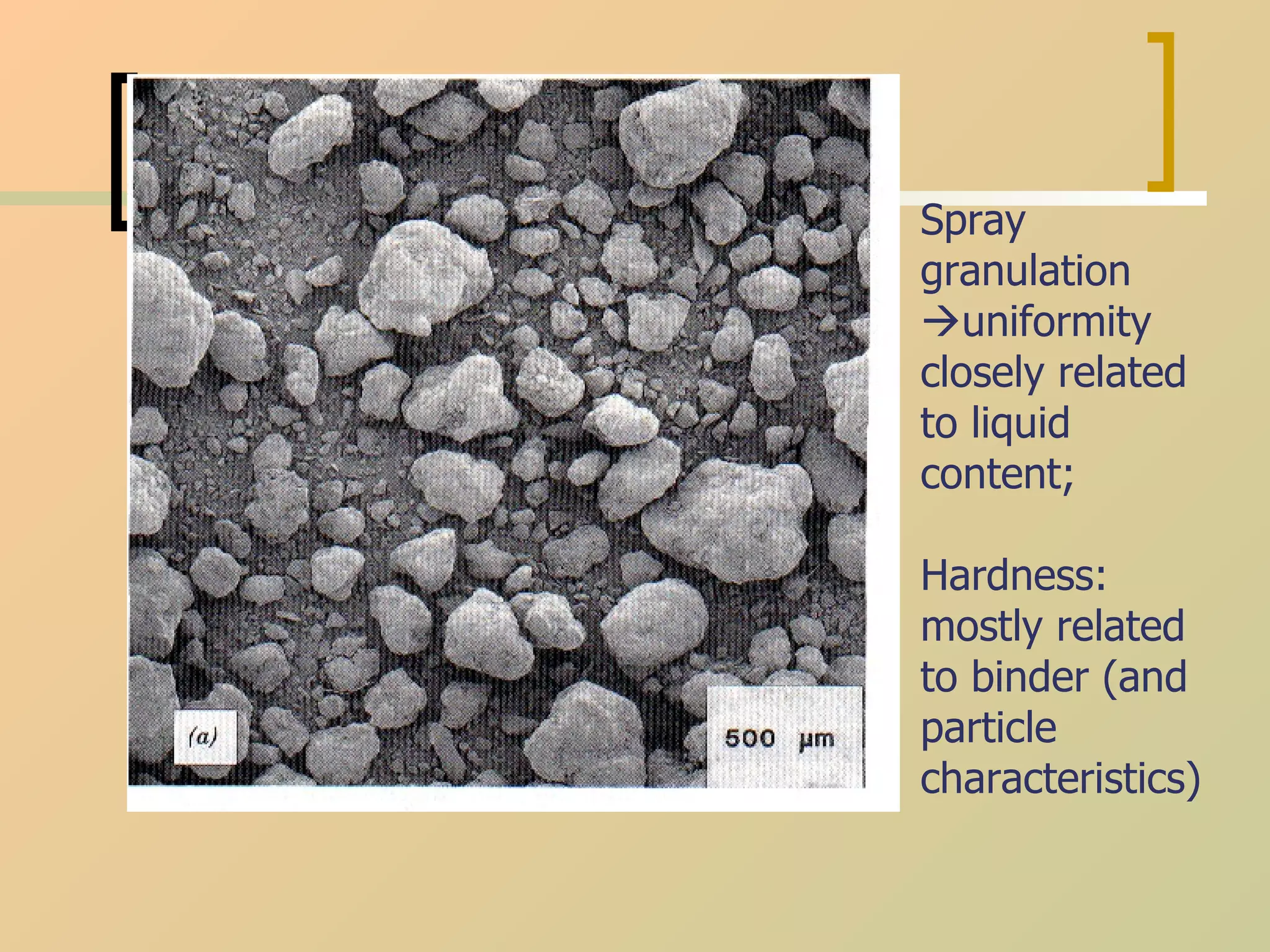

The document discusses various methods for granulation of ceramic powder including spray drying, extruding, and mixing with a perforated plate. It explains that granulation aims to produce free-flowing particles and may require a binder. The critical liquid content range for granulation depends on the particle system. Spray drying is a common granulation method that can produce spherical particles around 20 micrometers in size with high productivity. Key parameters for spray drying include droplet size, viscosity, feed rate, drying rate, and temperature.

![Spraying Drying (3) Foam index: bubbles in slurry low quality of granules, use foam index to represent bubbles in slurry: foam index (%) = [ T – E ] 100/ T ; T , E = theoretical and experimental density of slurry (the latter contain bubbles) If necessary, add anti-foam agent; wall deposit problem two-fluid nozzle: to lower pressure drop and to get smaller particles Mass and heat transfer during drying, relative rate may get dry surface with some internal liquid Che5700 陶瓷粉末處理](https://image.slidesharecdn.com/granulation-jp-1232310821883720-1/75/Granulation-11-2048.jpg)